ASTM F2170-16

(Test Method)Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using in situ Probes

Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using in situ Probes

SIGNIFICANCE AND USE

5.1 Moisture permeating from concrete floor slabs affects the performance of flooring systems such as resilient and textile floor coverings and coatings. Manufacturers of such systems generally require moisture testing to be performed before installation on concrete. Internal relative humidity testing is one such method.

5.2 Excessive moisture permeating from floor slabs after installation can cause floor covering system failures such as debonding and deterioration of finish flooring and coatings and microbial growth.

5.3 Moisture test results indicate the moisture condition of the slab only at the time of the test.

SCOPE

1.1 This test method covers the quantitative determination of percent relative humidity in concrete slabs for field or laboratory tests.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Specific warnings are given in Section 7, 10.3.2, and 10.4.4.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2170 − 16

StandardTest Method for

Determining Relative Humidity in Concrete Floor Slabs

1

Using in situ Probes

This standard is issued under the fixed designation F2170; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 service temperature and relative humidity, n—average

ambient air temperature and relative humidity that typically

1.1 This test method covers the quantitative determination

will be found in a building’s occupied spaces during normal

of percent relative humidity in concrete slabs for field or

use.

laboratory tests.

1.2 The values stated in inch-pound units are to be regarded 4. Summary of Test Method

as standard. The values given in parentheses are mathematical

4.1 This test method comprises two procedures for forming

conversions to SI units that are provided for information only

holes in concrete into which a relative humidity probe is

and are not considered standard.

placed. Procedure A for hardened concrete involves drilling a

cylindrical hole in concrete with a rotary hammerdrill, then

1.3 This standard does not purport to address all of the

placing a hollow sleeve to line the hole. Procedure B is an

safety concerns, if any, associated with its use. It is the

alternative procedure for fresh concrete, which involves form-

responsibility of the user of this standard to establish appro-

ing a cylindrical hole in concrete by placing a hollow cylin-

priate safety and health practices and determine the applica-

drical tube in the formwork, then placing and consolidating

bility of regulatory limitations prior to use.

concrete around the tube. The liner or tube permits measure-

Specific warnings are given in Section 7, 10.3.2, and 10.4.4.

ment of RH at a specific, well-defined depth in the concrete.

2. Referenced Documents

4.2 Methods of probe calibration and factors affecting

2 equilibration are described in Section 8.

2.1 ASTM Standards:

E104 Practice for Maintaining Constant Relative Humidity

5. Significance and Use

by Means of Aqueous Solutions

5.1 Moisture permeating from concrete floor slabs affects

E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods the performance of flooring systems such as resilient and

F710 Practice for Preparing Concrete Floors to Receive textile floor coverings and coatings. Manufacturers of such

Resilient Flooring systems generally require moisture testing to be performed

before installation on concrete. Internal relative humidity

3. Terminology testing is one such method.

5.2 Excessive moisture permeating from floor slabs after

3.1 Definitions:

installation can cause floor covering system failures such as

3.1.1 relative humidity, n—ratio of the amount of water

debonding and deterioration of finish flooring and coatings and

vaporactuallyintheaircomparedtotheamountofwatervapor

microbial growth.

required for saturation at that particular temperature and

pressure, expressed as a percentage.

5.3 Moisture test results indicate the moisture condition of

the slab only at the time of the test.

6. Apparatus

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF06onResilient

Floor Coverings and is the direct responsibility of Subcommittee F06.40 on

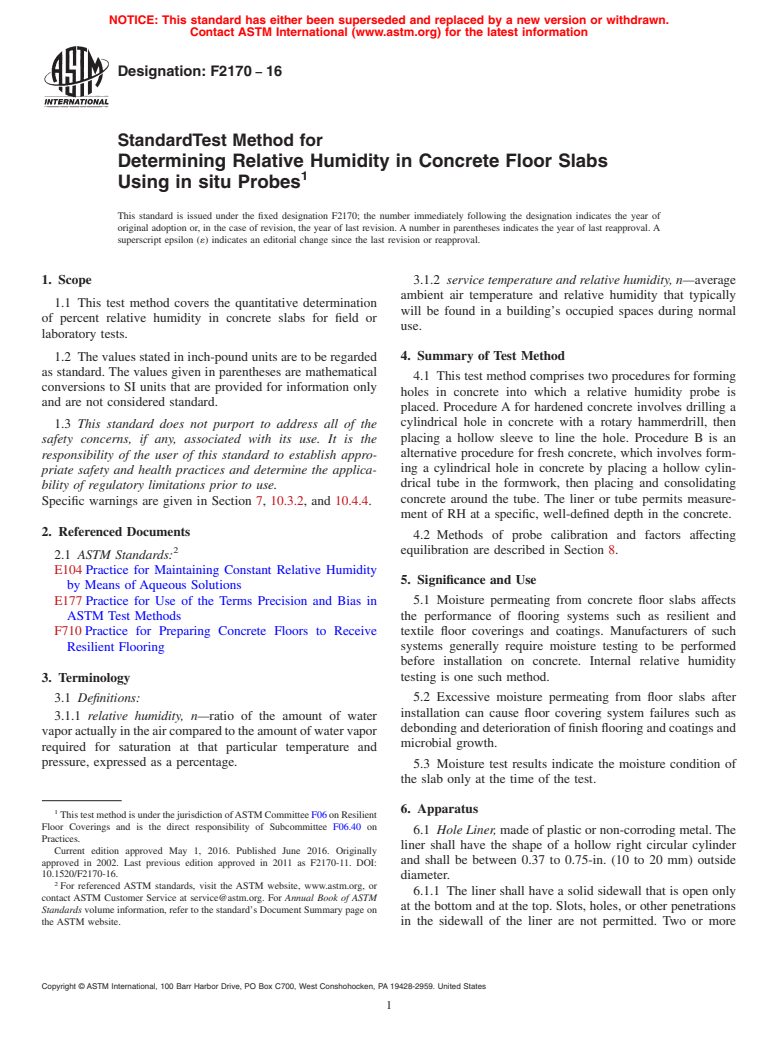

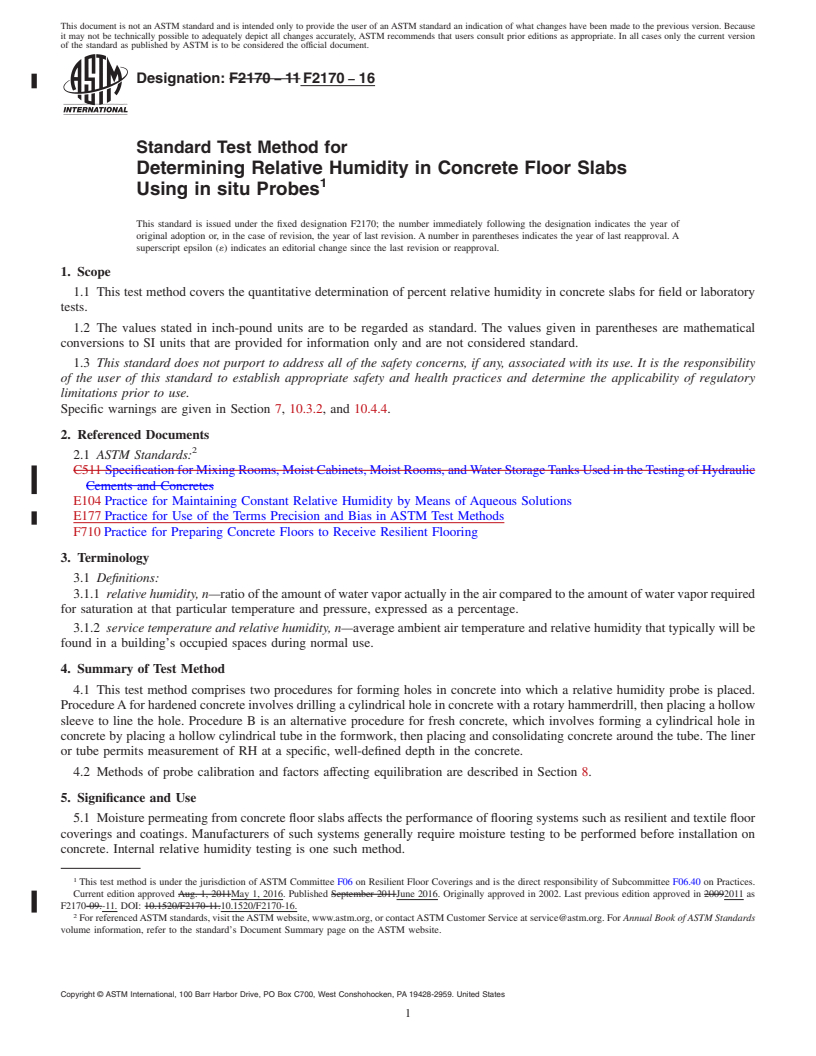

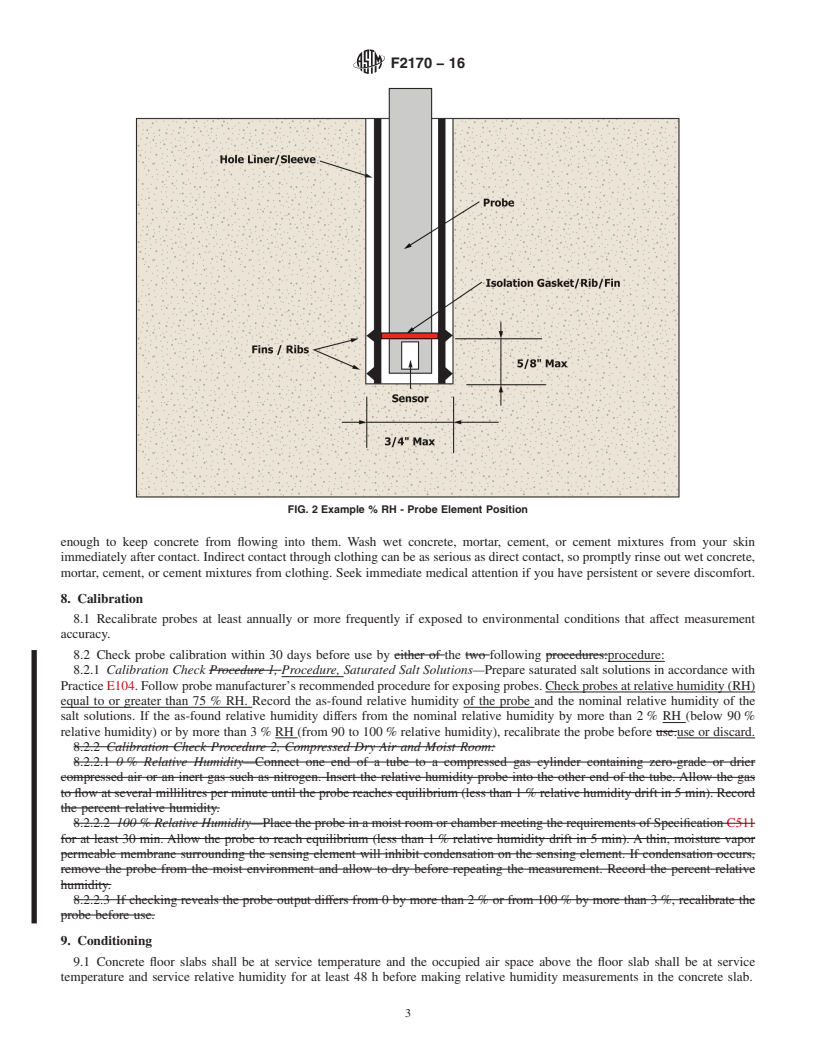

6.1 Hole Liner, made of plastic or non-corroding metal. The

Practices.

liner shall have the shape of a hollow right circular cylinder

Current edition approved May 1, 2016. Published June 2016. Originally

and shall be between 0.37 to 0.75-in. (10 to 20 mm) outside

approved in 2002. Last previous edition approved in 2011 as F2170-11. DOI:

10.1520/F2170-16.

diameter.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1.1 The liner shall have a solid sidewall that is open only

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

at the bottom and at the top. Slots, holes, or other penetrations

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. in the sidewall of the liner are not permitted. Two or more

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2170 − 16

deformable circumferential fins located around the exterior floor coverings should be consulted for a defined set of

circumference near the bottom of the liner shall be provided to instructions addressed to the task of removing all resilient floor

3

create a positive seal against the concrete. The liner shall be of covering structures.

sufficientlengthtoextendfromthebottomdiameterofthehole

7.2 Lead Warning—Certain paints

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2170 − 11 F2170 − 16

Standard Test Method for

Determining Relative Humidity in Concrete Floor Slabs

1

Using in situ Probes

This standard is issued under the fixed designation F2170; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the quantitative determination of percent relative humidity in concrete slabs for field or laboratory

tests.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

Specific warnings are given in Section 7, 10.3.2, and 10.4.4.

2. Referenced Documents

2

2.1 ASTM Standards:

C511 Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of Hydraulic

Cements and Concretes

E104 Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

F710 Practice for Preparing Concrete Floors to Receive Resilient Flooring

3. Terminology

3.1 Definitions:

3.1.1 relative humidity, n—ratio of the amount of water vapor actually in the air compared to the amount of water vapor required

for saturation at that particular temperature and pressure, expressed as a percentage.

3.1.2 service temperature and relative humidity, n—average ambient air temperature and relative humidity that typically will be

found in a building’s occupied spaces during normal use.

4. Summary of Test Method

4.1 This test method comprises two procedures for forming holes in concrete into which a relative humidity probe is placed.

Procedure A for hardened concrete involves drilling a cylindrical hole in concrete with a rotary hammerdrill, then placing a hollow

sleeve to line the hole. Procedure B is an alternative procedure for fresh concrete, which involves forming a cylindrical hole in

concrete by placing a hollow cylindrical tube in the formwork, then placing and consolidating concrete around the tube. The liner

or tube permits measurement of RH at a specific, well-defined depth in the concrete.

4.2 Methods of probe calibration and factors affecting equilibration are described in Section 8.

5. Significance and Use

5.1 Moisture permeating from concrete floor slabs affects the performance of flooring systems such as resilient and textile floor

coverings and coatings. Manufacturers of such systems generally require moisture testing to be performed before installation on

concrete. Internal relative humidity testing is one such method.

1

This test method is under the jurisdiction of ASTM Committee F06 on Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.40 on Practices.

Current edition approved Aug. 1, 2011May 1, 2016. Published September 2011June 2016. Originally approved in 2002. Last previous edition approved in 20092011 as

F2170-09.-11. DOI: 10.1520/F2170-11.10.1520/F2170-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2170 − 16

5.2 Excessive moisture permeating from floor slabs after installation can cause floor covering system failures such as debonding

and deterioration of finish flooring and coatings and microbial growth.

5.3 Moisture test results indicate the moisture condition of the slab only at the time of the test.

6. Apparatus

6.1 Hole Liner, made of plastic or non-corroding metal. The liner shall have the shape of a hollow right circular cylinder and

shall be between 0.37 to 0.75-in. (10 to 20 mm) outside diameter.

6.1.1 The liner shall have a solid sidewall that is open only at the bottom and at the top. Slots, holes, or o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.