ASTM D4020-00a

(Specification)Standard Specification for Ultra-High-Molecular-Weight Polyethylene Molding and Extrusion Materials

Standard Specification for Ultra-High-Molecular-Weight Polyethylene Molding and Extrusion Materials

SCOPE

1.1 This specification provides for the identification of virgin, unmodified ultra-high-molecular-weight polyethylene (UHMW-PE) plastics molding and extrusion materials. This identification is made in such a manner that the seller and purchaser can agree on the acceptability of different commercial lots or shipments.

1.2 It is not intended to differentiate between various molecular weight grades of ultra-high-molecular-weight polyethylene commercially available.

1.3 It is not the function of this specification to provide specific engineering data for design purposes.

1.4 Ultra-high-molecular-weight polyethylenes, as defined in this specification, are those linear polymers of ethylene which have a relative viscosity of 1.44 or greater, in accordance with the test procedures described herein.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 The following precautionary caveat pertains only to the test method portion. Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no ISO equivalent specification. However, in ISO 11542-1, a range of viscosity numbers defines the viscosity of UHMW-PE grades. The viscosity numbers are determined in accordance with ISO 1628-3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4020 – 00a

Standard Specification for

Ultra-High-Molecular-Weight Polyethylene Molding and

Extrusion Materials

This standard is issued under the fixed designation D 4020; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * D 1601 Test Method for Dilute Solution Viscosity of Eth-

ylene Polymers

1.1 This specification provides for the identification of

D 1898 Practice for Sampling of Plastics

virgin, unmodified ultra-high-molecular-weight polyethylene

2.2 ISO Standards:

(UHMW-PE) plastics molding and extrusion materials. This

ISO 11542-1 Plastics—Ultra High Molecular-Weight Poly-

identification is made in such a manner that the seller and

ethylene (PE-UHMW) Moulding and Extrusion

purchaser can agree on the acceptability of different commer-

Materials—Part 1: Designation System and Basis for

cial lots or shipments.

Specification

1.2 It is not intended to differentiate between various

ISO 1628-3 Plastics—Determination of Viscosity Number

molecular weight grades of ultra-high-molecular-weight poly-

and Limiting Viscosity Number—Part 3: Polyethylenes

ethylene commercially available.

and Polypropylenes

1.3 It is not the function of this specification to provide

specific engineering data for design purposes.

3. Terminology

1.4 Ultra-high-molecular-weight polyethylenes, as defined

3.1 Definitions—Definitions of terms used in this specifica-

in this specification, are those linear polymers of ethylene

tion are in accordance with Terminology D 883.

which have a relative viscosity of 1.44 or greater, in accor-

3.2 Definitions of Terms Specific to This Standard:

dance with the test procedures described herein.

3.2.1 ultra-high-molecular-weight polyethylene molding

1.5 The values stated in SI units are to be regarded as the

and extrusion materials—as defined by this specification, those

standard. The values given in parentheses are for information

substantially linear polyethylenes which have a relative viscos-

only.

ity of 1.44 or greater, at a concentration of 0.02 %, at 135°C, in

1.6 The following precautionary caveat pertains only to the

decahydronaphthalene.

test method portion. Section 7, of this specification: This

3.2.1.1 Discussion—It has been common practice to refer to

standard does not purport to address all of the safety concerns,

the “molecular weight” of UHMW-PE resins. The following

if any, associated with its use. It is the responsibility of the user

calculations shall be used to approximate the specific viscosity

of this standard to establish appropriate safety and health

(h ), reduced viscosity (hred or R.S.V.), intrinsic viscosity (h

sp

practices and determine the applicability of regulatory limita-

or I.V.), and the approximate viscosity average molecular

tions prior to use.

weight of virgin resin. The solution viscosity test on thermally

NOTE 1—There is no ISO equivalent specification. However, in ISO

processed material is invalid due to inadequate solubility and

11542-1, a range of viscosity numbers defines the viscosity of UHMW-PE

possible crosslinking.

grades. The viscosity numbers are determined in accordance with ISO

k

1628-3.

t 2

s

t

s

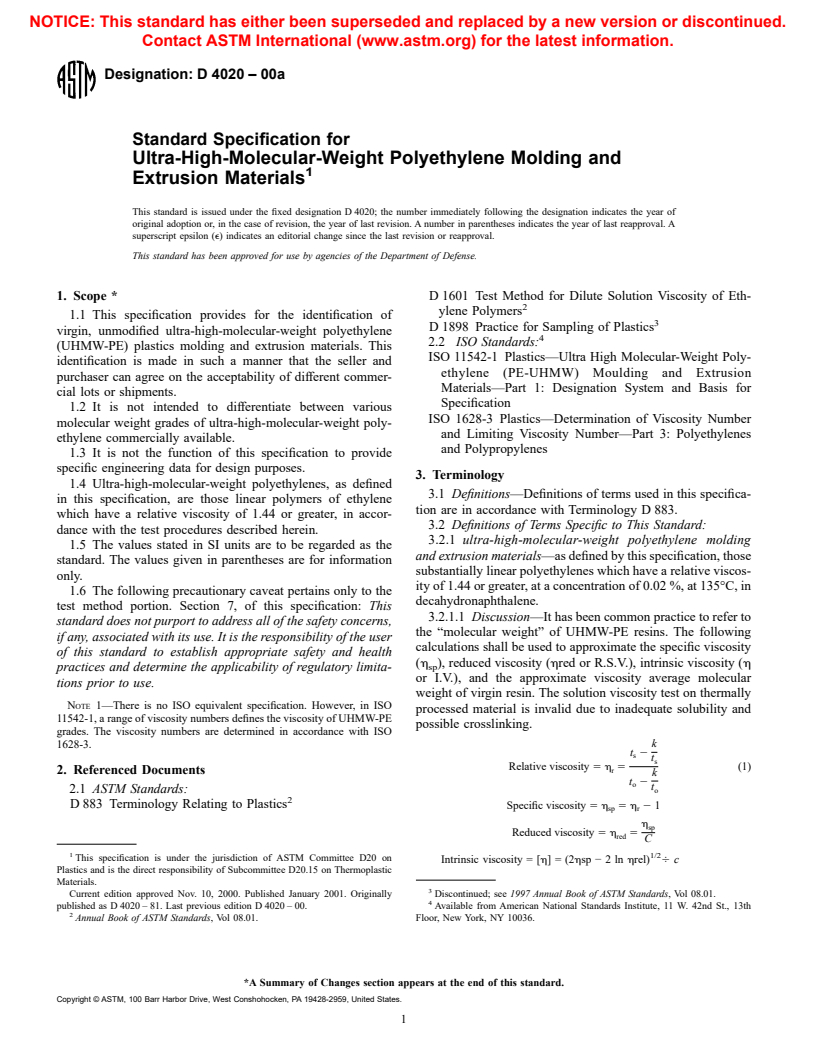

Relative viscosity5h 5 (1)

r

2. Referenced Documents

k

t 2

o

t

2.1 ASTM Standards: o

D 883 Terminology Relating to Plastics Specific viscosity5h 5h 2 1

sp r

h

sp

Reduced viscosity5h 5

red

C

1/2

This specification is under the jurisdiction of ASTM Committee D20 on

Intrinsic viscosity = [h]=(2hsp−2ln hrel) 4 c

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials.

Current edition approved Nov. 10, 2000. Published January 2001. Originally Discontinued; see 1997 Annual Book of ASTM Standards, Vol 08.01.

published as D 4020 – 81. Last previous edition D 4020 – 00. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 08.01. Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4020

limiting viscosity number at 0 % concentration

in this specification, the color and translucence of molded or

4 1.37

Nominal viscosity molecular weight = 5.37 3 10 [h]

extruded pieces, formed under conditions recommended by the

manufacturer of the material, will be comparable within

where:

commercial match tolerances to the color and translucence of

k = kinetic energy correction constant for the particular

standard molded or extruded samples of the same thickness

viscometer used,

supplied in advance by the manufacturer of the material.

t = flow time of solution at 135°C, s,

s

t = flow time of pure solvent at 135°C, s, and

o

C = concentration.

6. Sampling

NOTE 2—There are other equations being used in industry to calculate

6.1 A batch or lot shall be considered as a unit of manufac-

the viscosity average molecular weights. Refer to Appendix X3 for the

ture and may consist of a blend of two or more production runs

other equations and their relationship to the viscosity average molecular

of the same material.

weight equation in 3.2.1.1. The equation in 3.2.1.1 is the only equation

that shall be used for reporting of viscosity average molecular weight. 6.2 Unless otherwise agreed upon between the seller and the

purchaser, the material shall be sampled in accordance with the

4. Classification

procedure described in the general and specific sampling

4.1 It is recognized that dilute solution viscosity measure-

procedures of Practice D 1898. Adequate statistical sampling

ments can only be made on virgin resin. Therefore, the

prior to packaging shall be considered an acceptable alterna-

following test and limits shall be used to determine the

tive.

properties of virgin polymer only.

5. Materials and Manufacture

7. Test Method

5.1 The molding and extrusion material shall be UHMW

7.1 Dilute Solution Viscosity—Use Test Method D 1601, as

polyethylene in the form of powder, granules, or pellets.

modified in Annex A1.

5.2 The molding and extrusion materials shall be as uniform

in composition and size and as free of contamination as can be

8. Keywords

achieved by good manufacturing practice. If necessary, the

level of contamination may be agreed upon between the seller

8.1 extrusion materials; molding materials; plastics; poly-

and the purchaser.

ethylene; ultra-high-molecular-weight; UHMW-PE; viscosity

5.3 Unless controlled by requirements specified elsewhere

ANNEX

(Mandatory Information)

A1. DILUTE SOLUTION VISCOSITY

A1.1 General Description A1.3 Reagents

A1.1.1 The test sequence consists of dissolving UHMW-PE A1.3.1 Decahydronaphthalene, freshly distilled.

in decahydronaphthalene (0.02 g/100 mL) at 150°C and then A1.3.2 Tetrakis [methylene 3-(38,58-di-tert-butyl-48-

measuring the relative viscosity at 135°C in an Ubbelohde No. hydroxyphenyl) propionate] methane.

1 viscometer. The relative solution viscosity may be calculated A1.3.3 Xylene, industrial-grade.

from these experimental data. A1.3.4 Sulfuric Acid-Potassium Dichromate Cleaning

Solution—To 35 mL of a saturated solution of potassium

A1.2 Apparatus

dichromate (K Cr O ), carefully add 1 L of concentrated

2 2 7

A1.2.1 Analytical Balance.

sulfuric acid (H SO ).

2 4

A1.2.2 Microscope Slide Cover Slip.

A1.3.5 Acetone, reagent grade.

A1.2.3 Hot Plate, with magnetic stirrer.

A1.2.4 Erlenmeyer Flask, 250-mL, with glass stopper. A1.4 Procedure

A1.2.5 Vacuum Drying Oven.

A1.4.1 Decahydronaphthalene Preparation—Distill in ac-

A1.2.6 Vacuum Aspirator.

cordance with Test Method D 1061 and add 0.2 % tetrakis

A1.2.7 Viscometer, Ubbelohde No. 1.

[methylene 3-(38,58-di-tert-butyl-48-hydroxyphenyl) propi-

A1.2.8 Constant-Temperature Bath, 135 6 0.1°C, with a

onate] methane.

305-mm diameter by 460 mm (12 by 18-in.) tall glass jar as a

A1.4.2 Cleaning the Viscometer—Clean the viscometer

container, and having a suitable support for the viscometer.

thoroughly with the cleaning solution, wash several times with

A1.2.9 Buret, 100-mL capacity, 0.1-mL subdivisions.

distilled water, rinse with acetone, and purge with dry nitrogen.

A1.2.10 Stopwatch, 0.2-s reading.

A1.2.11 Still, for decahydronaphthalene.

A1.2.12 Glass Funnel, with heating mantle. The anitioxidant (Irganoxt 1010) is available from Ciba-Geigy, Ardsley, NY.

D 4020

A1.4.3 Solution Preparation—Dry the UHMW-PE in a sufficient solution to fill the viscometer to the mark (see Note

vacuum oven for2hat 60°C. Weigh 14 to 17 mg of the dry A1.1) and determine the viscosity of the solution.

UHMW-PE onto a slide cover slip. Use the buret to transfer the A1.4.4.3 Between uses, clean the viscometer as described in

decahydronaphthalene at room temperature into the Erlenm- A1.4.2. Prolonged waits between uses (overnight, etc.) will

eyer flask, measuring, in millilitres, a volume equal to 4.5 times require the use of the H SO –K Cr O cleaning solution.

2 4 2 2 7

the UHMW-PE weight in milligrams, for example, 15 mg of

NOTE A1.1—Filling of the viscometer is made easier by the use of a

UHMW-PE and 67.5 mL of decahydronaphthalene. Heat the

glass funnel warmed with a heating mantle. This helps to prevent the

decahydronaphthalene, with stirring, to 150°C, and drop in the

UHMW-PE from precipitating.

UHMW-PE and its slide cover slip. Continue stirring at 150°C

A1.5 Calculation

for 1 h, with the flask lightly stoppered.

A1.4.4 Viscosity Measurement: A1.5.1 Calculate the relative solution viscosity as follows:

A1.4.4.1 Place the clean viscometer into the constant-

k

t –

temperature bath, fill with decahydronaphthalene, and allow s

t

s

h 5 (A1.1)

the viscometer and solvent to come to thermal equilibrium at r

k

t –

o

135 6 0.1°C. Determine the viscosity of the solvent. Remove

t

o

the decahydronaphthalene with vacuum and wash the viscom-

where:

eter with 200 mL of warm (110 to 120°C) xylene. Remove with

k = kinectic energy correction constant for the particular

vacuum and aspirate dry air or nitrogen to dry the viscometer

viscometer used,

(2 or 3 min). It is essential that the whole viscometer be dry.

t = flow time of solution at 135°C, and

s

A1.4.4.2 Meanwhile, place the flask of polymer solution

t = flow time of pure solvent at 135°C.

o

into the 135°C bath and allow it to equilibrate. Transfer

APPENDIXES

(Nonmandatory Information)

X1. IMPACT TEST METHOD FOR ULTRA-HIGH-MOLECULAR-WEIGHT POLYETHYLENE

X1.1 Scope X1.2.2 ISO Standards:

ISO 180-1982 (E) Determination of Izod Impact Strength of

X1.1.1 This test method covers determination of the impact

Rigid Materials

strength of UHMW-PE, which is extremely impact resistant.

ISO/CD 11542-2 Plastics—Ultra-High Molecular Weight

When tested in accordance with Test Method D 256, Method

Polyethylene (PE-UHMW) Moulding and Extrusion

A, UHMW-PE generally gives the NBF type of failure,

Materials—Part 2: Preparation of Test Specimens and

rendering the test result invalid. This test method specifies the

Determination of Properties

same type of pendulum impact test machine as that given in

Test Method D 256 but introduces a much higher degree of

X1.3 Apparatus

stress concentration into the specimen by double notching with

X1.3.1 The Izod-type impact machine that conforms to the

a razor blade. Application of this test method shall be limited

requirements of Test Method D 256, including the calibration

to the characterization of virgin, unmodified UHMW-PE res-

and checking methods, shall be used.

ins, not commercially processed products. It is advised that the

user be familiar with Test Method D 256 before attempting to

X1.4 Test Specimen

use this test method.

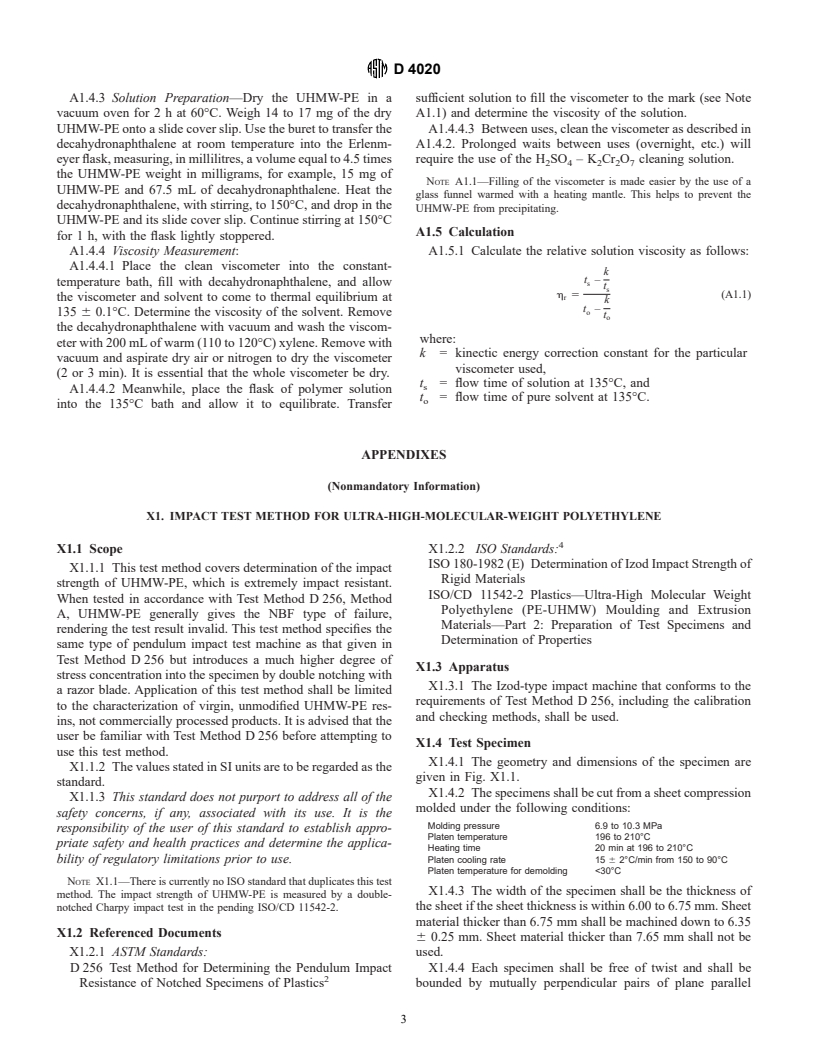

X1.4.1 The geometry and dimensions of the specimen are

X1.1.2 The values stated in SI units are to be regarded as the

given in Fig. X1.1.

standard.

X1.4.2 The specimens shall be cut from a sheet compression

X1.1.3 This standard does not purport to address all of the

molded under the following conditions:

safety concerns, if any, associated with its use. It is the

Molding pressure 6.9 to 10.3 MPa

responsibility of the user of this standard to establish appro-

Platen temperature 196 to 210°C

priate safety and health practices and determine the applica-

Heating time 20 min at 196 to 210°C

bility of regulatory limitations prior to use.

Platen cooling rate 15 6 2°C/min from 150 to 90°C

Platen temperature for demolding <30°C

NOTE X1.1—There is currently no ISO standard that duplicates this test

X1.4.3 The width of the specimen shall be the thickness of

method. The impact strength of UHMW-PE is measured by a double-

the sheet if the sheet thickness is within 6.00 to 6.75 mm. Sheet

notched Charpy impact test in the pending ISO/CD 11542-2.

material thicker than 6.75 mm shall be machined down to 6.35

X1.2 Referenced Documents

6 0.25 mm. Sheet material thicker than 7.65 mm shall not be

X1.2.1 ASTM Standards: used.

D 256 Test Method for Determining the Pendulum Impact X1.4.4 Each specimen shall be free of twist and shall be

Resistance of Notched Specimens of Plastics bounded by mutually perpendicular pairs of plane parallel

D 4020

X1.7.4.1 With the excess energy indicating pointer in its

normal starting position, but without a specimen in the vise,

release the pendulum from its normal starting position and note

the position that the pointer attains after the swing as one

reading of Factor A.

X1.7.4.2 Without resetting the pointer, raise the pendulum

and release again. The pointer should move up the scale an

additional amount. Repeat this procedure until a swing causes

no additional movement of the pointer, and note the final

A = 6.7/6.0 Q 90 6 2°

reading as one reading of Factor B.

B = 12.8/12.6

X1.7.4.3 Repeat the above two operations several times,

C = 32.0/31.5

and calculate and record the average A and B readings.

D = 64.0/63.0

E = 4.60/4.50

X1.7.5 Position the specimen precisely and rigidly but not

F= 60.10

clamped too tightly in the vise. The relationship of the vise,

FIG. X1.1 Dimensions of Double-Notched Izod Test Specimens

specimen, and striking edge of the pendulum to one another is

given in Fig. X1.2. Note that the top plane of the vise shall be

surfaces, free from scratches, pits, and sink marks.

0.13 6 0.13 mm below the notches.

X1.7.6 Release the pendulum and note and record the

X1.5 Notching of Specimens

excess energy remaining in the pendulum after breaking the

X1.5.1 Notching shall be performed on the side parallel to

specimen.

the direction of the a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.