ASTM D6311-98(2009)

(Guide)Standard Guide for Generation of Environmental Data Related to Waste Management Activities: Selection and Optimization of Sampling Design

Standard Guide for Generation of Environmental Data Related to Waste Management Activities: Selection and Optimization of Sampling Design

SIGNIFICANCE AND USE

The intended use of this guide is to provide practical assistance in the development of an optimized sampling design. This standard describes or discusses:

Sampling design selection criteria,

Factors impacting the choice of a sampling design,

Selection of a sampling design,

Techniques for optimizing candidate designs, and

The criteria for evaluating an optimized sampling design.

Within a formal USEPA data generation activity, the planning process or Data Quality Objectives (DQO) development is the first step. The second and third are the implementation of the sampling and analysis design and the data quality assessment. Within the DQO planning process, the selection and optimization of the sampling design is the last step, and therefore, the culmination of the DQO process. The preceding steps in the DQO planning process address:

The problem that needs to be addressed,

The possible decisions,

The data input and associated activities,

The boundaries of the study,

The development of decision rules, and

The specified the limits on decision error.

This guide is not intended to address the aspects of the planning process for development of the project objectives. However, the project objectives must be outlined and communicated to the design team, prior to the selection and optimization of the sample design.

This guide references statistical aspects of the planning and implementation process and includes an appendix for the statistical calculation of the optimum number of samples for a given sampling design.

This guide is intended for those who are responsible for making decisions about environmental waste management activities.

SCOPE

1.1 This document provides practical guidance on the selection and optimization of sample designs in waste management sampling activities, within the context of the requirements established by the data quality objectives or other planning process.

1.2 This document (1) provides guidance for selection of sampling designs; (2) outlines techniques to optimize candidate designs; and (3) describes the variables that need to be balanced in choosing the final optimized design.

1.3 The contents of this guide are arranged by section as follows:

1.Scope 2.Referenced Documents 3.Terminology 4.Significance and Use 5.Summary of Guide 6.Factors Affecting Sampling Design Selection 6.1Sampling Design Performance Characteristics 6.2Regulatory Considerations 6.3Project Objectives 6.4Knowledge of the Site 6.5Physical Sample Issues 6.6Communication with the Laboratory 6.7Analytical Turn Around Time 6.8Analytical Method Constraints 6.9Health and Safety 6.10Budget/Cost Considerations 6.11Representativeness 7.Initial Design Selection 8.Optimization Criteria 9.Optimization Process 9.2Practical Evaluation of Design Alternatives 9.3Statistical and Cost Evaluation 10.Final Selection Annex A1Types of Sampling Designs A1.1Commonly Used Sampling Designs A1.2Sampling Design Tools A1.3Combination Sample Designs Appendix X1. Additional References Appendix X2. Choosing Analytical Method Based on Variance and Cost Appendix X3. Calculating the Number of Samples: A Statistical Treatment

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6311 − 98(Reapproved 2009)

Standard Guide for

Generation of Environmental Data Related to Waste

Management Activities: Selection and Optimization of

Sampling Design

This standard is issued under the fixed designation D6311; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

10. Final Selection

1.1 This document provides practical guidance on the se-

lection and optimization of sample designs in waste manage- Annex Types of Sampling Designs

A1

ment sampling activities, within the context of the require-

A1.1 Commonly Used Sampling Designs

ments established by the data quality objectives or other

A1.2 Sampling Design Tools

planning process. A1.3 Combination Sample Designs

1.2 This document (1) provides guidance for selection of

Appendix X1. Additional References

samplingdesigns;(2)outlinestechniquestooptimizecandidate

Appendix X2. Choosing Analytical Method Based on Variance and Cost

designs; and (3) describes the variables that need to be

balanced in choosing the final optimized design.

Appendix X3. Calculating the Number of Samples: A Statistical Treatment

1.4 This standard does not purport to address all of the

1.3 The contents of this guide are arranged by section as

safety concerns, if any, associated with its use. It is the

follows:

responsibility of the user of this standard to establish appro-

1. Scope

priate safety and health practices and determine the applica-

2. Referenced Documents

bility of regulatory limitations prior to use.

3. Terminology

2. Referenced Documents

4. Significance and Use

2.1 ASTM Standards:

D5956 Guide for Sampling Strategies for Heterogeneous

5. Summary of Guide

Wastes

6. Factors Affecting Sampling Design Selection

D6044 Guide for Representative Sampling for Management

6.1 Sampling Design Performance Characteristics

of Waste and Contaminated Media

6.2 Regulatory Considerations

6.3 Project Objectives

D6051 Guide for Composite Sampling and Field Subsam-

6.4 Knowledge of the Site

pling for Environmental Waste Management Activities

6.5 Physical Sample Issues

D6232 Guide for Selection of Sampling Equipment for

6.6 Communication with the Laboratory

6.7 Analytical Turn Around Time

WasteandContaminatedMediaDataCollectionActivities

6.8 Analytical Method Constraints

E135 Terminology Relating to Analytical Chemistry for

6.9 Health and Safety

Metals, Ores, and Related Materials

6.10 Budget/Cost Considerations

6.11 Representativeness

E943 Terminology Relating to Biological Effects and Envi-

ronmental Fate

7. Initial Design Selection

2.2 USEPA Documents:

8. Optimization Criteria

9. Optimization Process

USEPA, Guidance for the Data Quality Objectives Process,

9.2 Practical Evaluation of Design Alternatives

EPA QA/G-4, Quality Assurance Management Staff,

9.3 Statistical and Cost Evaluation

Washington, DC, March 1995

1 2

This guide is under the jurisdiction of ASTM Committee D34 on Waste For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Management and is the direct responsibility of Subcommittee D34.01.01 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Planning for Sampling. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Sept. 1, 2009. Published November 2009. Originally the ASTM website.

approvedin1998.Lastpreviouseditionapprovedin2003asD6311–98(2003).DOI: Available from the Superintendent of Documents, U.S. Government Printing

10.1520/D6311-98R09. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6311 − 98 (2009)

USEPA, Data Quality Objectives Process for Superfund - 3.11 false positive error, n—an error which occurs when

Workbook, EPA 540/R-93/078 (OSWER 9355.9-01A), environmental data misleads the decision maker(s) into taking

Office of Emergency and Remedial Response, action when action should not be taken.

Washington, D.C., September, 1993

3.12 heterogeneity, n—theconditionofthepopulationunder

USEPA, Environmental Investigations Branch Standard Op-

which items of the population are not identical with respect to

erating Procedures and Quality Assurance Manual

the characteristic of interest. (D5956)

(EISOPQAM), Region 4 - Science and Ecosystem Sup-

3.13 homogeneity, n—the condition of the population under

port Division, Athens, GA, May 1996

which all items of the population are identical with respect to

2.3 There are numerous useful references available from

the characteristic of interest. (D5956)

ASTM, USEPA, and private sector publishers. Appendix X1

3.14 representative sample, n—a sample collected such that

contains a list, which is by no means comprehensive, of

it reflects one or more characteristics of interest (as defined by

additional commonly used references.

the project objectives) of a population from which it was

3. Terminology

collected. (D5956)

3.1 accuracy, n—closeness of a measured value to the true

3.15 risk, n—the probability or likelihood that an adverse

or an accepted reference or standard value. (E135)

effect will occur. (E943)

3.2 attribute, n—a quality of samples or a population.

3.16 sample, n—a portion of material which is collected for

(D5956)

testing or for record purposes. (D5956)

3.3 characteristic, n—a property of items in a sample or 3.16.1 Discussion—Sample is a term with numerous mean-

population that can be measured, counted, or otherwise

ings. The project team member collecting physical samples

observed. (D5956) (for example, from a landfill, drum or waste pipe) or analyzing

3.3.1 Discussion—A characteristic of interest may be the

samples considers a sample to be that unit of the population

cadmium concentration or ignitability of a population. collected and placed in a container. In statistics, a sample is

considered to be a subset of the population and this subset may

3.4 composite sample, n—a combination of two or more

consist of one or more physical samples. To minimize

samples.

confusion, the term “physical sample” is a reference to the

3.5 confidence interval, n—a numerical range used to bound

sample held in a sample container or that portion of the

the value of a population parameter with a specified degree of

population which is subjected to measurement.

confidence (that the interval would include the true parameter

3.17 sampling design, n—(1) the sampling schemes speci-

value).

fying the point(s) for sample collection; (2) the sampling

3.5.1 Discussion—When providing a confidence interval,

schemes and associated components for implementation of a

the number of observations on which the interval is based

sampling event.

should be identified.

3.17.1 Discussion—Both of the above definitions are com-

3.6 confidence level, n—the probability, usually expressed

monly used within the environmental community. Therefore,

as a percent, that a confidence interval will contain the

both are used within this document.

parameter of interest.

3.7 data quality objectives (DQO), n—qualitative and quan- 4. Significance and Use

titative statements derived from the DQO process describing

4.1 The intended use of this guide is to provide practical

the decision rules and the uncertainties of the decision(s)

assistance in the development of an optimized sampling

within the context of the problem(s). (D5956)

design. This standard describes or discusses:

3.8 data quality objective process, n—aqualitymanagement

4.1.1 Sampling design selection criteria,

tool based on the scientific method and developed by the U.S.

4.1.2 Factors impacting the choice of a sampling design,

Environmental Protection Agency to facilitate the planning of

4.1.3 Selection of a sampling design,

environmental data collection activities. (D5956)

4.1.4 Techniques for optimizing candidate designs, and

3.8.1 Discussion—The DQO process enables planners to

4.1.5 The criteria for evaluating an optimized sampling

focus their planning efforts by specifying the use of the data

design.

(the decision), the decision criteria (action level) and the

4.2 Within a formal USEPA data generation activity, the

decision maker’s acceptable decision error rates. The products

planning process or Data Quality Objectives (DQO) develop-

of the DQO Process are the DQOs.

ment is the first step. The second and third are the implemen-

3.9 decision rule, n—a set of directions in the form of

tation of the sampling and analysis design and the data quality

conditional statements that specifies: (1) how the sample data

assessment. Within the DQO planning process, the selection

will be compared to the decision point or action level, (2)

and optimization of the sampling design is the last step, and

whichdecisionwillbemadeasaresultofthatcomparison,and

therefore, the culmination of the DQO process. The preceding

(3) what subsequent action will be taken based on the deci-

steps in the DQO planning process address:

sions.

4.2.1 The problem that needs to be addressed,

3.10 false negative error, n—an error which occurs when 4.2.2 The possible decisions,

(environmental) data misleads the decision maker(s) into not 4.2.3 The data input and associated activities,

taking action when action should be taken. 4.2.4 The boundaries of the study,

D6311 − 98 (2009)

4.2.5 The development of decision rules, and 5. Summary of Guide

4.2.6 The specified the limits on decision error.

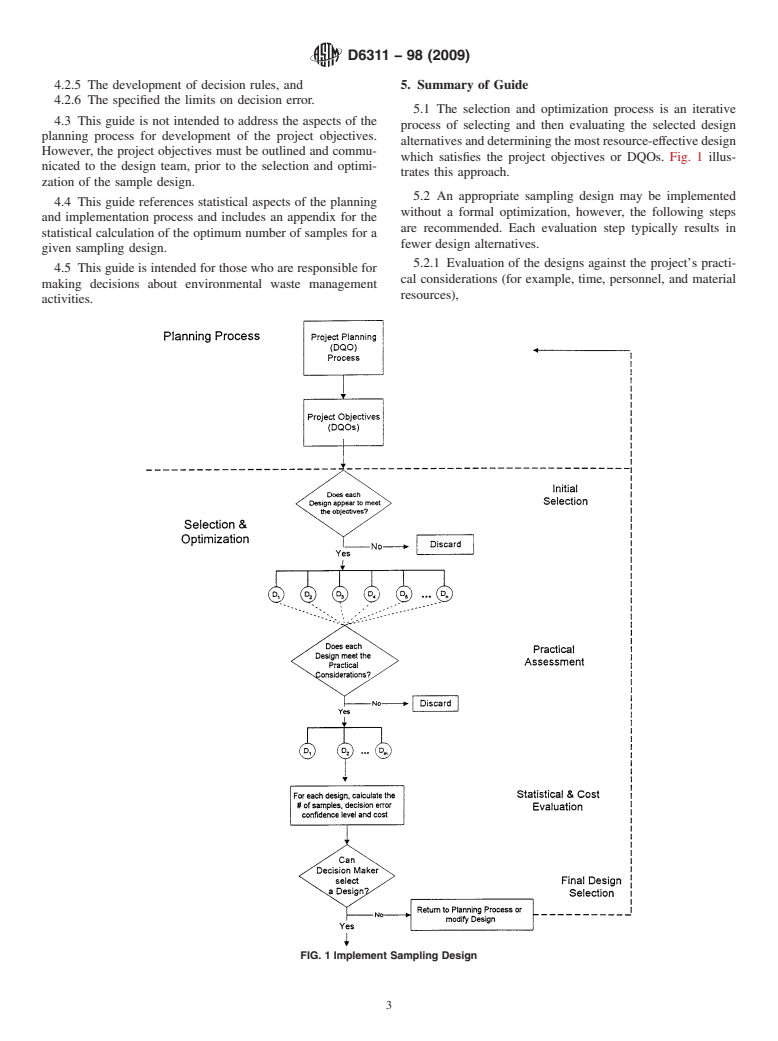

5.1 The selection and optimization process is an iterative

4.3 This guide is not intended to address the aspects of the

process of selecting and then evaluating the selected design

planning process for development of the project objectives.

alternativesanddeterminingthemostresource-effectivedesign

However, the project objectives must be outlined and commu-

which satisfies the project objectives or DQOs. Fig. 1 illus-

nicated to the design team, prior to the selection and optimi-

trates this approach.

zation of the sample design.

5.2 An appropriate sampling design may be implemented

4.4 This guide references statistical aspects of the planning

without a formal optimization, however, the following steps

and implementation process and includes an appendix for the

are recommended. Each evaluation step typically results in

statistical calculation of the optimum number of samples for a

fewer design alternatives.

given sampling design.

5.2.1 Evaluation of the designs against the project’s practi-

4.5 This guide is intended for those who are responsible for

cal considerations (for example, time, personnel, and material

making decisions about environmental waste management

resources),

activities.

FIG. 1 Implement Sampling Design

D6311 − 98 (2009)

5.2.2 Calculation of the design cost and statistical resource efficient sampling design, for example, divide a site

uncertainty, and intoseparatedesignareasforsamplingorexcludeanareafrom

5.2.3 Choice of the sample design decision by the decision sampling.

makers.

6.5 Physical Sample Issues—The physical material to be

5.3 The process steps for the evaluation can be followed in

sampled and its location on or within the site will usually

any order. And for a small project, the entire selection and

impact the sampling design and limit the choices of equipment

optimization process may be conducted at the same time. If

and methods.

ultimately, a design meeting the project constraints, for

6.5.1 Number of Samples:

example, schedule and budget, cannot be identified among the

6.5.1.1 The project objectives should specify the confidence

candidate sampling designs, it may be necessary to modify the

levels for decision making. Using this level of decision error,

closest candidate design or reevaluate and revise the project

the proximity to a threshold or action limit and the anticipated

objectives.

population variance, the number of samples can be calculated.

The statistical parameter of interest, for example, mean or 95

6. Factors Affecting Sampling Design Selection

percentile, and type of frequency of distribution, for example,

normal or log normal, will determine which equation is used to

6.1 Sampling Design Performance Characteristics:

calculate the appropriate number of samples. Equation X3.5

6.1.1 The sampling design provides the structure and detail

from Appendix X3, can be used to calculate the number of

for the sampling activity and should be chosen in light of the

samples when the objective is to measure the mean for a

project objectives. Prior to this point, the planning process

population that has a normal distribution for the characteristic

shouldhaveaddressedanddefinedtheprojectneedsforeachof

of interest.

the sampling design characteristics, including the characteris-

tics of interest, population boundaries, decision rule, accept- 6.5.1.2 Appendix X3 contains statistical approaches to cal-

culatingthenumberofsamplesneededforestimatingthemean

able decision errors and budgets. In considering all aspects of

theproject,theselecteddesignshouldaccommodatethespatial concentration, for simple random, statistical random, multi-

stage sampling and search sampling (where the objective is to

and temporal distribution of contaminants at the site, be

practical, cost effective and generate data that allow the project detect hot spots).

objectives to be met. 6.5.2 Sample Mass or Volume:

6.1.2 Whenever possible, technical guidelines for measure-

6.5.2.1 The sample mass or volume is determined by the

ment of the sources of variability and levels of uncertainty

size of the items that constitute the population, the heteroge-

should be established prior to developing sampling design

neity of the population, the characteristics of available sam-

alternatives, to ensure that it is possible to establish that the

pling equipment (for example, dimensions) and the mass or

program objectives are met.

volume needed for analysis.

6.1.3 Annex A1 presents an overview of some of the more

6.5.2.2 It is important that the sample mass be large enough

commonly used sampling designs and design tools and sum-

to accommodate all item sizes or parts of all items. If items

marizes their advantages and disadvantages. Because numer-

such as fine granular sand or large discarded automobile parts

ous sampling strategies exist, this is limited to the more

constitutethepopulation,thesamplemayneedtoincludethose

common. If the more common sampling strategies are not

items or wipes of those items.

cost-effective or applicable to the population of interest, a

6.5.3 Sample Access and Logistics—Site access and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.