ASTM A727/A727M-14(2019)

(Specification)Standard Specification for Carbon Steel Forgings for Piping Components with Inherent Notch Toughness

Standard Specification for Carbon Steel Forgings for Piping Components with Inherent Notch Toughness

ABSTRACT

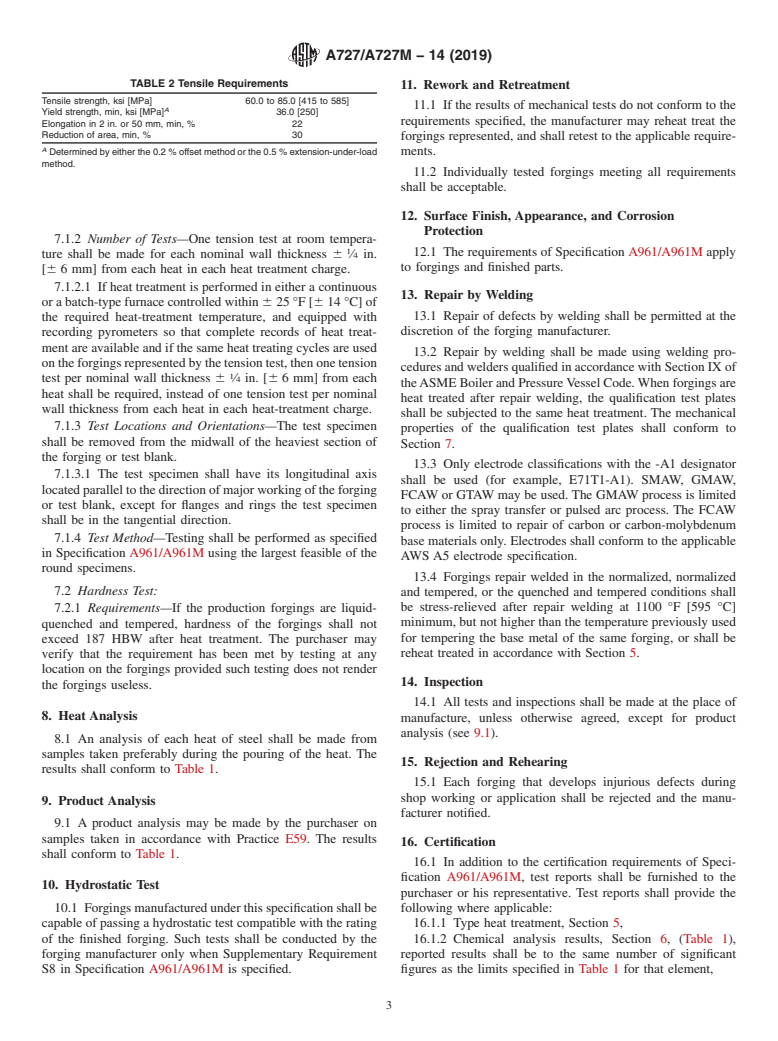

This specification covers forged carbon steel piping components intended primarily for service in pressure piping systems from a specific temperature range where inherent notch toughness is desired, but where notch toughness testing is not required. Included are forged or ring-rolled flanges, forged fittings, and valves made to specified dimensions. The steel shall be made by one or more of the following processes: open-hearth, basic-oxygen, or electric-furnace, and shall be fully killed, fine-grain practice. Following plastic working, the forgings shall be heat treated by normalizing, or normalizing and tempering, or quenching and tempering. The forgings shall be subjected to tension, hardness, and hydrostatic tests.

SCOPE

1.1 This specification2 covers forged carbon steel piping components intended primarily for service in pressure piping systems from −20 to +650 °F [−30 to +345 °C] where inherent notch toughness is desired, but where notch toughness testing is not required. Included are forged or ring-rolled flanges, forged fittings, and valves made to specified dimensions, or to dimensional standards such as the ASME and API specifications referenced in Section 2.

1.2 This specification is limited to forgings with maximum finished section thicknesses no larger than 2 in. [51 mm].

1.3 It shall be the responsibility of the purchaser to determine whether material meeting the requirements of this specification is satisfactory for the service application.

1.4 Supplementary requirements are provided for use when additional testing or inspection is desired. These shall apply only when specified by the purchaser in the order.

Note 1: There are no provisions for impact testing in this specification. When impact testing is required, refer to Specification A350/A350M.

1.5 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable “M” specification designation (SI units), the material shall be furnished to inch-pound units.

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A727/A727M −14 (Reapproved 2019)

Standard Specification for

Carbon Steel Forgings for Piping Components with Inherent

1

Notch Toughness

This standard is issued under the fixed designationA727/A727M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ization established in the Decision on Principles for the

2 Development of International Standards, Guides and Recom-

1.1 This specification covers forged carbon steel piping

mendations issued by the World Trade Organization Technical

components intended primarily for service in pressure piping

Barriers to Trade (TBT) Committee.

systems from −20 to +650 °F [−30 to +345 °C] where inherent

notch toughness is desired, but where notch toughness testing

2. Referenced Documents

is not required. Included are forged or ring-rolled flanges,

2.1 In addition to those reference documents listed in

forged fittings, and valves made to specified dimensions, or to

Specification A961/A961M, the following list of standards

dimensional standards such as the ASME and API specifica-

apply to this specification.

tions referenced in Section 2.

3

2.2 ASTM Standards:

1.2 This specification is limited to forgings with maximum

A350/A350MSpecificationforCarbonandLow-AlloySteel

finished section thicknesses no larger than 2 in. [51 mm].

Forgings, Requiring Notch Toughness Testing for Piping

1.3 It shall be the responsibility of the purchaser to deter-

Components

mine whether material meeting the requirements of this speci-

A788/A788MSpecification for Steel Forgings, General Re-

fication is satisfactory for the service application.

quirements

1.4 Supplementary requirements are provided for use when A961/A961MSpecification for Common Requirements for

additional testing or inspection is desired. These shall apply

Steel Flanges, Forged Fittings, Valves, and Parts for

only when specified by the purchaser in the order. Piping Applications

E59Practice for Sampling Steel and Iron for Determination

NOTE 1—There are no provisions for impact testing in this specifica-

4

of Chemical Composition (Withdrawn 1996)

tion.Whenimpacttestingisrequired,refertoSpecificationA350/A350M.

5

2.3 ASME Boiler and Pressure Vessel Codes:

1.5 This specification is expressed in both inch-pound units

Section II, Material Specifications, Part C

and in SI units. However, unless the order specifies the

SFA5.5Low-Alloy Steel Covered Arc-Welding Electrodes

applicable “M” specification designation (SI units), the mate-

B16.5 Steel Pipe Flanges and Flanged Fittings

rial shall be furnished to inch-pound units.

B16.10Face-to-Face and End-to-End Dimensions of Fer-

1.6 The values stated in either SI units or inch-pound units

rous Valves

are to be regarded separately as standard. Within the text, the

B16.11ForgedSteelFittings,Socket-WeldingandThreaded

SI units are shown in brackets. The values stated in each

B16.30Unfired Pressure Vessel Flange Dimensions

system may not be exact equivalents; therefore, each system 6

2.4 API Standards:

shall be used independently of the other. Combining values

600Steel Gate Valves with Flanged or Butt-Welding Ends

from the two systems may result in non-conformance with the

602 CompactDesignCarbonSteelGateValvesforRefinery

standard.

Use

1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel, Standards volume information, refer to the standard’s Document Summary page on

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee the ASTM website.

4

A01.22onSteelForgingsandWroughtFittingsforPipingApplicationsandBolting The last approved version of this historical standard is referenced on

Materials for Piping and Special Purpose Applications. www.astm.org.

5

Current edition approved Dec. 1, 2019. Published December 2019. Originally Available from American Society of Mechanical Engineers (ASME), ASME

approved in 1976. Last previous edition approved in 2014 as A727/A727M–14. International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

DOI: 10.1520/A0727_A0727M-14R19. www.asme.org.

6

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi- Available from American Petroleum Institute (API), 1220 L. St., NW,

cation SA

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.