ASTM C158-95

(Test Method)Standard Test Methods for Strength of Glass by Flexure (Determination of Modulus of Rupture)

Standard Test Methods for Strength of Glass by Flexure (Determination of Modulus of Rupture)

SCOPE

1.1 These test methods cover the determination of the modulus of rupture in bending of glass and glass-ceramics.

1.2 These test methods are applicable to annealed and prestressed glasses and glass-ceramics available in varied forms. Alternative test methods are described; the test method used shall be determined by the purpose of the test and geometric characteristics of specimens representative of the material.

1.2.1 Test Method A is a test for modulus of rupture of flat glass.

1.2.2 Test Method B is a comparative test for modulus of rupture of glass and glass-ceramics.

1.3 The test methods appear in the following order:SectionsTest Method A6 to 9Test Method B10 to 15

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 10 and A1.5, A2.3.3, A2.4.3 and A2.5.3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 158 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Methods for

Strength of Glass by Flexure (Determination of Modulus of

Rupture)

This standard is issued under the fixed designation C 158; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 glass-ceramics—solid materials, predominantly crys-

talline in nature, formed by the controlled crystallization of

1.1 These test methods cover the determination of the

glasses.

modulus of rupture in bending of glass and glass-ceramics.

3.1.2 modulus of rupture in bending—the value of maxi-

1.2 These test methods are applicable to annealed and

mum tensile or compressive stress (whichever causes failure)

prestressed glasses and glass-ceramics available in varied

in the extreme fiber of a beam loaded to failure in bending

forms. Alternative test methods are described; the test method

computed from the flexure formula:

used shall be determined by the purpose of the test and

geometric characteristics of specimens representative of the Mc

S 5 (1)

b

I

material.

1.2.1 Test Method A is a test for modulus of rupture of flat

where:

glass.

M 5 maximum bending moment, computed from the

1.2.2 Test Method B is a comparative test for modulus of

maximum load and the original moment arm,

rupture of glass and glass-ceramics.

c 5 initial distance from the neutral axis to the extreme

1.3 The test methods appear in the following order:

fiber where failure occurs, and

Sections

I 5 initial moment of inertia of the cross section about the

Test Method A 6to9

neutral axis.

Test Method B 10 to 15

3.1.3 prestressed—material in which a significant and con-

1.4 This standard does not purport to address all of the

trolled degree of compressive stress has been deliberately

safety concerns, if any, associated with its use. It is the

produced in the surfaces.

responsibility of the user of this standard to establish appro-

3.1.4 standard laboratory atmosphere—an atmosphere hav-

priate safety and health practices and determine the applica-

ing a temperature of 23 6 2°C and a relative humidity of 40 6

bility of regulatory limitations prior to use. Specific hazard

10 %.

statements are given in Section 10 and A1.5, A2.3.3, A2.4.3

3.2 Definitions of Terms Specific to This Standard:

and A2.5.3.

3.2.1 abraded—describes a test specimen that has at least a

portion of the area of maximum surface tensile stress subjected

2. Referenced Documents

to an operationally defined procedure for mechanical abrasion.

2.1 ASTM Standards:

The severity and uniformity of abrasion should be sufficient to

C 148 Test Methods for Polariscopic Examination of Glass

ensure origin of failure substantially in the region of maximum

Containers

stress.

E 4 Practices for Load Verification of Testing Machines

3.2.2 annealed glass—describes a specimen that shall not

E 380 Practice for Use of the International System of Units

have a temper or degree of residual stress resulting from prior

(SI) (the Modernized Metric System)

thermal treatment in excess of the following limits when

measured polarimetrically (see Annex A1):

3. Terminology

3.2.2.1 Specimens of rectangular section shall not have a

3.1 Definitions:

tensile stress at the midplane of more than 1.38-MPa (200-psi)

nor more than 2.76-MPa (400-psi) compression at the surface.

3.2.2.2 Specimens in rod form may be examined by viewing

These test methods are under the jurisdiction of ASTM Committee C-14 on

through a diameter at least four diameters from an end. The

Glass and Glass Products and are the direct responsibility of Subcommittee C14.04

apparent central axial tension shall not exceed 0.92 MPa (133

on Physical and Mechanical Properties.

Current edition approved Sept. 10, 1995. Published November 1995. Originally psi). Surface compression, if measured on sections cut from the

e1

published as C 158 – 40 T. Last previous edition C 158 – 84 (1989) .

rods, shall not exceed 2.76 MPa (400 psi) when viewed axially.

Annual Book of ASTM Standards, Vol 15.02.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 14.02.

C 158

4. Significance and Use to be characteristic of a product or material, but are considered

to be determined by the procedures used to prepare the

4.1 For the purpose of this test, glasses and glass-ceramics

specimens. Though the stated procedure permits a wide varia-

are considered brittle (perfectly elastic) and to have the

tion in both specimen size and test geometry, it is necessary to

property that fracture normally occurs at the surface of the test

use identical test conditions and equivalent procedures for

specimen from the principal tensile stress. The modulus of

specimen preparation to obtain comparable strength values.

rupture is considered a valid measure of the tensile strength

The use of a controlled abrasion of the specimen as a final

subject to the considerations discussed below.

normalizing procedure is recommended for such comparative

4.2 It is recognized that the modulus of rupture for a group

tests.

of test specimens is influenced by variables associated with the

4.6 A comparative abraded strength, determined as sug-

test procedure. These include the rate of stressing, test envi-

gested in Test Method B, is not to be considered as a minimum

ronment, and the area of the specimen subjected to stress. Such

value characteristic of the material tested nor as directly related

factors are specified in the test procedure or required to be

to a maximum attainable strength value through test of

stated in the report.

specimens with identical flaws. The operationally defined

4.3 It is also recognized that the variables having the

abrasion procedure undoubtedly produces flaws of differing

greatest effect on the modulus of rupture value for a group of

severity when applied to varied materials, and the measured

test specimens are the condition of the surfaces and glass

comparative strengths describe the relative ability to withstand

quality near the surfaces in regard to the number and severity

externally induced stress as affected by the specific abrasion

of stress-concentrating discontinuities or flaws, and the degree

procedure.

of prestress existing in the specimens. Each of these can

represent an inherent part of the strength characteristic being

5. Apparatus

determined or can be a random interfering factor in the

measurement. 5.1 Testing Machine—The loading mechanism shall be

4.4 Test Method A is designed to include the condition of sufficiently adjustable to give the required uniform rate of

the surface of the specimen as a factor in the measured increase of stress. The load-measuring system shall be essen-

strength. It is, therefore, desirable to subject a fixed and tially free of inertial lag at the loading rates used and shall be

significant area of the surface to the maximum tensile stress. equipped with means for retaining indication of the maximum

Since the number and severity of surface flaws in glass are load applied to the specimen. The accuracy of the testing

primarily determined by manufacturing and handling pro- machine shall conform to the requirements of Practice E 4.

cesses, this test method is limited to products from which 5.2 Bearing Edges—Cylindrical bearing edges of approxi-

specimens of suitable size can be obtained with minimal mately 3-mm ( ⁄8-in.) radius shall be used for the support of the

dependence of measured strength upon specimen preparation test specimen and the application of the load. The bearing

techniques. This test method is therefore designated as a test edges shall be of steel and sufficiently hardened to prevent

for modulus of rupture of flat glass. excessive deformation under load. Two-point loading tests

4.5 Test Method B describes a general procedure for test, shall be performed with the loading member pivoted about a

applicable to specimens of rectangular or elliptical cross central transverse axis to ensure equal distribution of load

section. This test method is based on the assumption that a between the two bearing edges. For the testing of specimens of

comparative measurement of strength on groups of specimens rectangular section, both loading bearing edges and one sup-

is of significance for many purposes, such as determining the port bearing edge also shall be provided laterally to compen-

sate for irregularities of the test specimen. Fig. 1 shows a

effect of environment or stress duration, or the effectiveness of

varied prestressing techniques or strengths characteristic of suitable arrangement using pinned bearing edges. In test of

glass-ceramics of differing composition or heat treatment. In specimens of a circular or elliptical section, the fixed cylindri-

this test method the surfaces of the specimens are not assumed cal support edges may have a curvature of approximately 76

FIG. 1 Pinned Bearing Edges

C 158

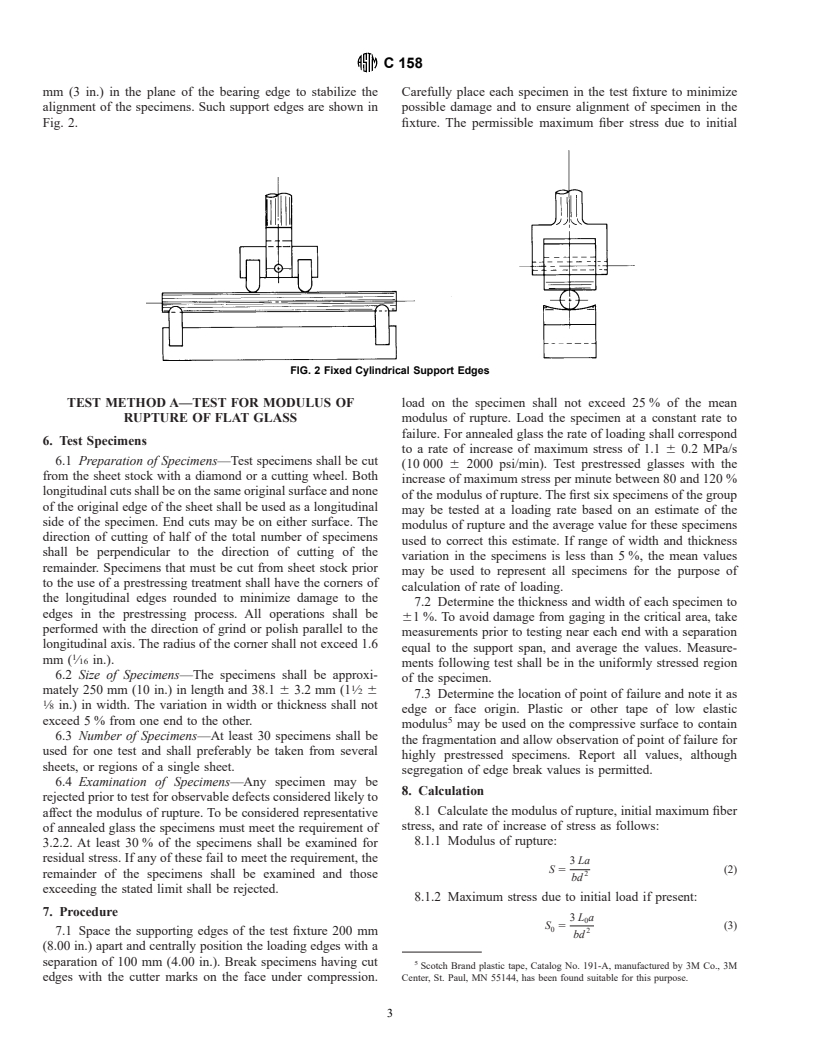

mm (3 in.) in the plane of the bearing edge to stabilize the Carefully place each specimen in the test fixture to minimize

alignment of the specimens. Such support edges are shown in possible damage and to ensure alignment of specimen in the

Fig. 2. fixture. The permissible maximum fiber stress due to initial

FIG. 2 Fixed Cylindrical Support Edges

TEST METHOD A—TEST FOR MODULUS OF load on the specimen shall not exceed 25 % of the mean

RUPTURE OF FLAT GLASS modulus of rupture. Load the specimen at a constant rate to

failure. For annealed glass the rate of loading shall correspond

6. Test Specimens

to a rate of increase of maximum stress of 1.1 6 0.2 MPa/s

6.1 Preparation of Specimens—Test specimens shall be cut

(10 000 6 2000 psi/min). Test prestressed glasses with the

from the sheet stock with a diamond or a cutting wheel. Both

increase of maximum stress per minute between 80 and 120 %

longitudinal cuts shall be on the same original surface and none

of the modulus of rupture. The first six specimens of the group

of the original edge of the sheet shall be used as a longitudinal

may be tested at a loading rate based on an estimate of the

side of the specimen. End cuts may be on either surface. The

modulus of rupture and the average value for these specimens

direction of cutting of half of the total number of specimens

used to correct this estimate. If range of width and thickness

shall be perpendicular to the direction of cutting of the

variation in the specimens is less than 5 %, the mean values

remainder. Specimens that must be cut from sheet stock prior

may be used to represent all specimens for the purpose of

to the use of a prestressing treatment shall have the corners of

calculation of rate of loading.

the longitudinal edges rounded to minimize damage to the

7.2 Determine the thickness and width of each specimen to

edges in the prestressing process. All operations shall be

61 %. To avoid damage from gaging in the critical area, take

performed with the direction of grind or polish parallel to the

measurements prior to testing near each end with a separation

longitudinal axis. The radius of the corner shall not exceed 1.6

equal to the support span, and average the values. Measure-

mm ( ⁄16 in.).

ments following test shall be in the uniformly stressed region

6.2 Size of Specimens—The specimens shall be approxi-

of the specimen.

mately 250 mm (10 in.) in length and 38.1 6 3.2 mm (1 ⁄2 6

7.3 Determine the location of point of failure and note it as

⁄8 in.) in width. The variation in width or thickness shall not

edge or face origin. Plastic or other tape of low elastic

exceed 5 % from one end to the other.

modulus may be used on the compressive surface to contain

6.3 Number of Specimens—At least 30 specimens shall be

the fragmentation and allow observation of point of failure for

used for one test and shall preferably be taken from several

highly prestressed specimens. Report all values, although

sheets, or regions of a single sheet.

segregation of edge break values is permitted.

6.4 Examination of Specimens—Any specimen may be

8. Calculation

rejected prior to test for observable defects considered likely to

8.1 Calculate the modulus of rupture, initial maximum fiber

affect the modulus of rupture. To be considered representative

stress, and rate of increase of stress as follows:

of annealed glass the specimens must meet the requirement of

8.1.1 Modulus of rupture:

3.2.2. At least 30 % of the specimens shall be examined for

residual stress. If any of these fail to meet the requirement, the

3 La

S 5 (2)

remainder of the specimens shall be examined and those

bd

exceeding the stated limit shall be rejected.

8.1.2 Maximum stress due to initial load if present:

7. Procedure

3 L a

S 5 (3)

0 2

7.1 Space the supporting edges of the test fixture 200 mm

bd

(8.00 in.) apart and centrally position the loading edges with a

separation of 100 mm (4.00 in.). Break specimens having cut

Scotch Brand plastic tape, Catalog No. 191-A, manufactured by 3M Co., 3M

edges with the cutter marks on the face under compression. Center, St. Paul, MN 55144, has been found suitable for this purpose.

C 158

8.1.3 Rate of increase of maximum stress: equilibrium to eliminate the presence of thermally induced

stresses in the specimen. The report should indicate the thermal

3a DL

R 5 3 (4)

history prior to testing.

Dt

bd

S

11. Test Specimens

R 5 S 2

t

11.1 Preparation of Specimens:

11.1.1 Specimens of rectangular cross section may be pre-

where:

pared by any sequence of conventional operations such as

S 5 modulus of rupture, MPa (psi),

cutting, sawing, grinding, or polishing. Longitudinal edges on

S 5 maximum fiber stress due to initial load if

the face to be placed in tension should be chamfered or

present, MPa (psi),

rounded. The corner radius shall be a minimum value sufficient

R 5 rate of increase of maximum fiber stress, MPa/s

(psi/min), to eliminate edge breaks and shall not exceed one tenth the

L 5 breaking load including initial load, N (lbf), thickness in specimens approaching a square cross section.

L 5 initial load, N (lbf),

Specimens shall have equivalent size and manufacturing pro-

a 5 moment arm or distance between adjacent sup-

cedures in groups to be compared. The specimen length shall

port and loading edges, mm (in.),

be at least 12.7 mm ( ⁄2 in.) greater in length than the support

b 5 width of specimen, mm (in.),

span used in test. The width to thickness ratio is recomm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.