ASTM D6404-99(2009)

(Practice)Standard Practice for Sampling Vegetable Materials Containing Tannin

Standard Practice for Sampling Vegetable Materials Containing Tannin

SIGNIFICANCE AND USE

This practice provides standard procedures for obtaining representative samples of various materials used as a source of tannins for the tanning industry.

Procedures are described for obtaining representative samples of economical and convenient quantities from a lot, or sections of a lot, of material for examination and analysis so that agreement may be reached with regard to the extent of variation of quality in different portions of a lot and the average quality of the entire lot of material.

No directions for sampling, however explicit, can take the place of judgment, skill, and previous experience on the part of persons actually engaged in the sampling or the supervision of the sampling. These directions are intended to supplement that experience and, particularly, to serve as a guide in the selection of the method which is to be used, in common, by each of two or more contracting parties.

Tanning materials contain moisture in varying amounts, depending both on the nature of the material and on the climatic conditions, so that sampling must be carried out as quickly as is consistent with thoroughness in order to avoid changes in moisture content.

SCOPE

1.1 This practice covers obtaining representative samples from shipment lots of botanical materials containing tannin.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6404 − 99 (Reapproved2009)

Standard Practice for

Sampling Vegetable Materials Containing Tannin

This standard is issued under the fixed designation D6404; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope which have the chemical and physical properties necessary to

convert animal hides and skins into leather.

1.1 This practice covers obtaining representative samples

from shipment lots of botanical materials containing tannin.

4. Summary of Practice

1.2 The values stated in SI units are to be regarded as the

4.1 This practice describes methods for obtaining represen-

standard. The inch-pound units given in parentheses are for

tative samples for analysis from shipments of vegetable tan-

information only.

ning materials and tannin extracts.

1.3 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

5.1 Thispracticeprovidesstandardproceduresforobtaining

responsibility of the user of this standard to establish appro-

representative samples of various materials used as a source of

priate safety and health practices and determine the applica-

tannins for the tanning industry.

bility of regulatory limitations prior to use.

5.2 Procedures are described for obtaining representative

2. Referenced Documents

samples of economical and convenient quantities from a lot, or

sections of a lot, of material for examination and analysis so

2.1 ASTM Standards:

that agreement may be reached with regard to the extent of

D1517 Terminology Relating to Leather

variationofqualityindifferentportionsofalotandtheaverage

2.2 ALCA Method:

quality of the entire lot of material.

J10 Sampling Vegetable Materials Containing Tannin

5.3 No directions for sampling, however explicit, can take

3. Terminology

the place of judgment, skill, and previous experience on the

3.1 Definitions:

part of persons actually engaged in the sampling or the

3.1.1 For definitions of general leather and tanning terms

supervision of the sampling. These directions are intended to

used in this practice refer to Terminology D1517.

supplement that experience and, particularly, to serve as a

3.1.2 quartering—the term applied to a method described in

guide in the selection of the method which is to be used, in

this practice of reducing the size of samples without impairing

common, by each of two or more contracting parties.

their representative quality.

5.4 Tanning materials contain moisture in varying amounts,

3.1.3 tannin—an astringent substance found in the various

depending both on the nature of the material and on the

parts of plants such as bark, wood, leaves, nuts, fruits, roots,

climatic conditions, so that sampling must be carried out as

etc.

quickly as is consistent with thoroughness in order to avoid

3.1.4 vegetable tannins—mixtures of substances (natural changes in moisture content.

products) obtained from plant tissues by water extraction

6. Apparatus

6.1 Balance, analytical balance which will weigh the quan-

This practice is under the jurisdiction ofASTM Committee D31 on Leather and

tity of material specified in this practice to an accuracy of 610

is the direct responsibility of Subcommittee D31.01 on Vegetable Leather. This test

g(6 0.35 oz).

method has been adapted from and is a replacement for Method J10 of the Official

Methods of the American Leather Chemists Association.

6.2 Canvas, 11-oz weight and of sufficient size (as deter-

Current edition approved April 1, 2009. Published July 2009. Originally

mined by the discretion of the sampler or analyst) for use in

approved in 1999. Last previous edition approved in 2004 as D6404 – 99 (2004).

mixing and quartering samples.

DOI: 10.1520/D6404-99R09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.3 Sieve, with round openings 1.27 cm (0.50 in.) in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

diameter.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

6.4 Sampling Tool, this tool shall be made of brass or other

Official Methods of the American Leather Chemists Association. Available

corrosion-resistant metal tubing, with solid handle attached,

from the American Leather Chemists Association, University of Cincinnati, P.O.

Box 210014, Cincinnati, OH 45221-0014. similar to that described below and illustrated in Fig. 1.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6404 − 99 (2009)

8. Filling Containers

8.1 Immediately after the final samples are obtained, they

shall be put into clean, dry containers, closed airtight, sealed,

and labeled as described in the procedure (11.11).

8.2 Liquid and powdered extracts and tannery liquor

samples shall be put into stoppered glass bottles of the required

size.

8.3 Solid and pasty extracts shall be wrapped in aluminum

foil and put into Mason-type jars or tin cans of the required

FIG. 1 Sampling Tool

size.

8.4 Cut bark, fruits, roots, galls, nuts, leaves, etc., and spent

materials, shall be placed in lacquered, pressed-top tins of the

required size, which close airtight. Boxes or bags must not be

6.4.1 Thin brass or other corrosion-resistant metal tubing,

used as containers.

37cmlongand17.5mmdiameter,isused.Asolidsteelhandle,

8.5 Sample containers shall be of no greater capacity than

6 cm long, is welded to one end of the tube. A section 11 mm

will conveniently be filled by the sample taken.

wide and 30 cm long is cut out of the side of the tube and the

edges of this opening sharply beveled. The working end is cut

9. Number of Packages to be Sampled

to a sharp point for piercing sacks, or other tough materials,

like plantation gambier.

9.1 The number of packages to be sampled from any given

lot of tanning material composed of solid, powdered or pasty

7. Quartering Samples

extract, crude or manufactured tanning materials, in bales,

boxes, bags, barrels, or similar packages, shall be as shown in

7.1 “Quartering” is a term applied to the following method

Table 1. The samples shall be selected from as uniformly

of reducing the size of samples without impairing their

distributed parts of the lot as is possible at the time of

representative quality.

weighing.

7.1.1 All of the material, taken from the various containers

9.1.1 Where the shipment exceeds 10 000 packages, it shall

or parts of the shipment of solid material being sampled, shall

bedividedintoasfew,equal,sections(ofnotmorethan10 000

be immediately and thoroughly mixed on a square piece of 11

packages each) as possible and each section shall be sampled

oz canvas. In the case of solid extracts, large pieces shall have

and analyzed as if it were an individual shipment. In such case,

been broken previously so as to pass a screen having round

the mean of the analyses of the sections shall constitute the

openings 1.27 cm (0.50 in.) in diameter. The pile shall be

analysis of the shipment.

divided into four equal portions and quarters A and B shall be

discarded as illustrated in diagram X of Fig. 2. The remaining

10. Number of Samples

two quarters shall then be re-mixed thoroughly and again

divided into four equal portions and quarters C and D shall be

10.1 In addition to the representative samples for submis-

discarded as illustrated in diagram Y of Fig. 2. This process siontothecontractingparties,atleastoneextrasampleshallbe

shall be repeated until the mixture of any two remaining

taken and held in reserve by the sampler, in case one of the

quarters of the sample be of sufficient size to secure the regular samples is lost or damaged.

individual samples as specified below. The individual samples

11. Procedure

shall be obtained by thoroughly mixing the two remaining

quarters and dividing the mixture into as many uniform

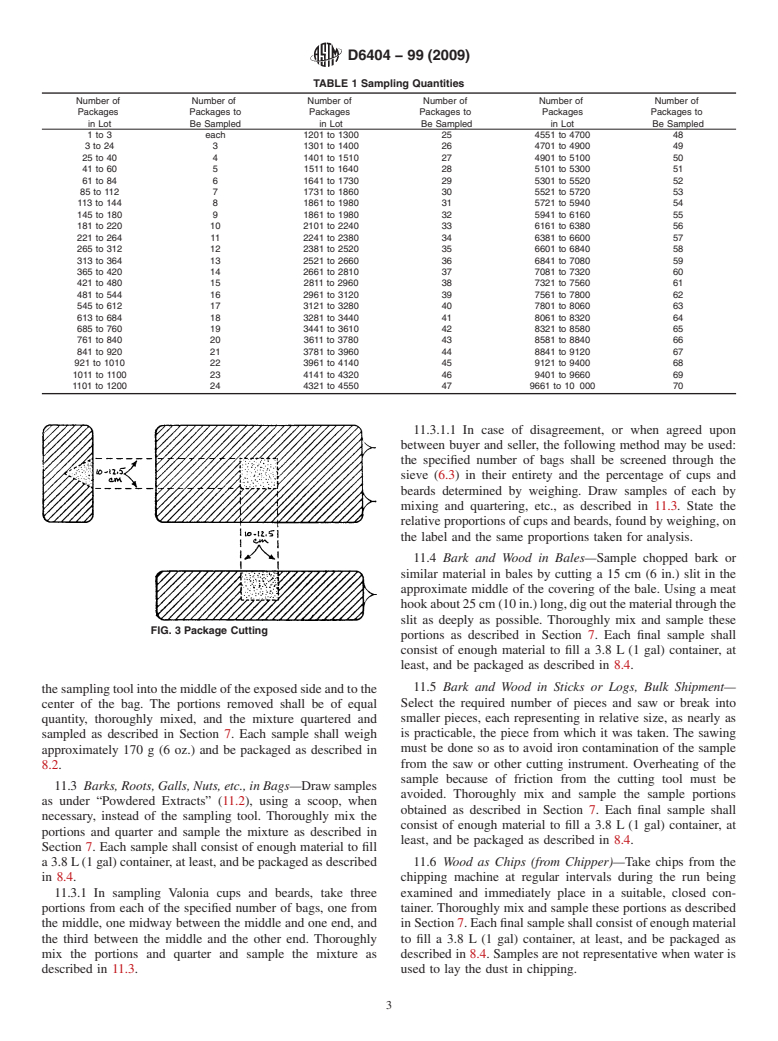

11.1 Solid Extracts—Cutasuitabletriangularopeninginthe

sections as necessary, such that each section will be large

middle of the exposed side of the package to be sampled. Then

enough to fill one of the required number of containers. All

cutaV-shapedwedge,10to12.5cm(4to5in.)inwidthonthe

fine, powdery material in each section shall be completely

surface of the exposed side of the package, as near to the

removed with its respective section, whether the section is

middle as possible and to the depth shown in the diagram

discarded or placed in a sample container.

illustrated in Fig. 3.

11.1.1 Remove this piece, including any dry or crumbly

exterior portion of it, place on the quartering canvas and

covered to prevent loss of moisture. Promptly break the

V-shaped samples from all the selected packages to a size

which will pass the sieve (6.3). Quarter the mixture and sample

as described in Section 7. Each final sample shall weigh

approximately 225 g (8 oz) and shall be packaged as described

in 8.3.

11.2 Powdered Extracts—Draw a portion from each of the

specified number of bags, using the sampling tool (6.4). Lay

FIG. 2 Quartering Samples the bags horizontally, with the narrow side exposed, and insert

D6404 − 99 (2009)

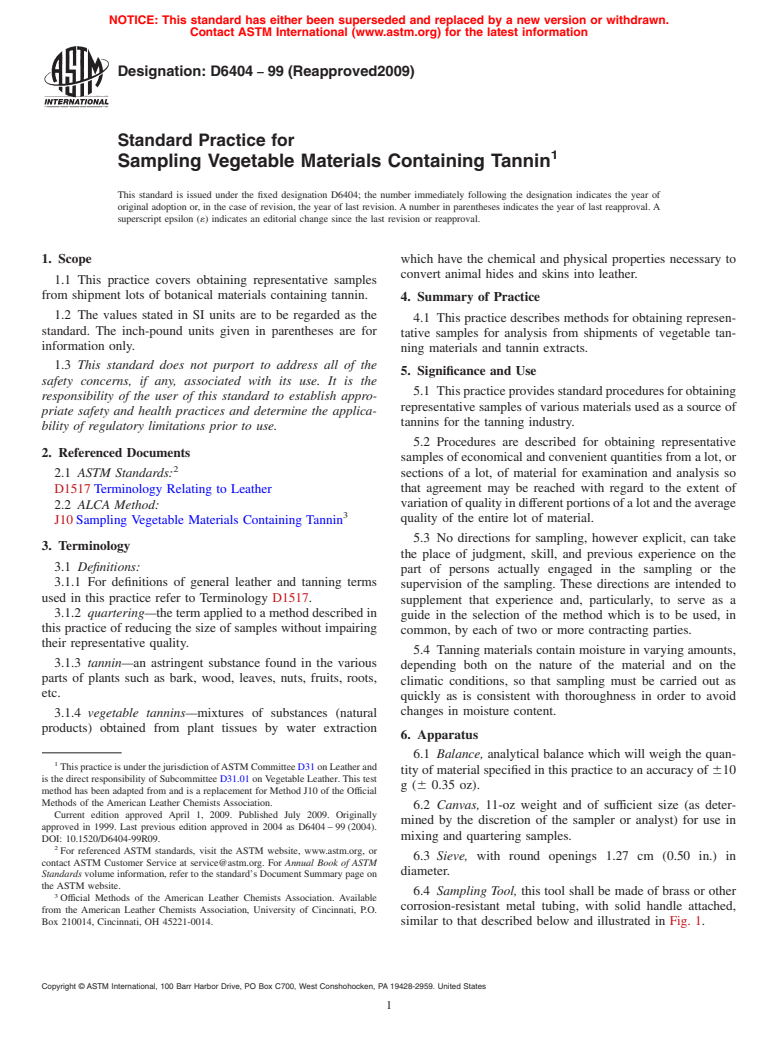

TABLE 1 Sampling Quantities

Number of Number of Number of Number of Number of Number of

Packages Packages to Packages Packages to Packages Packages to

in Lot Be Sampled in Lot Be Sampled in Lot Be Sampled

1 to 3 each 1201 to 1300 25 4551 to 4700 48

3 to 24 3 1301 to 1400 26 4701 to 4900 49

25 to 40 4 1401 to 1510 27 4901 to 5100 50

41 to 60 5 1511 to 1640 28 5101 to 5300 51

61 to 84 6 1641 to 1730 29 5301 to 5520 52

85 to 112 7 1731 to 1860 30 5521 to 5720 53

113 to 144 8 1861 to 1980 31 5721 to 5940 54

145 to 180 9 1861 to 1980 32 5941 to 6160 55

181 to 220 10 2101 to 2240 33 6161 to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.