ASTM D4533-04(2009)

(Test Method)Standard Test Method for Trapezoid Tearing Strength of Geotextiles

Standard Test Method for Trapezoid Tearing Strength of Geotextiles

SIGNIFICANCE AND USE

The trapezoid tear method is a test that produces tension along a reasonably defined course such that the tear propagates across the width of the specimen. The trapezoid tearing strength for woven fabrics is determined primarily by the properties of the yarns that are gripped in the clamps. In nonwoven fabrics, because the individual fibers are more or less randomly oriented and capable of some reorientation in the direction of the applied load, the maximum trapezoid tearing strength is reached when the resistance to further reorientation is greater than the force required to rupture one or more fibers simultaneously.

The trapezoid tearing strength method is useful for estimating the relative tear resistance of different fabrics or different directions in the same fabric.

This test method may be used for acceptance testing of commercial shipments; however, caution is advised since information about between-laboratory precision is incomplete. Comparative tests as directed in 5.3.1 may be advisable.

In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type in question. Test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using the appropriate Student's t-test and an acceptable probability level chosen by the two parties before testing is begun. If a bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results in the light of the kno...

SCOPE

1.1 This test method is an index test used to measure the force required to continue or propagate a tear in woven or non-woven geotextiles by the trapezoid method. While useful for quality control and acceptance testing, the trapezoid tear test does not provide all the information needed for all design applications and other test methods should be used.

1.2 This test method is applicable to most geotextiles that include woven fabrics, nonwoven fabrics, layered fabrics, knit fabrics, and felts that are used for geotextile applications.

1.3 The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4533–04 (Reapproved 2009)

Standard Test Method for

Trapezoid Tearing Strength of Geotextiles

This standard is issued under the fixed designation D4533; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.1 atmosphere for testing geotextiles, n—air maintained

at a relative humidity of 65 6 5 % and a temperature of 21 6

1.1 This test method is an index test used to measure the

2°C (70 6 4°F).

force required to continue or propagate a tear in woven or

3.1.2 geotextile, n—any permeable textile material used

non-woven geotextiles by the trapezoid method. While useful

with foundation, soil, rock, earth, or any other geotechnical

for quality control and acceptance testing, the trapezoid tear

engineering related material as an integral part of a man-made

test does not provide all the information needed for all design

product, structure, or system.

applications and other test methods should be used.

3.1.3 tearing strength, n—the force required to either (1)

1.2 This test method is applicable to most geotextiles that

start, or (2) continue or propagate a tear in a fabric under

include woven fabrics, nonwoven fabrics, layered fabrics, knit

specified conditions.

fabrics, and felts that are used for geotextile applications.

3.1.3.1 Discussion—This test method uses the maximum

1.3 The values stated in SI units are to be regarded as the

value of the tearing force as the tearing strength.

standard. No other units of measurement are included in this

3.1.4 For definitions of other terms used in this test method,

standard.

refer to Terminology D123 or Terminology D4439.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

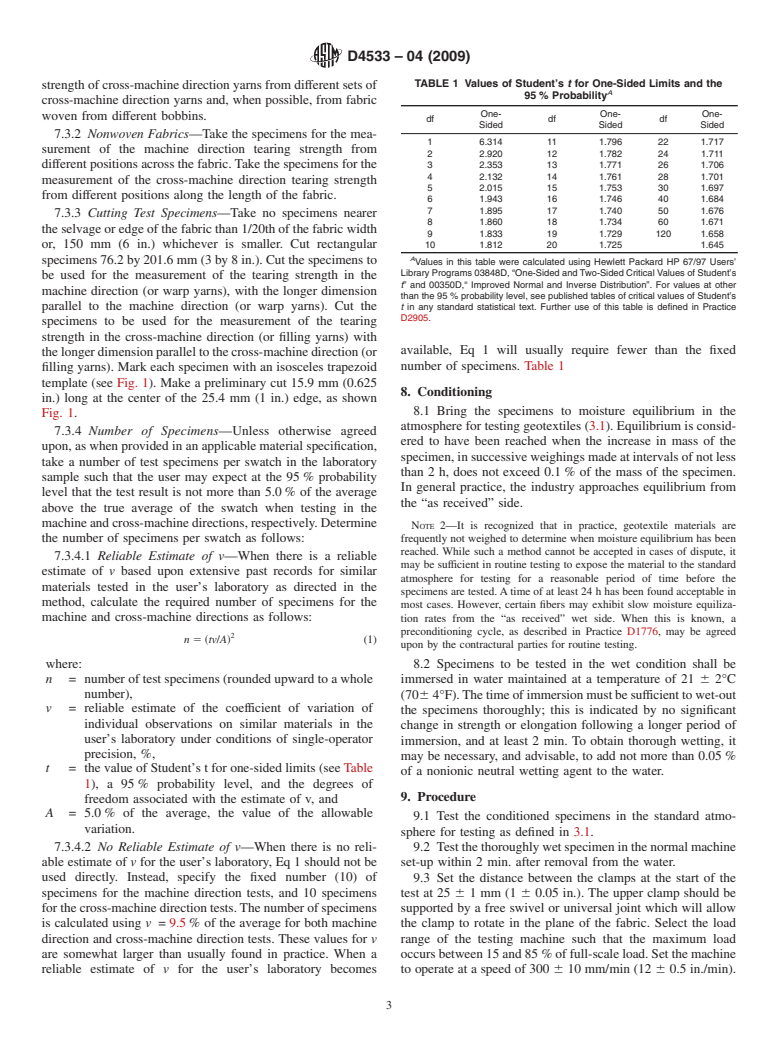

4.1 An outline of an isosceles trapezoid is marked on a

priate safety and health practices and determine the applica-

rectangular specimen cut for the determination of tearing

bility of regulatory limitations prior to use.

strength (see Fig. 1), and the nonparallel sides of the trapezoid

2. Referenced Documents marked on the specimen are clamped in parallel jaws of a

tensile testing machine. The separation of the jaws is continu-

2.1 ASTM Standards:

ously increased so the tear propagates across the specimen. At

D76 Specification for Tensile Testing Machines for Textiles

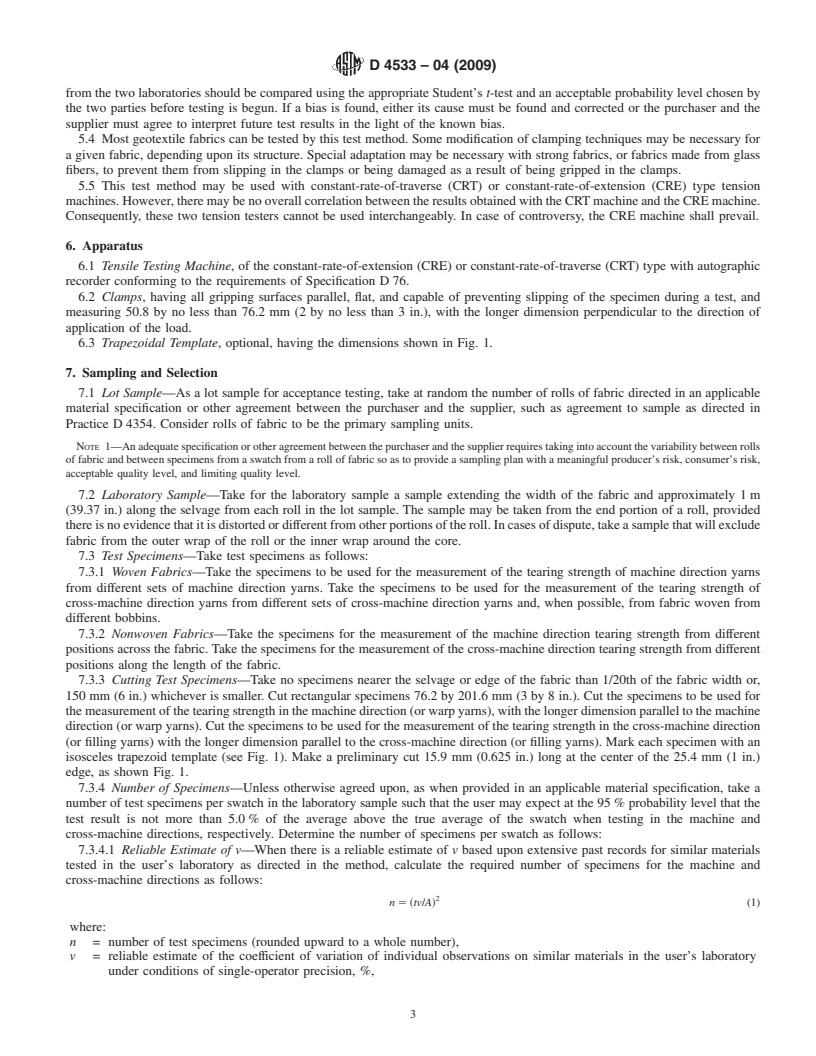

the same time, the force developed is recorded. The tearing

D123 Terminology Relating to Textiles

strength, which is the maximum value of the tearing force, is

D1776 Practice for Conditioning and Testing Textiles

obtainedfromtheautographicforce–extensioncurve(seeFig.

D2905 PracticeforStatementsonNumberofSpecimensfor

3 2).

Textiles

D4354 Practice for Sampling of Geosynthetics for Testing

5. Significance and Use

D4439 Terminology for Geosynthetics

5.1 The trapezoid tear method is a test that produces tension

3. Terminology along a reasonably defined course such that the tear propagates

across the width of the specimen. The trapezoid tearing

3.1 Definitions:

strength for woven fabrics is determined primarily by the

properties of the yarns that are gripped in the clamps. In

This test method is under the jurisdiction of ASTM Committee D35 on

nonwoven fabrics, because the individual fibers are more or

Geosynthetics and is the direct responsibility of Subcommittee D35.01 on Mechani-

lessrandomlyorientedandcapableofsomereorientationinthe

cal Properties.

CurrenteditionapprovedJune1,2009.PublishedJuly2009.Originallyapproved

direction of the applied load, the maximum trapezoid tearing

in 1991. Last previous edition approved in 2004 as D4533 – 04. DOI: 10.1520/

strength is reached when the resistance to further reorientation

D4533-04R09.

2 is greater than the force required to rupture one or more fibers

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

simultaneously.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

5.2 The trapezoid tearing strength method is useful for

the ASTM website.

estimating the relative tear resistance of different fabrics or

Withdrawn. The last approved version of this historical standard is referenced

different directions in the same fabric.

on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4533–04 (2009)

laboratories should be compared using the appropriate Stu-

dent’s t-test and an acceptable probability level chosen by the

two parties before testing is begun. If a bias is found, either its

cause must be found and corrected or the purchaser and the

supplier must agree to interpret future test results in the light of

the known bias.

5.4 Mostgeotextilefabricscanbetestedbythistestmethod.

Some modification of clamping techniques may be necessary

for a given fabric, depending upon its structure. Special

adaptation may be necessary with strong fabrics, or fabrics

made from glass fibers, to prevent them from slipping in the

clamps or being damaged as a result of being gripped in the

FIG. 1 Trapezoidal Template for Trapezoid Tearing Strength Test clamps.

5.5 This test method may be used with constant-rate-of-

traverse (CRT) or constant-rate-of-extension (CRE) type ten-

sion machines. However, there may be no overall correlation

between the results obtained with the CRT machine and the

CRE machine. Consequently, these two tension testers cannot

be used interchangeably. In case of controversy, the CRE

machine shall prevail.

6. Apparatus

6.1 Tensile Testing Machine, of the constant-rate-of-

extension (CRE) or constant-rate-of-traverse (CRT) type with

autographic recorder conforming to the requirements of Speci-

fication D76.

6.2 Clamps, having all gripping surfaces parallel, flat, and

capable of preventing slipping of the specimen during a test,

and measuring 50.8 by no less than 76.2 mm (2 by no less than

3 in.), with the longer dimension perpendicular to the direction

of application of the load.

6.3 Trapezoidal Template, optional, having the dimensions

shown in Fig. 1.

7. Sampling and Selection

7.1 Lot Sample—As a lot sample for acceptance testing,

take at random the number of rolls of fabric directed in an

applicable material specification or other agreement between

the purchaser and the supplier, such as agreement to sample as

directed in Practice D4354. Consider rolls of fabric to be the

primary sampling units.

FIG. 2 Typical Tearing Force – Extension Curves for Individual

NOTE 1—An adequate specification or other agreement between the

Test Specimens

purchaser and the supplier requires taking into account the variability

between rolls of fabric and between specimens from a swatch from a roll

of fabric so as to provide a sampling plan with a meaningful producer’s

5.3 This test method may be used for acceptance testing of

risk, consumer’s risk, acceptable quality level, and limiting quality level.

commercial shipments; however, caution is advised since

information about between-laboratory precision is incomplete. 7.2 Laboratory Sample—Take for the laboratory sample a

Comparative tests as directed in 5.3.1 may be advisable. sample extending the width of the fabric and approximately

5.3.1 In case of a dispute arising from differences in 1 m (39.37 in.) along the selvage from each roll in the lot

reported test results when using this test method for acceptance sample. The sample may be taken from the end portion of a

testing of commercial shipments, the purchaser and the sup- roll, provided there is no evidence that it is distorted or

plier should conduct comparative tests to determine if there is different from other portions of the roll. In cases of dispute,

a statistical bias between their laboratories. Competent statis- take a sample that will exclude fabric from the outer wrap of

tical assistance is recommended for the investigation of bias. the roll or the inner wrap around the core.

As a minimum, the two parties should take a group of test 7.3 Test Specimens—Take test specimens as follows:

specimens that are as homogeneous as possible and that are 7.3.1 Woven Fabrics—Take the specimens to be used for

from a lot of material of the type in question. Test specimens the measurement of the tearing strength of machine direction

should then be randomly assigned in equal numbers to each yarns from different sets of machine direction yarns. Take the

laboratory for testing. The average results from the two specimens to be used for the measurement of the tearing

D4533–04 (2009)

TABLE 1 Values of Student’s t for One-Sided Limits and the

strength of cross-machine direction yarns from different sets of

A

95% Probability

cross-machine direction yarns and, when possible, from fabric

One- One- One-

woven from different bobbins.

df df df

Sided Sided Sided

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4533–91(Reapproved 1996) Designation:D4533–04 (Reapproved 2009)

Standard Test Method for

Trapezoid Tearing Strength of Geotextiles

This standard is issued under the fixed designation D 4533; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method is an index test used to measure the force required to continue or propagate a tear in woven or non-woven

geotextilesbythetrapezoidmethod.Whileusefulforqualitycontrolandacceptancetesting,thetrapezoidteartestdoesnotprovide

all the information needed for all design applications and other test methods should be used.

1.2 Thistestmethodisapplicabletomostgeotextilesthatincludewovenfabrics,nonwovenfabrics,layeredfabrics,knitfabrics,

and felts that are used for geotextile applications.

1.3The values stated in SI units are to be regarded as the standard.

1.3 The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D76 Specification for Tensile Testing Machines for Textiles

D 123 Terminology Relating to Textiles

D 1776 Practice for Conditioning Textiles for Testing Practice for Conditioning and Testing Textiles

D 2905 Practice for Statements on Number of Specimens for Textiles

D 4354 Practice for Sampling of Geosynthetics for Testing

D 4439 Terminology for Relating to Geosynthetics Terminology for Geosynthetics

3. Terminology

3.1 Definitions:

3.1.1 atmosphere for testing geotextiles, n— air maintained at a relative humidity of 65 6 5 % and a temperature of 21 6 2°C

(70 6 4°F).

3.1.2 geotextile, n—anypermeabletextilematerialusedwithfoundation,soil,rock,earth,oranyothergeotechnicalengineering

related material as an integral part of a man-made product, structure, or system.

3.1.3 tearing strength, n—the force required to either (1) start, or (2) continue or propagate a tear in a fabric under specified

conditions.

3.1.3.1 Discussion—This test method uses the maximum value of the tearing force as the tearing strength.

3.1.4 For definitions of other terms used in this test method, refer to Terminology D 123 or Terminology D 4439.

4. Summary of Test Method

4.1 An outline of an isosceles trapezoid is marked on a rectangular specimen cut for the determination of tearing strength (see

Fig.1),andthenonparallelsidesofthetrapezoidmarkedonthespecimenareclampedinparalleljawsofatensiletestingmachine.

The separation of the jaws is continuously increased so the tear propagates across the specimen. At the same time, the force

developed is recorded. The tearing strength, which is the maximum value of the tearing force, is obtained from the autographic

force – extension curve (see Fig. 2).

This test method is under the jurisdiction of ASTM Committee D-35 D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.01 on Mechanical

Properties.

Current edition approved Aug. 15, 1991. Published December 1991.

Current edition approved June 1, 2009. Published July 2009. Originally approved in 1991. Last previous edition approved in 2004 as D 4533 – 04.

Annual Book of ASTM Standards, Vol 07.01.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4533–04 (2009)

FIG. 1 Trapezoidal Template for Trapezoid Tearing Strength Test

FIG. 2 Typical Tearing Force – Extension Curves for Individual

Test Specimens

5. Significance and Use

5.1 The trapezoid tear method is a test that produces tension along a reasonably defined course such that the tear propagates

across the width of the specimen. The trapezoid tearing strength for woven fabrics is determined primarily by the properties of the

yarns that are gripped in the clamps. In nonwoven fabrics, because the individual fibers are more or less randomly oriented and

capable of some reorientation in the direction of the applied load, the maximum trapezoid tearing strength is reached when the

resistance to further reorientation is greater than the force required to rupture one or more fibers simultaneously.

5.2 The trapezoid tearing strength method is useful for estimating the relative tear resistance of different fabrics or different

directions in the same fabric.

5.3 This test method may be used for acceptance testing of commercial shipments; however, caution is advised since

information about between-laboratory precision is incomplete. Comparative tests as directed in 5.3.1 may be advisable.

5.3.1 In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of

commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias

between their laboratories. Competent statistical assistance is recommended for the investigation of bias.As a minimum, the two

parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type

in question. Test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results

D4533–04 (2009)

from the two laboratories should be compared using the appropriate Student’s t-test and an acceptable probability level chosen by

the two parties before testing is begun. If a bias is found, either its cause must be found and corrected or the purchaser and the

supplier must agree to interpret future test results in the light of the known bias.

5.4 Most geotextile fabrics can be tested by this test method. Some modification of clamping techniques may be necessary for

a given fabric, depending upon its structure. Special adaptation may be necessary with strong fabrics, or fabrics made from glass

fibers, to prevent them from slipping in the clamps or being damaged as a result of being gripped in the clamps.

5.5 This test method may be used with constant-rate-of-traverse (CRT) or constant-rate-of-extension (CRE) type tension

machines.However,theremaybenooverallcorrelationbetweentheresultsobtainedwiththeCRTmachineandtheCREmachine.

Consequently, these two tension testers cannot be used interchangeably. In case of controversy, the CRE machine shall prevail.

6. Apparatus

6.1 Tensile Testing Machine, of the constant-rate-of-extension (CRE) or constant-rate-of-traverse (CRT) type with autographic

recorder conforming to the requirements of Specification D 76.

6.2 Clamps, having all gripping surfaces parallel, flat, and capable of preventing slipping of the specimen during a test, and

measuring 50.8 by no less than 76.2 mm (2 by no less than 3 in.), with the longer dimension perpendicular to the direction of

application of the load.

6.3 Trapezoidal Template, optional, having the dimensions shown in Fig. 1.

7. Sampling and Selection

7.1 Lot Sample—As a lot sample for acceptance testing, take at random the number of rolls of fabric directed in an applicable

material specification or other agreement between the purchaser and the supplier, such as agreement to sample as directed in

Practice D 4354. Consider rolls of fabric to be the primary sampling units.

NOTE 1—Anadequatespecificationorotheragreementbetweenthepurchaserandthesupplierrequirestakingintoaccountthevariabilitybetweenrolls

of fabric and between specimens from a swatch from a roll of fabric so as to provide a sampling plan with a meaningful producer’s risk, consumer’s risk,

acceptable quality level, and limiting quality level.

7.2 Laboratory Sample—Take for the laboratory sample a sample extending the width of the fabric and approximately 1 m

(39.37 in.) along the selvage from each roll in the lot sample. The sample may be taken from the end portion of a roll, provided

thereisnoevidencethatitisdistortedordifferentfromotherportionsoftheroll.Incasesofdispute,takeasamplethatwillexclude

fabric from the outer wrap of the roll or the inner wrap around the core.

7.3 Test Specimens—Take test specimens as follows:

7.3.1 Woven Fabrics—Take the specimens to be used for the measurement of the tearing strength of machine direction yarns

from different sets of machine direction yarns. Take the specimens to be used for the measurement of the tearing strength of

cross-machine direction yarns from different sets of cross-machine direction yarns and, when possible, from fabric woven from

different bobbins.

7.3.2 Nonwoven Fabrics—Take the specimens for the measurement of the machine direction tearing strengt

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.