ASTM E2751-11

(Practice)Standard Practice for Design and Performance of Supported Glass Walkways

Standard Practice for Design and Performance of Supported Glass Walkways

SIGNIFICANCE AND USE

Glass is a brittle material with different time and temperature-dependent properties than other solid materials used as walkways surfaces. Therefore, the type of glass is an important consideration in the design and construction of glass treads and glass landings constructed with laminated glass.

Post-breakage glass retention is an important consideration in the design of a glass walkway system as a means of minimizing tripping, cutting/piercing injuries, or fall-through or fallout of the glass.

The structural design shall be confirmed by calculations by a licensed design professional in accordance with Section 5.

The post-breakage behavior of the glass walkway shall be verified by testing in accordance with Section 6.

For laminates with two glass plies, verification testing is required.

For laminates with more than two glass plies, verification testing is not required provided that calculations completed in accordance with 4.3 demonstrate that the glass assembly has sufficient strength to sustain the full design load with any one glass ply broken.

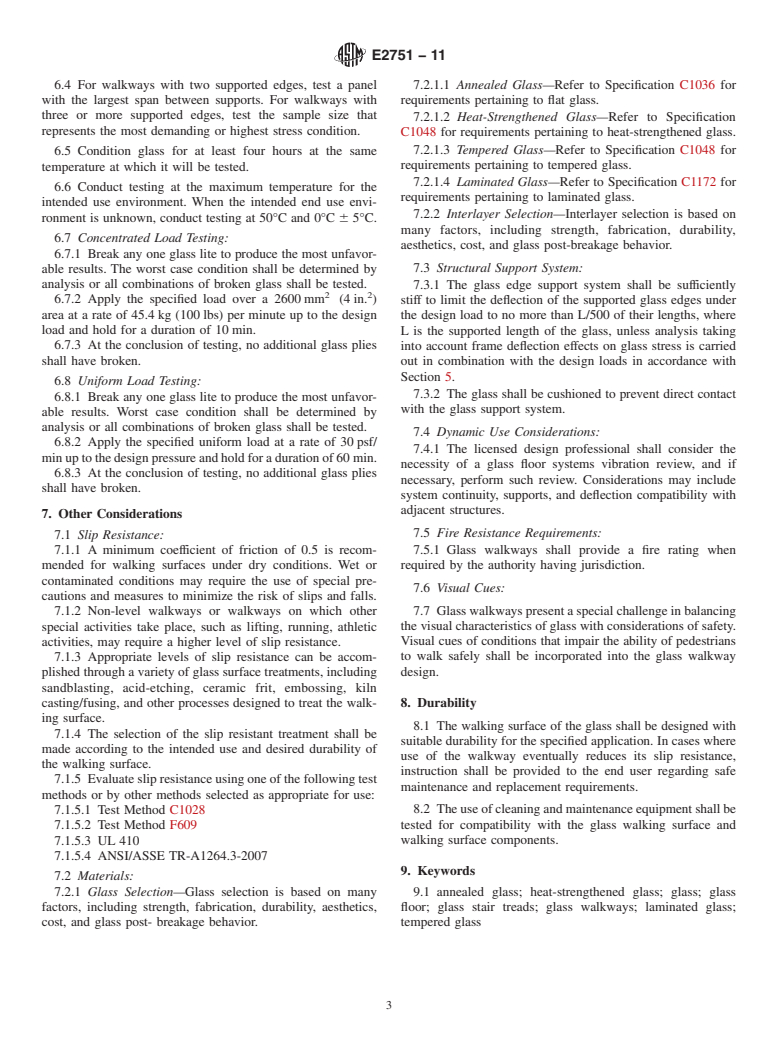

When verifying post-breakage behavior by calculation, allowable glass stress for 10 min load duration in accordance with Table 1 shall be used for all load cases.

The manufacturer or designer of glass walkway systems shall provide installation directions and fabrication and installation tolerances of their systems.

The structural integrity of the glass walkway system after glass breakage shall be sufficient to support the design loads after any one glass ply is broken. If damage of any kind occurs, the walkway shall be cordoned off and the installation shall be inspected to ensure structural integrity and pedestrian safety of the system.

TABLE 1 Allowable Glass Stresses for Nominal Load Conditions

Note 1—An allowable stress reduction factor of 0.5 is recommended for disruptive surface treatments, for example, acid etching or sandblasting, unless otherwise provided by the manufacturer. A glass stres...

SCOPE

1.1 This practice addresses elements related to load-bearing glass walkways, glass treads, and glass landings constructed with laminated glass. This standard includes performance, design, and safe behavior considerations. It addresses the characteristics unique to glass and laminated glass. Issues that are common to all walkways, such as slip resistance, are addressed in existing referenced standards.

1.2 This practice does not address glass walkways constructed with monolithic glass, glass block, insulating glass units, glass tiles that are directly bonded to a non-glass structural substrate, or glass walkways intended to support vehicular traffic.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2751 − 11

StandardPractice for

Design and Performance of Supported Glass Walkways

This standard is issued under the fixed designation E2751; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1300 Practice for Determining Load Resistance of Glass in

Buildings

1.1 This practice addresses elements related to load-bearing

F609 Test Method for Using a Horizontal Pull Slipmeter

glass walkways, glass treads, and glass landings constructed

(HPS)

with laminated glass. This standard includes performance,

design, and safe behavior considerations. It addresses the 2.2 ANSI Standards:

characteristics unique to glass and laminated glass. Issues that ANSI/ASSETR-A1264.3-2007 ANSITechnicalReport,Us-

are common to all walkways, such as slip resistance, are ingVariableAngleTribometers(VAT)forMeasurementof

addressed in existing referenced standards. the Slip Resistance of Walkway Surfaces

1.2 This practice does not address glass walkways con- 2.3 UL Standards:

structed with monolithic glass, glass block, insulating glass UL 410 Standard for Safety for Slip Resistance of Floor

units, glass tiles that are directly bonded to a non-glass Surface Materials

structural substrate, or glass walkways intended to support

vehicular traffic. 3. Terminology

1.3 The values stated in SI units are to be regarded as the

3.1 Definitions—For definitions of general terms related to

standard.The values given in parentheses are for mathematical building construction used in this practice, refer to Terminol-

conversions to inch-pound units that are provided for informa-

ogy E631.

tion only and are not considered standard. 3.2 Definitions of Terms Specific to This Standard:

3.2.1 duration of load—theperiodofcontinuousapplication

1.4 This standard does not purport to address all of the

of a given load, or the aggregate of periods of intermittent

safety concerns, if any, associated with its use. It is the

applications of the same load.

responsibility of the user of this standard to establish appro-

3.2.1.1 Discussion—Anyloaddurationlongerthanonehour

priate safety and health practices and determine the applica-

shall be considered a permanent load. Uniformly distributed

bility of regulatory limitations prior to use.

live loads shall have a load duration of at least one hour.

Concentrated live loads shall have a load duration of at least

2. Referenced Documents

ten minutes.

2.1 ASTM Standards:

3.2.2 ethylene vinyl acetate (EVA) interlayer—co-polymer

C1028 TestMethodforDeterminingtheStaticCoefficientof

of ethylene and vinyl acetate used to permanently bond two or

Friction of Ceramic Tile and Other Like Surfaces by the

more lites of glass.

Horizontal Dynamometer Pull-Meter Method

C1036 Specification for Flat Glass

3.2.3 glass-clad polycarbonate laminate—assembly con-

C1048 Specification for Heat-Strengthened and Fully Tem-

sisting of two or more lites of glass and one or more sheets of

pered Flat Glass

polycarbonate bonded by interlayers.

C1172 Specification for Laminated Architectural Flat Glass

3.2.4 ionomer interlayer—a partially neutralized copolymer

E631 Terminology of Building Constructions

of ethylene and acrylic or methacrylic acid, used to perma-

nently bond two or more lites of glass.

3.2.5 laminated glass—an assembly consisting of two or

This practice is under the jurisdiction of ASTM Committee E06 on Perfor-

more lites of glass bonded by an interlayer.

mance of Buildings and is the direct responsibility of Subcommittee E06.56 on

Performance of Railing Systems and Glass for Floors and Stairs.

Current edition approved Oct. 1, 2011. Published October 2011. DOI: 10.1520/

E2751-11.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Underwriters Laboratories (UL), 2600 N.W. Lake Rd., Camas,

the ASTM website. WA 98607-8542, http://www.ul.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2751 − 11

TABLE 1 Allowable Glass Stresses for Nominal Load Conditions

3.2.6 liquid resin interlayer—liquid formulations, generally

polyester-, urethane-, or acrylic-based, that react to form solid

NOTE 1—An allowable stress reduction factor of 0.5 is recommended

interlayers after being introduced between two lites of glass.

for disruptive surface treatments, for example, acid etching or

sandblasting, unless otherwise provided by the manufacturer. A glass

3.2.7 polyurethane interlayer—polymer sheeting based on

stressreductionfactormayberequiredforsomepatternedglasses;consult

isocyanates and mostly polyester or acrylic polyols, or both.

the manufacturer.

3.2.8 polyvinyl butyral (PVB) interlayer—polymer sheeting

NOTE 2—Values derived from Practice E1300, Table X9.1 (seamed

prepared from polyvinyl alcohol by reaction with butyralde- edges), factored for load duration using Practice E1300, Equation X7.1,

where n = 16 for annealed glass, n = 32 for heat strengthened glass, and

hyde used to permanently bond two or more lites of glass.

n = 48 for tempered glass.

3.2.9 post-breakage glass retention—the ability of the bro-

3-sec 10-min 60-min Permanent

Glass Type

kenglasstoremaininplacesoastoreducecuttingandpiercing

MPa (psi) MPa (psi) MPa (psi) MPa (psi)

Annealed 18.3 (2650) 13.2 (1902) 11.7 (1701) 5.7 (827)

injuries from the broken shards and to prevent fall through or

Heat- 36.5 (5300) 30.9 (4482) 29.2 (4235) 20.3 (2944)

glass fallout.

strengthened

Tempered 73.0 (10 600) 65.3 (9471) 63.0 (9137) 49.4 (7165)

3.2.10 slip resistant—the provision of adequate slip resis-

tance to reduce the likelihood of slip for pedestrians using

reasonable care on the walking surface under expected use

conditions.

3.2.11 supported glass walkway—any glass walkway with a

occurs, the walkway shall be cordoned off and the installation

free spanning section, including continuous or local multiple

shall be inspected to ensure structural integrity and pedestrian

supports at the edge or any location of the glass.

safety of the system.

3.2.12 walkway surfaces—interior and exterior walking sur-

5. Calculation Procedure

faces constructed and intended for pedestrian use, including

but not limited to floors, ramps, sidewalks, and stair treads. 5.1 Use established engineering methods, such as engineer-

ing mechanics or finite element analysis, to determine glass

4. Significance and Use assembly stresses and deflections. Such methods shall account

for temperature, boundary conditions, loading requirements,

4.1 Glass is a brittle material with different time and

load duration, interlayer properties, and glass strength.

temperature-dependent properties than other solid materials

5.2 Design Criteria:

used as walkways surfaces. Therefore, the type of glass is an

5.2.1 Assign nominal load conditions or combinations of

important consideration in the design and construction of glass

load conditions as required by the specifying authority.

treads and glass landings constructed with laminated glass.

Additionally, the final design shall include consideration of a

4.2 Post-breakage glass retention is an important consider-

concentrated live load of at least 136 kg (300 lb) applied to all

ation in the design of a glass walkway system as a means of 2 2

glass walking surfaces in a 2600 mm (4 in. ) area.

minimizing tripping, cutting/piercing injuries, or fall-through

5.2.2 Determine maximum allowable material stress.

or fallout of the glass.

5.2.2.1 Glass—Refer to Table 1 to determine allowable

glass stress.

4.3 The structural design shall be confirmed by calculations

(1) Use minimum glass thickness in accordance with

by a licensed design professional in accordance with Section 5.

Specification C1036, Table 2, for design purposes.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.