ASTM E837-01e1

(Test Method)Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method

Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method

SIGNIFICANCE AND USE

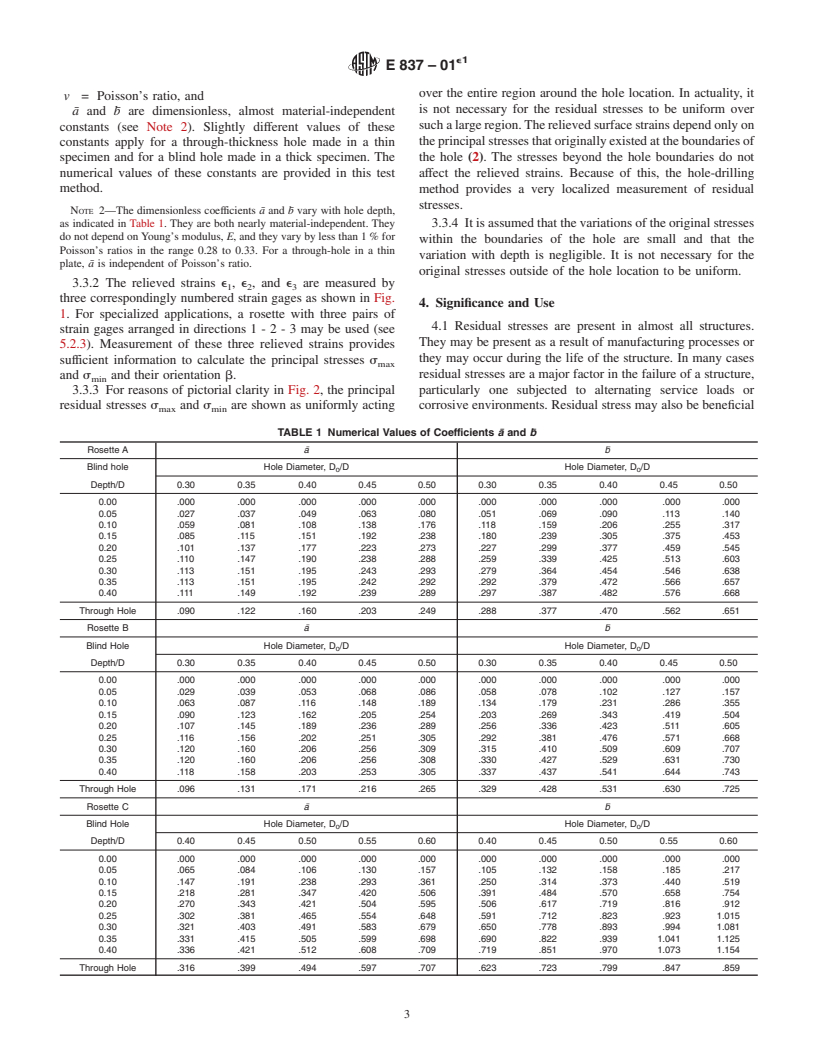

Residual stresses are present in almost all structures. They may be present as a result of manufacturing processes or they may occur during the life of the structure. In many cases residual stresses are a major factor in the failure of a structure, particularly one subjected to alternating service loads or corrosive environments. Residual stress may also be beneficial as, for example, compressive stresses produced by shot peening. The hole-drilling strain-gage technique is a practical method for determining residual stresses. See Table 1.

SCOPE

1.1 This test method covers the procedure for determining residual stresses near the surface of isotropic linearly-elastic materials. Although the concept is quite general, the test method described here is applicable in those cases where the stresses do not vary significantly with depth and do not exceed one half of the yield strength. The test method is often described as "semi-destructive" because the damage that it causes is very localized and in many cases does not significantly affect the usefulness of the specimen. In contrast, most other mechanical methods for measuring residual stress substantially destroy the specimen. Since the test method described here does cause some damage, it should be applied only in those cases either where the specimen is expendable or where the introduction of a small shallow hole will not significantly affect the usefulness of the specimen.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: E 837 – 01

Standard Test Method for

Determining Residual Stresses by the Hole-Drilling Strain-

1

Gage Method

This standard is issued under the fixed designation E837; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE— Equations 17 and 18, Sections 9.2.2, 9.2.3, 11.2.5 , 11.2.6 and Table 2 were editorially upated in January 2002.

INTRODUCTION

The hole-drilling strain-gage method measures residual stresses near the surface of a material. The

method involves attaching strain gages to the surface, drilling a hole in the vicinity of the gages, and

measuring the relieved strains. The measured strains are then related to relieved principal stresses

through a series of equations.

1. Scope E251 Test Methods for Performance Characteristics of

2

Metallic Bonded Resistance Strain Gages

1.1 This test method covers the procedure for determining

residual stresses near the surface of isotropic linearly-elastic

3. Summary of Test Method

materials. Although the concept is quite general, the test

3.1 Astrain gage rosette with three or more elements of the

method described here is applicable in those cases where the

general type schematically illustrated in Fig. 1 is placed in the

stresses do not vary significantly with depth and do not exceed

area under consideration.The numbering scheme for the strain

one half of the yield strength. The test method is often

3

gages follows a clockwise (CW) convention (1).

described as “semi-destructive” because the damage that it

causes is very localized and in many cases does not signifi-

NOTE 1—The gage numbering convention used for the rosette illus-

cantly affect the usefulness of the specimen. In contrast, most tratedinFig.1differsfromthecounter-clockwise(CCW)conventionused

for some designs of general-purpose strain gage rosettes and for some

other mechanical methods for measuring residual stress sub-

other types of residual stress rosette. If a strain gage rosette with CCW

stantially destroy the specimen. Since the test method de-

gage numbering is used, the residual stress calculation methods described

scribed here does cause some damage, it should be applied

in this test method still apply. The only change is a reversal in the

only in those cases either where the specimen is expendable or

assignment of the direction of the most tensile principal stress. This

where the introduction of a small shallow hole will not

change is described in Note 7. All other aspects of the residual stress

significantly affect the usefulness of the specimen.

calculation are unaffected.

1.2 This standard does not purport to address all of the

3.2 A hole is drilled at the geometric center of the strain

safety concerns, if any, associated with its use. It is the

gagerosettetoadepthofabout0.4ofthemeandiameterofthe

responsibility of the user of this standard to establish appro-

strain gage circle, D.

priate safety and health practices and determine the applica-

3.2.1 The residual stresses in the area surrounding the

bility of regulatory limitations prior to use.

drilled hole relax. The relieved strains are measured with a

suitable strain-recording instrument. Within the close vicinity

2. Referenced Documents

of the hole, the relief is nearly complete when the depth of the

2.1 ASTM Standards:

drilled hole approaches 0.4 of the mean diameter of the strain

gage circle, D.

1

This test method is under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.13 on

2

Residual Stress Measurement. Annual Book of ASTM Standards, Vol 03.01.

3

Current edition approved Oct. 10, 2001. Published November 2001. Originally Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

published as E837–81. Last previous edition E837–99. this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

E837–01

FIG. 1 Schematic Diagram Showing the Geometry of a Typical Three-Element Clockwise (CW) Strain Gage Rosette for the Hole-Drilling

Method

¯ ¯ ¯ ¯

3.3 Fig. 2 shows a schematic representation of the residual

e 5 ~A 1 Bcos2b!s 1 ~A 2 Bcos2b!s (1)

r max min

where:

e = relieved strain measured by a radially aligned

r

strain gage centered at P,

¯ ¯

A,B = calibration constants,

s = maximum (most tensile) and

max

s = minimum (most compressive) principal stresses

min

present at the hole location before drilling,

b = angle measured clockwise from the direction of

gage 1 to the direction of s ,

max

D = diameter of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.