ASTM D6267-08

(Test Method)Standard Test Method for Apparent Viscosity of Hydrocarbon Resins at Elevated Temperatures

Standard Test Method for Apparent Viscosity of Hydrocarbon Resins at Elevated Temperatures

SIGNIFICANCE AND USE

This test method is used to measure the apparent viscosity of hydrocarbon resins at elevated temperatures. Elevated temperature viscosity values of a hydrocarbon resin may be related to the properties of coatings, adhesives and the like, containing such a resin.

For hydrocarbon resins, values of apparent viscosity will usually be a function of shear rate under the conditions of test. Although the type of viscometer described in this test method operates under conditions of relatively low shear rate, shear rate depends on the spindle and rotational speed selected for a determination; therefore, comparisons between apparent viscosity values should be made only for measurements made with similar viscometers under conditions of equivalent shear rate.

SCOPE

1.1 This test method covers the determination of the apparent viscosity of hydrocarbon resins having apparent viscosities up to 2,000,000 millipascal seconds (mPa·s) (Note 1) at temperatures up to 300°C (572°F).

Note 1—The SI unit of (dynamic) viscosity is the pascal second. The centipoise (cP) is one millipascal second (mPa·s) and is frequently used as a viscosity unit.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6267 − 08

StandardTest Method for

Apparent Viscosity of Hydrocarbon Resins at Elevated

1

Temperatures

This standard is issued under the fixed designation D6267; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.3.1 Discussion—Its value may vary with the spindle and

rotational speed selected.

1.1 This test method covers the determination of the appar-

ent viscosity of hydrocarbon resins having apparent viscosities

4. Summary of Test Method

up to 2,000,000 millipascal seconds (mPa·s) (Note 1)at

temperatures up to 300°C (572°F). 4.1 The viscometer described in this test method can be

used to determine the apparent viscosity of hydrocarbon resins

NOTE 1—The SI unit of (dynamic) viscosity is the pascal second. The

at elevated temperatures. Apparent viscosity is determined

centipoise (cP) is one millipascal second (mPa·s) and is frequently used as

a viscosity unit. under temperature equilibrium conditions using a rotating

spindle type viscometer. The torque on a spindle rotating in a

1.2 The values stated in SI units are to be regarded as the

thermostatted sample holder containing a small amount of

standard. The values given in parentheses are for information

sample is used to measure the relative resistance to rotation.A

only.

factor is applied to the torque reading to yield the viscosity in

1.3 This standard does not purport to address all of the

mPa·s.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 This test method is used to measure the apparent

bility of regulatory limitations prior to use.

viscosity of hydrocarbon resins at elevated temperatures.

2. Referenced Documents

Elevated temperature viscosity values of a hydrocarbon resin

2

may be related to the properties of coatings, adhesives and the

2.1 ASTM Standards:

like, containing such a resin.

D6440 Terminology Relating to Hydrocarbon Resins

E691 Practice for Conducting an Interlaboratory Study to

5.2 For hydrocarbon resins, values of apparent viscosity

Determine the Precision of a Test Method

will usually be a function of shear rate under the conditions of

E2251 Specification for Liquid-in-Glass ASTM Thermom-

test. Although the type of viscometer described in this test

eters with Low-Hazard Precision Liquids

method operates under conditions of relatively low shear rate,

shear rate depends on the spindle and rotational speed selected

3. Terminology

for a determination; therefore, comparisons between apparent

3.1 The definitions in Terminology D6440 are applicable to

viscosity values should be made only for measurements made

this test method.

with similar viscometers under conditions of equivalent shear

rate.

3.2 Definition Specific to This Standard:

3.3 apparent viscosity, n—of a hydrocarbon resin, the vis-

6. Apparatus

cosity determined by this test method, expressed in millipascal

seconds. 6.1 Rotational Viscometer—rotating-spindle type with lev-

eling stand.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

6.2 Viscometer Spindles, stainless steel. (Warning—Care

and Related Coatings, Materials, andApplications and is the direct responsibility of

must be taken in the storage and handling of spindles and

Subcommittee D01.34 on Pine Chemicals and Hydrocarbon Resins.

assemblies. Protect them from scratches, dust, corrosion or

Current edition approved March 15, 2008. Published March 2008. Originally

deposits, and mechanical abuse. Replace the spindle extension

approved in 1998. Last previous edition approved in 2005 as D6267 – 05. DOI:

10.1520/D6267-08.

if it is bent.Avoid touching the calibrated section of the spindle

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

with hands. Clean the spindle and sample chamber thoroughly

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

after each use.Arecommended cleaning procedure is included

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. in the procedure.)

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

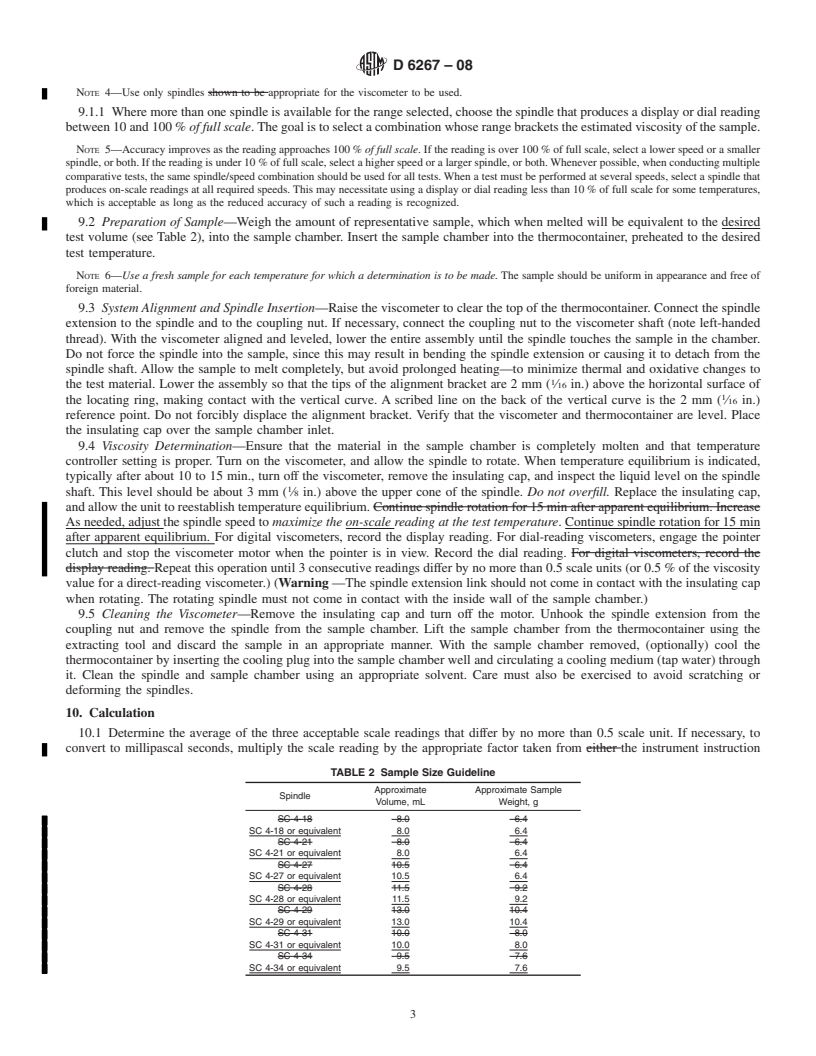

---------------------- Page: 1 ----------------------

D6267 − 08

6.3 Temperature Controller, Thermocontainer (a heater for 8.3.2 Insert the thermometer through the insulating cover of

the sample chamber), and Sample Chamber, designed for use the sample container, in

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6267–05 Designation:D6267–08

Standard Test Method for

Apparent Viscosity of Hydrocarbon Resins at Elevated

1

Temperatures

This standard is issued under the fixed designation D 6267; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This test method covers the determination of the apparent viscosity of hydrocarbon resins having apparent viscosities up to

2 000 000 millipascal seconds (mPa·s) (*

1.1 This test method covers the determination of the apparent viscosity of hydrocarbon resins having apparent viscosities up to

2,000,000 millipascal seconds (mPa·s) (Note 1) at temperatures up to 300°C (572°F).

NOTE 1—The SI unit of (dynamic) viscosity is the pascal second. The centipoise (cP) is one millipascal second (mPa·s) and is frequently used as a

viscosity unit.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 6440 Terminology Relating to Hydrocarbon Resins

E1Specification forASTM Liquid-in-Glass Thermometers 691 Practice for Conducting an Interlaboratory Study to Determine

the Precision of a Test Method

E691Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method 2251 Specification for

Liquid-in-Glass ASTM Thermometers with Low-Hazard Precision Liquids

3. Terminology

3.1 The definitions in Terminology D 6440 are applicable to this test method.

3.2 Definition Specific to This Standard:

3.3 apparent viscosity, n— of a hydrocarbon resin, the viscosity determined by this test method, expressed in millipascal

seconds.

3.3.1 Discussion—Its value may vary with the spindle and rotational speed selected.

4. Summary of Test Method

4.1 The viscometer described in this test method can be used to determine the apparent viscosity of hydrocarbon resins at

elevated temperatures. Apparent viscosity is determined under temperature equilibrium conditions using a rotating spindle type

viscometer. The torque on a spindle rotating in a thermostatted sample holder containing a small amount of sample is used to

measure the relative resistance to rotation. A factor is applied to the torque reading to yield the viscosity in mPa·s.

5. Significance and Use

5.1 This test method is used to measure the apparent viscosity of hydrocarbon resins at elevated temperatures. Elevated

temperature viscosity values of a hydrocarbon resin may be related to the properties of coatings, adhesives and the like, containing

such a resin.

5.2 For hydrocarbon resins, values of apparent viscosity will usually be a function of shear rate under the conditions of test.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials , and Applications and is the direct responsibility of

Subcommittee D01.38 on Hydrocarbon Resins.

Current edition approved Jan. 1, 2005. Published February 2005. Originally approved in 1998. Last previous edition approved in 1998 as D6267–98.

Current edition approved March 15, 2008. Published March 2008. Originally approved in 1998. Last previous edition approved in 2005 as D 6267 – 05.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6267–08

Although the type of viscometer described in this test method operates under conditions of relatively low shear rate, shear rate

depends on the spindle and rotational speed selected for a determination; therefore, comparisons between apparent viscosity values

should be made only for measurements made with similar viscometers under conditions of equivalent shear rate.

5.3Approximate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.