ASTM D5470-06

(Test Method)Standard Test Method for Thermal Transmission Properties of Thermally Conductive Electrical Insulation Materials

Standard Test Method for Thermal Transmission Properties of Thermally Conductive Electrical Insulation Materials

SCOPE

1.1 This standard covers a test method for measurement of thermal impedance and calculation of an apparent thermal conductivity for thermally conductive electrical insulation materials ranging from liquid compounds to hard solid materials.

1.2 The term "thermal conductivity" applies only to homogeneous materials. Thermally conductive electrical insulating materials are usually heterogeneous and to avoid confusion this test method uses "apparent thermal conductivity" for determining thermal transmission properties of both homogeneous and heterogeneous materials.

1.3 The values stated in SI units are to be regarded as standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D5470–06

Standard Test Method for

Thermal Transmission Properties of Thermally Conductive

1

Electrical Insulation Materials

This standard is issued under the fixed designation D5470; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 3.1.1 apparent thermal conductivity (l), n—the time rate of

heat flow, under steady conditions, through unit area of a

1.1 This standard covers a test method for measurement of

heterogeneous material, per unit temperature gradient in the

thermal impedance and calculation of an apparent thermal

direction perpendicular to the area.

conductivity for thermally conductive electrical insulation

3.1.2 average temperature (of a surface), n—the area-

materials ranging from liquid compounds to hard solid mate-

weighted mean temperature.

rials.

3.1.3 composite, n—a material made up of distinct parts

1.2 The term “thermal conductivity” applies only to homo-

whichcontribute,eitherproportionallyorsynergistically,tothe

geneous materials. Thermally conductive electrical insulating

properties of the combination.

materialsareusuallyheterogeneousandtoavoidconfusionthis

3.1.4 homogeneous material, n—a material in which rel-

testmethoduses“apparentthermalconductivity”fordetermin-

evant properties are not a function of the position within the

ing thermal transmission properties of both homogeneous and

material.

heterogeneous materials.

3.1.5 thermal impedance (u), n—the total opposition that an

1.3 The values stated in SI units are to be regarded as

assembly (material, material interfaces) presents to the flow of

standard.

heat.

1.4 This standard does not purport to address all of the

3.1.6 thermal interfacial resistance (contact resistance),

safety concerns, if any, associated with its use. It is the

n—the temperature difference required to produce a unit of

responsibility of the user of this standard to establish appro-

heat flux at the contact planes between the specimen surfaces

priate safety and health practices and determine the applica-

and the hot and cold surfaces in contact with the specimen

bility of regulatory limitations prior to use.

under test. The symbol for contact resistance is R .

I

2. Referenced Documents 3.1.7 thermal resistivity, n—the reciprocal of thermal con-

2

ductivity. Under steady-state conditions, the temperature gra-

2.1 ASTM Standards:

dient, in the direction perpendicular to the isothermal surface

D374 Test Methods for Thickness of Solid Electrical Insu-

per unit of heat flux.

lation

3.2 Symbols Used in This Standard:

E691 Practice for Conducting an Interlaboratory Study to

3.2.1 l = apparent thermal conductivity, W/m·K.

Determine the Precision of a Test Method

2

3.2.2 A = area of a specimen, m .

E1225 Test Method for Thermal Conductivity of Solids by

3.2.3 d = thickness of specimen, m.

Means of the Guarded-Comparative-Longitudinal Heat

3.2.4 Q = time rate of heat flow, W or J/s.

Flow Technique

3.2.5 q = heat flux, or time rate of heat flow per unit area,

2

3. Terminology

W/m .

3.2.6 u = thermal impedance, temperature difference per

3.1 Definitions of Terms Specific to This Standard:

2

unit of heat flux, (K·m )/W.

1

This test method is under the jurisdiction of ASTM Committee D09 on 4. Summary of Test Method

Electrical and Electronic Insulating Materials and is the direct responsibility of

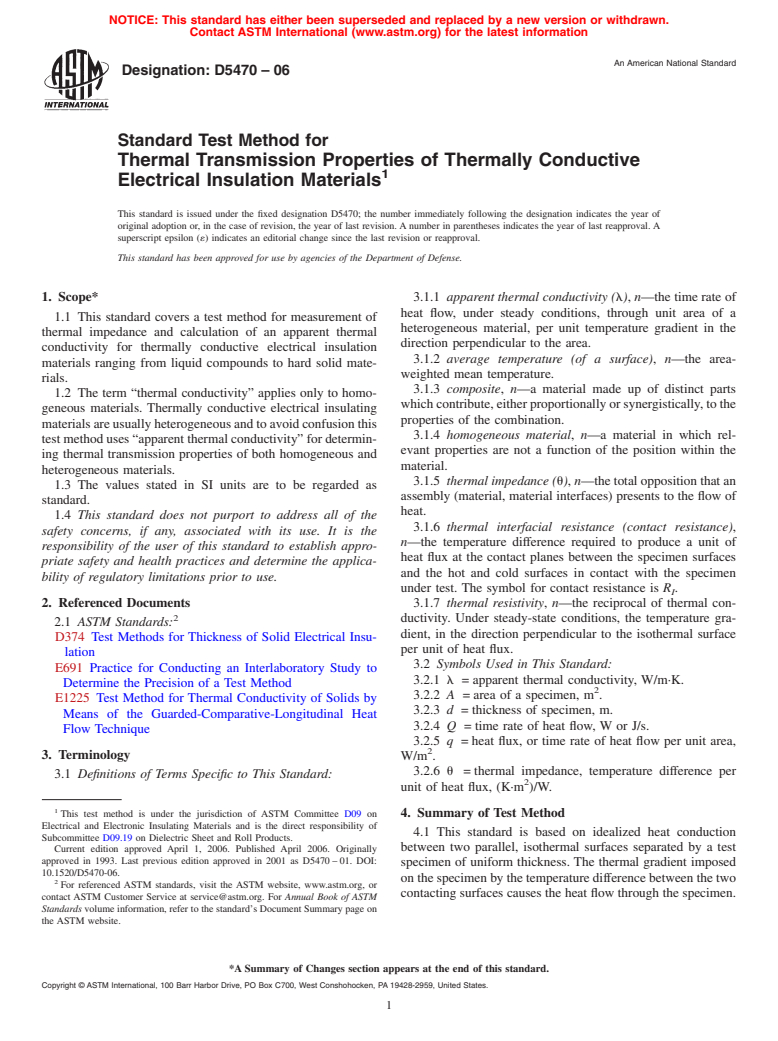

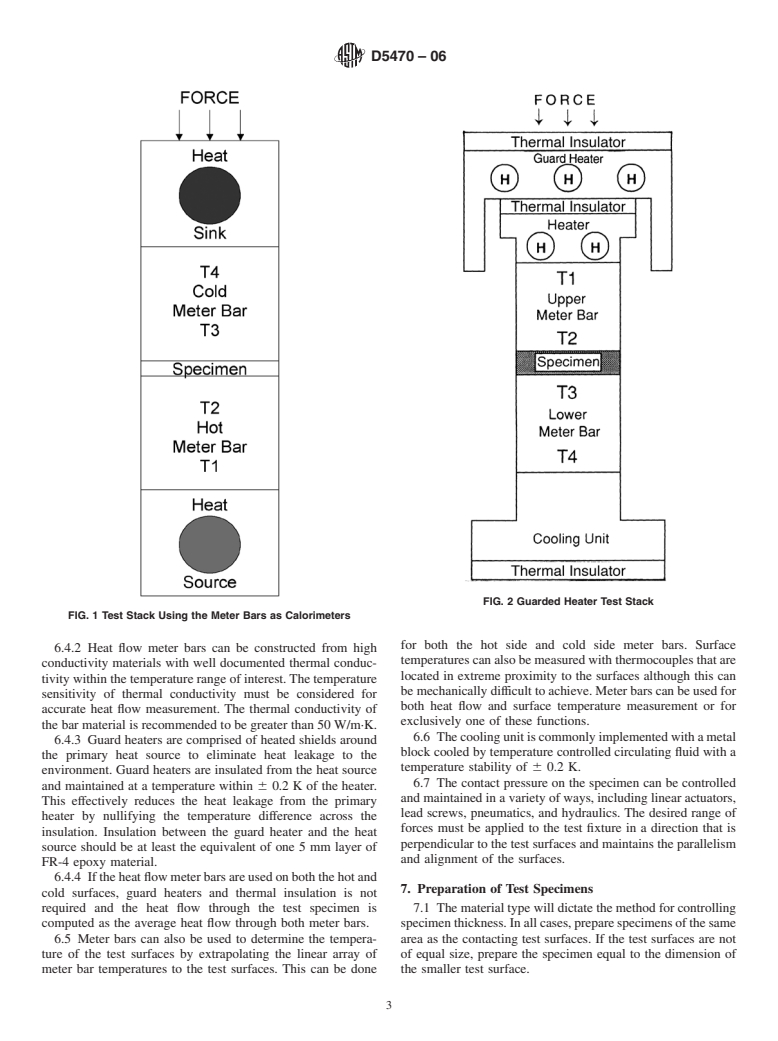

4.1 This standard is based on idealized heat conduction

Subcommittee D09.19 on Dielectric Sheet and Roll Products.

between two parallel, isothermal surfaces separated by a test

Current edition approved April 1, 2006. Published April 2006. Originally

approved in 1993. Last previous edition approved in 2001 as D5470 – 01. DOI:

specimen of uniform thickness. The thermal gradient imposed

10.1520/D5470-06.

on the specimen by the temperature difference between the two

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contacting surfaces causes the heat flow through the specimen.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5470–06

This heat flow is perpendicular to the test surfaces and is practical applications where these required uniform, parallel

uniform across the surf

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.