ASTM F521-83(2010)

(Test Method)Standard Test Methods for Bond Integrity of Transparent Laminates

Standard Test Methods for Bond Integrity of Transparent Laminates

SIGNIFICANCE AND USE

These test methods provide a means to measure quantitatively the bond integrity between the outer layers of the transparency and the interlayer, or to measure the cohesive properties of the interlayer, under various loading conditions.

These test methods provide empirical results useful for control purposes, correlation with service results, and as quality control tests for acceptance of production parts.

Test results obtained on small, laboratory-size samples shown herein should be considered indicative of full-size part capability, but not necessarily usable for design purposes.

SCOPE

1.1 These test methods cover determination of the bond integrity of transparent laminates. The laminates are usually made of two or more glass or hard plastic sheets held together by an elastomeric material. These test methods are intended to provide a means of determining the strength of the bond between the glass or plastic and the elastomeric interlayer under various mechanical or thermal loading conditions.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F521 − 83(Reapproved 2010)

Standard Test Methods for

Bond Integrity of Transparent Laminates

ThisstandardisissuedunderthefixeddesignationF521;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 interlayer—transparent material used as the bonding

agent between two or more hard, transparent materials.

1.1 These test methods cover determination of the bond

integrity of transparent laminates. The laminates are usually 3.2 Definitions of Terms Specific to This Standard:

made of two or more glass or hard plastic sheets held together 3.2.1 number of plies—a three-ply laminate is one having

by an elastomeric material. These test methods are intended to two transparent glass or plastic plies and one interlayer ply. A

provide a means of determining the strength of the bond five-ply laminate has three glass or plastic plies and two

between the glass or plastic and the elastomeric interlayer interlayer plies.

under various mechanical or thermal loading conditions.

4. Significance and Use

1.2 The test methods appear as follows:

4.1 These test methods provide a means to measure quan-

Test Methods Sections

titatively the bond integrity between the outer layers of the

Test MethodA—Flatwise Bond Tensile Strength 5–11

Test Method B—Interlaminar Shear Strength 12–17

transparency and the interlayer, or to measure the cohesive

Test Method C—Creep Rupture 18–25

properties of the interlayer, under various loading conditions.

Test Method D—Thermal Exposure 26–30

4.2 These test methods provide empirical results useful for

1.3 This standard does not purport to address all of the

control purposes, correlation with service results, and as

safety concerns, if any, associated with its use. It is the

quality control tests for acceptance of production parts.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.3 Test results obtained on small, laboratory-size samples

bility of regulatory limitations prior to use.

shown herein should be considered indicative of full-size part

capability, but not necessarily usable for design purposes.

2. Referenced Documents

TEST METHOD A—FLATWISE BOND TENSILE

2.1 ASTM Standards:

STRENGTH

D952 Test Method for Bond or Cohesive Strength of Sheet

Plastics and Electrical Insulating Materials

5. Summary of Test Method

2.2 ANSI Standard:

5.1 Thebondissubjectedtoamechanicalloadinadirection

B1.1 Standard for Unified Screw Threads

perpendicular to the plane of the bond. The adhesive or

3. Terminology

cohesive strength between the interlayer and the outer layers

(flatwisetensilestrength)isdetermined,andexpressedinterms

3.1 Definitions:

of pascals (or pounds-force per square inch).

3.1.1 delamination—avisibleseparationbetweentwolayers

of bonded material.

6. Apparatus

3.1.2 face plies—transparent glass or plastic outer materials

6.1 Metal Blocks—A pair of 50-mm (2-in.) square metal

joined together with an interlayer.

blocks of 24 ST aluminum alloy, each having a maximum

height of 50 mm (2 in.). Each block shall have in one end a

These test methods are under the jurisdiction of ASTM Committee F07 on

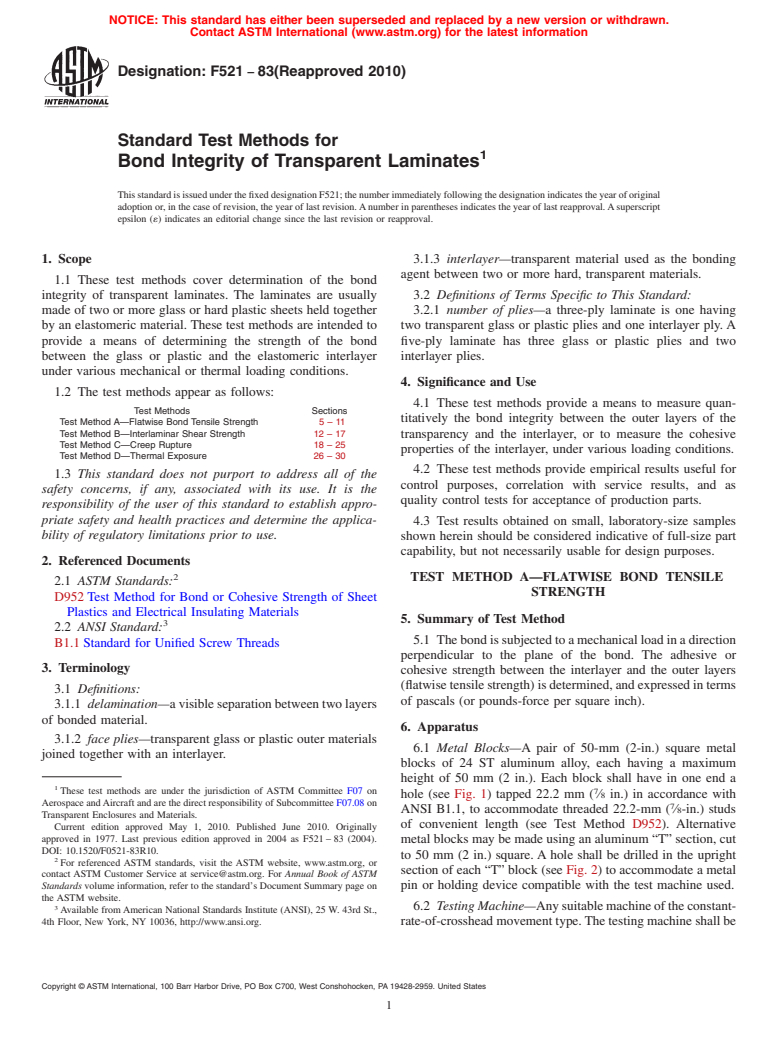

hole (see Fig. 1) tapped 22.2 mm ( ⁄8 in.) in accordance with

Aerospace andAircraft and are the direct responsibility of Subcommittee F07.08 on

ANSI B1.1, to accommodate threaded 22.2-mm ( ⁄8-in.) studs

Transparent Enclosures and Materials.

of convenient length (see Test Method D952). Alternative

Current edition approved May 1, 2010. Published June 2010. Originally

approved in 1977. Last previous edition approved in 2004 as F521 – 83 (2004).

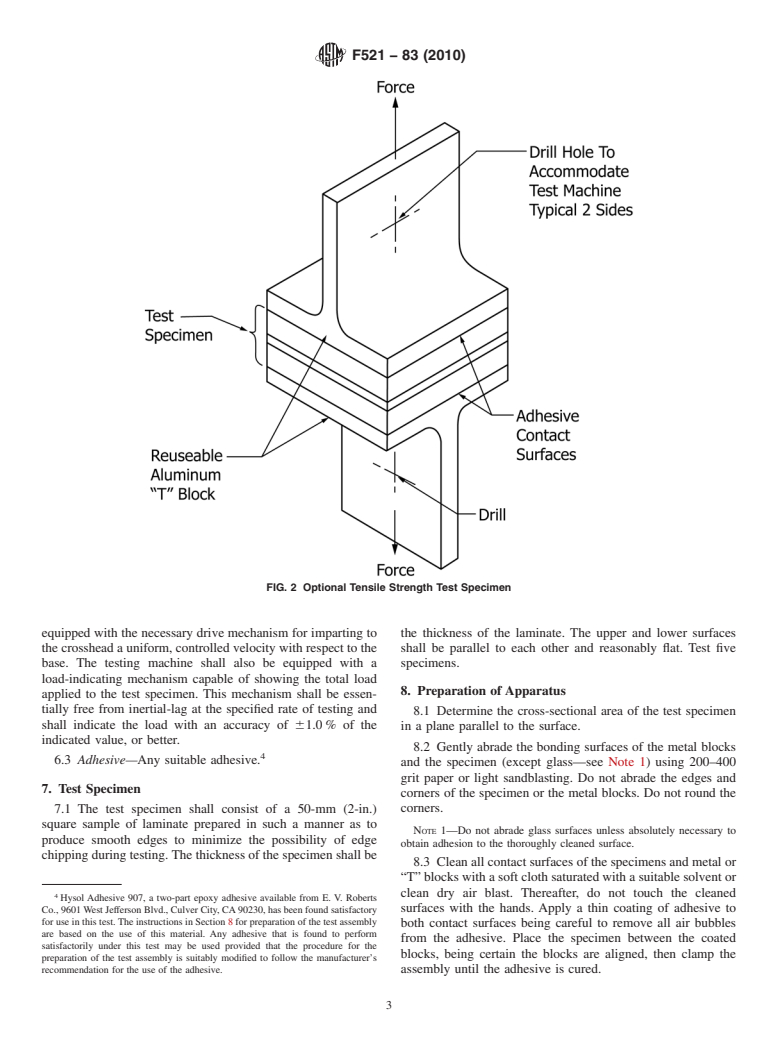

metal blocks may be made using an aluminum “T” section, cut

DOI: 10.1520/F0521-83R10.

to 50 mm (2 in.) square. A hole shall be drilled in the upright

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

section of each “T” block (see Fig. 2) to accommodate a metal

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on pin or holding device compatible with the test machine used.

the ASTM website.

6.2 Testing Machine—Anysuitablemachineoftheconstant-

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. rate-of-crossheadmovementtype.Thetestingmachineshallbe

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

F521 − 83 (2010)

FIG. 1 Test Assembly for Flatwise Tensile Strength Test

F521 − 83 (2010)

FIG. 2 Optional Tensile Strength Test Specimen

equipped with the necessary drive mechanism for imparting to the thickness of the laminate. The upper and lower surfaces

the crosshead a uniform, controlled velocity with respect to the shall be parallel to each other and reasonably flat. Test five

base. The testing machine shall also be equipped with a specimens.

load-indicating mechanism capable of showing the total load

8. Preparation of Apparatus

applied to the test specimen. This mechanism shall be essen-

tially free from inertial-lag at the specified rate of testing and

8.1 Determine the cross-sectional area of the test specimen

shall indicate the load with an accuracy of 61.0 % of the

in a plane parallel to the surface.

indicated value, or better.

8.2 Gently abrade the bonding surfaces of the metal blocks

6.3 Adhesive—Any suitable adhesive.

and the specimen (except glass—see Note 1) using 200–400

grit paper or light sandblasting. Do not abrade the edges and

7. Test Specimen

corners of the specimen or the metal blocks. Do not round the

corners.

7.1 The test specimen shall consist of a 50-mm (2-in.)

square sample of laminate prepared in such a manner as to

NOTE 1—Do not abrade glass surfaces unless absolutely necessary to

produce smooth edges to minimize the possibility of edge

obtain adhesion to the thoroughly cleaned surface.

chipping during testing.The thickness of the specimen shall be

8.3 Clean all contact surfaces of the specimens and metal or

“T” blocks with a soft cloth saturated with a suitable solvent or

4 clean dry air blast. Thereafter, do not touch the cleaned

Hysol Adhesive 907, a two-part epoxy adhesive available from E. V. Roberts

surfaces with the hands. Apply a thin coating of adhesive to

Co., 9601 West Jefferson Blvd., Culver City, CA90230, has been found satisfactory

for use in this test. The instructions in Section 8 for preparation of the test assembly

both contact surfaces being careful to remove all air bubbles

are based on the use of this material. Any adhesive that is found to perform

from the adhesive. Place the specimen between the coated

satisfactorily under this test may be used provided that the procedure for the

blocks, being certain the blocks are aligned, then clamp the

preparation of the test assembly is suitably modified to follow the manufacturer’s

recommendation for the use of the adhesive. assembly until the adhesive is cured.

F521 − 83 (2010)

9. Conditioning tion is preferred, especially for specimens with relatively thick

interlayers of 2.5 mm (0.1 in.) or more.

9.1 Condition the test specimen at 23 6 2 °C (73.4 6 3.6

°F) and 50 6 5 % relative humidity for not less than 24 h prior

14.2 The test specimen shall be 50 mm (2 in.) square

to testing. minimum. Increasing specimen size will give slightly better

accuracy up to the point where the face plies begin to fracture.

9.2 Conduct tests in the Standard LaboratoryAtmosphere of

Prepare the specimens in such a manner as to produce smooth

23 6 2 °C (73.4 6 3.6 °F) and 50 6 5 % relative humidity

edges to minimize premature edge chipping during testing.

unless otherwise specified.

14.3 Orient the samples to duplicate the actual loading

10. Procedure

conditions in service whenever possible.

10.1 Unless otherwise specified, test five specimens. Insert

14.4 Number of Test Specimens:

the specimen assembly in the tension testing machine with

14.4.1 Test at least five specimens for each sample in the

self-aligning holders and load to failure at a rate of 1.25 mm

case of isotropic materials.

(0.05 in.)/min.

14.4.2 Test ten specimens, five normal to, and five parallel

10.2 If block adhesive failure occurs, discard the test and

with the principal axis of anisotropy, for each sample of

test another specimen.

anisotropic material.

14.4.3 Discard specimens that break at some obvious flaw

NOTE 2—If aluminum blocks are to be reused, one method of removing

the adhesive is to insert the blocks in an oven at 150°C (300°F) for 1.5 h. and retest, unless such flaws constitute a variable whose effect

When the blocks have cooled, the remaining portion of the test specimen

is desired for study.

can be easily removed by a surface sanding wheel or sandblast. In order

to maintain a plane surface, it is recommended that the metal blocks be

15. Conditioning

finished on a flat emery surface.

15.1 Condition the specimens in accordance with Section 9.

11. Report

11.1 The report shall include the following:

16. Procedure

11.1.1 Completeidentificationofthematerialtested,includ-

16.1 Measure and record the length and width of the bond

ing type or grade of substrate and interlayer, thickness,

area with a suitable micrometer to the nearest 0.025 mm (0.001

manufacturing history, etc.,

in.).

11.1.2 The block adhesive used,

16.2 Place the specimen in the test fixture, taking care to

11.1.3 The atmospheric conditions in the test room,

11.1.4 The total load, in newtons (or pounds-force), re- aligntheloadedendofthespecimenparalleltotheloadingbar.

quired to break each specimen,

16.3 Set the speed of testing at 1.25 mm (0.05 in.)/min and

11.1.5 The unit stress, in pascals (or pounds-force per

start the testing machine.

square inch), required for failure (calculate the unit stress by

16.4 Record the maximum load carried by the specimen up

dividing the load by the area of the test specimen), and

to the point of rupture.

11.1.6 Failure mode (such as within the interlayer, or at

which interface).

16.5 Remove and examine the test specimen for evidence of

premature failure due to edge chipping or slippage of the

TEST METHOD B—INTERLAMINAR SHEAR

specimen in the fixture. If premature failure has occurred,

STRENGTH

discard the sample and retest another sample.

12. Sum

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.