ASTM E1190-11(2018)

(Test Method)Standard Test Methods for Strength of Power-Actuated Fasteners Installed in Structural Members

Standard Test Methods for Strength of Power-Actuated Fasteners Installed in Structural Members

SIGNIFICANCE AND USE

4.1 These test methods are intended to measure the anchoring capability and shear resistance of power-actuated fasteners to provide information from which applicable design values are to be derived for use in structural applications, such as in members of concrete, concrete masonry, and steel.

SCOPE

1.1 These test methods describe procedures for determining the static axial tensile and shear strengths of power-actuated fasteners installed in structural members made of concrete, concrete masonry, and steel.

1.2 These test methods are intended for use with fasteners that are installed perpendicular to a plane surface of the structural member.

1.3 Tests for combined tension and shear, fatigue, dynamic, and torsional load resistance are not covered.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 6.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1190 − 11 (Reapproved 2018)

Standard Test Methods for

Strength of Power-Actuated Fasteners Installed in Structural

1

Members

This standard is issued under the fixed designation E1190; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Building Constructions, Elements, Connections, and As-

semblies

1.1 These test methods describe procedures for determining

E631 Terminology of Building Constructions

the static axial tensile and shear strengths of power-actuated

3

fasteners installed in structural members made of concrete, 2.2 ANSI Standard:

ANSIA10.3 Safety Requirements for Powder-Actuated Fas-

concrete masonry, and steel.

tening Systems

1.2 These test methods are intended for use with fasteners

that are installed perpendicular to a plane surface of the

3. Terminology

structural member.

3.1 Definitions of general terms may be found in Terminol-

1.3 Tests for combined tension and shear, fatigue, dynamic,

ogy E631.

and torsional load resistance are not covered.

3.2 Definitions of Terms Specific to This Standard:

1.4 The values stated in SI units are to be regarded as

3.2.1 displacement—movement of a fastener relative to the

standard. The values given in parentheses are mathematical

structural member. In tensile tests, displacement is measured

conversions to inch-pound units that are provided for informa-

alongtheaxisofthefastener;insheartestsitismeasuredinthe

tion only and are not considered standard.

direction of the applied load perpendicular to the axis of the

1.5 This standard does not purport to address all of the

fastener.

safety concerns, if any, associated with its use. It is the

3.2.2 drive pin—anail-likemetalfastenerdesignedtoattach

responsibility of the user of this standard to establish appro-

one material to another.

priate safety, health, and environmental practices and deter-

3.2.3 edge distance, c—the distance from the longitudinal

mine the applicability of regulatory limitations prior to use.

axis (center) of a fastener to the nearest edge of the structural

Specific hazard statements are given in Section 6.

member in which it is installed.

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3.2.4 embedment depth, h —the distance from the surface

ef

ization established in the Decision on Principles for the

of the structural member to the installed end of the fastener

Development of International Standards, Guides and Recom-

including its point, if any.

mendations issued by the World Trade Organization Technical

3.2.5 fastener spacing, s—the distance between the longitu-

Barriers to Trade (TBT) Committee.

dinal axes of two fasteners in the same plane. Also, distance

between longitudinal axis of fastener and nearest edge of

2. Referenced Documents

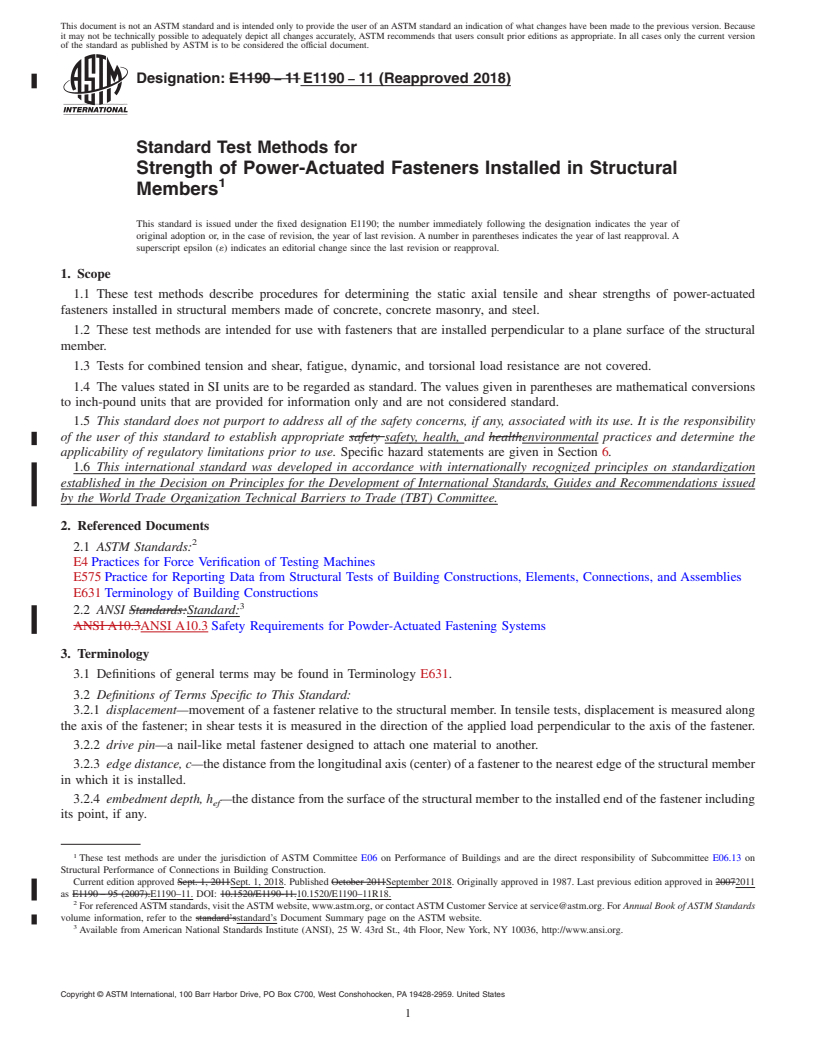

test-system supports (see s in Fig. 1).

2

2.1 ASTM Standards:

3.2.6 powder-actuated fastening system—a system that uses

E4 Practices for Force Verification of Testing Machines

explosive powder to embed the fastener in structural elements.

E575 Practice for Reporting Data from Structural Tests of

3.2.7 power-actuated fastening system—a system that uses

explosive powder, gas combustion, or compressed air or other

gas to embed the fastener in structural elements.

1

These test methods are under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and are the direct responsibility of Subcommittee E06.13

3.2.8 shear test—a test in which a force is applied perpen-

on Structural Performance of Connections in Building Construction.

dicularly to the axis of the fastener and parallel to the surface

Current edition approved Sept. 1, 2018. Published September 2018. Originally

of the structural member.

approved in 1987. Last previous edition approved in 2011 as E1190–11. DOI:

10.1520/E1190–11R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1190 − 11 (2018)

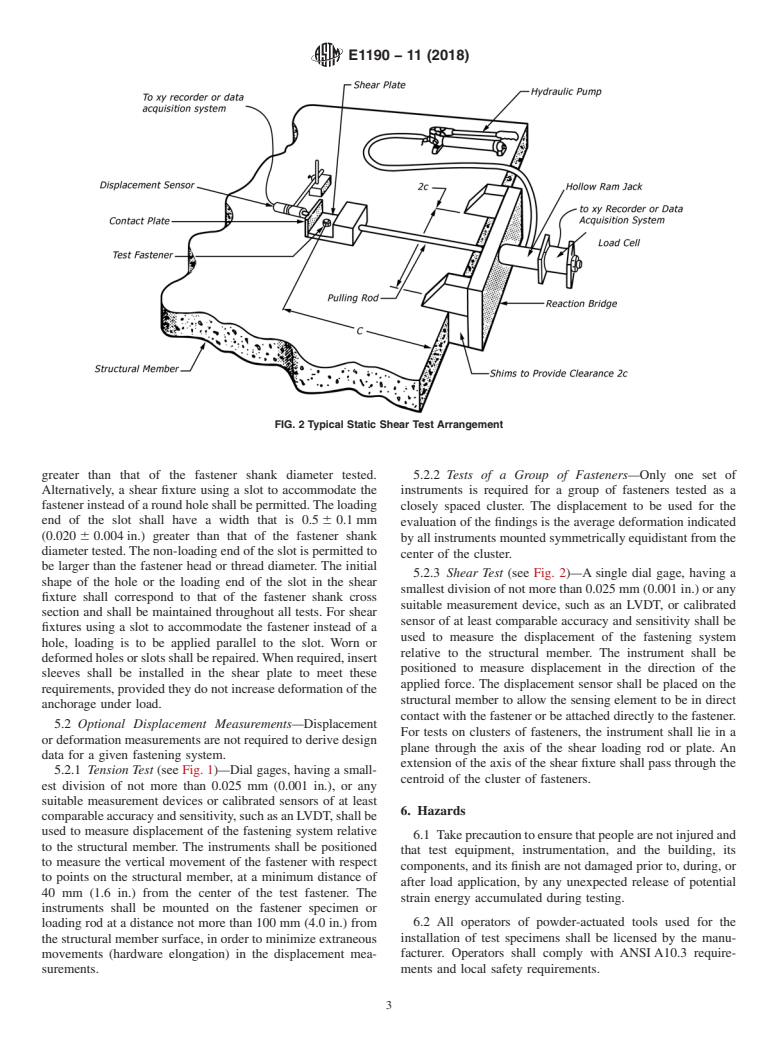

FIG. 1 Typical Static Tension Test Arrangement

3.2.9 static load—aloadorseriesofloadsthataresupported surface of the structural member during testing. Load cells

by or are applied to a structure so gradually that

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1190 − 11 E1190 − 11 (Reapproved 2018)

Standard Test Methods for

Strength of Power-Actuated Fasteners Installed in Structural

1

Members

This standard is issued under the fixed designation E1190; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods describe procedures for determining the static axial tensile and shear strengths of power-actuated

fasteners installed in structural members made of concrete, concrete masonry, and steel.

1.2 These test methods are intended for use with fasteners that are installed perpendicular to a plane surface of the structural

member.

1.3 Tests for combined tension and shear, fatigue, dynamic, and torsional load resistance are not covered.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions

to inch-pound units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 6.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

E575 Practice for Reporting Data from Structural Tests of Building Constructions, Elements, Connections, and Assemblies

E631 Terminology of Building Constructions

3

2.2 ANSI Standards:Standard:

ANSI A10.3ANSI A10.3 Safety Requirements for Powder-Actuated Fastening Systems

3. Terminology

3.1 Definitions of general terms may be found in Terminology E631.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 displacement—movement of a fastener relative to the structural member. In tensile tests, displacement is measured along

the axis of the fastener; in shear tests it is measured in the direction of the applied load perpendicular to the axis of the fastener.

3.2.2 drive pin—a nail-like metal fastener designed to attach one material to another.

3.2.3 edge distance, c—the distance from the longitudinal axis (center) of a fastener to the nearest edge of the structural member

in which it is installed.

3.2.4 embedment depth, h —the distance from the surface of the structural member to the installed end of the fastener including

ef

its point, if any.

1

These test methods are under the jurisdiction of ASTM Committee E06 on Performance of Buildings and are the direct responsibility of Subcommittee E06.13 on

Structural Performance of Connections in Building Construction.

Current edition approved Sept. 1, 2011Sept. 1, 2018. Published October 2011September 2018. Originally approved in 1987. Last previous edition approved in 20072011

as E1190 – 95 (2007).E1190–11. DOI: 10.1520/E1190-11.10.1520/E1190–11R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1190 − 11 (2018)

3.2.5 fastener spacing, s—the distance between the longitudinal axes of two fasteners in the same plane. Also, distance between

longitudinal axis of fastener and nearest edge of test-system supports (see s in Fig. 1).

3.2.6 powder-actuated fastening system—a system that uses explosive powder to embed the fastener in structural elements.

3.2.7 power-actuated fastening system—a system that uses explosive powder, gas combustion, or compressed air or other gas

to embed the f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.