ASTM D4066-13

(Classification)Standard Classification System for Nylon Injection and Extrusion Materials (PA)

Standard Classification System for Nylon Injection and Extrusion Materials (PA)

SCOPE

1.1 This classification system covers nylon materials suitable for injection molding and extrusion. Some of these compositions are also suitable for compression molding and application from solution.

1.2 The properties included in this classification system are those required to identify the compositions covered. There may be other requirements necessary to identify particular characteristics important to specialized applications. These may be specified by using the suffixes as given in Section 5.

1.3 This classification system and subsequent line call-out (specification) are intended to provide a means of calling out plastic materials used in the fabrication of end items or parts. It is not intended for the selection of materials. Material selection should be made by those having expertise in the plastic field after careful consideration of the design and the performance required of the part, the environment to which it will be exposed, the fabrication process to be employed, the costs involved, and the inherent properties of the material other than those covered by this classification system.

1.4 The values stated in SI units are to be regarded as the standard.

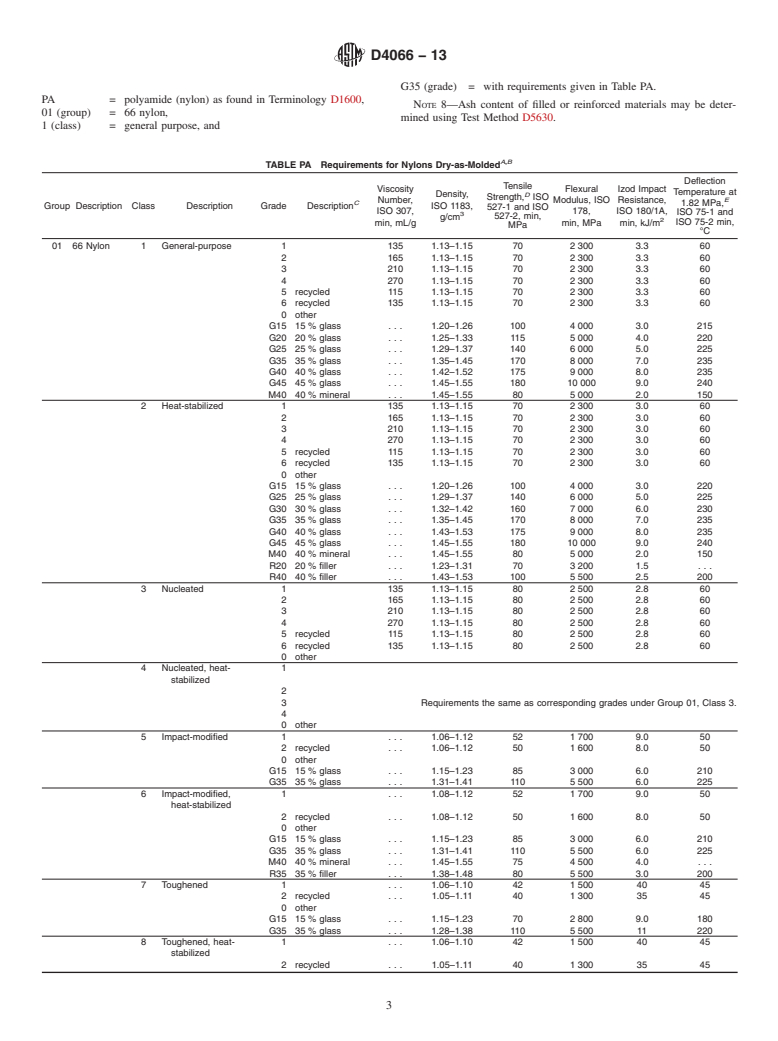

1.5 The following precautionary caveat pertains only to the test methods portion, Section 11, of this classification system. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 1—There is no known ISO equivalent to this standard.Note 2—This classification system is being revised to include international 4-mm specimens and test procedures as the standard for compliance. The 3.2-mm specimens; test methods; and Tables PA, A, and B are included in Appendix X3 as a reference for those wishing to use them. It is recommended that the material manufacturer be consulted on all call-outs against this classification system.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4066 −13

Standard Classification System for

1

Nylon Injection and Extrusion Materials (PA)

This standard is issued under the fixed designation D4066; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This standard is maintained in order to support products that must utilize ASTM D4066 in the

productdefinition.Thisisnecessarybecausetherearesomedifferencesbetweenthematerialproperty

test requirements ofASTM D4066 andASTM D6779, Standard Classification System for and Basis

of Specification for Polyamide Molding and Extrusion Materials (PA). There are also differences

betweenthetwospecificationsinsomeoftheGroup/Class/Gradecallouts.Designersofnewproducts

are urged to use ASTM D6779 rather than ASTM D4066.

1. Scope* health practices and determine the applicability of regulatory

limitations prior to use.

1.1 This classification system covers nylon materials suit-

able for injection molding and extrusion. Some of these

NOTE 1—There is no known ISO equivalent to this standard.

NOTE 2—This classification system is being revised to include interna-

compositions are also suitable for compression molding and

tional 4-mm specimens and test procedures as the standard for compli-

application from solution.

ance. The 3.2-mm specimens; test methods; and Tables PA,A, and B are

1.2 The properties included in this classification system are included in Appendix X3 as a reference for those wishing to use them. It

is recommended that the material manufacturer be consulted on all

thoserequiredtoidentifythecompositionscovered.Theremay

call-outs against this classification system.

be other requirements necessary to identify particular charac-

teristics important to specialized applications. These may be

2. Referenced Documents

specified by using the suffixes as given in Section 5.

2

2.1 ASTM Standards:

1.3 This classification system and subsequent line call-out

D149Test Method for Dielectric Breakdown Voltage and

(specification) are intended to provide a means of calling out

DielectricStrengthofSolidElectricalInsulatingMaterials

plastic materials used in the fabrication of end items or parts.

at Commercial Power Frequencies

It is not intended for the selection of materials. Material

D150Test Methods forAC Loss Characteristics and Permit-

selection should be made by those having expertise in the

tivity (Dielectric Constant) of Solid Electrical Insulation

plastic field after careful consideration of the design and the

D256Test Methods for Determining the Izod Pendulum

performance required of the part, the environment to which it

Impact Resistance of Plastics

will be exposed, the fabrication process to be employed, the

D257Test Methods for DC Resistance or Conductance of

costsinvolved,andtheinherentpropertiesofthematerialother

Insulating Materials

than those covered by this classification system.

D618Practice for Conditioning Plastics for Testing

1.4 The values stated in SI units are to be regarded as the

D638Test Method for Tensile Properties of Plastics

standard.

D648Test Method for Deflection Temperature of Plastics

1.5 The following precautionary caveat pertains only to the Under Flexural Load in the Edgewise Position

test methods portion, Section 11, of this classification system.

D789Test Methods for Determination of Solution Viscosi-

This standard does not purport to address all of the safety ties of Polyamide (PA)

concerns, if any, associated with its use. It is the responsibility

D790Test Methods for Flexural Properties of Unreinforced

of the user of this standard to establish appropriate safety and and Reinforced Plastics and Electrical Insulating Materi-

als

1

ThisclassificationsystemisunderthejurisdictionofASTMCommitteeD20on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

2

Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJuly1,2013.PublishedJuly2013.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1982. Last previous edition approved in 2008 as D4066- 01a(2008), which was Standards volume information, refer to the standard’s Document Summary page on

withdrawn November 2012 and reinstated in July 2013. DOI: 10.1520/D4066-13. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4066−13

D792Test Methods for Density and Specific Gravity (Rela- ISO 3146:Plastics—Determination of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.