ASTM B916-01

(Test Method)Standard Test Method for Adherence of Porcelain Enamel Coatings to Sheet Metal

Standard Test Method for Adherence of Porcelain Enamel Coatings to Sheet Metal

SCOPE

1.1 The scope of this test method is:

1.1.1 To determine quantitatively the amount of enamel remaining after the porcelain enamel coating specimen has been deformed;

1.1.2 To standardize the deformation parameters for testing adherence of porcelain enamel to sheet metal; and,

1.1.3 To provide a quantitative adherence rating scale for comparison to reference standards.

1.2 This adherence test method is applicable to porcelain enamel coatings on substrates from 18 to 24 gage (0.0478 to 0.025 in. or from 1.214 to 0.654 mm).

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 916 – 01

Standard Test Method for

Adherence of Porcelain Enamel Coatings to Sheet Metal

This standard is issued under the fixed designation B 916; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.3 A satisfactory degree of deformation and damage are

obtained if the conditions in 3.2 use the following parameters:

1.1 The scope of this test method is:

0.50-in. (12.7-mm) diameter hemispherical indenter, 0.75-in.

1.1.1 To determine quantitatively the amount of enamel

(19.1-mm) diameter bottomless die (lower plunger guide in

remaining after the porcelain enamel coating specimen has

Fig. 1) with sharp edge, and 80–in./lb (9.03–J) energy at

been deformed;

impact.

1.1.2 To standardize the deformation parameters for testing

3.4 Deformation Devices, of other designs may be used

adherence of porcelain enamel to sheet metal; and,

provided that the parameters in 3.3 are used.

1.1.3 To provide a quantitative adherence rating scale for

3.5 Adherence Reference Standards, see 7.1.

comparison to reference standards.

1.2 This adherence test method is applicable to porcelain

4. Test Specimens

enamel coatings on substrates from 18 to 24 gage (0.0478 to

4.1 The test specimens shall be flat enameled panels not less

0.025 in. or from 1.214 to 0.654 mm).

2 2

in size than 4 in. (101.6 mm ). Larger sizes and shapes may be

1.3 This standard does not purport to address all of the

used provided that a flat surface can be held firmly against and

safety concerns, if any, associated with its use. It is the

parallel to the lower plunger guide during deformation.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Safety Precautions

bility of regulatory limitations prior to use.

5.1 During the procedure in 6.1, fine enameled chips may be

2. Significance and Use released with some force from the steel surface; therefore, it is

recommended that personnel in the immediate vicinity of the

2.1 The measurement of adherence in porcelain enamel

test wear safety goggles.

systems, such as ground coat, ground coat/cover coat, and

direct-on cover-coat enamels, is an important procedure for

6. Procedure

monitoring process variables in metal preparation, enamel

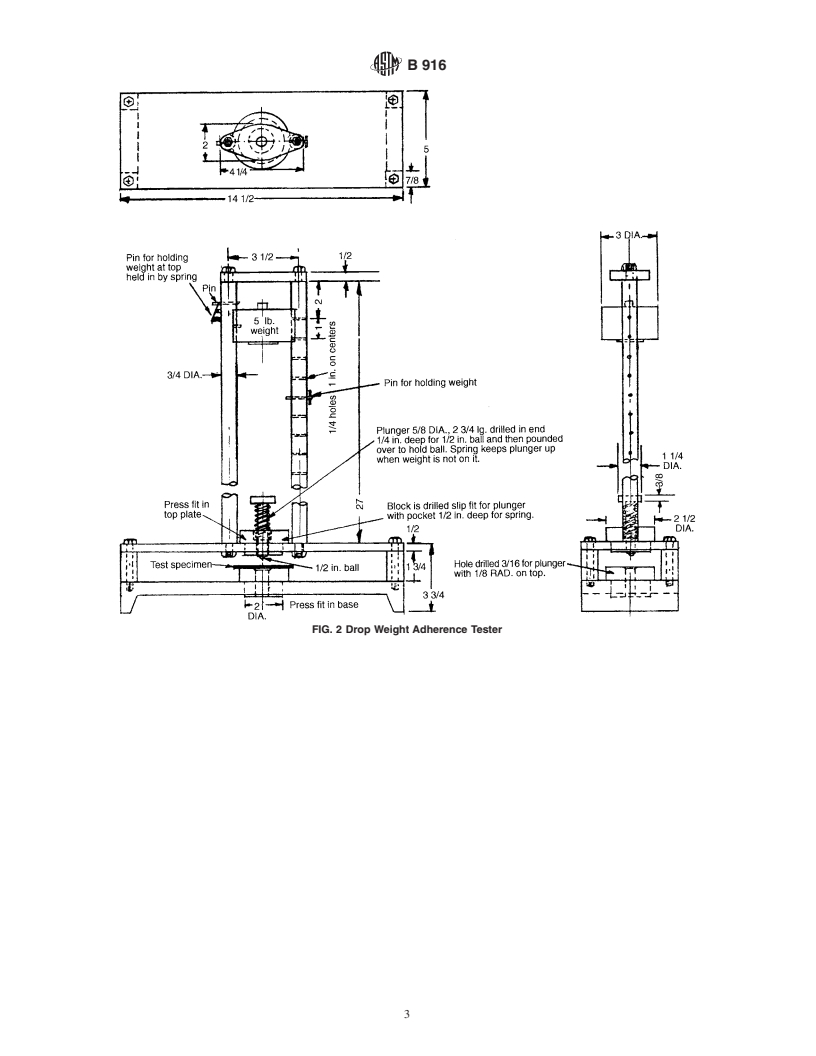

6.1 Specimen Deformation—The hammer weight of the

application thickness, steel selection, and enamel selection, as

suggested drop weight device is 5 lb (2268 g), which requires

well as assuring the ultimate quality of the finished product.

a 16-in. (406.4-mm) drop distance to yield the specified

3. Apparatus 80-in./lb (9.03-J) energy at impact. The hammer weight of the

2 drop weight device may range from 2 to 8 lb (907 to 3629 g).

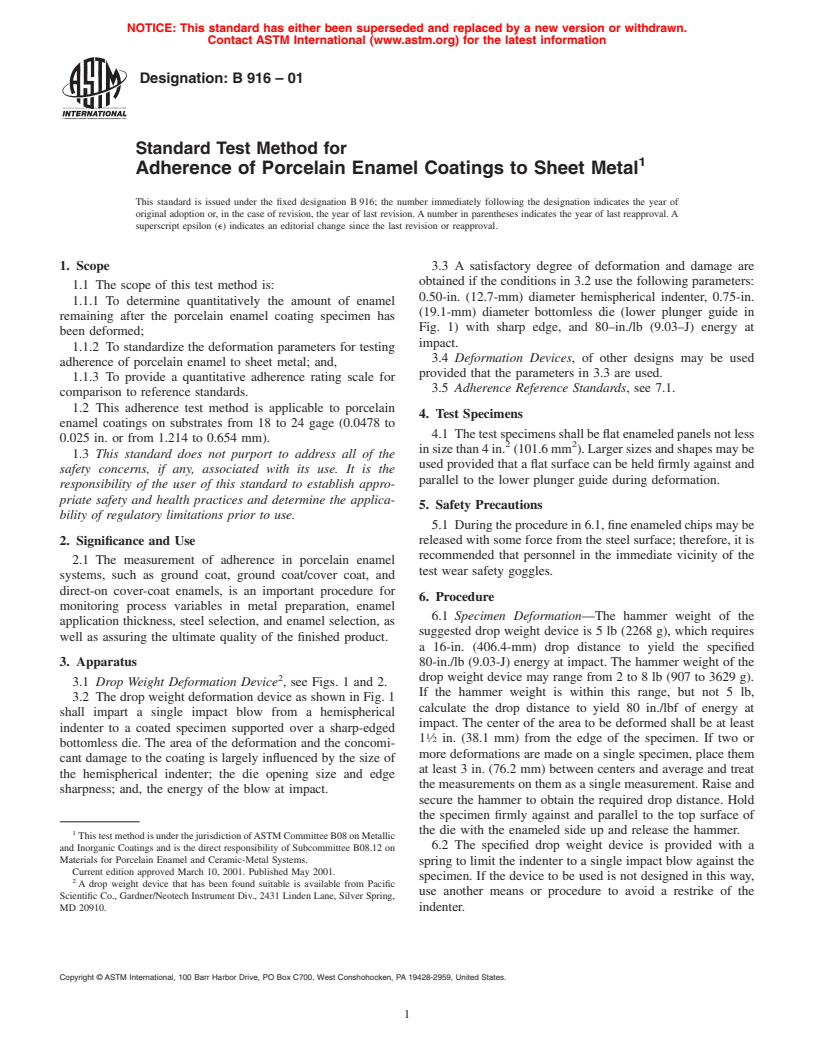

3.1 Drop Weight Deformation Device , see Figs. 1 and 2.

If the hammer weight is within this range, but not 5 lb,

3.2 The drop weight deformation device as shown in Fig. 1

calculate the drop distance to yield 80 in./lbf of energy at

shall impart a single impact blow from a hemispherical

impact. The center of the area to be deformed shall be at least

indenter to a coated specimen supported over a sharp-edged

1 ⁄2 in. (38.1 mm) from the edge of the specimen. If two or

bottomless die. The area of the deformation and the concomi-

more deformations are made on a single specimen, place them

cant damage to the coating is largely influenced by the size of

at least 3 in. (76.2 mm) between centers and average and treat

the hemispherical indenter; the die opening size and edge

the measurements on them as a single measurement. Raise and

sharpness; and, the energy of the blow at impact.

secure the hammer to obtain the required drop distance. Hold

the specimen firmly against and parallel to the top surface of

the die with the enam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.