ASTM D3730-10

(Guide)Standard Guide for Testing High-Performance Interior Architectural Wall Coatings

Standard Guide for Testing High-Performance Interior Architectural Wall Coatings

ABSTRACT

This guide covers the selection and use of test methods for high-performance interior architectural wall coatings (HIPAC) designed for wall surfaces of steel, masonry (poured concrete, concrete block, or cinder block), and plaster or gypsum wallboard. HIPAC are tough, extra-durable organic coating systems applied as continuous (seamless) film and cure to a hard finish. HIPAC are not usually intended for ceilings and floors, and would not ordinarily be used in homes. The types of resin ordinarily used are epoxy-polyamide, two-package; polyester-epoxy, twopackage; and polyurethane, one-package or two-package. Practical requirements for HIPAC vary with substrate type and climate conditions. The tests for measuring the properties enumerated below are detailed. Liquid coating properties include: (1) skinning, (2) condition in container, (3) coarse particles and foreign matter, (4) density or weight per gallon, (5) fineness of dispersion, (6) odor, (7) flash point, (8) dilution stability, (9) volatile content, (10) free diisocyanate content, and (11) package stability. Coating application and film formation properties include: (1) brush, roller, and spray application properties, (2) rheological properties, (3) curing, (4) wet-film thickness, and (5) touch-up uniformity. Dry coating appearance includes: (1) color difference, (2) directional reference, (3) gloss, (4) hiding power, and (5) yellowness index. Dry coating properties include: (1) abrasion resistance, (2) adhesion, (3) impact resistance, (4) chemical resistance, (5) washability and cleansability, (6) mildew resistance, (7) perspiration resistance, (8) heat and cold resistance, (9) heat and humidity resistance, (10) fire hazards, and (11) dry-film thickness.

SCOPE

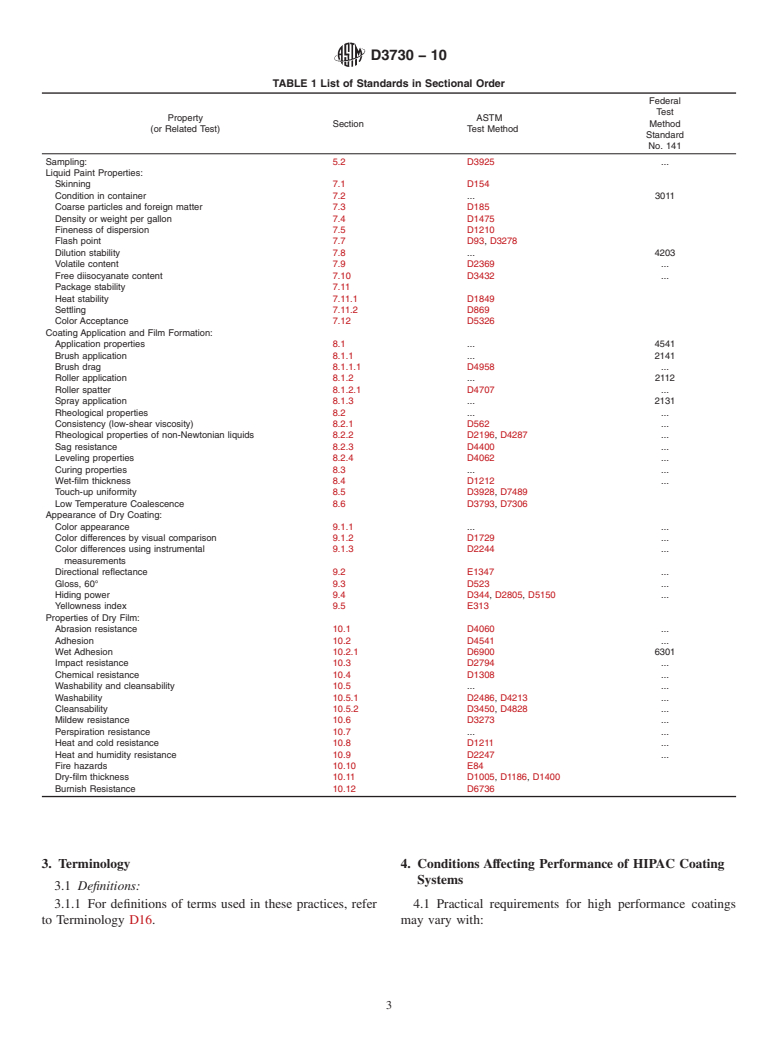

1.1 This guide covers the selection and use of test methods for high-performance interior architectural wall coatings (HIPAC) that differ from more conventional coatings by being tougher, more stain-resistant, more abrasion-resistant and, ordinarily, designed to be applied to wall surfaces of steel, masonry (poured concrete, concrete block, or cinder block), and plaster or gypsum wallboard. The tests that are listed in Table 1 and Table 1 are designed to measure performance properties. These tests may not all be required for each HIPAC system. Selection of the test methods to be followed must be governed by experience and the requirements in each individual case, together with agreement between the purchaser and the seller.

1.2 High-performance architectural coatings are tough, extra-durable organic coating systems that are applied as a continuous (seamless) film and cure to a hard finish. The finish can be high gloss, semigloss, or low gloss as desired. These coatings are resistant to persistent heat, humidity, abrasion, staining, chemicals, and fungus growth. They are used in areas where humidity, wear, or unusual chemical resistance requirements, particularly to soiling, are required and where strong detergents are used to maintain sanitary conditions. Halls and stairways in public buildings, lavatories, stall showers, locker areas, animal pens, and biological laboratories are typical applications. In addition, food processing plants, dairies, restaurants, schools, and transport terminals frequently use HIPAC systems. These are effective in many areas of building interiors compared with tile and are of low materials and maintenance costs. They are used as a complete system only as recommended by the manufacturer since the individual coats in a system are formulated to be compatible with each other. HIPAC systems should be applied only to properly prepared surfaces such as steel or masonry, including cinder blocks and cement blocks. They can be applied over plaster and gypsum wallboard. Ordinarily, a prime or fill coat, if required, is part of the system.

1.3 While they are excellent for walls, HIPAC are not usually intended for ceilings and floors. They would not ordinarily be used in...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3730 − 10

Standard Guide for

Testing High-Performance Interior Architectural Wall

1

Coatings

This standard is issued under the fixed designation D3730; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope blocksandcementblocks.Theycanbeappliedoverplasterand

gypsum wallboard. Ordinarily, a prime or fill coat, if required,

1.1 This guide covers the selection and use of test methods

is part of the system.

for high-performance interior architectural wall coatings

1.3 While they are excellent for walls, HIPAC are not

(HIPAC) that differ from more conventional coatings by being

usually intended for ceilings and floors. They would not

tougher, more stain-resistant, more abrasion-resistant and,

ordinarily be used in homes, although parents with small

ordinarily, designed to be applied to wall surfaces of steel,

children might want to use HIPAC coatings on some walls.

masonry (poured concrete, concrete block, or cinder block),

and plaster or gypsum wallboard. The tests that are listed in 1.4 The types of resin ordinarily used are the following:

Table 1 and Table 2 are designed to measure performance epoxy-polyamide, two-package; polyester-epoxy, two-

properties.These tests may not all be required for each HIPAC package; polyurethane, one-package or two-package.

system. Selection of the test methods to be followed must be However, other resin types are not excluded provided they can

meet the requirements (performance specifications) laid down

governed by experience and the requirements in each indi-

vidual case, together with agreement between the purchaser by the purchaser.

and the seller.

1.5 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

1.2 High-performance architectural coatings are tough,

only.

extra-durable organic coating systems that are applied as a

continuous(seamless)filmandcuretoahardfinish.Thefinish 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

can be high gloss, semigloss, or low gloss as desired. These

coatings are resistant to persistent heat, humidity, abrasion, responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

staining, chemicals, and fungus growth.They are used in areas

bility of regulatory limitations prior to use. For a specific

where humidity, wear, or unusual chemical resistance

hazard statement, see the note in 7.6.

requirements, particularly to soiling, are required and where

strong detergents are used to maintain sanitary conditions.

2. Referenced Documents

Halls and stairways in public buildings, lavatories, stall

2

2.1 ASTM Standards:

showers, locker areas, animal pens, and biological laboratories

D16TerminologyforPaint,RelatedCoatings,Materials,and

are typical applications. In addition, food processing plants,

Applications

dairies, restaurants, schools, and transport terminals frequently

D93Test Methods for Flash Point by Pensky-Martens

use HIPAC systems. These are effective in many areas of

Closed Cup Tester

building interiors compared with tile and are of low materials

D154Guide for Testing Varnishes

and maintenance costs. They are used as a complete system

D185Test Methods for Coarse Particles in Pigments

onlyasrecommendedbythemanufacturersincetheindividual

D344Test Method for Relative Hiding Power of Paints by

coats in a system are formulated to be compatible with each

the Visual Evaluation of Brushouts

other. HIPAC systems should be applied only to properly

D523Test Method for Specular Gloss

prepared surfaces such as steel or masonry, including cinder

D562Test Method for Consistency of Paints Measuring

KrebsUnit(KU)ViscosityUsingaStormer-TypeViscom-

eter

1

This guide is under the jurisdiction of ASTM Committee D01 on Paint and

Related Coatings, Materials, and Applications and is the direct responsibility of

2

Subcommittee D01.42 on Architectural Coatings. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2010. Published February 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1978. Last previous edition approved in 2003 as D3730–03. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D3730-10. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3730 − 10

D869TestM

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3730–03 Designation:D3730–10

Standard Guide for

Testing High-Performance Interior Architectural Wall

1

Coatings

This standard is issued under the fixed designation D3730; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers the selection and use of test methods for high-performance interior architectural wall coatings (HIPAC)

that differ from more conventional coatings by being tougher, more stain-resistant, more abrasion-resistant and, ordinarily,

designedtobeappliedtowallsurfacesofsteel,masonry(pouredconcrete,concreteblock,orcinderblock),andplasterorgypsum

wallboard. The tests that are listed in Tables 1 and 2 Table 1 and Table 1 are designed to measure performance properties. These

testsmaynotallberequiredforeachHIPACsystem.Selectionofthetestmethodstobefollowedmustbegovernedbyexperience

and the requirements in each individual case, together with agreement between the purchaser and the seller.

1.2 High-performance architectural coatings are tough, extra-durable organic coating systems that are applied as a continuous

(seamless) film and cure to a hard finish. The finish can be high gloss, semigloss, or low gloss as desired. These coatings are

resistant to persistent heat, humidity, abrasion, staining, chemicals, and fungus growth. They are used in areas where humidity,

wear, or unusual chemical resistance requirements, particularly to soiling, are required and where strong detergents are used to

maintain sanitary conditions. Halls and stairways in public buildings, lavatories, stall showers, locker areas, animal pens, and

biological laboratories are typical applications. In addition, food processing plants, dairies, restaurants, schools, and transport

terminalsfrequentlyuseHIPACsystems.Theseareeffectiveinmanyareasofbuildinginteriorscomparedwithtileandareoflow

materials and maintenance costs. They are used as a complete system only as recommended by the manufacturer since the

individual coats in a system are formulated to be compatible with each other. HIPAC systems should be applied only to properly

prepared surfaces such as steel or masonry, including cinder blocks and cement blocks. They can be applied over plaster and

gypsum wallboard. Ordinarily, a prime or fill coat, if required, is part of the system.

1.3 While they are excellent for walls, HIPAC are not usually intended for ceilings and floors. They would not ordinarily be

used in homes, although parents with small children might want to use HIPAC coatings on some walls.

1.4 The types of resin ordinarily used are the following: epoxy-polyamide, two-package; polyester-epoxy, two-package;

polyurethane, one-package or two-package. However, other resin types are not excluded provided they can meet the requirements

(performance specifications) laid down by the purchaser.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For a specific hazard statement, see the note in 7.6.

2. Referenced Documents

2

2.1 ASTM Standards:

D16 Terminology for Paint, Related Coatings, Materials, and Applications

D93 Test Methods for Flash Point by Pensky-Martens Closed Cup Tester

D154 Guide for Testing Varnishes

D185 Test Methods for Coarse Particles in Pigments

D344 Test Method for Relative Hiding Power of Paints by the Visual Evaluation of Brushouts

D523 Test Method for Specular Gloss

D562 Test Method for Consistency of Paints Measuring Krebs Unit (KU) Viscosity Using a Stormer-Type Viscometer

1

ThisguideisunderthejurisdictionofASTMCommitteeD01onPaintandRelatedCoatings,Materials,andApplicationsandisthedirectresponsibilityofSubcommittee

D01.42 on Architectural Coatings.

CurrenteditionapprovedMay10,2003.PublishedJune2003.Originallyapprovedin1978.Lastpreviouseditionapprovedin1998asD3730–98.DOI:10.1520/D3730-03.

Current edition approved Dec. 1, 2010. Published February 2011. Originally approved in 1978. Last previous edition approved in 2003 as D3730–03. DOI:

10.1520/D3730-10.

2

ForreferencedASTMstandards,visitt

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.