ASTM B794-97(2009)

(Test Method)Standard Test Method for Durability Wear Testing of Separable Electrical Connector Systems Using Electrical Resistance Measurements

Standard Test Method for Durability Wear Testing of Separable Electrical Connector Systems Using Electrical Resistance Measurements

SIGNIFICANCE AND USE

Materials for electrical connector contacts must satisfy a number of requirements in the areas of electrical, mechanical, and economic characteristics. The stability of electrical properties is one of the most important of these characteristics. Wear of contact surfaces may adversely affect these electrical properties, especially in designs where the contact surfaces are relatively thin coatings. This test method provides a means to compare various material systems on a basis relevant to their application in electrical connector contacts.

Repeated insertion and withdrawal of a connector may cause wear or other mechanical damage to the electrical contact surfaces, rendering those surfaces more susceptible to environmental degradation. This test method is intended to detect degradation of the electrical properties of the connector by such processes.

This test method describes procedures for conducting wear and durability testing of electrical connectors; the procedures produce quantitative results. These results may be used to compare the performance of different connector designs so that meaningful design choices can be made. Such results may also be used to compare the performance of a connector to a previously established standard to evaluate the quality of the samples under test.

The test results obtained from this test method are limited in their applicability to connector combinations that are equivalent in design and manufacture to those actually tested.

The user is cautioned that the conditions in this test should be compared to the conditions that the connector will experience in the intended application in order to determine the relevance of this test method to the particular needs of the user. For example, the environmental stress in this test method is less severe than certain industrial and marine environments and therefore test results are not directly applicable to predict the performance of product intended for use in such areas.

It is recomm...

SCOPE

1.1 This test method covers the effects of repeated insertion and withdrawal of separable electrical connectors which are harmful to the electrical performance of the connector.

1.2 This test method is limited to electrical connectors designed for use in applications where the current through any one connection in the connector does not exceed 5 A, and where the connector may be separated a number of times during the life of the connector.

1.3 This test method is limited to electrical connectors intended for use in air ambients where the operating temperature is less than 65°C.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B794 − 97(Reapproved 2009)

Standard Test Method for

Durability Wear Testing of Separable Electrical Connector

Systems Using Electrical Resistance Measurements

This standard is issued under the fixed designation B794; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

1.1 This test method covers the effects of repeated insertion

3.1 Sample connectors are wired for precision resistance

and withdrawal of separable electrical connectors which are

measurements of each test contact. The samples are divided

harmful to the electrical performance of the connector.

into two groups; then resistance measurements are made of

each test contact. The connectors in one group undergo a

1.2 This test method is limited to electrical connectors

designed for use in applications where the current through any number of insertion/withdrawal cycles appropriate for the

one connection in the connector does not exceed 5 A, and particular connector under test, and the resistances of these

where the connector may be separated a number of times connectors are measured again. The connectors in the other

during the life of the connector. group are not disturbed. All samples are subjected to an

accelerated aging test; then the resistances are measured again.

1.3 This test method is limited to electrical connectors

All samples are separated (withdrawn), exposed to an acceler-

intended for use in air ambients where the operating tempera-

ated aging test in the uninserted condition, removed from the

ture is less than 65°C.

test, reinserted, and resistances measured again. The various

1.4 The values stated in SI units are to be regarded as

resistance measurements are compared to detect effects of the

standard. No other units of measurement are included in this

wear and aging on electrical performance.

standard.

1.5 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 Materials for electrical connector contacts must satisfy a

responsibility of the user of this standard to become familiar

number of requirements in the areas of electrical, mechanical,

with all hazards including those identified in the appropriate

and economic characteristics. The stability of electrical prop-

Material Safety Data Sheet (MSDS) for this product/material

erties is one of the most important of these characteristics.

as provided by the manufacturer, to establish appropriate

Wear of contact surfaces may adversely affect these electrical

safety and health practices, and determine the applicability of

regulatory limitations prior to use. properties, especially in designs where the contact surfaces are

relatively thin coatings. This test method provides a means to

2. Referenced Documents

compare various material systems on a basis relevant to their

2.1 ASTM Standards:

application in electrical connector contacts.

B539 Test Methods for Measuring Resistance of Electrical

4.2 Repeated insertion and withdrawal of a connector may

Connections (Static Contacts)

3 cause wear or other mechanical damage to the electrical

2.2 Military Standard:

contact surfaces, rendering those surfaces more susceptible to

MIL-STD-1344A Test Methods for Electrical Connectors

environmental degradation. This test method is intended to

detect degradation of the electrical properties of the connector

This test method is under the jurisdiction of ASTM Committee B02 on

by such processes.

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.11 on Electrical Contact Test Methods.

4.3 This test method describes procedures for conducting

Current edition approved April 15, 2009. Published April 2009. Originally

approved in 1988. Last previous edition approved in 2003 as B794 – 97 (2003).

wear and durability testing of electrical connectors; the proce-

DOI: 10.1520/B0794-97R09.

dures produce quantitative results. These results may be used

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

to compare the performance of different connector designs so

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

that meaningful design choices can be made. Such results may

the ASTM website.

also be used to compare the performance of a connector to a

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

previously established standard to evaluate the quality of the

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

www.dodssp.daps.mil. samples under test.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B794 − 97 (2009)

4.4 The test results obtained from this test method are dure __ , shall meet the limits in the supplied table.” This table

limited in their applicability to connector combinations that are supplied by the purchaser may set limits on all of the values in

equivalent in design and manufacture to those actually tested. Fig. 1, or only on a subset of those values that the purchaser

deems adequate to ensure the performance of the product.

4.5 The user is cautioned that the conditions in this test

should be compared to the conditions that the connector will

5. Apparatus

experienceintheintendedapplicationinordertodeterminethe

5.1 Environmental Test Chamber, capable of controlling the

relevance of this test method to the particular needs of the user.

testambientinaccordancewiththesequenceshowninTable1.

For example, the environmental stress in this test method is

The test chamber shall be sufficiently large that each test

lessseverethancertainindustrialandmarineenvironmentsand

sample shall be positioned with at least 100 mm separating it

therefore test results are not directly applicable to predict the

from the nearest wall of the test chamber. The test chamber

performance of product intended for use in such areas.

design and operation procedure shall conform to the require-

4.6 It is recommended that this test method be used in one

ments contained in MIL-STD-1344A, Method 1002.2.

of two ways. First, it may be used to evaluate and report the

5.2 An instrument is required for measuring resistance by

performance of a particular connector system. In such a case,

the four-wire method. This instrument shall operate within the

it is appropriate to report the results in a table in the format

limits on current and open-circuit voltage set forth in Test

shown in Fig. 1 and to state “The results shown in the table

Methods B539, Test Method C. The instrument shall be

were obtained for (insert connector designation or description)

capable of measuring a resistance less than 0.100 Ω with a

when tested in accordance with ASTM Standard B794,

resolution of 0.0001Ω. For a resistance 0.100Ω or larger, the

Method __ , Procedure __ .” Second, it may be used to impose

instrument shall be capable of measuring it with a resolution of

requirements for acceptance of product. In this case, limits for

0.1 % of the resistance value.

the values shown in Fig. 1 must be established prior to product

acceptance testing. Such limits may be established by various

6. Sampling and Test Specimens

methodssuchasbyevaluationofproductwhichisknowntobe

6.1 Selection of Sample Connectors—Obtain sufficient

acceptable or by application of appropriate experience. These

sample connectors so that the electrical resistance of at least

limits must be documented in a manner that the entity

200 contacts contained in at least 20 separate connectors will

performing the product test can refer to the limits to determine

be measured in the test. Obtain sample connectors that are

if the test product conforms to such limits. A purchaser may

representative of those that will be used in the intended

wish to supply a table of limits and include on the purchase

application. Recognize that a connector consists of two halves

order a statement similar to: “The product, when tested in

and both halves must be representative of the product to be

accordance with ASTM Standard B794, Method __ , Proce-

used. In some cases one half will be a conductive area or pad

on a printed wiring-board surface, therefore printed wiring

boards must be obtained that have representative conductive

pads. Specifically, the conductive pads shall be manufactured

to the same requirements as those that will be required of parts

to be used in the system application. These requirements will

normally cover the manufacturing process, thickness,

composition,hardness,androughnessofboththefinishcoating

and of any underplating or undercoating. Protective treatments,

if used, shall also be specified. For the purpose of connector

testing, such printed wiring boards are generally fabricated

with appropriate circuitry to permit four-wire resistance mea-

surements.

6.2 Selection of Sample Contacts—In the case where the

samples are multicontact connectors and electrical measure-

ments are performed only on a fraction of the total number of

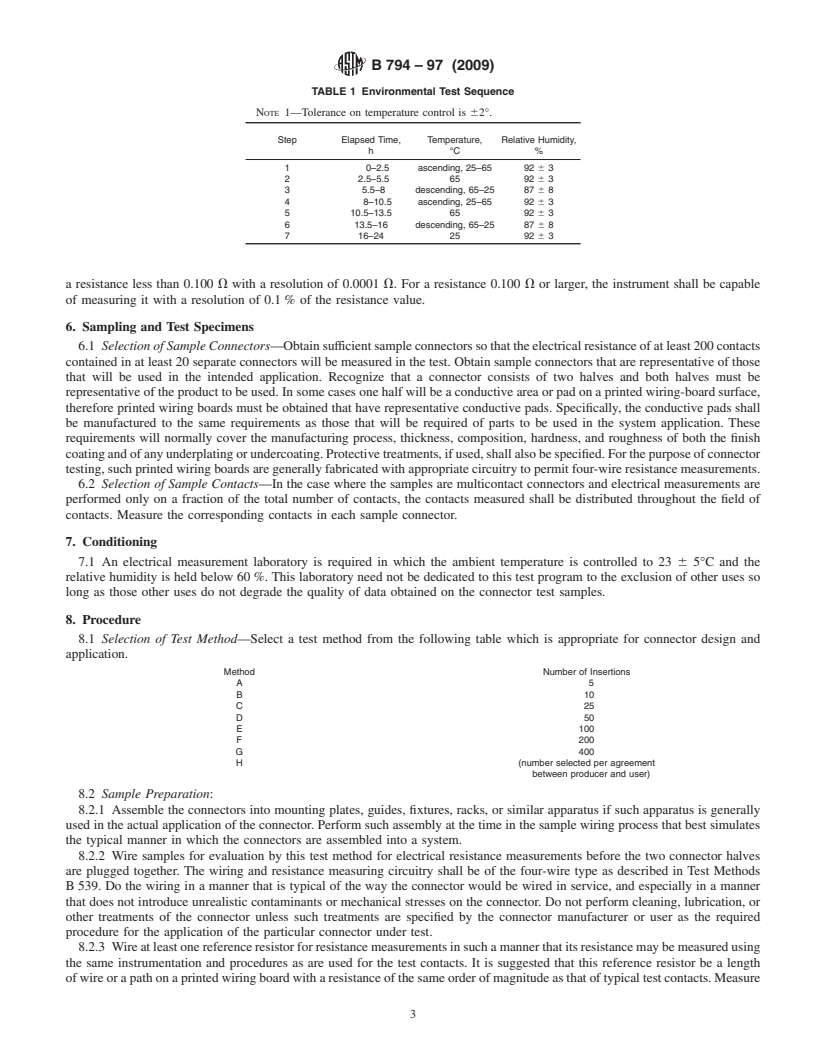

TABLE 1 Environmental Test Sequence

NOTE 1—Tolerance on temperature control is ±2°.

Step Elapsed Time, Temperature, Relative Humidity,

h °C %

1 0–2.5 ascending, 25–65 92 ± 3

2 2.5–5.5 65 92 ± 3

3 5.5–8 descending, 65–25 87 ± 8

4 8–10.5 ascending, 25–65 92 ± 3

5 10.5–13.5 65 92 ± 3

6 13.5–16 descending, 65–25 87 ± 8

7 16–24 25 92 ± 3

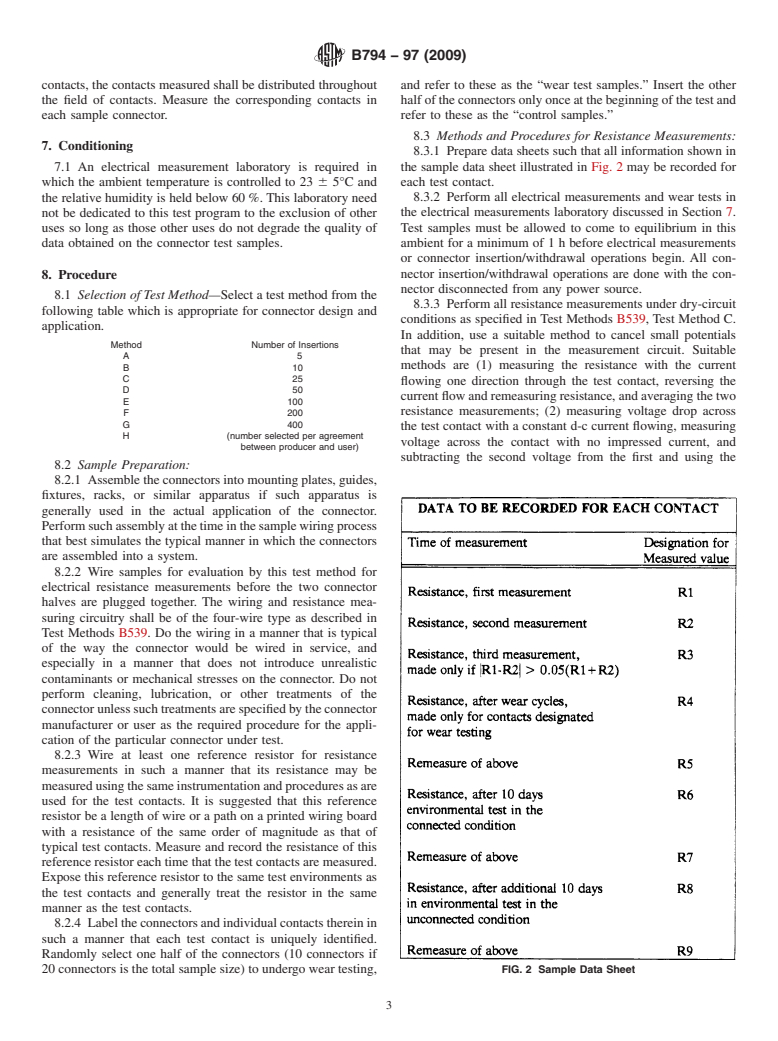

FIG. 1 Sample Format for Reporting Results

B794 − 97 (2009)

contacts, the contacts measured shall be distributed throughout and refer to these as the “wear test samples.” Insert the other

the field of contacts. Measure the corresponding contacts in halfoftheconnectorsonlyonceatthebeginningofthetestand

each sample connector. refer to these as the “control samples.”

8.3 Methods and Procedures for Resistance Measurements:

7. Conditioning

8.3.1 Prepare data sheets such that all information shown in

7.1 An electrical measurement laboratory is required in the sample data sheet illustrated in Fig. 2 may be recorded for

each test contact.

which the ambient temperature is controlled to 23 6 5°C and

the relative humidity is held below 60 %. This laboratory need 8.3.2 Perform all electrical measurements and wear tests in

the electrical measurements laboratory discussed in Section 7.

not be dedicated to this test program to the exclusion of other

uses so long as those other uses do not degrade the quality of Test samples must be allowed to come to equilibrium in this

data obtained on the connector test samples. ambient for a minimum of 1 h before electrical measurements

or connector insertion/withdrawal operations begin. All con-

nector insertion/withdrawal operations are done with the con-

8. Procedure

nector disconnected from any power source.

8.1 Selection of Test Method—Select a test method from the

8.3.3 Perform all resistance measurements under dry-circuit

following table which is appropriate for connector design and

conditions as specified in Test Methods B539, Test Method C.

application.

In addition, use a suitable method to cancel small potentials

Method Number of Insertions

that may be present in the measurement circuit. Suitable

A5

methods are (1) measuring the resistance with the current

B10

C25

flowing one direction through the test contact, reversing the

D50

current flow and remeasuring resistance, and averaging the two

E 100

resistance measurements; (2) measuring voltage drop across

F 200

G 400

the test contact with a constant d-c current flowing, measuring

H (number selected per agreement

voltage across the contact with no impressed current, and

between producer and user)

subtracting the second voltage from the first and using the

8.2 Sample Preparation:

8.2.1 Assemble the connectors into mounting plates, guides,

fixtures, racks, or similar apparatus if such apparatus is

generally used in the actual application of the connector.

Performsuchassemblyatthetimeinthesamplewiringprocess

that best simulates the typical manner in which the connectors

are assembled into a system.

8.2.2 Wire samples for evaluation by this test method for

electrical resistance measurements before the two connector

halves are plugged together. The wiring and resistance mea-

suring circuitry shall be of the four-wire type as described in

Test Methods B539. Do the wiring in a manner that is typical

of the way the connector would be wired in service, and

especially in a manner that does not introduce unrealistic

contaminants or mechanical stresses on the connector. Do not

perform cleaning, lubrication, or other treatments of the

connectorunlesssuchtreatmentsarespecifiedbytheconnector

manufacturer or user as the required procedure for the appli-

cation of the particular connector under test.

8.2.3 Wire at least one reference resistor for resistance

measurements in such a manner that its resistance may be

measuredusingthesameinstrumentationandproceduresasare

used for the test contacts. It is suggested that this reference

resistor be a length of wire or a path on a printed wiring board

with a resistance of the same order of magnitude as that of

typical test contacts. Measure and record the resistance of this

reference resistor each time that the test contacts are measured.

Expose this reference resistor to the same test environments as

the test contacts and generally treat the resistor in the same

manner as the test contacts.

8.2.4 Labeltheconnectorsandindividualcontactsthereinin

such a manner that each test contact is uniquely identified.

Randomly select one half of the connectors (10 connectors if

20 connectors is the total sample size) to undergo wear testing, FIG. 2 Sample Data Sheet

B794 − 97 (2009)

result to calculate resistance; or (3) measuring resistance using Provideaminimumdwelltimeof5sinboththeconnectedand

an a-c method. The user shall select one method and use it the unconnected position. Insertion and withdrawal velocity

throughout the experiment. shall be reasonably typical of that seen by the particular

8.3.4 Make all resistance measurements in such a manner connector in actual usage.

that the value is recorded with the resolution meeting the 8.4.5 Remeasure the resistance of each contact in the

following requirements: For contacts with a measured resis-

wear-test group and record the result as R4.After a value of R4

tance less than 0.100Ω, record the resistance with a resolution has been recorded for all contacts on a connector

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B794–97(Reapproved2003) Designation:B794–97(Reapproved2009)

Standard Test Method for

Durability Wear Testing of Separable Electrical Connector

Systems Using Electrical Resistance Measurements

This standard is issued under the fixed designation B 794; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thistestmethodcoverstheeffectsofrepeatedinsertionandwithdrawalofseparableelectricalconnectorswhichareharmful

to the electrical performance of the connector.

1.2 This test method is limited to electrical connectors designed for use in applications where the current through any one

connection in the connector does not exceed 5A, and where the connector may be separated a number of times during the life of

the connector.

1.3 This test method is limited to electrical connectors intended for use in air ambients where the operating temperature is less

than 65°C.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data

Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and

determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

B 539 Test Methods for Measuring Resistance of Electrical Connections (Static Contacts)Contacts)

2.2 Military Standard:

MIL-STD-1344A Test Methods for Electrical Connectors

3. Summary of Test Method

3.1 Sample connectors are wired for precision resistance measurements of each test contact. The samples are divided into two

groups; then resistance measurements are made of each test contact. The connectors in one group undergo a number of

insertion/withdrawalcyclesappropriatefortheparticularconnectorundertest,andtheresistancesoftheseconnectorsaremeasured

again. The connectors in the other group are not disturbed. All samples are subjected to an accelerated aging test; then the

resistances are measured again. All samples are separated (withdrawn), exposed to an accelerated aging test in the uninserted

condition, removed from the test, reinserted, and resistances measured again. The various resistance measurements are compared

to detect effects of the wear and aging on electrical performance.

4. Significance and Use

4.1 Materials for electrical connector contacts must satisfy a number of requirements in the areas of electrical, mechanical, and

economic characteristics.The stability of electrical properties is one of the most important of these characteristics.Wear of contact

surfaces may adversely affect these electrical properties, especially in designs where the contact surfaces are relatively thin

coatings. This test method provides a means to compare various material systems on a basis relevant to their application in

electrical connector contacts.

4.2 Repeated insertion and withdrawal of a connector may cause wear or other mechanical damage to the electrical contact

This test method is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.11 on

Electrical Contact Test Methods.

Current edition approved June 10, 2003. Published July 2003. Originally approved in 1988. Last previous edition approved in 1997 as B794–97.

Current edition approved April 15, 2009. Published April 2009. Originally approved in 1988. Last previous edition approved in 2003 as B 794 – 97 (2003).

Annual Book of ASTM Standards, Vol 03.04.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.19111-5098,

http://www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B794–97 (2009)

surfaces, rendering those surfaces more susceptible to environmental degradation. This test method is intended to detect

degradation of the electrical properties of the connector by such processes.

4.3 This test method describes procedures for conducting wear and durability testing of electrical connectors; the procedures

produce quantitative results. These results may be used to compare the performance of different connector designs so that

meaningful design choices can be made. Such results may also be used to compare the performance of a connector to a previously

established standard to evaluate the quality of the samples under test.

4.4 Thetestresultsobtainedfromthistestmethodarelimitedintheirapplicabilitytoconnectorcombinationsthatareequivalent

in design and manufacture to those actually tested.

4.5 The user is cautioned that the conditions in this test should be compared to the conditions that the connector will experience

in the intended application in order to determine the relevance of this test method to the particular needs of the user. For example,

the environmental stress in this test method is less severe than certain industrial and marine environments and therefore test results

are not directly applicable to predict the performance of product intended for use in such areas.

4.6 It is recommended that this test method be used in one of two ways. First, it may be used to evaluate and report the

performance of a particular connector system. In such a case, it is appropriate to report the results in a table in the format shown

in Fig. 1 and to state “ The results shown in the table were obtained for (insert connector designation or description) when tested

in accordance with ASTM Standard B 794, Method __ , Procedure __ .” Second, it may be used to impose requirements for

acceptance of product. In this case, limits for the values shown in Fig. 1 must be established prior to product acceptance testing.

Such limits may be established by various methods such as by evaluation of product which is known to be acceptable or by

application of appropriate experience. These limits must be documented in a manner that the entity performing the product test

can refer to the limits to determine if the test product conforms to such limits. A purchaser may wish to supply a table of limits

and include on the purchase order a statement similar to: “The product, when tested in accordance with ASTM Standard B 794,

Method __ , Procedure __ , shall meet the limits in the supplied table.” This table supplied by the purchaser may set limits on all

of the values in Fig. 1, or only on a subset of those values that the purchaser deems adequate to ensure the performance of the

product.

5. Apparatus

5.1 Environmental Test Chamber,capableofcontrollingthetestambientinaccordancewiththesequenceshowninTable1.The

test chamber shall be sufficiently large that each test sample shall be positioned with at least 100 mm separating it from the nearest

wall of the test chamber. The test chamber design and operation procedure shall conform to the requirements contained in

MIL-STD-1344A,, Method 1002.2.

5.2 An instrument is required for measuring resistance by the four-wire method. This instrument shall operate within the limits

on current and open-circuit voltage set forth in Test Methods B 539, Test Method C. The instrument shall be capable of measuring

FIG. 1 Sample Format for Reporting Results

B794–97 (2009)

TABLE 1 Environmental Test Sequence

NOTE 1—Tolerance on temperature control is 62°.

Step Elapsed Time, Temperature, Relative Humidity,

h °C %

1 0–2.5 ascending, 25–65 92 6 3

2 2.5–5.5 65 92 6 3

3 5.5–8 descending, 65–25 87 6 8

4 8–10.5 ascending, 25–65 92 6 3

5 10.5–13.5 65 92 6 3

6 13.5–16 descending, 65–25 87 6 8

7 16–24 25 92 6 3

a resistance less than 0.100 V with a resolution of 0.0001 V. For a resistance 0.100 V or larger, the instrument shall be capable

of measuring it with a resolution of 0.1 % of the resistance value.

6. Sampling and Test Specimens

6.1 Selection of Sample Connectors—Obtainsufficientsampleconnectorssothattheelectricalresistanceofatleast200contacts

contained in at least 20 separate connectors will be measured in the test. Obtain sample connectors that are representative of those

that will be used in the intended application. Recognize that a connector consists of two halves and both halves must be

representative of the product to be used. In some cases one half will be a conductive area or pad on a printed wiring-board surface,

therefore printed wiring boards must be obtained that have representative conductive pads. Specifically, the conductive pads shall

be manufactured to the same requirements as those that will be required of parts to be used in the system application. These

requirements will normally cover the manufacturing process, thickness, composition, hardness, and roughness of both the finish

coatingandofanyunderplatingorundercoating.Protectivetreatments,ifused,shallalsobespecified.Forthepurposeofconnector

testing, such printed wiring boards are generally fabricated with appropriate circuitry to permit four-wire resistance measurements.

6.2 Selection of Sample Contacts—In the case where the samples are multicontact connectors and electrical measurements are

performed only on a fraction of the total number of contacts, the contacts measured shall be distributed throughout the field of

contacts. Measure the corresponding contacts in each sample connector.

7. Conditioning

7.1 An electrical measurement laboratory is required in which the ambient temperature is controlled to 23 6 5°C and the

relative humidity is held below 60 %. This laboratory need not be dedicated to this test program to the exclusion of other uses so

long as those other uses do not degrade the quality of data obtained on the connector test samples.

8. Procedure

8.1 Selection of Test Method—Select a test method from the following table which is appropriate for connector design and

application.

Method Number of Insertions

A 5

B 10

C 25

D 50

E 100

F 200

G 400

H (number selected per agreement

between producer and user)

8.2 Sample Preparation:

8.2.1 Assemble the connectors into mounting plates, guides, fixtures, racks, or similar apparatus if such apparatus is generally

used in the actual application of the connector. Perform such assembly at the time in the sample wiring process that best simulates

the typical manner in which the connectors are assembled into a system.

8.2.2 Wire samples for evaluation by this test method for electrical resistance measurements before the two connector halves

are plugged together. The wiring and resistance measuring circuitry shall be of the four-wire type as described in Test Methods

B 539. Do the wiring in a manner that is typical of the way the connector would be wired in service, and especially in a manner

that does not introduce unrealistic contaminants or mechanical stresses on the connector. Do not perform cleaning, lubrication, or

other treatments of the connector unless such treatments are specified by the connector manufacturer or user as the required

procedure for the application of the particular connector under test.

8.2.3 Wireatleastonereferenceresistorforresistancemeasurementsinsuchamannerthatitsresistancemaybemeasuredusing

the same instrumentation and procedures as are used for the test contacts. It is suggested that this reference resistor be a length

ofwireorapathonaprintedwiringboardwitharesistanceofthesameorderofmagnitudeasthatoftypicaltestcontacts.Measure

B794–97 (2009)

and record the resistance of this reference resistor each time that the test contacts are measured. Expose this reference resistor to

the same test environments as the test contacts and generally treat the resistor in the same manner as the test contacts.

8.2.4 Label the connectors and individual contacts therein in such a manner that each test contact is uniquely identified.

Randomly select one half of the connectors (10 connectors if 20 connectors is the total sample size) to undergo wear testing, and

refer to these as the “wear test samples.” Insert the other half of the connectors only once at the beginning of the test and refer

to these as the “control samples.”

8.3 Methods and Procedures for Resistance Measurements:

8.3.1 Prepare data sheets such that all information shown in the sample data sheet illustrated in Fig. 2 may be recorded for each

test contact.

8.3.2 Perform all electrical measurements and wear tests in the electrical measurements laboratory discussed in Section 7. Test

samples must be allowed to come to equilibrium in this ambient for a minimum of 1 h before electrical measurements or connector

insertion/withdrawal operations begin. All connector insertion/withdrawal operations are done with the connector disconnected

from any power source.

8.3.3 Perform all resistance measurements under dry-circuit conditions as specified in Test Methods B 539, Test Method C. In

addition, use a suitable method to cancel small potentials that may be present in the measurement circuit. Suitable methods are

(1) measuring the resistance with the current flowing one direction through the test contact, reversing the current flow and

remeasuring resistance, and averaging the two resistance measurements; (2) measuring voltage drop across the test contact with

a constant d-c current flowing, measuring voltage across the contact with no impressed current, and subtracting the second voltage

from the first and using the result to calculate resistance; or (3) measuring resistance using an a-c method. The user shall select

one method and use it throughout the experiment.

8.3.4 Make all resistance measurements in such a manner that the value is recorded with the resolution meeting the following

requirements: For contacts with a measured resistance less than 0.100 V

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.