ASTM D4912-07

(Test Method)Standard Test Method for Fabric Stability of Vinyl-Coated Glass Yarn Insect Screening and Louver Cloth

Standard Test Method for Fabric Stability of Vinyl-Coated Glass Yarn Insect Screening and Louver Cloth

SIGNIFICANCE AND USE

p>This test method is considered satisfactory for acceptance testing of commerical shipments since the method has been used extensively in the trade for acceptance testing.

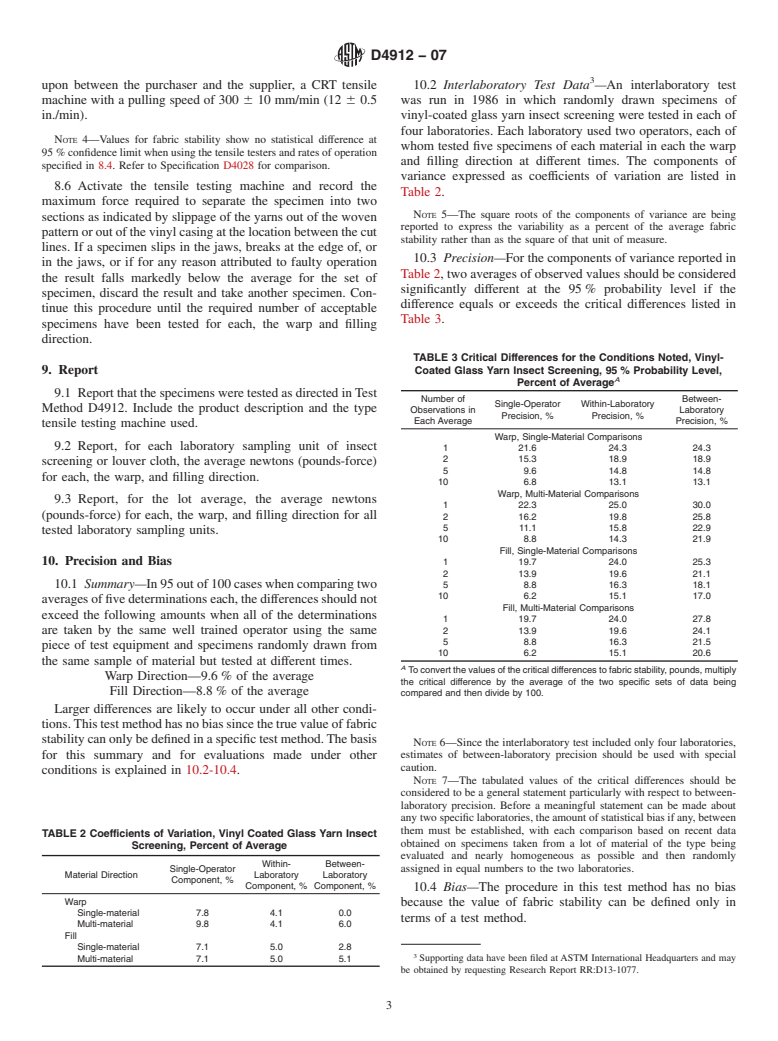

In cases of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens which are as homogeneous as possible and which are from a lot of material of the type in question. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using Student's t-test for unpaired data and an acceptable probability level chosen by the two parties before the testing begins. If a bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results in the light of the known bias.

Vinyl-coated glass yarn insect screening and louver cloth are subjected to a heating process to fuse the warp yarns to the filling yarns of the woven structure. The force at which yarns in one direction move over yarns in the opposite direction is a measure of the bond of fusion. The degree of the bond of fusion on the vinyl-coated glass yarn insect screening and louver cloth is used for process control. Fabric stability was formerly called resistance to yarn slippage.

SCOPE

1.1 This test method provides a procedure for evaluating fabric stability by measuring the resistance to yarn slippage of filling yarns over warp yarns, or warp yarns over filling yarns in vinyl-coated glass yarn insect screening and louver cloth.

1.2 This test method shows the values in both SI units and inch-pound units. “SI units” is the technically correct name for a system of metric units known as the International System of Units. “Inch-pound units” is the technically correct name for the customary units used in the United States. The values expressed in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4912 − 07

StandardTest Method for

Fabric Stability of Vinyl-Coated Glass Yarn Insect Screening

1

and Louver Cloth

This standard is issued under the fixed designation D4912; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 The following terms are relevant to this standard:

atmosphere for testing textiles, fabric stability.

1.1 This test method provides a procedure for evaluating

fabric stability by measuring the resistance to yarn slippage of 3.2 For all other terms related to textiles, refer to Terminol-

filling yarns over warp yarns, or warp yarns over filling yarns ogy D123

in vinyl-coated glass yarn insect screening and louver cloth.

4. Summary of Test Method

1.2 This test method shows the values in both SI units and

4.1 Samples of the vinyl-coated glass yarn insect screening

inch-pound units. “SI units” is the technically correct name for

or louver cloth are subjected to a breaking force test where

a system of metric units known as the International System of

yarns have been severed within the gage length area.The force

Units. “Inch-pound units” is the technically correct name for

requiredtobreakthefusedbondbetweenyarncomponentsand

the customary units used in the United States. The values

slip yarn segments in one direction over yarn segments in the

expressed in each system may not be exact equivalents;

opposite direction is reported as the fabric stability.

therefore,eachsystemshallbeusedindependentlyoftheother.

Combining values from the two systems may result in non-

5. Significance and Use

conformance with this standard.

5.1 This test method is considered satisfactory for accep-

1.3 This standard does not purport to address all of the

tance testing of commerical shipments since the method has

safety concerns, if any, associated with its use. It is the

been used extensively in the trade for acceptance testing.

responsibility of the user of this standard to establish appro-

5.1.1 In cases of a dispute arising from differences in

priate safety and health practices and determine the applica-

reported test results when using this test method for acceptance

bility of regulatory limitations prior to use.

testing of commercial shipments, the purchaser and the sup-

plier should conduct comparative tests to determine if there is

2. Referenced Documents

a statistical bias between their laboratories. Competent statis-

2

2.1 ASTM Standards:

tical assistance is recommended for the investigation of bias.

D76 Specification for Tensile Testing Machines for Textiles

As a minimum, the two parties should take a group of test

D123 Terminology Relating to Textiles

specimens which are as homogeneous as possible and which

D4028 Specification for Solar ScreeningWoven fromVinyl-

are from a lot of material of the type in question. The test

Coated Fiber Glass Yarn

specimens should then be randomly assigned in equal numbers

D7018 Terminology Relating to Glass Fiber and Its Products

to each laboratory for testing.The average results from the two

laboratories should be compared using Student’s t-test for

3. Terminology

unpaireddataandanacceptableprobabilitylevelchosenbythe

3.1 For all terminology relating to D13.18, Glass Fiber and two parties before the testing begins. If a bias is found, either

its cause must be found and corrected or the purchaser and the

Its Products, refer to Terminology D7018.

supplier must agree to interpret future test results in the light of

the known bias.

1

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

5.2 Vinyl-coated glass yarn insect screening and louver

and is the direct responsibility of Subcommittee D13.18 on Glass Fiber and its

cloth are subjected to a heating process to fuse the warp yarns

Products.

to the filling yarns of the woven structure. The force at which

Current edition approved Dec. 1, 2007. Published January 2008. Originally

yarns in one direction move over yarns in the opposite

approved in 1989. Last previous edition approved in 2002 as D4912–02 DOI:

10.1520/D4912-07.

direction is a measure of the bond of fusion. The degree of the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

bond of fusion on the vinyl-coated glass yarn insect screening

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and louver cloth is used for process control. Fabric stability

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. was formerly called resistance to yarn slippage.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohoc

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4912–02 Designation:D4912–07

Standard Test Method for

Fabric Stability of Vinyl-Coated Glass Yarn Insect Screening

1

and Louver Cloth

This standard is issued under the fixed designation D 4912; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method provides a procedure for evaluating fabric stability by measuring the resistance to yarn slippage of filling

yarns over warp yarns, or warp yarns over filling yarns in vinyl-coated glass yarn insect screening and louver cloth.

1.2 This test method shows the values in both SI units and inch-pound units. “SI units” is the technically correct name for a

system of metric units known as the International System of Units. “Inch-pound units” is the technically correct name for the

customary units used in the United States. The values expressed in each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining values from the two systems may result in non-conformance with this

standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 76 Specification for Tensile Testing Machines for Textiles

D 123 Terminology Relating to Textiles

D 4028 Specification for Solar Screening Woven from Vinyl-Coated Fiber Glass Yarn E171Specification for Standard

Atmospheres for Conditioning and

Testing Materials

D 7018 Terminology Relating to Glass Fiber and Its Products

3. Terminology

3.1Definitions:

3.1.1atmosphere for testing textiles, n—for glass, air maintained at a relative humidity of at least 48% and no greater than 67%,

and at a temperature of at least 20°C (68°F) and no greater than 25°C (77°F).

3.1.1.1Discussion—Glasstextilesareusedinvariousproductssuchasreinforcedplastics,mat-likematerial,tirecords,electrical

insulation, etc. Each of these materials requires different testing atmospheres. It is the intent of the wide spread in testing

atmosphere to allow testing of glass textiles in respective laboratories where end-product test atmosphere requirements differ. The

test atmospheres for respective products should be controlled as specified in Specification E171. It is the opinion of ASTM

Subcommittee D13.18 that fabric stability of insect screening and louver cloth would not be affected by the range selected. In any

event, the test atmosphere should be stated in the report.

3.1.2fabric stability, n—in vinyl coated glass screening and louver cloth, the property denoting the ability to resist slippage of

yarn segments in one direction over yarn segments in the opposite direction.

3.1.3For definitions of other textile terms used in this test method, refer to Terminology D123.

3.1 For all terminology relating to D13.18, Glass Fiber and Its Products, refer to Terminology D 7018.

3.1.1 The following terms are relevant to this standard: atmosphere for testing textiles, fabric stability.

3.2 For all other terms related to textiles, refer to Terminology D 123

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextilesandisthedirectresponsibilityofSubcommitteeD13.18onGlassFiberandItsitsProducts.

Current edition approved May 10, 2002.Dec. 1, 2007. Published August 2002.January 2008. Originally published as D4912–89.approved in 1989. Last previous edition

D4912–89(1994)approved in 2002 as D 4912–02

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 07.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4912–07

4. Summary of Test Method

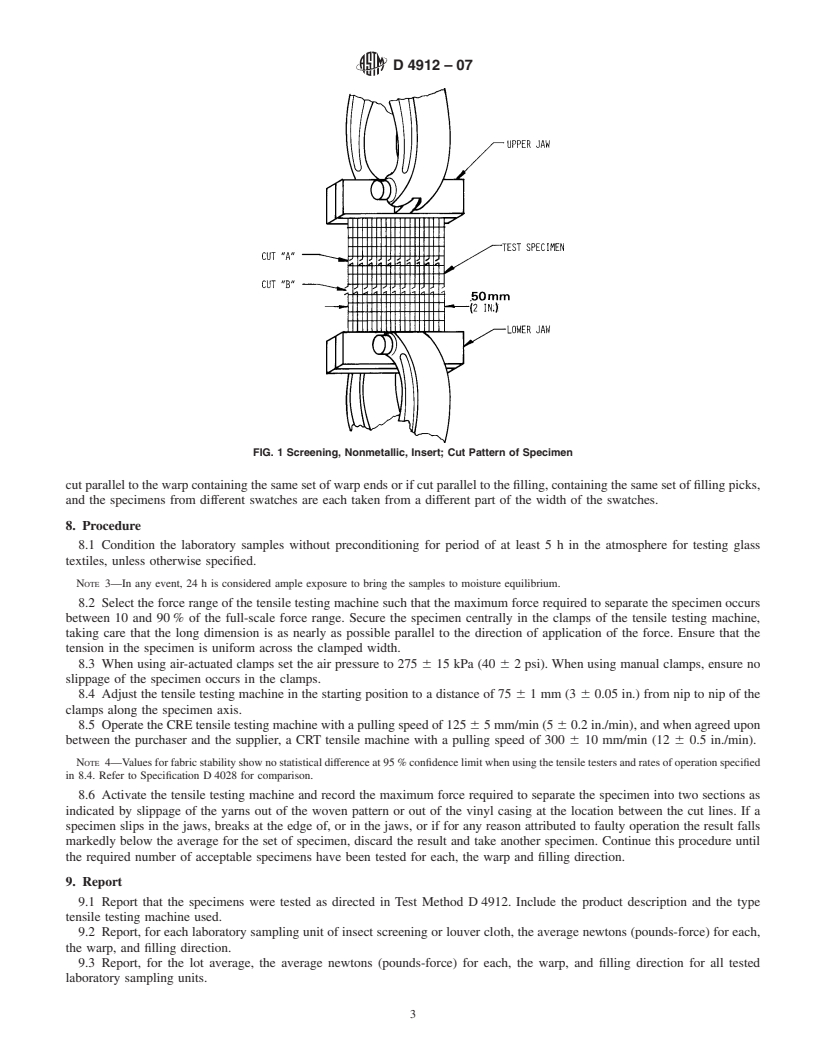

4.1 Samples of the vinyl-coated glass yarn insect screening or louver cloth are subjected to a breaking force test where yarns

have been severed within the gage length area. The force required to break the fused bond between yarn components and slip yarn

segments in one direction over yarn segmen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.