ASTM F782-01(2007)

(Specification)Standard Specification for Doors, Furniture, Marine

Standard Specification for Doors, Furniture, Marine

ABSTRACT

This specification covers the construction of doors in marine furniture requiring hinged doors. Doors may be flush, right-hand, left-hand, or panel doors. Sheet metal shall be cold-rolled steel, commercial quality, furniture grade. Aluminum extrusions shall be Type 6063-T6 aluminum alloy. Aluminum sheet shall be Type 5052-H32 aluminum alloy. Metal components shall be joined by welding or gluing with a structural adhesive. Doors shall be capable of supporting a specified vertical load, applied at the lock edge of door, with door in any position. Doors shall be subject to tilt test.

SCOPE

1.1 This specification covers the construction of furniture doors for use where invoked by other marine furniture specifications.

1.2 This specification applies to all furniture doors for marine furniture, in items requiring hinged doors.

1.3 Values stated in inch-pound units are to be regarded as the standard. The metric equivalents, given in parentheses, are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F782 −01(Reapproved 2007) An American National Standard

Standard Specification for

Doors, Furniture, Marine

ThisstandardisissuedunderthefixeddesignationF782;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.2 American Institute of Steel Construction Manual:

AISC Wire and Sheet Metal Gages—Equivalent Thickness

1.1 This specification covers the construction of furniture

in Decimals of an Inch, U.S. Standard Gage (USSG) for

doors for use where invoked by other marine furniture speci-

Uncoated Hot and Cold-Rolled Sheets

fications.

2.3 Federal Specifications:

1.2 This specification applies to all furniture doors for

DD-G-1403 Glass, Plate (Float), Sheet Figured, and Span-

marine furniture, in items requiring hinged doors.

drel (Heat Strengthened and Fully Tempered)

LP-391 Plastic Sheets, Rods and Tubing, Rigid Cast, Meth-

1.3 Values stated in inch-pound units are to be regarded as

the standard. The metric equivalents, given in parentheses, are acrylate (Multiapplication)

QQ-C-320 Chromium Plating (Electrodeposited)

for information only.

QQ-Z-325 Zinc Coating, Electrodeposited

2. Referenced Documents

2.4 American National Standard Institute Standards:

ANSI Z97.1-1975 Safety Performance Specifications and

2.1 ASTM Standards:

A240/A240M Specification for Chromium and Chromium- Methods of Test for Safety Glazing Material Used in

Buildings

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

Vessels and for General Applications

3. Terminology

A1008/A1008M Specification for Steel, Sheet, Cold-Rolled,

Carbon, Structural, High-Strength Low-Alloy, High- 3.1 Definitions of Terms Specific to This Standard:

Strength Low-Alloy with Improved Formability, Solution 3.1.1 flush doors—metal doors with a smooth surface on the

Hardened, and Bake Hardenable exterior face.

A582/A582M Specification for Free-Machining Stainless

3.1.2 hinged door—door equipped with hinges that permit it

Steel Bars

to swing about the vertical hinge axis, either right hand or left

B209 Specification for Aluminum and Aluminum-Alloy

hand.

Sheet and Plate

3.1.2.1 right-hand door—door with hinges on the right side

B221 Specification forAluminum andAluminum-Alloy Ex-

when viewed from the exterior of the furniture item containing

truded Bars, Rods, Wire, Profiles, and Tubes

the door.

C1036 Specification for Flat Glass

3.1.2.2 left-hand door—door with hinges on the left side

D907 Terminology of Adhesives

when viewed from the exterior of the furniture item containing

F2119 Test Method for Evaluation of MR Image Artifacts

the door.

from Passive Implants

3.1.3 panel doors—doors with metal stiles and rails that

supportapanelinsertoftransparentsafetyglazingorexpanded

This specification is under the jurisdiction of ASTM Committee F25 on Ships

aluminum.

and Marine Technology and is the direct responsibility of Subcommittee F25.03 on

Outfitting and Deck Machinery.

Current edition approved May 1, 2007. Published June 2007. Originally

approved in 1982. Last previous edition approved in 2001 as F782 - 01. DOI: Available from the American Institute of Steel Construction, 400 N. Michigan

10.1520/F0782-01R07. Ave., Chicago, IL 60611.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F782−01 (2007)

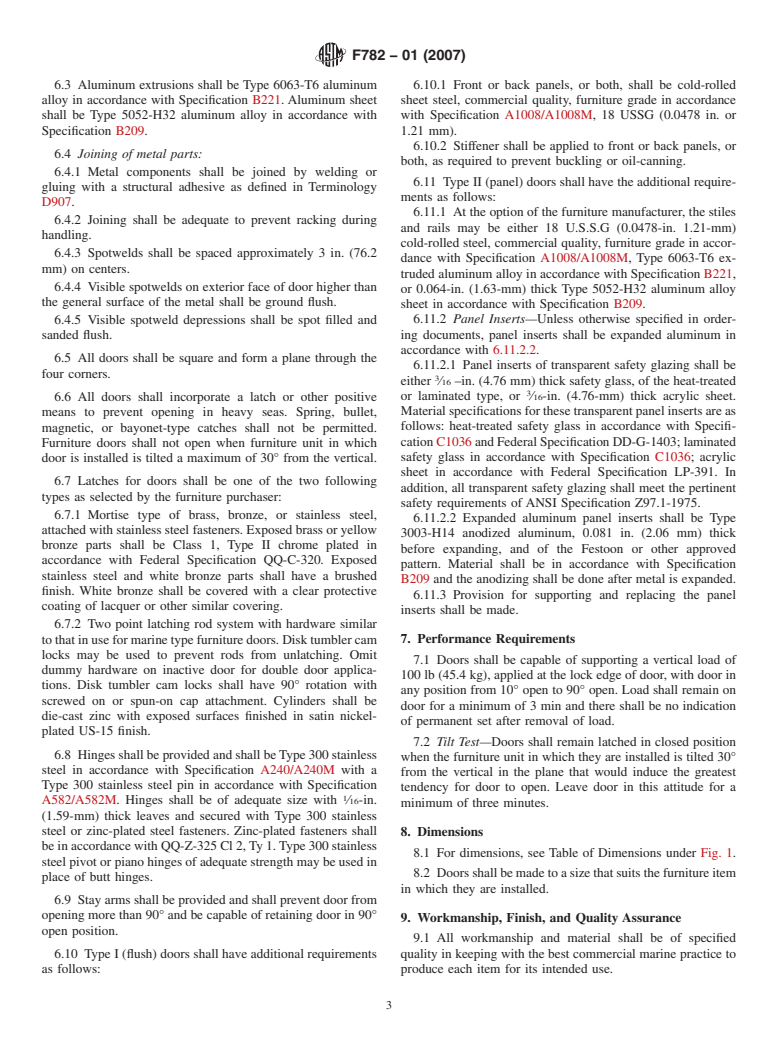

Table of Dimensions

Dimensions

Designation

in. mm

Door thickness A 1 max 25.4 max

Width of stile or height of rail B 3 max 76.2 max

NOTE 1—Panels of Type I (flush) doors shall be cold-rolled sheet steel, commercial quality, furniture grade in accordance with Specification

A1008/A1008M, 18 USSG (0.0478 in. or 1.21 mm). Stiffeners shall be applied to front and back as required to prevent buckling or oil-canning.

NOTE 2—At the option of the furniture manufacturer the stiles and rails for Type II (panel) door, may be either 18 USSG (0.0478 in. or 1.21 mm)

cold-rolled steel, commercial quality, furniture grade in accordance with Specification A1008/A1008M or Type 6063-T6 extruded aluminum in

accordance with Specification B221 or 0.064-in. (1.63-mm) thick Type 5052-H32 aluminum alloy sheet in accordance with Specification B209.

NOTE 3—Aluminum Panel inserts for Type II (panel) doors shall be Type 3003-H14 anodized aluminum, 0.081 in. (2.06 mm) thick before expanding

and of the Festoon or other approved pattern. Material shall be in accordance with Specification B209 and the anodizing shall be done after metal is

expanded. Alternative safety glazing can be furnished if specified in ordering documents. See 6.11.2.1 for description of these alternatives.

NOTE 4—Butt hinges are shown in Fig. 1 and shall be furnished in accordance with 6.8. Type 300 stainless steel pivot or hinges of adequate strength

may be used in place of butt hinges.

NOTE 5—Stay arms shall be provided and shall both prevent door from opening more than 90° and be capable of retaining door in 90° open position.

NOTE 6—Doors shall be equipped with latches. See 6.7.1 and 6.7.2 for description of alternative latches.

NOTE 7—Doors shall be capable of resisting vertical load applied at latch edge. See 7.1 for detail of test.

NOTE 8—Doors shall be comply with requirements of tilt test. See 7.2 for details of test.

FIG. 1 Furniture Doors

3.1.3.1 stiles—the vertical members in the frame of a panel 5.1.2 Size, see Section 8.

door that support the central panel.

5.1.3 Paint:

3.1.3.2 rails—the horizontal members in the frame of a

5.1.3.1 Color—Per the purchaser’s requirements.

panel door that support the central panel.

5.1.3.2 Manufacturer’s standard baked enamel will be fur-

nished unless otherwise required and indicated by the pur-

4. Classification

chaser.

4.1 Doors shall be of the following types as required by the

5.1.4 For single-hinged doors, indicate hand if not obvious

specifications for the item of furniture in which they are

or if a specific hand is required.

installed and as indicated in ordering documents. See Fig. 1 for

5.1.5 Material for Type II (panel) doors may be either steel

details.

or aluminum. Material selected shall be the option of the

4.1.1 Type I—Flush hinged door.

furniture purchaser.

4.1.2 Type II—Panel hinged door.

5. Ordering Information

6. Materials and Manufacture

5.1 Doors are included as part of the orders for items of

6.1 For typical design, see Fig. 1.

furniture requiring doors. To describe adequately the door or

doors required, these orders shall include, as necessary, the 6.2 Sheet metal shall be cold-rolled steel, commercial

quality, furniture grade in accordance with Specification

following information:

5.1.1 Type. A1008/A1008M.

F782−01 (2007)

6.3 Aluminum extrusions shall be Type 6063-T6 aluminum 6.10.1 Front or back panels, or both, shall be cold-rolled

alloy in accordance with Specification B221. Aluminum sheet sheet steel, commercial quality, furniture grade in accordance

s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.