ASTM F1140-00

(Test Method)Standard Test Methods for Internal Pressurization Failure Resistance of Unrestrained Packages for Medical Applications

Standard Test Methods for Internal Pressurization Failure Resistance of Unrestrained Packages for Medical Applications

SCOPE

1.1 These test methods explain the procedure for determining the ability of open or closed packages to withstand internal pressurization.

1.2 The burst test internally and increasingly pressurizes the package until the package fails.

1.3 The creep test maintains a specified pressure for a specified time.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1140–00

Standard Test Methods for

Internal Pressurization Failure Resistance of Unrestrained

Packages for Medical Applications

This standard is issued under the fixed designation F 1140; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope until the package bursts. The test measure is the maximum

pressure detected before the package fails.

1.1 These test methods explain the procedure for determin-

4.2 Test Method B (Creep Test)—Packages are tested in

ing the ability of packages to withstand internal pressurization.

apparatus that internally pressurizes the package to a specified

1.2 The burst test increasingly pressurizes the package until

pressure and maintains that internal package pressure for a

the package fails.

specific time. The test measure is pass/fail.

1.3 The creep test maintains a specified pressure for a

4.3 Test Method B (Creep to Failure)—Packages are creep-

specified time or until the package fails.

tested and held until the package fails. Test setup is similar to

1.4 This standard does not purport to address all of the

that of the Creep Test except the pressure setting will need to

safety concerns, if any, associated with its use. It is the

be higher to ensure the package fails in a reasonable amount of

responsibility of the user of this standard to establish appro-

time (that is, about 15 s). The test measure is the time until

priate safety and health practices and determine the applica-

failure.

bility of regulatory limitations prior to use.

5. Significance and Use

2. Referenced Documents

5.1 These test methods provide a rapid means of evaluating

2.1 ASTM Standards:

tendencies for package failure when the package is exposed to

D 1898 Practice for Sampling of Plastics

a pressure differential. Pressure differentials may occur during

D 4332 Practice for Conditioning Containers, Packages, or

processes such as sterilization and transportation.

Packaging Components for Testing

5.2 These test methods are frequently used to quickly

F88

evaluate packages during the manufacturing process and at

3. Terminology

various stages of the package’s life cycle.

5.3 If correlations between pieces of test equipment are to

3.1 Definitions of Terms Specific to This Standard:

be made, it is important that all parameters of the test method

3.1.1 flexible—indicates a material of the proper flexural

be exactly the same. Typical parameters may include, but are

strength and thickness to permit a turn back at an appropriate

not limited to, package size, material, seal configuration, test

180° angle. In order to fulfill all terms of the definition, at least

equipment, rate of air flow into the package, sensitivity

one of the sealed materials must be flexible.

(machine response to pressure drop), and position of test article

3.1.2 package failure—refers to rupture of seal or material.

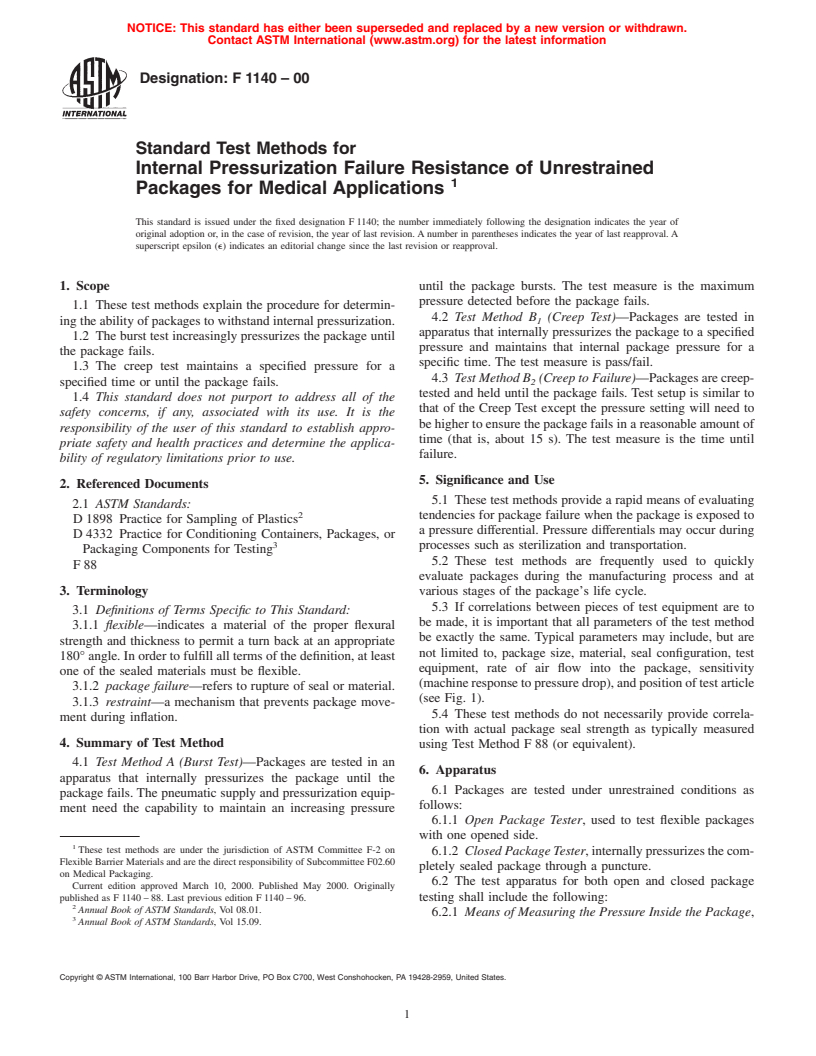

(see Fig. 1).

3.1.3 restraint—a mechanism that prevents package move-

5.4 These test methods do not necessarily provide correla-

ment during inflation.

tion with actual package seal strength as typically measured

4. Summary of Test Method

using Test Method F 88 (or equivalent).

4.1 Test Method A (Burst Test)—Packages are tested in an

6. Apparatus

apparatus that internally pressurizes the package until the

6.1 Packages are tested under unrestrained conditions as

package fails. The pneumatic supply and pressurization equip-

follows:

ment need the capability to maintain an increasing pressure

6.1.1 Open Package Tester, used to test flexible packages

with one opened side.

These test methods are under the jurisdiction of ASTM Committee F-2 on

6.1.2 Closed Package Tester,internallypressurizesthecom-

Flexible Barrier Materials and are the direct responsibility of Subcommittee F02.60

pletely sealed package through a puncture.

on Medical Packaging.

6.2 The test apparatus for both open and closed package

Current edition approved March 10, 2000. Published May 2000. Originally

testing shall include the following:

published as F 1140 – 88. Last previous edition F 1140 – 96.

Annual Book of ASTM Standards, Vol 08.01.

6.2.1 Means of Measuring the Pressure Inside the Package,

Annual Book of ASTM Standards, Vol 15.09.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1140–00

D 1898 provides guidance to test specimen selection. Testing

of specimens with visual defects or other deviations from

normality may or may not be appropriate, depending on the

purpose of investigation. Indiscriminate elimination of defects

can bias results.

8. Conditioning

8.1 Standard Test Conditions—Condition packages and

conduct testing in accordance with Practice D 4332.

8.2 If the test methods are conducted in other than standard

test conditions, record the temperature and relative humidity at

the time of the test method.

9. Procedure

9.1 Test Method A (Burst Test)—Place the package in the

apparatus and increase the internal pressure until a failure

occurs.

9.1.1 Open Package Test:

9.1.1.1 Package Preparation—The package may be tested

with or without the product enclosed. Record the package test

preparation.

9.1.1.2 Place the package in the test apparatus, and set the

specified parameters.The open package tester must be adjusted

such that the tester does not restrain the package from forming

its normal unrestricted height at the time of the burst.

NOTE 2—The package is typically positioned in one of the positions

shown in Fig. 1. Different positions may result in different test values and,

therefore, the final report should specify which position was chosen.

9.1.1.3 Begin the test method by starting the inflation

process. The rate of pressurization may affect the test results

and must not exceed the response rate of the pressure indicator.

Continue pressurization until a failure occurs.

9.1.1.4 Visually examine the package, and note the position

and type of failure (material or seal) and the pressure at which

it occurred.

9.1.2 Closed Package Test:

9.1.2.1 Package Preparation—The package may be tested

with or without the product enclosed. Record the package test

preparation.

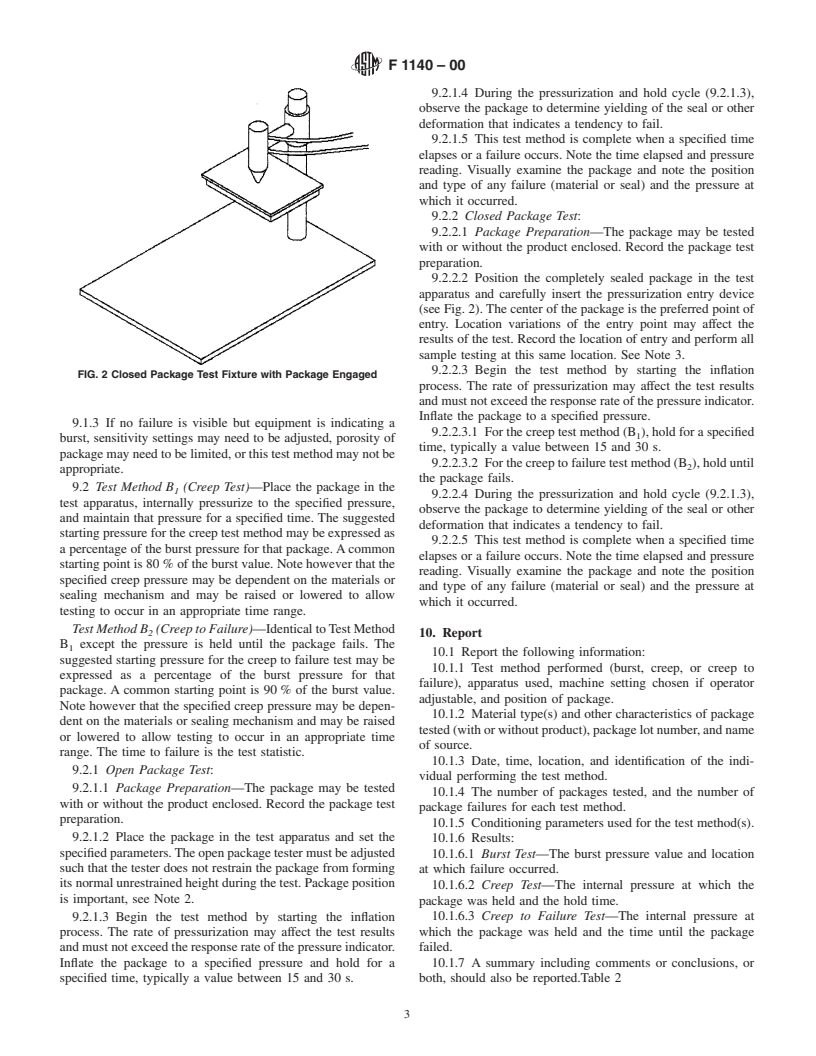

9.1.2.2 Position the completely sealed package in the test

apparatus and carefully insert the pressurization entry device

(see Fig. 2). The center of the package is the preferred point of

entry. Location variations of the entry point may affect the

results of the test. Record the location of entry and perform all

sample testing at this same location.

FIG. 1 Open Package Test Positions

NOTE 3—Caution: It is important not to damage other package sur-

faces when inserting the needle. If the package material tears easily,

6.2.2 Timer, and

reinforce the point of entry with tape or equivalent.

6.2.3 Pressure Regulator, intended to maintain steady or

9.1.2.3 Begin the test method by starting the inflation

increasing pressure in the package.

process. The rate of pressurization may affect the test results

NOTE 1—Ifthepressureregulatorcannotprovidethenecessaryvolume,

and must not exceed the response rate of the pressure indicator.

the porosity of the sample may need to be limited.

Continue pressurization until a failure occurs.

7. Sampling

9.1.2.4 Visually examine the package and note the position

7.1 Choose the number of test specimens to permit an and type of failure (material

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.