ASTM B891-98e1

(Specification)Standard Specification for Seamless and Welded Titanium and Titanium Alloy Condenser and Heat Exchanger Tubes With Integral Fins

Standard Specification for Seamless and Welded Titanium and Titanium Alloy Condenser and Heat Exchanger Tubes With Integral Fins

SCOPE

1.1 This specification covers seamless and welded titanium and titianium alloy tubing on which the external or internal surface, or both, has been modified by a cold forming process to produce an integral enhanced surface for improved heat transfer. The tubes are used in surface condensers, evaporators, heat exchangers and similar heat transfer apparatus in unfinned end diameters up to and including 1 in. (25.4 mm).

1.2 The following precautionary statement pertains to the test method portion only, Section 9 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

Designation: B 891 – 98

Standard Specification for

Seamless and Welded Titanium and Titanium Alloy

Condenser and Heat Exchanger Tubes With Integral Fins

This standard is issued under the fixed designation B 891; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made throughout this standard in March 1999.

1. Scope 3.1.1 ASTM designation and year of issue

2 3.1.2 Welded or Seamless

1.1 This specification covers seamless and welded titanium

3.1.3 Grade number

and titanium alloy tubing on which the external or internal

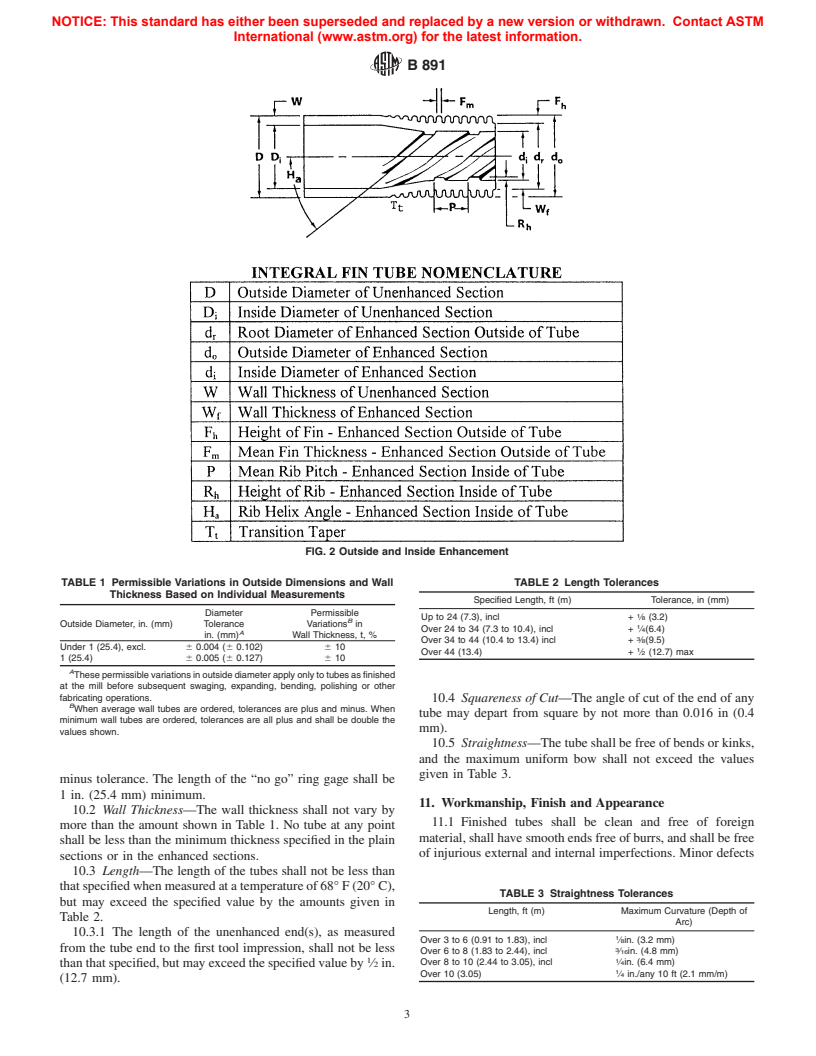

3.1.4 Dimensions; diameter, wall thickness (ave. or min.

surface, or both, has been modified by a cold forming process

specified), length and location of unenhanced surfaces and the

to produce an integral enhanced surface for improved heat

total tube length. Configuration of enhanced surfaces (fins per

transfer.The tubes are used in surface condensers, evaporators,

unit length, fin height, wall thickness under fin, etc.) shall be as

heat exchangers and similar heat transfer apparatus in unfinned

agreeduponbetweenthemanufacturerandpurchaser.(Referto

end diameters up to and including 1 in. (25.4 mm).

Figs. 1 and 2)

1.2 The values stated in inch-pound units are to be regarded

3.1.5 Quantity

as the standard. The values given in parentheses are for

3.1.6 Packaging

information only.

3.1.7 Nondestructive tests

1.3 The following precautionary statement pertains to the

3.1.8 Mill test report

test method portion only: Section 9 of this specification: This

3.1.9 Certification

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

4. General Requirements

of this standard to establish appropriate safety and health

4.1 Tubes described by this specification shall be furnished

practices and determine the applicability of regulatory limita-

with unenhanced ends.

tions prior to use.

4.2 Enhanced sections of the tube are normally supplied in

2. Referenced Documents the “as-finned” condition (cold worked condition produced by

the enhancing operation). The unenhanced sections of the tube

2.1 ASTM Standards:

shall be in the annealed condition and shall be suitable for

B 338 Specification for Seamless and Welded Titanium and

rolling-in operations.

Titanium Alloy Tubes for Condensers and Heat Exchang-

ers

5. Materials and Manufacture

E 426 Practice for Electromagnetic (Eddy-Current) Exami-

5.1 The integrally enhanced (finned) tubes shall be manu-

nation of Seamless and Welded Tubular Products, Austen-

4 factured from seamless, welded, or welded/cold worked

itic Stainless Steel and Similar Alloys

4 (WCW) plain tubes that conform to all requirements as

E 1316 Terminology for Nondestructive Testing

specified in Specification B 338.

3. Ordering Information 5.2 Enhanced areas shall be produced by cold forming.

3.1 Purchase orders for tubes described in this specification

6. Condition

should include the following, to describe the tubes adequately.

6.1 The tube after enhancing shall normally be supplied in

the “as-finned” condition.When specified by the purchaser, for

This specification is under the jurisdiction of ASTM Committee B-10 on coiling or other fabricating operations, the tube may be

Reactive and Refractory Metals and Alloysand is the direct responsibility of

annealed after enhancing.

Subcommittee B10.01 on Titanium.

Current edition approved October 10, 1998. Published January 1999.

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

cation SB-_____ in Section II of that Code.

Annual Book of ASTM Standards, Vol 02.04.

Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

B 891

should they not cause output signals beyond acceptable limits

when retested. Tubes causing irrelevant signals because of

visible and identifiable handling marks shall be considered to

conform, provided the wall thickness in the enhanced and

unenhanced areas is not less than the minimum specified.

9.1.1.5 Tubes causing relevant signals because of injurious

defects that reduce the wall thickness below the minimum

specified shall be rejected. If, after retest and examination, no

source for the reject signal can be discerned, the tube shall be

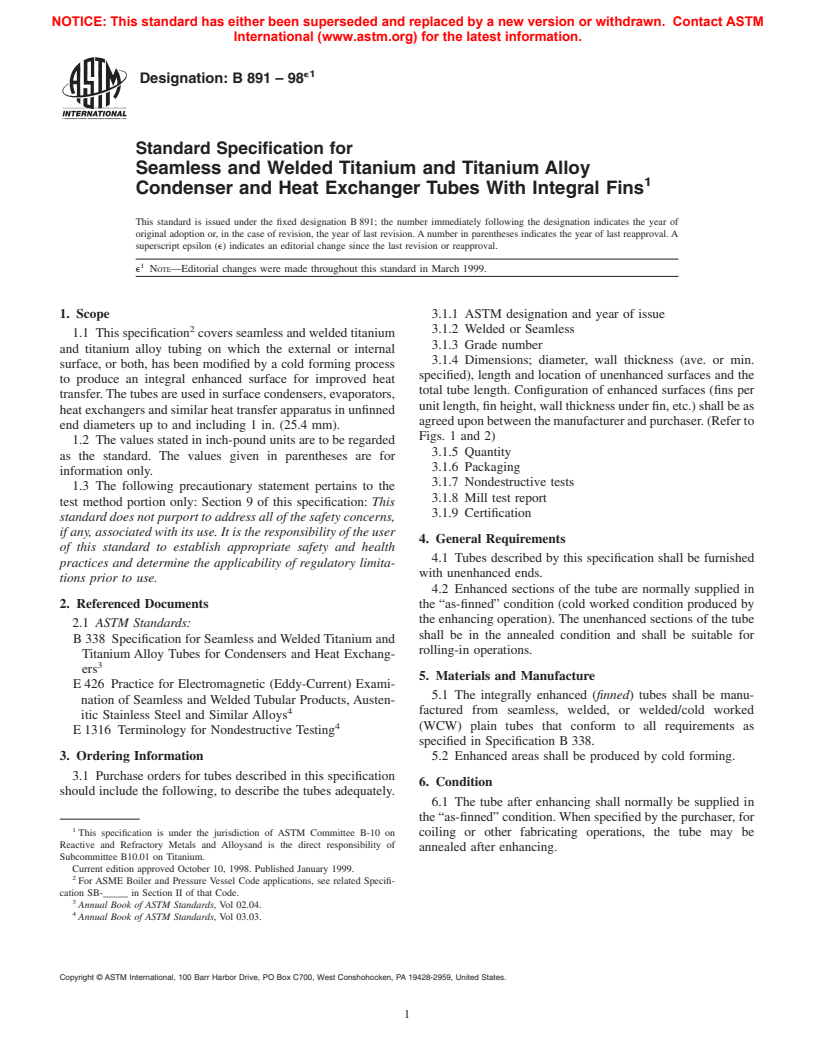

FIG. 1 Outside Enhancement Only

rejected.

9.1.2 Pneumatic Test—Each tube so tested shall withstand a

7. Chemical Composition minimum internal air pressure of 250 psi (1.72 MPa) for a

minimum of 5 s without showing evidence of leakage. The test

7.1 The grade titanium or titanium alloy specified shall

method used shall permit easy detection of any leakage by

conform to the chemical requirements prescribed in Specifica-

placing the tube underwater or by using the pressure differen-

tion B 338.

tial method. Any evidence of leakage shall be cause for

rejection of that tube.

8. Tensile Requirements

9.1.3 Hydrostatic Test—Each tube so tested shall withstand,

8.1 The tube prior to the finning operation, or unenhanced

without showing bulges, leaks or other defects, an internal

portions of the finned tube, shall conform to the grade

hydrostatic pressure that will produce in the tube wall a stress

requirements for tensile properties prescribed in Specification

of 50 % of the minimum specified yield strength at room

B 338

temperature.Thispressureshallbedeterminedbytheequation:

9. Nondestructive Tests

P 5 SEW /~d /2 2 0.4W ! (1)

f r f

9.1 After enhancing operations, subject each tube to a

where:

nondestructive electromagnetic test, and either a pneumatic or

P 5 minimum hydrostatic test pressure, psi (or MPa),

hydrostatic test as specified in the purchase order. Tubes shall

S 5 one half the minimum yield strength, psi (or MPa),

normally be tested in the as-fabricated condition but, at the

W 5 wall under fin thickness, in. (or mm),

f

option of the manufacturer or purchaser, may be tested in the

d 5 fin root diameter, in. (or mm),

r

annealed condition.

E 5 0.85 welded tube, and

9.1.1 Eddy Current Test—Eddy current inspect the tube in

E 5 1.0 seamless and welded/cold worked tube.

accordance with Practice E 426 by passing it through an

9.1.3.1 The maximum hydrostatic test pressure shall not

encircling coil designed to test the entire cross section of the

exceed 2500 psi (17.2 MPa) for sizes 1 in. (25.4 mm) and

tube.

under. Hydrostatic pressure shall be maintained for not less

9.1.1.1 The reference standard used to adjust the sensitivity

than 5 s. When requested by the purchaser and so stated in the

setting of the apparatus shall be sound and of the same nominal

order, tubes shall be tested to one and one half times the

alloy, enhanced configuration, condition and nominal dimen-

specified working pressure, provided the fiber stress corre-

sions as the lot of tubes to be tested on a production basis. Drill

sponding to those test pressures does not exceed one half the

four holes not larger than 0.031 in. (0.787 mm) in diameter

minimum specified yield strength of the material as determined

radially through the enhanced wall in each of four successive

bytheequationgivenin9.1.3.Whenoneandonehalftimesthe

planes at 0, 90, 180 and 270°. Use a suitable drill jig to guide

working pressure exceeds 2500 psi (17.2 MPa), the hydrostatic

the drill, taking care to avoid distortion of the adjacent fins.

test pressure shall be a matter of agreement between the

Locate one hole in the weld for welded material. Space

manufacturer and purchaser.

artificial discontinuities at least 16 in. (406 mm) apart to

provide signal resolution adequate for interpretation. Discard

10. Permissible Variations in Dimensions

the reference standard and replace when erroneous signals are

10.1 Diameter—The outside diameter of the unenhanced

produced from mechanical, metallurgical or other damage to

sections shall not vary by more than the amount in Table 1, as

the tube.

measured by “go” and “no go” ring gages. The diameter over

9.1.1.2 A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.