ASTM E1250-88(2005)

(Test Method)Standard Test Method for Application of Ionization Chambers to Assess the Low Energy Gamma Component of Cobalt-60 Irradiators Used in Radiation-Hardness Testing of Silicon Electronic Devices

Standard Test Method for Application of Ionization Chambers to Assess the Low Energy Gamma Component of Cobalt-60 Irradiators Used in Radiation-Hardness Testing of Silicon Electronic Devices

SIGNIFICANCE AND USE

Although Co-60 nuclei only emit monoenergetic gamma rays at 1.17 and 1.33 MeV, the finite thickness of sources, and encapsulation materials and other surrounding structures that are inevitably present in irradiators can contribute a substantial amount of low-energy gamma radiation, principally by Compton scattering (1, 2).3 In radiation-hardness testing of electronic devices this low-energy photon component of the gamma spectrum can introduce significant dosimetry errors for a device under test since the equilibrium absorbed dose as measured by a dosimeter can be quite different from the absorbed dose deposited in the device under test because of absorbed dose enhancement effects (3, 4). Absorbed dose enhancement effects refer to the deviations from equilibrium absorbed dose caused by non-equilibrium electron transport near boundaries between dissimilar materials.

The ionization chamber technique described in this method provides an easy means for estimating the importance of the low-energy photon component of any given irradiator type and configuration.

When there is an appreciable low-energy spectral component present in a particular irradiator configuration, special experimental techniques should be used to ensure that dosimetry measurements adequately represent the absorbed dose in the device under test. (See Practice E 1249.)

SCOPE

1.1 Low energy components in the photon energy spectrum of Co-60 irradiators lead to absorbed dose enhancement effects in the radiation-hardness testing of silicon electronic devices. These low energy components may lead to errors in determining the absorbed dose in a specific device under test. This method covers procedures for the use of a specialized ionization chamber to determine a figure of merit for the relative importance of such effects. It also gives the design and instructions for assembling this chamber.

1.2 This method is applicable to measurements in Co-60 radiation fields where the range of exposure rates is 7 10 6 to 3 102 C kg 1 s1 (approximately 100 R/h to 100 R/s). For guidance in applying this method to radiation fields where the exposure rate is >100 R/s, see . Note 1See Terminology E 170 for definition of exposure and its units.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1250 – 88 (Reapproved 2005)

Standard Test Method for

Application of Ionization Chambers to Assess the Low

Energy Gamma Component of Cobalt-60 Irradiators Used in

Radiation-Hardness Testing of Silicon Electronic Devices

This standard is issued under the fixed designation E1250; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E170 TerminologyRelatingtoRadiationMeasurementsand

Dosimetry

1.1 Low energy components in the photon energy spectrum

E668 Practice for Application of Thermoluminescence-

ofCo-60irradiatorsleadtoabsorbeddoseenhancementeffects

Dosimetry(TLD)SystemsforDeterminingAbsorbedDose

in the radiation-hardness testing of silicon electronic devices.

in Radiation-Hardness Testing of Electronic Devices

These low energy components may lead to errors in determin-

E1249 Practice for Minimizing Dosimetry Errors in Radia-

ing the absorbed dose in a specific device under test. This

tion Hardness Testing of Silicon Electronic Devices Using

method covers procedures for the use of a specialized ioniza-

Co-60 Sources

tion chamber to determine a figure of merit for the relative

importance of such effects. It also gives the design and

3. Terminology

instructions for assembling this chamber.

3.1 absorbed dose, D—quotient of d ´¯by dm, where d ´¯is

1.2 This method is applicable to measurements in Co-60

−6

themeanenergyimpartedbyionizingradiationtothematterin

radiation fields where the range of exposure rates is 7 310

−2 −1 −1

a volume element and dm is the mass of matter in that volume

to3 310 Ckg s (approximately100R/hto100R/s).For

element.

guidance in applying this method to radiation fields where the

D 5 d´¯/dm (1)

exposure rate is >100 R/s, see Appendix X1.

3.2 absorbed dose enhancement factor— ratio of the ab-

NOTE 1—See Terminology E170 for definition of exposure and its

units. sorbed dose at a point in a material of interest to the

equilibrium absorbed dose in that same material.

1.3 The values stated in SI units are to be regarded as the

3.3 average absorbed dose—mass-weighted mean of the

standard. The values given in parentheses are for information

absorbed dose over a region of interest.

only.

3.4 average absorbed dose enhancement factor—ratio of

1.4 This standard does not purport to address all of the

the average absorbed dose in a region of interest to the

safety concerns, if any, associated with its use. It is the

equilibrium absorbed dose.

responsibility of the user of this standard to establish appro-

3.5 dosimeter—any device used to determine the equilib-

priate safety and health practices and determine the applica-

rium absorbed dose in the material and at the irradiation

bility of regulatory limitations prior to use.

position of interest. Examples of such devices include ther-

moluminescence dosimeters (TLDs), liquid chemical dosim-

2. Referenced Documents

2 eters, and radiochromic dye films. (See Practice E668, for a

2.1 ASTM Standards:

discussion of TLDs.)

3.6 equilibrium absorbed dose—absorbed dose at some

This method is under the jurisdiction of ASTM Committee E10 on Nuclear

incremental volume within the material in which the condition

Technology and Applications and is the direct responsibility of Subcommittee

of electron equilibrium (the energies, number, and direction of

E10.07 on Radiation Dosimetry for Radiation Effects on Materials and Devices.

charged particles induced by the radiation are constant

Current edition approved Jan. 1, 2005. Published January 2005. Originally

approved in 1988. Last previous approved in 2000 as E1250-88(2000). DOI:

throughout the volume) exists. (See Terminology E170.)

10.1520/E1250-88R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1250 – 88 (2005)

4. Significance and Use

4.1 AlthoughCo-60nucleionlyemitmonoenergeticgamma

rays at 1.17 and 1.33 MeV, the finite thickness of sources, and

encapsulation materials and other surrounding structures that

areinevitablypresentinirradiatorscancontributeasubstantial

amount of low-energy gamma radiation, principally by Comp-

tonscattering(1,2). Inradiation-hardnesstestingofelectronic

devices this low-energy photon component of the gamma

spectrum can introduce significant dosimetry errors for a

device under test since the equilibrium absorbed dose as

measured by a dosimeter can be quite different from the

absorbed dose deposited in the device under test because of

absorbed dose enhancement effects (3, 4). Absorbed dose

enhancement effects refer to the deviations from equilibrium

FIG. 1 Schematic Diagram of Experimental Setup

absorbed dose caused by non-equilibrium electron transport

near boundaries between dissimilar materials.

6. Procedure

4.2 The ionization chamber technique described in this

6.1 Assemble the ionization chamber, bias supply, and

method provides an easy means for estimating the importance

electrometer as shown in Fig. 1.

of the low-energy photon component of any given irradiator

6.2 Turn on the bias supply, set the voltage to at least 60 V,

type and configuration.

and ensure that there is no appreciable leakage current (I -

4.3 When there is an appreciable low-energy spectral com-

leak

age< 0.1 pA). Turn the bias supply off.

ponent present in a particular irradiator configuration, special

6.3 Assemble the ionization chamber with the gold/

experimental techniques should be used to ensure that dosim-

aluminum electrodes (the gold sides facing the inside of the

etry measurements adequately represent the absorbed dose in

chamber). Place the ionization chamber in the irradiation

the device under test. (See Practice E1249.)

position of interest. For directional sources, position the

ionization chamber so that the direction of the main beam is

5. Apparatus

perpendicular to the electrode plates.

5.1 Ionization Chamber,aspeciallyfabricatedparallel-plate

6.4 Turn on the bias supply and measure the ionization

ionization chamber with interchangeable gold and aluminum

current, I , with the gold/aluminum electrodes in place, gold

Au

electrodes. A specific design is described in Appendix X2.

side facing inward.

5.2 Bias Supply, a battery or power supply capable of

6.5 Repeat steps 6.3 and 6.4 with aluminum electrodes and

delivering 60 to 100 V dc at a current up to 1 mA.

measure the ionization current I . The ionization chamber

Al

5.3 Electrometer, an electrometer or picoammeter capable

location and orientation shall be the same for both measure-

of measuring currents as low as 30 pA with a resolution of at

ments.

least 0.1 pA.

6.6 Calculate the ionization current ratio a as follows:

5.4 Twinaxial Cable, the twinaxial cable that connects the

a5 I / I (2)

Au Al

ionization chamber to the bias supply and electrometer is an

This ratio provides a figure of merit for the particular Co-60

integral part of the ionization chamber (see Fig. 1).

irradiator configuration under investigation.

NOTE 2—TheionizationchamberdimensionsgiveninAppendixX2are

appropriate to TWC 78-2 twinaxial cable. This cable has the following NOTE 3—Since the relationship between ionization chamber current

physical dimensions (all dimensions given in inches): and exposure rate depends on such environmental factors as temperature,

atmospheric pressure, and relative humidity, it is important to make the

Nominal outer diameter 0.242

Conductor spacing (center to center) 0.076 twomeasurementsofI andI asnearlyatthesametimeaspossibleto

Au Al

Conductor dielectric outer diameter 0.076

minimize the influence of environmental factors on the ratio I /I .

Au Al

Conductor diameter 0.037

7. Interpretation of Measurement Results

Other equivalent twinaxial cable types can be used, but the applicable

7.1 Low values of the figure of merit, a ('2 to 2.5) are

dimensionsoftheionizationchamberbody,clamp,stem,andcableclamp

nut in Appendix X2 must then be adjusted.

indicative of a relatively small low-energy photon component,

and high values of a (>5) indicate a very large low-energy

5.5 Triaxial Cable, the triaxial cable that connects the

photon component. Appendix X3 gives a table of measured

ionization chamber and the bias supply to the electrometer is

values of a for a variety of typical Co-60 irradiator facilities

usually supplied with the electrometer, and must be of a type

and experimental arrangements.

that is compatible with the electrometer type used (see Fig. 1).

NOTE 4—Monoenergetic 1.25 MeV photon radiation would theoreti-

callyproduceavalueof a=1.6.Althoughthisvalueisnotattainablewith

any realistic Co-60 irradiator configuration, it is a theoretical lower limit

The boldface numbers in parentheses refer to the list of references appended to

on a.

this test method.

7.2 If the measured value of a is >2.5, steps 6.1-6.5 should

Available from Trompeter Electronics, 31186 La Baya Dr., Westlake Village,

CA91362-4047. be repeated with the ionization chamber surrounded by a filter

E1250 – 88 (2005)

can or box of 1.5 to 2.0 mm (approximately 0.063 in.) of lead

on the outside and 0.7 to 1.0 mm (approximately 0.030 in.) of

aluminumontheinside.Useofsuchafilterwillnormallygive

a significant reduction in the low-energy component of the

spectrum (see Practice E1249).

7.3 By repeating the procedure for a number of source

configurations and filter options, the experimental conditions

can be determined that minimize the low-energy photon

component of the source spectrum and thus minimize the

dosimetry errors for the device under test.

8. Application to Hardness Testing

8.1 Estimating the Absorbed Dose Enhancement Factor:

8.1.1 Although it is not possible to determine the absorbed

dose enhancement factor for a particular geometry of a device

undertestusingthismethod,thefigureofmerit, a,canbeused

toestimateanupperboundfortheabsorbeddoseenhancement

factor near an interface between any two materials (5).

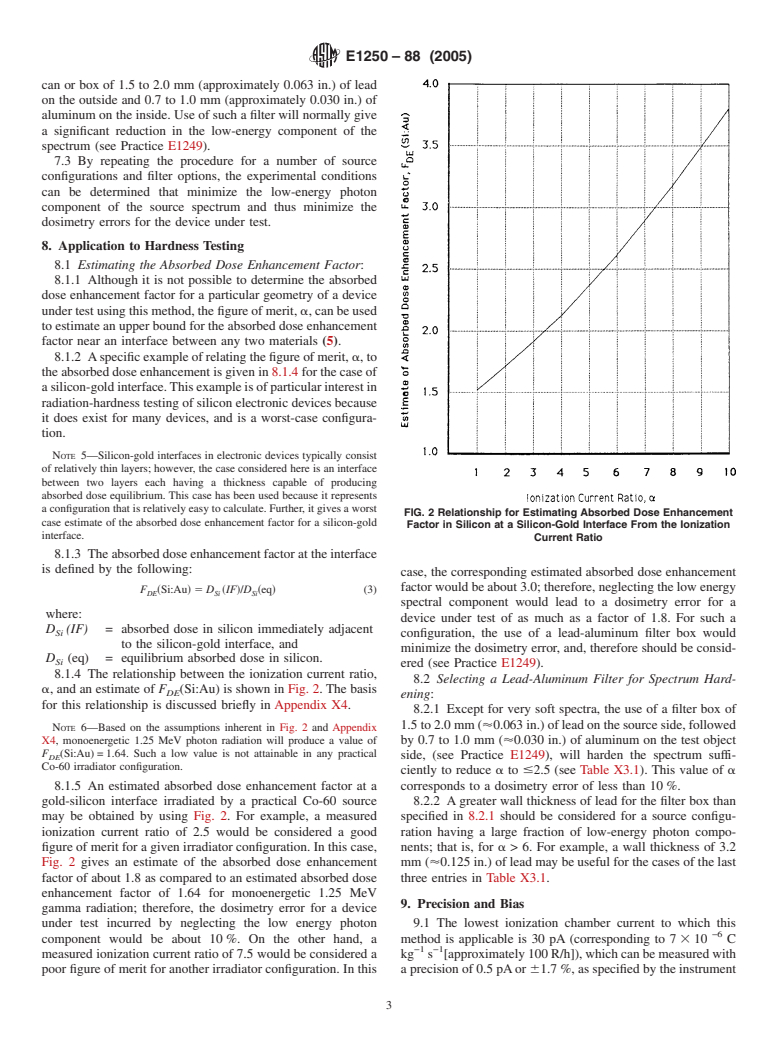

8.1.2 Aspecificexampleofrelatingthefigureofmerit, a,to

theabsorbeddoseenhancementisgivenin8.1.4forthecaseof

asilicon-goldinterface.Thisexampleisofparticularinterestin

radiation-hardnesstestingofsiliconelectronicdevicesbecause

it does exist for many devices, and is a worst-case configura-

tion.

NOTE 5—Silicon-gold interfaces in electronic devices typically consist

of relatively thin layers; however, the case considered here is an interface

between two layers each having a thickness capable of producing

absorbed dose equilibrium. This case has been used because it represents

aconfigurationthatisrelativelyeasytocalculate.Further,itgivesaworst

FIG. 2 Relationship for Estimating Absorbed Dose Enhancement

case estimate of the absorbed dose enhancement factor for a silicon-gold

Factor in Silicon at a Silicon-Gold Interface From the Ionization

interface.

Current Ratio

8.1.3 Theabsorbeddoseenhancementfactorattheinterface

is defined by the following:

case, the corresponding estimated absorbed dose enhancement

factorwouldbeabout3.0;therefore,neglectingthelowenergy

F ~Si:Au!5 D ~IF!/D ~eq! (3)

DE Si Si

spectral component would lead to a dosimetry error for a

where:

device under test of as much as a factor of 1.8. For such a

D (IF) = absorbed dose in silicon immediately adjacent

Si

configuration, the use of a lead-aluminum filter box would

to the silicon-gold interface, and

minimize the dosimetry error, and, therefore should be consid-

D (eq) = equilibrium absorbed dose in silicon.

Si

ered (see Practice E1249).

8.1.4 The relationship between the ionization current ratio,

8.2 Selecting a Lead-Aluminum Filter for Spectrum Hard-

a, and an estimate of F (Si:Au) is shown in Fig. 2.The basis

DE

ening:

for this relationship is discussed briefly in Appendix X4.

8.2.1 Except for very soft spectra, the use of a filter box of

1.5to2.0mm('0.063in.)ofleadonthesourceside,followed

NOTE 6—Based on the assumptions inherent in Fig. 2 and Appendix

X4, monoenergetic 1.25 MeV photon radiation will produce a value of by 0.7 to 1.0 mm ('0.030 in.) of aluminum on the test object

F (Si:Au)=1.64. Such a low value is not attainable in any practical

DE side, (see Practice E1249), will harden the spectrum suffi-

Co-60 irradiator configuration.

ciently to reduce a to#2.5 (see Table X3.1). This value of a

8.1.5 An estimated absorbed dose enhancement factor at a corresponds to a dosimetry error of less than 10%.

gold-silicon interface irradiated by a practical Co-60 source 8.2.2 Agreater wall thickness of lead for the filter box than

may be obtained by using Fig. 2. For example, a measured specified in 8.2.1 should be considered for a source configu-

ionization current ratio of 2.5 would be considered a good ration having a large fraction of low-energy photon compo-

figureofmeritforagivenirradiatorconfiguration.Inthiscase, nents; that is, for a > 6. For example, a wall thickness of 3.2

Fig. 2 gives an estimate of the absorbed dose enhancement mm('0.125in.)ofleadmaybeusefulforthecasesofthelast

factor of about 1.8 as compared to an estimated absorbed dose three entries in Table X3.1.

enhancement factor of 1.64 for monoenergetic 1.25 MeV

9. Precision and Bias

gamma radiation; therefore, the dosimetry error for a device

under test incurred by neglecting the low energy photon 9.1 The lowest ionization chamber current to which this

−6

component would be about 10%. On the other hand, a method is applicable is 30 pA (corresponding to 7 310 C

−1 −1

measured ionization current ratio of 7.5 would be considered a kg s [approximately100R/h]),whichcanbemeasuredwith

poorfigureofmeritforanotherirradiatorconfiguration.Inthis aprecisionof0.5pAor 61.7%,asspecifiedbytheinstrument

E1250 – 88 (2005)

manufacturer. The ratio I /I can therefore be determined to 10. Keywords

Au Al

an overall uncertainty of 62.4% or better.

10.1 absorbed dose; Co-60 irradiators; dose enhancement;

9.2 This method provides a figure of merit usable for

ionization chamber; radiation hardness testing

comparing various source configurations, and for assessing the

relative improvement that is achievable with a lead-aluminum

filter. This method gives no quantitative information about

absorbeddoseenhancementfactorotherthananestimateofits

upper limit.

APPENDIXES

(Nonmandatory Information)

X1. APPLICATION OF THIS METHOD TO HIGH EXPOSURE RATES

−3 −1

X1.1 Thelimitsofapplicabilityofthismethodgivenin1.2 ˙

X = ex

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.