ASTM F1541-99

(Specification)Standard Specification and Test Methods for External Skeletal Fixation Devices

Standard Specification and Test Methods for External Skeletal Fixation Devices

SCOPE

1.1 This specification provides a characterization of the design and mechanical function of external skeletal fixation devices (ESFDs), test methods for characterization of ESFD mechanical properties, and identifies needs for further development of test methods and performance criteria. The ultimate goal is to develop a specification, which defines performance criteria and methods for measurement of performance-related mechanical characteristics of ESFDs and their fixation to bone. It is not the intention of this specification to define levels of performance or case-specific clinical performance of the devices, as insufficient knowledge is available to predict the consequences of the use of any of these devices in individual patients for specific activities of daily living. Furthermore, it is not the intention of this specification to describe or specify specific designs for ESFDs.

1.2 This specification describes ESFDs for surgical fixation of the skeletal system. It provides basic ESFD geometrical definitions, dimensions, classification, and terminology; material specifications; performance definitions; test methods; and characteristics determined to be important to the in-vivo performance of the device.

1.3 This specification includes a terminology and classification annex and five standard test method annexes as follows:

1.3.1 Classification of External Fixators--Annex A1.

1.3.2 Test Method for External Skeletal Fixator Connectors--Annex A2.

1.3.3 Test Method for Determining In-Plane Compressive Properties of Circular Ring or Ring Segment Bridge Elements--Annex A3.

1.3.4 Test Method for External Skeletal Fixator Joints--Annex A4-.

1.3.5 Test Method for External Skeletal Fixator Pin Anchorage Elements--Annex A5.

1.3.6 Test Method for External Skeletal Fixator Subassemblies--Annex A6.

1.3.7 Test Method for External Skeletal Fixator/Constructs Subassemblies--Annex A7.

1.4 A rationale is given in Appendix X1.

1.5 The values stated in SI units are to be regarded as the standard.

1.6 The following safety hazards caveat pertains only to the test method portions (Annex A2-Annex A6):

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1541 – 99

Standard Specification and Test Methods for

External Skeletal Fixation Devices

This standard is issued under the fixed designation F 1541; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope test method portions (Annex A2-Annex A6):

1.7 This standard does not purport to address all of the

1.1 This specification provides a characterization of the

safety concerns, if any, associated with its use. It is the

design and mechanical function of external skeletal fixation

responsibility of the user of this standard to establish appro-

devices (ESFDs), test methods for characterization of ESFD

priate safety and health practices and determine the applica-

mechanical properties, and identifies needs for further devel-

bility of regulatory limitations prior to use.

opment of test methods and performance criteria. The ultimate

goal is to develop a specification, which defines performance

2. Referenced Documents

criteria and methods for measurement of performance-related

2.1 ASTM Standards:

mechanical characteristics of ESFDs and their fixation to bone.

A 938 Method for Torsion Testing of Wire

It is not the intention of this specification to define levels of

D 790 Test Methods for Flexural Properties of Unreinforced

performance or case-specific clinical performance of the de-

and Reinforced Plastics and Electrical Insulating Materi-

vices, as insufficient knowledge is available to predict the

als

consequences of the use of any of these devices in individual

E 4 Practices for Force Verification of Testing Machines

patients for specific activities of daily living. Furthermore, it is

F 67 Specification for Unalloyed Titanium for Surgical

not the intention of this specification to describe or specify

Implant Applications

specific designs for ESFDs.

F 90 Specification for Wrought Cobalt-Chromium-

1.2 This specification describes ESFDs for surgical fixation

Tungsten Nickel Alloy for Surgical Implant Applications

of the skeletal system. It provides basic ESFD geometrical

F 136 Specification for Wrought Titanium-6 Al

definitions, dimensions, classification, and terminology; mate-

(Aluminum-4 Vanadium ELI (Extra Low Interstitial) Alloy

rial specifications; performance definitions; test methods; and

(R56401) for Surgical Implant Applications

characteristics determined to be important to the in-vivo

F 138 Specification for Wrought-18 Chromium-14 Nickel-

performance of the device.

2.5 Molybdenum Stainless Steel Bar and Wire for Surgical

1.3 This specification includes a terminology and classifi-

Implants (UNS S31673)

cation annex and five standard test method annexes as follows:

F 366 Specification for Fixation Pins and Wires

1.3.1 Classification of External Fixators—Annex A1.

F 543 Specification for Cortical Bone Screws

1.3.2 Test Method for External Skeletal Fixator

F 544 Reference Chart for Pictorial Cortical Bone Screw

Connectors—Annex A2.

Classification

1.3.3 Test Method for Determining In-Plane Compressive

F 1058 Specification for Wrought Cobalt-Chromium-Nickel

Properties of Circular Ring or Ring Segment Bridge

Molybdenum-Iron Alloys for Surgical Implant Applica-

Elements—Annex A3.

tions (UNS R3003 and UNS R3008)

1.3.4 Test Method for External Skeletal Fixator Joints—

F 1264 Specification and Test Methods for Intermedullary

Annex A4.

Fixation Devices

1.3.5 Test Method for External Skeletal Fixator Pin Anchor-

F 1472 Specification for Wrought Ti-6Al-4V Alloy for Sur-

age Elements—Annex A5.

gical Implant Applications

1.3.6 Test Method for External Skeletal Fixator

F 1713 Specification for Wrought Titanium-13 Niobium-13

Subassemblies—Annex A6.

Zirconium Alloy for Surgical Implant Applications

1.4 A rationale is given in Appendix X1.

1.5 The values stated in SI units are to be regarded as the

3. Terminology

standard.

3.1 Definitions—The definitions of terms relating to exter-

1.6 The following safety hazards caveat pertains only to the

nal fixators are described in Annex A1.

This specification is under the jurisdiction of ASTM Committee F-4 on Medical

and Surgical Materials and Devices and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 01.03.

F04.21 on Osteosynthesis. Annual Book of ASTM Standards, Vol 08.01.

Current edition approved June 10, 1999. Published September 1999. Originally Annual Book of ASTM Standards, Vol 03.01.

published as F 1541 – 94. Last previous edition F 1541 – 94. Annual Book of ASTM Standards, Vol 13.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1541

4. Classification wires or thin pins, which pass transverse to the bone long axis,

and which are tensioned deliberately in order to control the

4.1 External skeletal fixators are modular devices assembled

longitudinal stiffness of the fixator. Tensioning these wires or

from component elements.

pins causes appreciable compressive load in the plane of the

4.2 Test methods can address individual elements, for ex-

ring element. A test method for evaluating the mechanical

ample, anchorage elements, bridge elements; subassemblies of

performance of ESFD ring elements in this loading mode is

elements, for example, connectors, joints, ring elements; or, the

described in Annex A3.

entire fixator.

6.2.3 The high loads often developed at ESFD junction sites

4.3 Tests of an entire assembled fixator may include the

fixator alone, or alternatively, the fixator as anchored to a are of concern both because of potentially excessive elastic

representation of the bone(s) upon which it typically would be deformation and because of potential irrecoverable deforma-

mounted in clinical usage. tion. In addition to the connecting element itself (Annex A2),

overall performance of the junction also depends on the

5. Materials

interface between the connecting element and the anchorage,

5.1 All ESFDs made of materials, which have an ASTM

or bridge elements, or both, which it grips. A test method for

standard, shall meet those requirements given in ASTM Stan- evaluating the overall strength, or stiffness, or both, at an

dards listed in 2.1

external fixator joint, as defined in Annex A1 as the connecting

element itself plus its interface with the anchorage, or bridge,

6. Performance Considerations and Test Methods

or both, elements, which it grips, is described in Annex A4.

6.1 Individual Components—The anchorage pins through

6.2.4 The modular nature of many ESFD systems affords

which an ESFD is attached to a skeletal member or members

the surgeon particularly great latitude as to configuration of the

typically experience high flexural, or torsional loads, or both.

frame subassembly, as defined in Annex A1 as the bridge

Often, the majority of the overall compliance of an ESFD is in

elements plus the connecting elements used to join bridge

its anchorage elements. A test method for evaluating the

elements, but specifically excluding the anchorage elements.

mechanical performance of an ESFD anchorage element in

Since configuration of the frame subassembly is a major

either of these loading modes is described in Annex A5.

determinant of overall ESFD mechanical behavior, it is impor-

6.2 Subassemblies of Elements:

tant to have procedures for unambiguously characterizing

6.2.1 The sites of junction between ESFD anchorage ele-

frame subassemblies, both geometrically and mechanically.

ments, for example, pins, and bridge elements, for example,

Test methodology suitable for that purpose is described in

rods, normally require specialized clamping or gripping mem-

Annex A6.

bers, known as connecting elements. Often, connecting ele-

6.3 Entire Assembled Fixator—No test methods are yet

ments are subjected to high loads, especially moments, so

approved for entire assembled fixators.

adequacy of their intrinsic mechanical stiffness, or strength, or

both, is critical to overall fixator performance. A test method

7. Keywords

for evaluating the mechanical performance of ESFD connector

elements is described in Annex A2. 7.1 anchorage element; bending; bridge element; connector;

6.2.2 ESFDs involving ring-type bridge elements are used external skeletal fixation device; fracture fixation; joints;

modularity; orthopaedic medical device; osteosynthesis; sub-

widely both for fracture treatment and for distraction osteo-

genesis. The anchorage elements in such fixators usually are assembly (frame); ring element; terminology; torsion

ANNEXES

(Mandatory Information)

A1. CLASSIFICATION OF EXTERNAL SKELETAL FIXATORS

A1.1 Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

A1.1.1 This classification covers the definitions of basic

A1.2 Referenced Documents

terms and considerations for external skeletal fixation devices

(ESFDs) and the mechanical analyses thereof.

A1.2.1 ASTM Standards:

F 366 Specification for Fixation Pins and Wires

A1.1.2 It is not the intent of this classification to define

F 543 Specification for Cortical Bone Screws

levels of acceptable performance or to make recommendations

F 544 Reference Chart for Pictorial Cortical Bone Screw

concerning the appropriate or preferred clinical usage of these

Classification

devices.

A1.3 Background

A1.1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

A1.3.1 ESFDs are in widespread use in orthopaedic surgery,

responsibility of the user of this standard to establish appro- primarily for applications involving fracture fixation or limb

F 1541

lengthening, or both. The mechanical demands placed on these

devices often are severe. Clinical success usually depends on

suitable mechanical integration of the ESFD with the host bone

or limb.

A1.3.2 It is important, therefore, to have broadly accepted

terminology and testing standards by which these devices can

be described and their mechanical behaviors measured.

A1.3.3 Useful terminology and testing standards must take

into account that the modular nature of most ESFDs deliber-

ately affords a great deal of clinical latitude in configuring the

assembled fixator.

A1.4 Significance and Use

A1.4.1 The purpose of this classification is to establish a

consistent terminology system by means of which these ESFD

configurations can be classified. It is anticipated that a com-

panion testing standard using this classification system will

subsequently be developed.

A1.5 Basis of Classification

A1.5.1 An assembled ESFD and the bone(s) or bone ana-

log(s) to which it is affixed constitute a fixator-bone construct.

A1.5.1.1 The assembled ESFD itself, apart from the host

bone, is termed the fixator assembly.

A1.5.1.2 The individual parts (or modules of individual

parts) from which the end user assembles the fixator are termed

its elements.

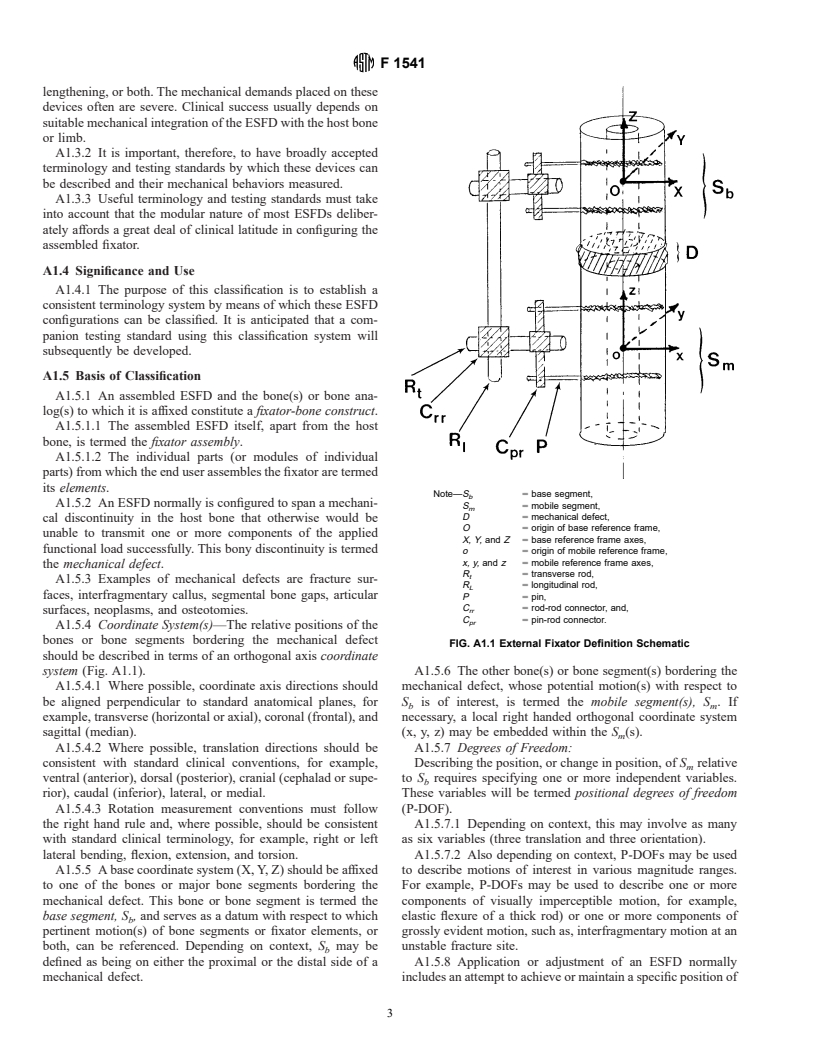

Note—S 5 base segment,

b

A1.5.2 An ESFD normally is configured to span a mechani-

S 5 mobile segment,

m

D 5 mechanical defect,

cal discontinuity in the host bone that otherwise would be

O 5 origin of base reference frame,

unable to transmit one or more components of the applied

X, Y, and Z 5 base reference frame axes,

functional load successfully. This bony discontinuity is termed

o 5 origin of mobile reference frame,

x, y, and z 5 mobile reference frame axes,

the mechanical defect.

R 5 transverse rod,

t

A1.5.3 Examples of mechanical defects are fracture sur-

R 5 longitudinal rod,

L

faces, interfragmentary callus, segmental bone gaps, articular

P 5 pin,

C 5 rod-rod connector, and,

rr

surfaces, neoplasms, and osteotomies.

C 5 pin-rod connector.

pr

A1.5.4 Coordinate System(s)—The relative positions of the

bones or bone segments bordering the mechanical defect

FIG. A1.1 External Fixator Definition Schematic

should be described in terms of an orthogonal axis coordinate

system (Fig. A1.1). A1.5.6 The other bone(s) or bone segment(s) bordering the

A1.5.4.1 Where possible, coordinate axis directions should mechanical defect, whose potential motion(s) with respect to

be aligned perpendicular to standard anatomical planes, for S is of interest, is termed the mobile segment(s), S .If

b m

example, transverse (horizontal or axial), coronal (frontal), and necessary, a local right handed orthogonal coordinate system

sagittal (median). (x, y, z) may be embedded within the S (s).

m

A1.5.4.2 Where possible, translation directions should be A1.5.7 Degrees of Freedom:

consistent with standard clinical conventions, for example, Describing the position, or change in position, of S relative

m

ventral (anterior), dorsal (posterior), cranial (cephalad or supe- to S requires specifying one or more independent variables.

b

rior), caudal (inferior), lateral, or medial. These variables will be termed positional degrees of freedom

A1.5.4.3 Rotation measurement conventions must follow (P-DOF).

the right hand rule and, where possible, should be consistent A1.5.7.1 Depending on context, this may involve as many

with standard clinical terminology, for example, right or left as six variables (three translation and three orientation).

A1.5.7.2 Also depending on context, P-DOFs may be used

lateral bending, flexion, extension, and torsion.

A1.5.5 A base coordinate system (X, Y, Z) should be affixed to describe motions of interest in various magnitude ranges.

to one of the bones or major bone segments bordering the For example, P-DOFs may be used to describe one or more

mechanical defect. This bone or bone segment is termed the components of visually imperceptible motion, for example,

base segment, S , and serves as a datum with respect to which elastic flexure of a thick rod) or one or more components of

b

pertinent motion(s) of bone segments or fixator elements, or grossly evident motion, such as, interfragmentary motion at an

both, can be referenced. Depending on context, S may be unstable fracture site.

b

defined as being on either the proximal or the distal side of a A1.5.8 Application or adjustment of an ESFD normally

mechanical defect. includes an attempt to achieve or maintain a specific position of

F 1541

S relative to S . The adjustability afforded by the ESFD in order to engage the attachment. Connectors should be

m b

design for this purpose, most commonly, fracture fragment described in terms of the types of elements that they connect

reduction, will be characterized in terms of adjustment degrees and, where appropriate, in terms of their adjustment or un-

of freedom (A-DOF). locked degrees of freedom. Examples of connectors are pin(-

rod) clamps,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.