ASTM D5781-95(2000)

(Guide)Standard Guide for Use of Dual-Wall Reverse-Circulation Drilling for Geoenvironmental Exploration and the Installation of Subsurface Water-Quality Monitoring Devices

Standard Guide for Use of Dual-Wall Reverse-Circulation Drilling for Geoenvironmental Exploration and the Installation of Subsurface Water-Quality Monitoring Devices

SCOPE

1.1 This guide covers how dual-wall reverse-circulation drilling may be used for geoenvironmental exploration and installation of subsurface water-quality monitoring devices.

Note 1--The term reverse circulation with respect to dual-wall drilling in this guide indicates that the circulating fluid is forced down the annular space between the double-wall drill pipe and transports soil and rock particles to the surface through the inner pipe.

Note 2--This guide does not include considerations for geotechnical site characterizations that are addressed in a separate guide.

1.2 Dual-wall reverse-circulation for geoenvironmental exploration and monitoring-device installations will often involve safety planning, administration, and documentation. This guide does not purport to specifically address exploration and site safety.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This guide offers an organized collection of information or a series of options and does not recommend a specific course of action. This document cannot replace education or experience and should be used in conjunction with professional judgment. Not all aspects of this guide may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project's many unique aspects. The word "Standard" in the title of this document means only that the document has been approved through the ASTM consensus process.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5781–95 (Reapproved 2000)

Standard Guide for

Use of Dual-Wall Reverse-Circulation Drilling for

Geoenvironmental Exploration and the Installation of

Subsurface Water-Quality Monitoring Devices

This standard is issued under the fixed designation D 5781; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This guide covers how dual-wall reverse-circulation 2.1 ASTM Standards:

drilling may be used for geoenvironmental exploration and D 653 Terminology Relating to Soil, Rock, and Contained

installation of subsurface water-quality monitoring devices. Fluids

D 1452 Practice for Soil Investigation and Sampling by

NOTE 1—The term reverse circulation with respect to dual-wall drilling

Auger Borings

in this guide indicates that the circulating fluid is forced down the annular

D 1586 Test Method for Penetration Test and Split-Barrel

space between the double-wall drill pipe and transports soil and rock

Sampling of Soils

particles to the surface through the inner pipe.

NOTE 2—This guide does not include considerations for geotechnical

D 1587 Test Method for Thin-Walled Tube Sampling of

site characterizations that are addressed in a separate guide.

Soils

D 2487 Classification of Soils for Engineering Purposes

1.2 Dual-wall reverse-circulation for geoenvironmental ex-

D 3550 Practice for Ring-Lined Barrel Sampling of Soils

ploration and monitoring-device installations will often in-

D 4428/D4428M Test Method for Crosshole Seismic Test-

volvesafetyplanning,administration,anddocumentation.This

ing

guide does not purport to specifically address exploration and

D 5088 Practice for Decontamination of Field Equipment

site safety.

Used at Non-Radioactive Waste Sites

1.3 The values stated in SI units are to be regarded as the

D 5092 Practice for Design and Installation of Ground

standard. The inch-pound units given in parentheses are for

Water Monitoring Wells in Aquifers

information only.

D 5099 Test Method for Rubber—Measurement of Process-

1.4 This standard does not purport to address all of the

ing Properties Using Capillary Rheometry

safety concerns, if any, associated with its use. It is the

D 5254 Practice for Minimum Set of Data Elements to

responsibility of the user of this standard to establish appro-

Identify a Ground-Water Site

priate safety and health practices and determine the applica-

D 5434 Guide for Field Logging of Subsurface Explora-

bility of regulatory limitations prior to use.

tions of Soil and Rock

1.5

1.6 This guide offers an organized collection of information

3. Terminology

or a series of options and does not recommend a specific

3.1 Definitions:

course of action. This document cannot replace education or

3.1.1 Terminology used within this guide is in accordance

experience and should be used in conjunction with professional

with Terminology D 653. Definitions of additional terms may

judgment. Not all aspects of this guide may be applicable in all

be found in Terminology D 653.

circumstances. This ASTM standard is not intended to repre-

3.2 Definitions of Terms Specific to This Standard:

sent or replace the standard of care by which the adequacy of

3.2.1 bentonite—common name for drilling-fluid additives

a given professional service must be judged, nor should this

and well-construction products consisting mostly of naturally-

document be applied without consideration of a project’s many

occurring montmorillonite. Some bentonite products have

unique aspects. The word “Standard” in the title of this

chemical additives that may affect water-quality analyses.

document means only that the document has been approved

3.2.2 bentonite granules and chips—irregularly-shaped par-

through the ASTM consensus process.

ticles of bentonite (free from additives) that have been dried

and separated into a specific size range.

This guide is under the jurisdiction of ASTM Committee D-18 on Soil and

Rock and is the direct responsibility of Subcommittee D18.21 on GroundWater and Annual Book of ASTM Standards, Vol 04.08.

Vadose Zone Investigations. Annual Book of ASTM Standards, Vol 04.09.

Current edition approved Oct. 10,1995. Published December 1995. Annual Book of ASTM Standards, Vol 09.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5781

3.2.3 bentonite pellets—roughly spherical- or disc-shaped analysis of the chemical, biological or radiological character-

units of compressed bentonite powder (some pellet manufac- istics of subsurface-pore water or to make in-situ measure-

turers coat the bentonite with chemicals that may affect the ments.

water quality analysis).

3.2.4 coeffıcient of uniformity— C (D), the ratio D /D , 4. Significance and Use

u 60 10

where D is the particle diameter corresponding to 60 % finer

60 4.1 Dual-wall reverse-circulation drilling can be used in

on the cumulative particle-size distribution curve, and D is

support of geoenvironmental exploration and for installation of

the particle diameter corresponding to 10 % finer on the

subsurface water-quality monitoring devices in unconsolidated

cumulative particle-size distribution curve.

and consolidated materials. Dual-wall reverse-circulation drill-

3.2.5 drawworks—a power-driven winch, or several

ing methods permit the collection of water-quality samples at

winches, usually equipped with a clutch and brake system(s)

any depth(s), allows the setting of temporary casing during

for hoisting or lowering a drilling string.

drilling, cuttings samples can be taken continuously as circu-

3.2.6 drill hole—a cylindrical hole advanced into the sub-

lation is maintained at all times during drilling. Other advan-

surface by mechanical means. Also known as a borehole or

tages of the dual-wall reverse-circulation drilling method

boring.

include: (1) the capability of drilling without the introduction

3.2.7 filter pack—also known as a gravel pack or a primary of any drilling fluid(s) to the subsurface; (2) maintenance of

filter pack in the practice of monitoring-well installations. The hole stability for sampling purposes and monitor-well

gravel pack is usually granular material, having selected grain installation/construction in poorly-indurated to unconsolidated

size characteristics, that is placed between a monitoring device materials.

and the borehole wall. The basic purpose of the filter pack or

NOTE 3—The user of dual-wall reverse-circulation drilling for geoen-

gravel envelope is to act as: ( 1) a non-clogging filter when the

vironmental exploration and monitoring-device installations should be

aquifer is not suited to natural development or, (2) act as a

cognizant of both the physical (temperature and airborne particles) and

formation stabilizer when the aquifer is suitable for natural

chemical (compressor lubricants and possible fluid additives) qualities of

development. compressed air that may be used as the circulating medium.

3.2.7.1 Discussion—Under most circumstances a clean,

4.2 The application of dual-wall reverse-circulation drilling

quartz sand or gravel should be used. In some cases a

to geoenvironmental exploration may involve soil or rock

pre-packed screen may be used.

sampling, or in-situ soil, rock, or pore-fluid testing.

3.2.8 hoisting line—or drilling line, is wire rope used on the

NOTE 4—The user may install a monitoring device within the same

drawworks to hoist and lower the drill string.

borehole wherein sampling, in-situ or pore-fluid testing, or coring was

3.2.9 in-situ testing devices—sensors or probes, used for

performed.

obtaining mechanical or chemical-test data, that are typically

4.3 The subsurface water-quality monitoring devices that

pushed, rotated or driven below the bottom of a borehole

are addressed in this guide consist generally of a screened- or

following completion of an increment of drilling. However,

porous-intake device and riser pipe(s) that are usually installed

some in-situ testing devices (such as electronic pressure

with a filter pack to enhance the longevity of the intake unit,

transducers, gas-lift samplers, tensiometers, and etc.) may

and with isolation seals and low-permeability backfill to deter

require lowering and setting of the device(s) in a pre-existing

the movement of fluids or infiltration of surface water between

borehole by means of a suspension line or a string of lowering

hydrologic units penetrated by the borehole (see Practice

rods or pipe. Centralizers may be required to correctly position

D 5092). Inasmuch as a piezometer is primarily a device used

the device(s) in the borehole.

for measuring subsurface hydraulic heads, the conversion of a

3.2.10 intermittent-sampling devices—usually barrel-type

piezometer to a water-quality monitoring device should be

samplers that are driven or pushed below the bottom of a

made only after consideration of the overall quality and

borehole following completion of an increment of drilling.The

integrity of the installation to include the quality of materials

user is referred to the following ASTM Standards relating to

that will contact sampled water or gas.

suggested sampling methods and procedures: Practice D 1452,

Test Method D 1586, Practice D 3550, and Practice D 1587.

NOTE 5—Both water-quality monitoring devices and piezometers

3.2.11 mast—or derrick, on a drilling rig is used for

should have adequate casing seals, annular isolation seals and backfills to

supporting the crown block, top drive, pulldown chains, deter communication of contaminants between hydrologic units.

hoisting lines, etc. It must be constructed to safely carry the

5. Apparatus

expected loads encountered in drilling and completion of wells

of the diameter and depth for which the rig manufacturer 5.1 The basic mechanical components of dual-wall reverse-

specifies the equipment.

circulation drilling systems include dual-wall pipe, drill com-

3.2.11.1 Discussion—To allow for contingencies, it is rec- pressor and filter(s), water pump, discharge hose, cleaning

ommendedthattheratedcapacityofthemastshouldbeatleast device (cyclone separator).The dual-wall drill advanced by the

twice the anticipated weight load or normal pulling load. percussive action of an above-ground pile hammer or by

rotation from a rotary-drive unit.

3.2.12 piezometer—an instrument for measuring pressure

head.

NOTE 6—Other methods, such as vibratory equipment sonic resonators,

3.2.13 subsurface water-quality monitoring device—an

may be used to apply the energy required to advance the dual-wall drill

instrument placed below ground surface to obtain a sample for pipe.

D5781

5.1.1 dual-wall drill pipe, consists of an inner pipe secured 5.1.7 Pile Hammer, is commonly used to advance dual-wall

concentrically within an outer pipe. Inner-pipe connections drill pipe. The percussive force of the pile hammer is applied

utilize pin and box components with seals. Outer-pipe connec- only to the outer pipe.

tions are flush threaded. 5.1.8 Rotary-Drive Unit, may be used to advance dual-wall

drillpipebyrotation.Torquegeneratedfromarotary-driveunit

NOTE 7—Drill pipes usually require lubricants on the threads to allow

is applied only to the outer pipe.

easy unthreading (breaking) of the connecting joints. Some lubricants

have organic or metallic constituents, or both, that could be interpreted as

6. Drilling Procedures

contaminants if detected in a sample. Various lubricants are available that

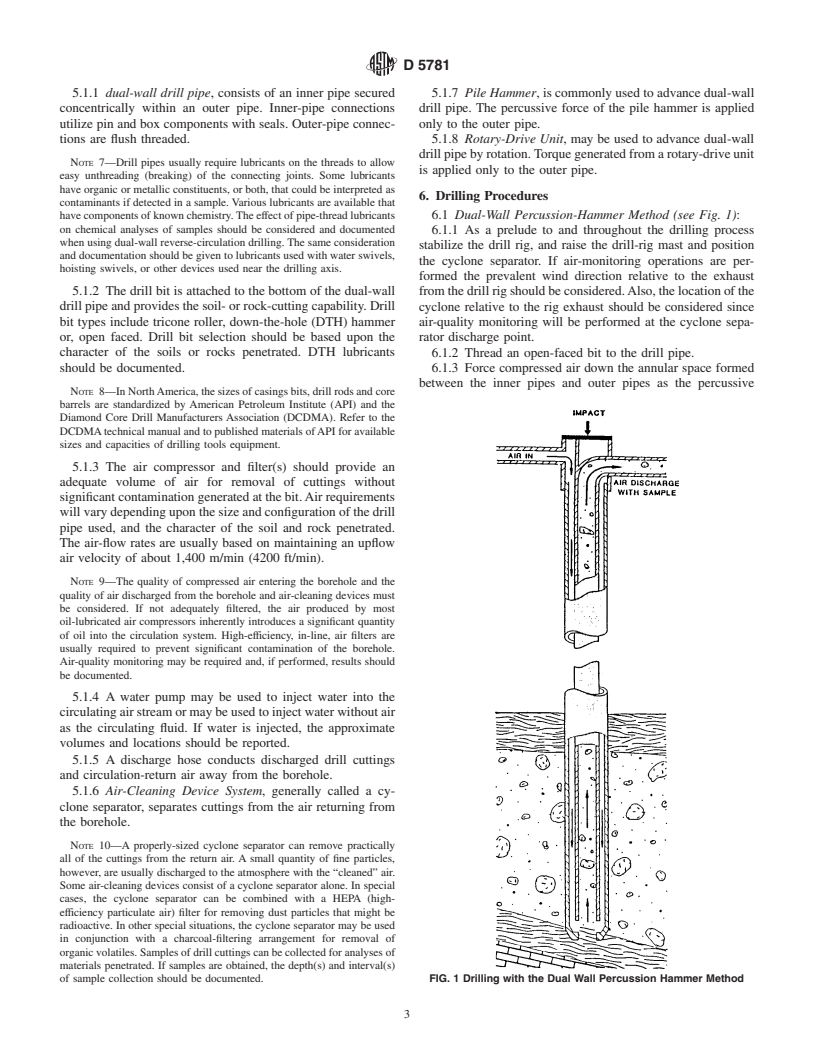

have components of known chemistry.The effect of pipe-thread lubricants 6.1 Dual-Wall Percussion-Hammer Method (see Fig. 1):

on chemical analyses of samples should be considered and documented

6.1.1 As a prelude to and throughout the drilling process

when using dual-wall reverse-circulation drilling. The same consideration

stabilize the drill rig, and raise the drill-rig mast and position

and documentation should be given to lubricants used with water swivels,

the cyclone separator. If air-monitoring operations are per-

hoisting swivels, or other devices used near the drilling axis.

formed the prevalent wind direction relative to the exhaust

5.1.2 The drill bit is attached to the bottom of the dual-wall fromthedrillrigshouldbeconsidered.Also,thelocationofthe

drill pipe and provides the soil- or rock-cutting capability. Drill cyclone relative to the rig exhaust should be considered since

bit types include tricone roller, down-the-hole (DTH) hammer air-quality monitoring will be performed at the cyclone sepa-

or, open faced. Drill bit selection should be based upon the rator discharge point.

character of the soils or rocks penetrated. DTH lubricants 6.1.2 Thread an open-faced bit to the drill pipe.

should be documented. 6.1.3 Force compressed air down the annular space formed

between the inner pipes and outer pipes as the percussive

NOTE 8—In NorthAmerica, the sizes of casings bits, drill rods and core

barrels are standardized by American Petroleum Institute (API) and the

Diamond Core Drill Manufacturers Association (DCDMA). Refer to the

DCDMAtechnical manual and to published materials ofAPI for available

sizes and capacities of drilling tools equipment.

5.1.3 The air compressor and filter(s) should provide an

adequate volume of air for removal of cuttings without

significant contamination generated at the bit.Air requirements

will vary depending upon the size and configuration of the drill

pipe used, and the character of the soil and rock penetrated.

The air-flow rates are usually based on maintaining an upflow

air velocity of about 1,400 m/min (4200 ft/min).

NOTE 9—The quality of compressed air entering the borehole and the

quality of air discharged from the borehole and air-cleaning devices must

be considered. If not adequately filtered, the air produced by most

oil-lubricated air compressors inherently introduces a significant quantity

of oil into the circulation system. High-efficiency, in-line, air filters are

usually required to prevent significant contamination of the borehole.

Air-quality monitoring may be required and, if performed, results should

be documented.

5.1.4 A water pump may be used to inject water into the

circulatingairstreamormaybeusedtoinjectwaterwithoutair

as the circulating fluid. If water is injected, the approximate

volumes and locations should be reported.

5.1.5 A discharge hose conducts discharged drill cuttings

and circulation-return air away from the borehole.

5.1.6 Air-Cleaning Device System, generally called a cy-

clone separator, separates cuttings from the air returning from

the boreho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.