ASTM A311/A311M-04(2015)

(Specification)Standard Specification for Cold-Drawn, Stress-Relieved Carbon Steel Bars Subject to Mechanical Property Requirements

Standard Specification for Cold-Drawn, Stress-Relieved Carbon Steel Bars Subject to Mechanical Property Requirements

ABSTRACT

This specification covers cold-drawn, stress-relieved carbon steel bars subject to mechanical property requirements. The bars are furnished in two classes, A and B. Class A are normal-draft cold-drawn and stress-relieved rounds, squares, hexagons, and flats. Class B are heavy-draft cold-drawn and stress-relieved rounds and hexagons. The steel shall be made by one or more of the following primary processes: open-hearth, basic-oxygen, or electric-furnace. The cast or heat analysis shall conform to the chemical composition requirements specified. Tension test shall be made to conform to the requirements specified.

SCOPE

1.1 This specification covers two classes, nine grades, and four conditions of stress-relieved cold-drawn carbon steel bars produced to mechanical property requirements. One class, B, is cold drawn with higher than normal (heavy) drafts to provide higher strength levels, and four grades provide improved machinability.

1.2 Supplementary Requirements, S1 through S6, of an optional nature are provided.

1.3 The values stated in inch-pound units or SI units are to be regarded as the standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents, therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A311/A311M −04 (Reapproved 2015)

Standard Specification for

Cold-Drawn, Stress-Relieved Carbon Steel Bars Subject to

Mechanical Property Requirements

This standard is issued under the fixed designationA311/A311M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 heavy draft—Using higher than normal drafts (ap-

1.1 This specification covers two classes, nine grades, and

proximately 10 % through 35 % reduction), followed by stress

four conditions of stress-relieved cold-drawn carbon steel bars

relieving, produces higher tensile and yield strengths provided

producedtomechanicalpropertyrequirements.Oneclass,B,is

an appropriate composition is used; for example, medium

cold drawn with higher than normal (heavy) drafts to provide

carbon with normal or higher manganese content.

higher strength levels, and four grades provide improved

machinability.

4. Classification

1.2 Supplementary Requirements, S1 through S6, of an

4.1 The bars are furnished in the following classes and

optional nature are provided.

grades, and in the conditions shown in 6.4.

1.3 The values stated in inch-pound units or SI units are to

4.1.1 Class A—Normal-draft cold-drawn and stress-relieved

be regarded as the standard. Within the text, the SI units are

rounds, squares, hexagons, and flats in the following grades:

shown in brackets. The values stated in each system are not

Grades UNS Designations

exact equivalents, therefore, each system must be used inde-

1018 G10180

1035 G10350

pendentlyoftheother.Combiningvaluesfromthetwosystems

1045 G10450

may result in nonconformance with the specification.

1050 G10500

1541 G15410

2. Referenced Documents

1117 G11170

2 1137 G11370

2.1 ASTM Standards:

1141 G11410

A29/A29M SpecificationforGeneralRequirementsforSteel

1144 G11440

Bars, Carbon and Alloy, Hot-Wrought

4.1.2 Class B—Heavy-draft cold-drawn and stress-relieved

A108 Specification for Steel Bar, Carbon and Alloy, Cold-

rounds and hexagons in the following grades:

Finished

Grade UNS Designations

A370 Test Methods and Definitions for Mechanical Testing

1045 G10450

of Steel Products 1050 G10500

1541 G15410

E527 Practice for Numbering Metals and Alloys in the

1141 G11410

Unified Numbering System (UNS)

1144 G11440

3. Terminology

5. Ordering Information

3.1 Definitions:

5.1 Orders for material under this specification should

3.1.1 stress relieving—heating to a suitable temperature,

include the following information as required to adequately

holding long enough to reduce residual stresses, and then

describe the desired material:

cooling slowly enough to minimize the development of new

5.1.1 Quantity (weight [mass] or number of pieces),

residual stresses.

5.1.2 Nameofmaterial(carbonsteelbars,colddrawn,stress

relieved),

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

5.1.3 Condition 8.3,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

5.1.4 Cross-sectional shape,

A01.15 on Bars.

Current edition approved March 1, 2015. Published March 2015. Originally

5.1.5 Size,

approved in 1947. Last previous edition approved in 2010 as A311/A311M – 04

5.1.6 Length,

(2010). DOI: 10.1520/A0311_A0311M-04R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on New designation established in accordance with Practice E527 and SAE

the ASTM website. J 1086.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A311/A311M − 04 (2015)

5.1.7 Class and grade, 6.4.3 Cold drawn, stress relieved, turned, ground, and pol-

5.1.8 Report of heat analysis, tensile properties Section 11, ished; and

5.1.9 ASTM designation A311 or A311M, 6.4.4 Cold drawn, stress relieved, ground, and polished.

5.1.10 Application,

NOTE 2—When turned bars are specified, turning may be performed

5.1.11 Leaded steel, when required (see Table 1, footnote

prior to cold-drawing.

A),

7. Chemical Composition

5.1.12 Supplementary requirements, if any, and

5.1.13 Additional requirements, if any.

7.1 Composition—Thecastorheatanalysisshallconformto

the chemical composition requirements specified in Table 1 for

NOTE 1—Atypical ordering description is as follows: 10 000 lb carbon

steel bars, cold drawn, stress relieved turned and polished, round 2.0 in. the grade ordered.

[50.8 mm] Diameter, 10 to 12 ft [3048 to 3658 mm] long, Class B, Grade

1050, (UNS G 10500), fine grain, test reports required, ASTM A311/

8. Mechanical Properties

A311M dated____, hydraulic cylinder piston rods. [5000

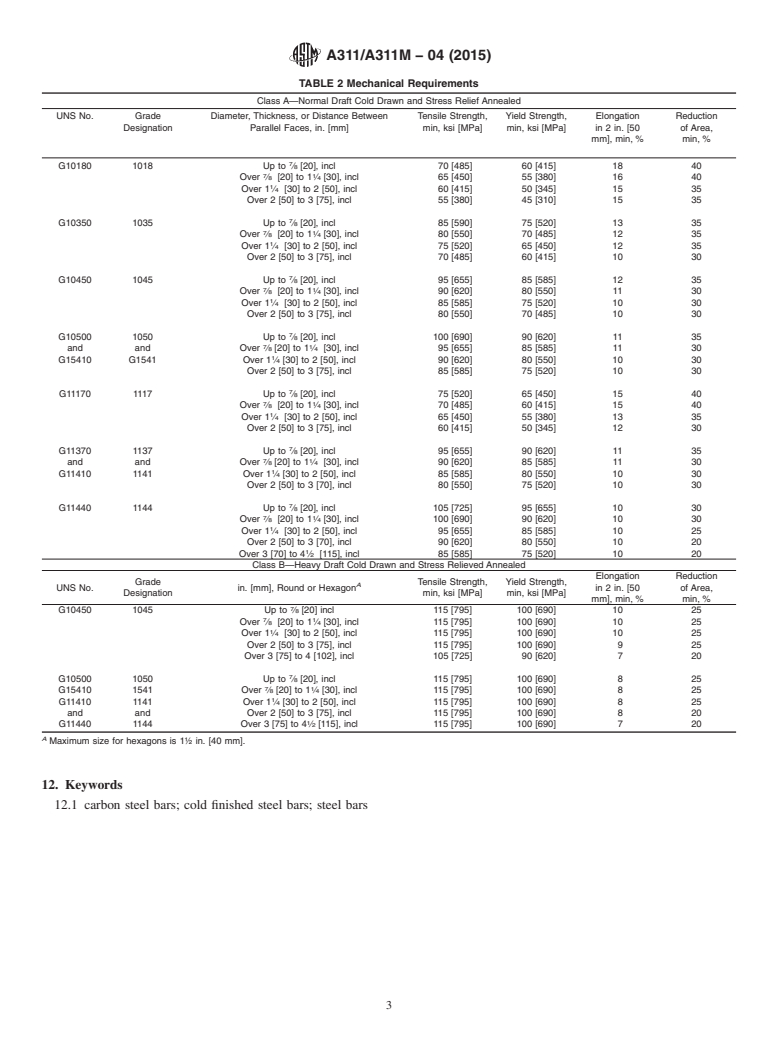

8.1 Requirements—The bars shall conform to the require-

kgcarbonsteelbars,colddrawn,stressrelievedturnedandpolishedround

50 mm diameter, 3050 to 3650 mm long, Class B, Grade 1050 (UNS G ments listed in Table 2.

10500), fine grain, test reports required, ASTM A311M

8.2 Number of Tests—Atleastonetensiontestshallbemade

dated ____, hydraulic cylinder piston rods.]

on each lot.Alot shall consist of bars of the same size from the

same heat which have been stress relieved in the same

6. Materials and Manufacture

stationary furnace charge. For continuous type of treatment, a

6.1 Melting Practice—The steel shall be made by one or

lot shall consist of 25 tons [25 Mg] or less of the same size of

more of the following primary processes: open-hearth, basic-

each heat, treated in the same cycle.

oxygen, or electric-furnace. The primary melting may incor-

8.3 Specimens—Tension test specimens shall be taken lon-

porate separate degassing or refining and may be followed by

gitudinally in accordance with and from the locations specified

secondary melting using electroslag remelting or vacuum arc

in Test Methods and Definitions A370.

remelting. Where secondary melting is employed, the heat

shall be defined as all of the ingots remelted from a single

8.4 Test Methods—Tension tests shall be made in accor-

primary heat.

dance with Test Methods and Definitions A370. The yield

strength shall be determined at 0.2 % offset or at 0.005 in./in.

6.2 Cold Working:

[0.005 mm/mm] of gage length, total extension under load.

6.2.1 ClassAbarsshallbecolddrawnusingnormaldrafting

practices.

9. Workmanship, Finish, and Appearance

6.2.2 Class B bars shall be cold drawn using heavy (higher

than normal) drafting practices. 9.1 Surface Finish—Unless otherwise specified, the bars

shallhaveacommercialbrightsmoothsurfacefinishconsistent

6.3 Thermal Treatment—After cold drawing, the bars shall

with the cold finishing operations specified in 6.4.

be stress relieved at a temperature of not less than 550°F

9.2 Bars that are thermal treated after cold finishing may

[288°C] to meet the mechanical requirements specified in

Table 2. have a discolored or oxidized surface.

9.3 Oiling—The bars shall be given a surface coating of oil

6.4 Condition—The bars shall be furnished in the following

cold finish conditions, as specified: or other rust inhibitor to protect against rust during shipment.

6.4.1 Cold drawn, stress relieved;

9.4 Workmanship—The bars shall be free of pipe, cracks,

6.4.2 Cold drawn, stress relieved, turned, and polished;

and flakes. Within the limits of good manufacturing and

inspection practices, the bars shall be free of injurious seams,

laps, segregation, or other imperfections that, due to their

A nature, degree, or extent, will interfere with the use of the

TABLE 1 Chemical Requirements (Cast or Heat Analysis)

material in machining or fabrication of suitable parts.

UNS Grade Carbon, Manga- Phos- Sulfur, %

Designation % nese, % phorus,

max %

10. General Requirements

G10180 1018 0.15-0.20 0.60-0.90 0.040 0.050 max

10.1 Material furnished under t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A311/A311M − 04 (Reapproved 2010) A311/A311M − 04 (Reapproved 2015)

Standard Specification for

Cold-Drawn, Stress-Relieved Carbon Steel Bars Subject to

Mechanical Property Requirements

This standard is issued under the fixed designation A311/A311M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers two classes, nine grades, and four conditions of stress-relieved cold-drawn carbon steel bars

produced to mechanical property requirements. One class, B, is cold drawn with higher than normal (heavy) drafts to provide

higher strength levels, and four grades provide improved machinability.

1.2 Supplementary Requirements, S1 through S6, of an optional nature are provided.

1.3 The values stated in inch-pound units or SI units are to be regarded as the standard. Within the text, the SI units are shown

in brackets. The values stated in each system are not exact equivalents, therefore, each system must be used independently of the

other. Combining values from the two systems may result in nonconformance with the specification.

2. Referenced Documents

2.1 ASTM Standards:

A29/A29M Specification for General Requirements for Steel Bars, Carbon and Alloy, Hot-Wrought

A108 Specification for Steel Bar, Carbon and Alloy, Cold-Finished

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

3. Terminology

3.1 Definitions:

3.1.1 stress relieving—heating to a suitable temperature, holding long enough to reduce residual stresses, and then cooling

slowly enough to minimize the development of new residual stresses.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 heavy draft—Using higher than normal drafts (approximately 10 % through 35 % reduction), followed by stress relieving,

produces higher tensile and yield strengths provided an appropriate composition is used; for example, medium carbon with normal

or higher manganese content.

4. Classification

4.1 The bars are furnished in the following classes and grades, and in the conditions shown in 6.4.

4.1.1 Class A—Normal-draft cold-drawn and stress-relieved rounds, squares, hexagons, and flats in the following grades:

Grades UNS Designations

1018 G10180

1035 G10350

1045 G10450

1050 G10500

1541 G15410

1117 G11170

1137 G11370

1141 G11410

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.15

on Bars.

Current edition approved April 1, 2010March 1, 2015. Published May 2010March 2015. Originally approved in 1947. Last previous edition approved in 20042010 as

A311/A311M – 04. 04 (2010). DOI: 10.1520/A0311_A0311M-04R10.10.1520/A0311_A0311M-04R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

New designation established in accordance with Practice E527 and SAE J 1086.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A311/A311M − 04 (2015)

Grades UNS Designations

1144 G11440

4.1.2 Class B—Heavy-draft cold-drawn and stress-relieved rounds and hexagons in the following grades:

Grade UNS Designations

1045 G10450

1050 G10500

1541 G15410

1141 G11410

1144 G11440

5. Ordering Information

5.1 Orders for material under this specification should include the following information as required to adequately describe the

desired material:

5.1.1 Quantity (weight [mass] or number of pieces),

5.1.2 Name of material (carbon steel bars, cold drawn, stress relieved),

5.1.3 Condition 8.3,

5.1.4 Cross-sectional shape,

5.1.5 Size,

5.1.6 Length,

5.1.7 Class and grade,

5.1.8 Report of heat analysis, tensile properties Section 11,

5.1.9 ASTM designation A311 or A311M,

5.1.10 Application,

5.1.11 Leaded steel, when required (see Table 1, footnote A),

5.1.12 Supplementary requirements, if any, and

5.1.13 Additional requirements, if any.

NOTE 1—A typical ordering description is as follows: 10 000 lb carbon steel bars, cold drawn, stress relieved turned and polished, round 2.0 in. (50.8

mm)[50.8 mm] Diameter, 10 to 12 ft (3048[3048 to 3658 mm)mm] long, Class B, Grade 1050, (UNS G 10500), fine grain, test reports required, ASTM

A311/A311M dated____ , dated____, hydraulic cylinder piston rods. [5000

kg carbon steel bars, cold drawn, stress relieved turned and polished round 50 mm diameter, 3050 to 3650 mm long, Class B, Grade 1050 (UNS G 10500),

fine grain, test reports required, ASTM A311M

dated ____ , ____, hydraulic cylinder piston rods.]

6. Materials and Manufacture

6.1 Melting Practice—The steel shall be made by one or more of the following primary processes: open-hearth, basic-oxygen,

or electric-furnace. The primary melting may incorporate separate degassing or refining and may be followed by secondary melting

using electroslag remelting or vacuum arc remelting. Where secondary melting is employed, the heat shall be defined as all of the

ingots remelted from a single primary heat.

6.2 Cold Working:

6.2.1 Class A bars shall be cold drawn using normal drafting practices.

6.2.2 Class B bars shall be cold drawn using heavy (higher than normal) drafting practices.

A

TABLE 1 Chemical Requirements (Cast or Heat Analysis)

UNS Grade Carbon, Manga- Phos- Sulfur, %

Designation % nese, % phorus,

max %

G10180 1018 0.15-0.20 0.60-0.90 0.040 0.050 max

G10350 1035 0.32-0.38 0.60-0.90 0.040 0.050 max

G10450 1045 0.43-0.50 0.60-0.90 0.040 0.050 max

G10500 1050 0.48-0.55 0.60-0.90 0.040 0.050 max

G15410 1541 0.36-0.44 1.35-1.65 0.040 0.050 max

G11170 1117 0.14-0.20 1.00-1.30 0.040 0.08-0.13

G11370 1137 0.32-0.39 1.35-1.65 0.040 0.08-0.13

G11410 1141 0.37-0.45 1.35-1.65 0.040 0.08-0.13

G11440 1144 0.40-0.48 1.35-1.65 0.040 0.24-0.33

A

When lead is required as an added element to a standard steel, a range from

0.15 to 0.35 % inclusive, is specified. Such a steel is identified by inserting the

letter “L” between the second and third numerals of the grade designation, for

example, 10L45. A cast or heat analysis is not determinable when lead is added to

the ladle stream.

A311/A311M − 04 (2015)

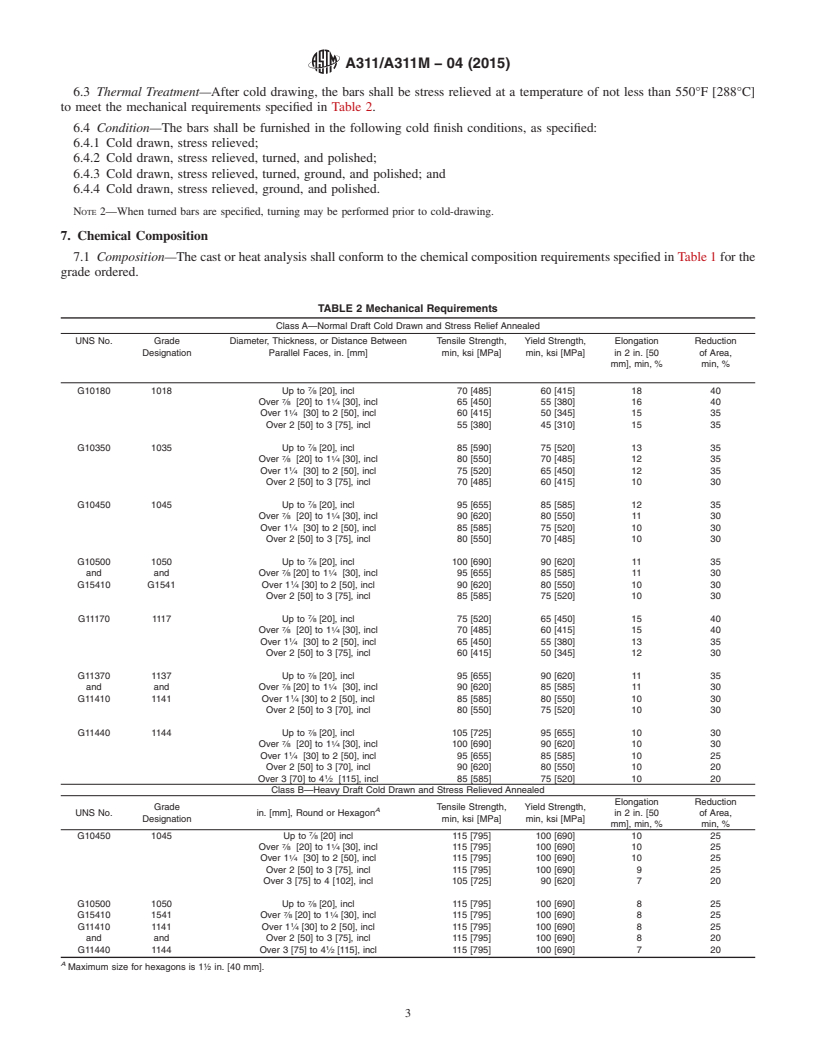

6.3 Thermal Treatment—After cold drawing, the bars shall be stress relieved at a temperature of not less than 550°F [288°C]

to meet the mechanical requirements specified in Table 2.

6.4 Condition—The bars shall be furnished in the following cold finish conditions, as specified:

6.4.1 Cold drawn, stress relieved;

6.4.2 Cold drawn, stress relieved, turned, and polished;

6.4.3 Cold drawn, stress relieved, turned, ground, and polished; and

6.4.4 Cold drawn, stress relieved, ground, and polished.

NOTE 2—When turned bars are specified, turning may be performed prior to cold-drawing.

7. Chemical Composition

7.1 Composition—The cast or heat analysis shall conform to the chemical composition requirements specified in Table 1 for the

grade ordered.

TABLE 2 Mechanical Requirements

Class A—Normal Draft Cold Drawn and Stress Relief Annealed

UNS No. Grade Diameter, Thickness, or Distance Between Tensile Strength, Yield Strength, Elongation Reduction

Designation Parallel Faces, in. [mm] min, ksi [MPa] min, ksi [MPa] in 2 in. [50 of Area,

mm], min, % min, %

G10180 1018 Up to ⁄8 [20], incl 70 [485] 60 [415] 18 40

7 1

Over ⁄8 [20] to 1 ⁄4 [30], incl 65 [450] 55 [380] 16 40

Over 1 ⁄4 [30] to 2 [50], incl 60 [415] 50 [345] 15 35

Over 2 [50] to 3 [75], incl 55 [380] 45 [310] 15 35

G10350 1035 Up to ⁄8 [20], incl 85 [590] 75 [520] 13 35

7 1

Over ⁄8 [20] to 1 ⁄4 [30], incl 80 [550] 70 [485] 12 35

Over 1 ⁄4 [30] to 2 [50],

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.