ASTM D6406-99(2020)

(Test Method)Standard Test Method for Analysis of Sugar in Vegetable Tanning Materials

Standard Test Method for Analysis of Sugar in Vegetable Tanning Materials

SIGNIFICANCE AND USE

5.1 This test method is used to determine the quantity of sugar present in vegetable tanning materials or vegetable tannin extracts. The amount of the reducing sugars, total sugars, and non-reducing sugars in a sample of material or extract can be determined by this method.

5.2 Because of the possibility of errors in this test method it is essential that the method be followed exactly in order to obtain reproducible results both among specimens within a laboratory and for analyses between laboratories.

SCOPE

1.1 This test method covers determining the sugars present in vegetable tanning materials.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6406 − 99 (Reapproved 2020)

Standard Test Method for

Analysis of Sugar in Vegetable Tanning Materials

This standard is issued under the fixed designation D6406; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ALCA Methods:

A30 Sugar in Tanning Materials

1.1 This test method covers determining the sugars present

in vegetable tanning materials.

3. Terminology

1.2 The values stated in SI units are to be regarded as

3.1 Definitions:

standard. The values given in parentheses after SI units are

3.1.1 dextrose—d-glucose.

provided for information only and are not considered standard.

3.1.2 glucose—a simple sugar with formula C H O , and

6 12 6

1.3 This standard does not purport to address all of the

known to exist in d-, l-, and racemic forms. The term

safety concerns, if any, associated with its use. It is the

commonly refers to the sweet, colorless, water-soluble dextro-

responsibility of the user of this standard to establish appro-

rotatoryformthatoccurswidelyinnatureandistheusualform

priate safety, health, and environmental practices and deter-

in which carbohydrate is assimilated by animals. The term

mine the applicability of regulatory limitations prior to use.

glucose can also refer to a light-colored syrup made from corn

1.4 This international standard was developed in accor-

starch.

dance with internationally recognized principles on standard-

3.1.3 sugar—any of various water-soluble compounds that

ization established in the Decision on Principles for the

vary widely in sweetness and comprise the oligosaccharides

Development of International Standards, Guides and Recom-

including sucrose.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4. Summary of Test Method

2. Referenced Documents

4.1 An analytical strength solution (that is, 4.00 6 0.25 g

tanninperlitre)ofthetanningmaterialisanalyzedforreducing

2.1 ASTM Standards:

sugars and total sugars by the Munson and Walker procedure.

D4901 Practice for Preparation of Solution of Liquid Veg-

etable Tannin Extracts

5. Significance and Use

D4905 Practice for Preparation of Solution of Solid, Pasty

and Powdered Vegetable Tannin Extracts 5.1 This test method is used to determine the quantity of

D6401 Test Method for Determining Non-Tannins and Tan-

sugar present in vegetable tanning materials or vegetable

nin in Extracts of Vegetable Tanning Materials tannin extracts. The amount of the reducing sugars, total

D6403 Test Method for Determining Moisture in Raw and

sugars, and non-reducing sugars in a sample of material or

Spent Materials extract can be determined by this method.

D6404 Practice for Sampling Vegetable Materials Contain-

5.2 Because of the possibility of errors in this test method it

ing Tannin

is essential that the method be followed exactly in order to

D6405 Practice for Extraction of Tannins from Raw and

obtain reproducible results both among specimens within a

Spent Materials

laboratory and for analyses between laboratories.

D6408 Test Method for Analysis of Tannery Liquors

6. Apparatus and Reagents

This test method is under the jurisdiction ofASTM Committee D31 on Leather

6.1 Saturated Solution of Normal Lead Acetate.

and is the direct responsibility of Subcommittee D31.01 on Vegetable Leather. This

6.2 Dipotassium Hydrogen Phosphate, Anhydrous

method has been adapted from and is a replacement for MethodA30 of the Official

Methods of the American Leather Chemists Association.

(K HPO ), dried in an oven at 100°C for 16 h then stored in a

2 4

Current edition approved Dec. 1, 2020. Published December 2020. Originally

tightly stoppered bottle.

approved in 1999. Last previous edition approved in 2014 as D6406 – 99 (2014).

DOI: 10.1520/D6406-99R20.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Official Methods of the American Leather Chemists Association. Available

Standards volume information, refer to the standard’s Document Summary page on from the American Leather Chemists Association, University of Cincinnati, P.O.

the ASTM website. Box 210014, Cincinnati, OH 45221-0014.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6406 − 99 (2020)

6.3 Toluene, assay ≥ 99.5 %. 6.24.6 Wash the mat with boiling Fehling’s solution.

6.24.7 Wash the mat with nitric acid diluted 1 to 3.

6.4 Fehling’s Solutions, A and B.

6.24.8 Wash and rinse the mat with hot distilled water.

6.5 Hydrochloric Acid, concentrated (sp.gr. 1.18).

6.24.9 Crucibles so prepared can be used for a long time.

6.6 Kerosene, commercial grade.

6.25 Suction Flask and Crucible Holder, with connections

6.7 Saturated Solution of Sodium Hydroxide. to a vacuum.

6.26 Balance,analyticalbalancewhichwillweighupto100

6.8 Phenolphthalein Solution, 0.5 g dissolved in 100 mL of

95 % ethanol. g with an accuracy of 6 0.1 mg (6 0.0001 g).

6.27 Drying Oven, a forced-air convection oven (or

6.9 Tartaric Acid, powdered.

mechanical-convection draft oven) capable of maintaining a

6.10 Copper Sulfate Solution, prepared by dissolving

temperature of 100 6 2.0°C.

69.278 g of CuSO •5H O in 1 Lof distilled water and filtering

4 2

through asbestos. 6.28 Thermometer, accurate to 60.2°C used to check and

monitor the oven set point.

6.11 Alkaline Tartrate Solution, prepared by dissolving 346

6.29 Dessicator, any convenient form or size, using any

g of Rochelle salt (sodium potassium tartrate tetrahydrate) and

100 g of sodium hydroxide in 1 L of distilled water. After normal desiccant.

standing for two days the solution shall be filtered through

7. Test Specimen

asbestos.

7.1 The specimen for the sugar analysis shall consist of 400

6.12 Alcohol, 95 % ethyl alcohol.

mL of a solution of the tanning material of analytical strength

6.13 Ether, diethyl ether.

(4.006 0.25 g tannin per L).

6.14 Filter Paper , 21.5 cm diameter, pleated to contain 32

8. Procedure

evenly divided creases.

8.1 Sample the tanning material using Practice D6404, and

6.15 Funnel,100-125mmtopdiameter,60°anglebowl,and

preparetheanalyticalsolutionasdescribedinPracticesD4901,

150 mm stem length.

D4905, D6405,or D6408.

6.16 Watch Glasses, a suitable size (approximately 150 mm

8.2 Detannization of Analytical Solution:

diameter) to be used as a cover for the funnel and filter paper.

8.2.1 Add to 400 mL of the analytical solution 50 mL of a

6.17 Graduated Cylinder, standard laboratory grade with

saturated lead acetate solution. Shake the mixture well and

500 mL capacity.

allow to stand for 5 to 10 min.

6.18 Pipets, capable of measuring and transferring 100 mL,

NOTE 1—It is important that the mixture of liquor and lead acetate

50 mL, and 7.5 mL.

solution be very well shaken. Good results are obtained by placing the

solution mixture in shake bottles and running in the shake machine for 10

6.19 Beakers, 400 mL, low form.

min (as described in Test Method D6401) to ensure complete detanniza-

6.20 Erlenmeyer Flasks, 500 mL capacity. tion of the liquor. The mixture filters better after complete detannization.

Complete detannization also results in less danger of residual quantities of

6.21 Reflux Condensers, to connect to the top of the

unreacted lead which may exceed the capacity of the potassium phosphate

Erlenmeyer flasks.

to remove and which could then interfere in the final copper precipitation

step.

6.22 Heat Source, either a Bunsen burner or a hotplate.

8.2.2 Then filter the mixture through a folded filter paper

6.23 Volumetric Flasks, 200 mL capacity.

and return the filtrate to the filter until it is clear. Continue

6.24 Filtering Crucibles, either porcelain crucibles of Fine

filtration until 360 to 380 mL of the clear filtrate has been

porosity or Gooch-asbestos crucibles prepared as follows:

collected; this may take an hour or more to accomplish. Cover

6.24.1 Digestfinelydividedlongfiberedasbestoswithnitric

the funnel during the filtration.

acid (diluted 1 to 3) for 2 to 3 days.

8.2.3 Measure the volume of the collected filtrate in a

6.24.2 Wash the asbestos free from acid.

graduated cylinder. Remove the excess lead from this filtrate

6.24.3 Digest the asbestos with 10 % sodium hydroxide

by adding dried dipotassium hydrogen phosphate (K HPO)at

2 4

solution for two to three days.

the rate of 2.5 g (6 0.1 g) phosphate per 100 mLof the filtrate.

6.24.4 Wash the asbestos free from alkali.

After addition of the phosphate shake the mixture well for 4 to

6.24.5 PreparetheGoochcruciblebymakingabottomlayer

5 min and then filter through a folded filter paper. Allow time

of 6.4 mm ( ⁄4 in.) thickness using the coarser particles of

for the solution to drain completely from the lead phosphate.

asbestos on the bottom and dress off the mat with the finer

Cover the funnel during the filtration.

asbestos particles.

8.3 Determination of Reducing Sugars:

8.3.1 Add to 100 mL of the clarified (de-tanned) and

The sole source of supply of S&S No. 610 filter paper known to the committee

de-leaded filtrate solution obtained from 8.2.3 33.3 mL of

at this time is Schleicher & Schuell, 10 OpticalAvenue, P.O. Box 2012, Keene, NH

distilled water. If the reduction is not to be made at once also

03431. If you are aware of alternative suppliers, please provide this information to

add eight to ten drops of toluene. Shake this mixture well and

ASTMHeadquarters.Yourcommentswillreceivecarefulconsiderationatameeting

of the responsible technical committee, which you may attend. stopper with a plug of cotton. Keep the prepared solution in a

D6406 − 99 (2020)

cool place and make the reduction within 24 h.When ready for 8.4.3 Dry the crucible and contents for 30 min in the oven,

reduction, filter the solution if toluene has been added. Deter- cool in a dessicator, and weigh.

mine reducing sugars by the Munson and Walker procedure in

8.5 Determination of Total Sugars:

8.4 using duplicate 50 mL aliquots.

8.5.1 To a 500 mL Erlenmeyer flask add 150 mL aliquot of

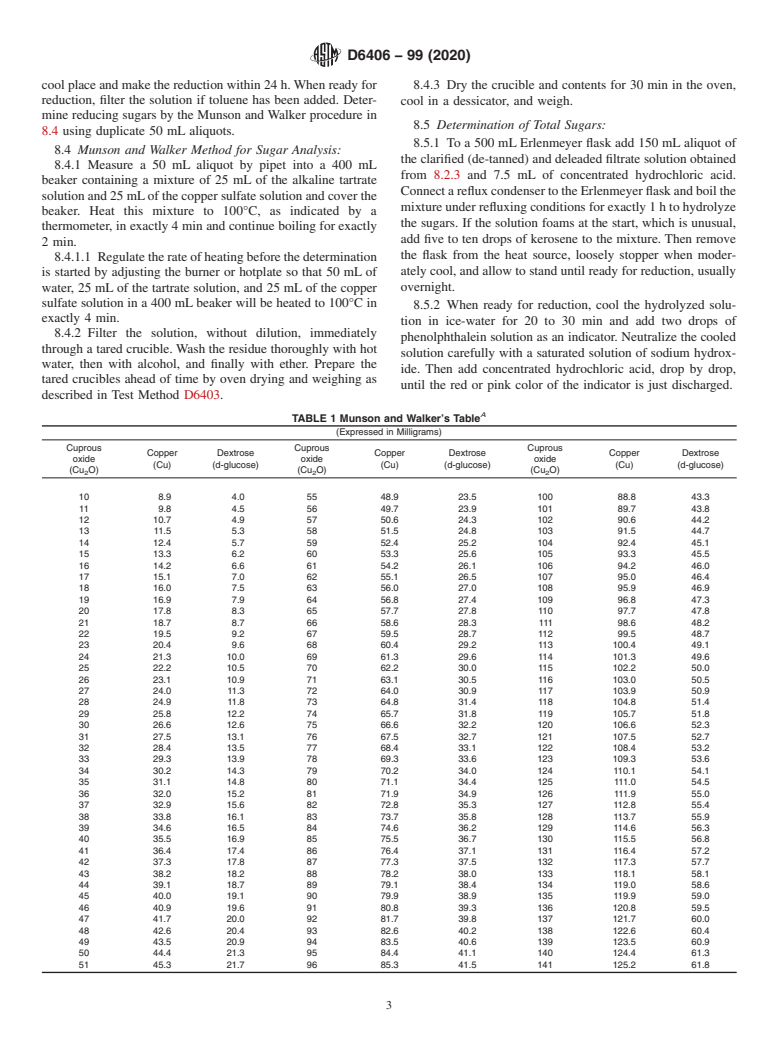

8.4 Munson and Walker Method for Sugar Analysis:

the clarified (de-tanned) and deleaded filtrate solution obtained

8.4.1 Measure a 50 mL aliquot by pipet into a 400 mL

from 8.2.3 and 7.5 mL of concentrated hydrochloric acid.

beaker containing a mixture of 25 mL of the alkaline tartrate

ConnectarefluxcondensertotheErlenmeyerflaskandboilthe

solutionand25mLofthecoppersulfatesolutionandcoverthe

mixture under refluxing conditions for exactly1hto hydrolyze

beaker. Heat this mixture to 100°C, as indicated by a

the sugars. If the solution foams at the start, which is unusual,

thermometer, in exactly 4 min and continue boiling for exactly

add five to ten drops of kerosene to the mixture. Then remove

2 min.

the flask from the heat source, loosely stopper when moder-

8.4.1.1 Regulatetherateofheatingbeforethedetermination

ately cool, and allow to stand until ready for reduction, usually

is started by adjusting the burner or hotplate so that 50 mL of

overnight.

water, 25 mL of the tartrate solution, and 25 mL of the copper

sulfate solution in a 400 mL beaker will be heated to 100°C in

8.5.2 When ready for reduction, cool the hydrolyzed solu-

exactly 4 min.

tion in ice-water for 20 to 30 min and add two drops of

8.4.2 Filter the solution, without dilution, immediately

phenolphthalein solution as an indicator. Neutralize the cooled

through a tared crucible. Wash the residue thoroughly with hot

solution carefully with a saturated solution of sodium hydrox-

water, then with alcohol, and finally with ether. Prepare the

ide. Then add concentrated hydrochloric acid, drop by drop,

tared crucibles ahead of time by oven drying and weighing as

until the red or pink color of the indicator is just discharged.

described in Test Method D6403.

A

TABLE 1 Munson and Walker’s Table

(Expressed in Milligrams)

Cuprous Cuprous Cuprous

Copper Dextrose Copper Dextrose Copper Dextrose

oxide oxide oxide

(Cu) (d-glucose) (Cu) (d-glucose) (Cu) (d-glucose)

(Cu O) (Cu O) (Cu O)

2 2 2

10 8.9 4.0 55 48.9 23.5 100 88.8 43.3

11 9.8 4.5 56 49.7 23.9 101 89.7 43.8

12 10.7 4.9 57 50.6 24.3 102 90.6 44.2

13 11.5 5.3 58 51.5 24.8 103 91.5 44.7

14 12.4 5.7 59 52.4 25.2 104 92.4 45.1

15 13.3 6.2 60 53.3 25.6 105 93.3 45.5

16 14.2 6.6 61 54.2 26.1 106 94.2 46.0

17 15.1 7.0 62 55.1 26.5 107 95.0 46.4

18 16.0 7.5 63 56.0 27.0 108 95.9 46.9

19 16.9 7.9 64 56.8 27.4 109 96.8 47.3

20 17.8 8.3 65 57.7 27.8 110 97.7 47.8

21 18.7 8.7 66 58.6 28.3 111 98.6 48.2

22 19.5 9.2 67 59.5 28.7 112 99.5 48.7

23 20.4 9.6 68 60.4 29.2 113 100.4 49.1

24 21.3 10.0 69 61.3 29.6 114 101.3 49.6

25 22.2 10.5 70 62.2 30.0 115 102.2 50.0

26 23.1 10.9 71 63.1 30.5 116 103.0 50.5

27 24.0 11.3 72 64.0 30.9 117 103.9 50.9

28 24.9 11.8 73 64.8 31.4 118 104.8 51.4

29 25.8 12.2 74 65.7 31.8 119 105.7 51.8

30 26.6 12.6 75 66.6 32.2 120 106.6 52.3

31 27.5 13.1 76 67.5 32.7 121 107.5 52.7

32 28.4 13.5 77 68.4 33.1 122 108.4 53.2

33 29.3 13.9 78 69.3 33.6 123 109.3 53.6

34 30.2 14.3 79 70.2 34.0 124 110.1 54.1

35 31.1 14.8 80 71.1 34.4 125 111.0 54.5

36 32.0 15.2 81 71.9 34.9 126 111.9 55.0

37 32.9 15.6 82 72.8 35.3 127 112.8 55.4

38 33.8 16.1 83 73.7 35.8 128 113.7 55.9

39 34.6 16.5 84 74.6 36.2 129 114.6 56.3

40 35.5 16.9 85 75.5 36.7 130 115.5 56.8

41 36.4 17.4 86 76.4 37.1 131 116.4 57.2

42 37.3 17.8 87 77.3 37.5 132 117.3 57.7

43 38.2 18.2 88 78.2 38.0 133 118.1 58.1

44 39.1 18.7 89 79.1 38.4 134 119.0 58.6

45 40.0 19.1 90 79.9 38.9 135 119.9 59.0

46 40.9 19.6 91 80.8 39.3 136 120.8 59.5

47 41.7 20.0 92 81.7 39.8 137 121.7 60.0

48 42.6 20.4 93 82.6 40.2 138 122.6 60.4

49 43.5 20.9 94 83.5 40.6 139 123.5 60.9

50 44.4 21.3 95 84.4 41.1 140 124.4 61.3

51 45.3 21.7 96 85.3 41.5 141 125.2 61.8

D6406 − 99 (2020)

TABLE 1 Continued

(Expressed in Milligrams)

Cuprous Cuprous Cuprous

Copper Dextrose Copper Dextrose Copper Dextrose

oxide oxide oxide

(Cu) (d-glucose) (Cu) (d-glucose) (Cu) (d-glucose)

(Cu O) (Cu O) (Cu O)

2 2 2

52 46.2 22.2 97 86.2 42.0 142 126.1 62.2

53 47.1 22.6 98 87.1 42.4 143 127.0 62.7

54 48.0 23.0 99 87.9 42.9 144 127.9 63.1

145 128.8 63.6 192 170.5 85.3 239 212.3 107.5

146 129.7 64.0 193 171.4 85.7 240 213.2 108.0

147 130.6 64.5 194 172.3 86.2 241 214.1 108.4

148 131.5 65.0 195 173.2 86.7 242 215.0 108.9

149 132.4 65.4 196 174.1 87.1 243 215.8 109.4

150 133.2 65.9 197 175.0 87.6 2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.