ASTM D6913-04(2009)

(Test Method)Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis

Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis

SIGNIFICANCE AND USE

The gradation of the soil is used for classification in accordance with Practice D2487.

The gradation (particle-size distribution) curve is used to calculate the coefficient of uniformity and the coefficient of curvature.

Selection and acceptance of fill materials are often based on gradation. For example, highway embankments, backfills, and earthen dams may have gradation requirements.

The gradation of the soil often controls the design and quality control of drainage filters, and groundwater drainage.

Selection of options for dynamic compaction and grouting is related to gradation of the soil.

The gradation of a soil is an indicator of engineering properties. Hydraulic conductivity, compressibility, and shear strength are related to the gradation of the soil. However, engineering behavior is dependent upon many factors (such as effective stress, stress history, mineral type, structure, plasticity, and geologic origins) and cannot be based solely upon gradation.

Note 1—The quality of the result produced by these test methods is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of these test methods are cautioned that compliance with Practice D3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D3740 provides a means of evaluating some of those factors.

SCOPE

1.1 Soils consist of particles with various shapes and sizes. This test method is used to separate particles into size ranges and to determine quantitatively the mass of particles in each range. These data are combined to determine the particle-size distribution (gradation). This test method uses a square opening sieve criterion in determining the gradation of soil between the 3-in. (75-mm) and No. 200 (75-µm) sieves.

1.2 The terms, soils and material, are used interchangeably throughout the standard.

1.3 In cases where the gradation of particles larger than 3 in. (75 mm) sieve is required, Test Method D5519 may be used.

1.4 In cases where the gradation of particles smaller than No. 200 (75-µm) sieve is required, Test Method D422 may be used.

1.5 Typically, if the maximum particle size is equal to or less than 4.75 mm (No. 4 sieve), then single-set sieving is applicable. Furthermore, if the maximum particle size is greater than 4.75 mm (No. 4 sieve) and equal to or less than 9.5 mm (3/8-in sieve), then either single-set sieving or composite sieving is applicable. Finally, if the maximum particle size is equal to or greater than 19.0 mm (3/4-in sieve), composite sieving is applicable. For special conditions see 10.3.

1.6 Two test methods are provided in this standard. The methods differ in the significant digits recorded and the size of the specimen (mass) required. The method to be used may be specified by the requesting authority; otherwise Method A shall be performed.

1.6.1 Method A—The percentage (by mass) passing each sieve size is recorded to the nearest 1 %. This method must be used when performing composite sieving. For cases of disputes, Method A is the referee method.

1.6.2 Method B—The percentage (by mass) passing each sieve size is recorded to the nearest 0.1 %. This method is only applicable for single sieve-set sieving and when the maximum particle size is equal to or less than the No. 4 (4.75-mm) sieve.

1.7 This test method does not cover, in any detail, procurement of the sample. It is assumed that the sample is obtained using appropriate methods and is representative.

1.8 Sample Processing—Three procedures (moist, air dry, and oven dry) are provided to process the sample to obtain a specimen. The procedure selected will depend on the type of sample, the maximum particle-size in the sample, the range of particle sizes, the initial c...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6913 −04(Reapproved 2009)

Standard Test Methods for

Particle-Size Distribution (Gradation) of Soils Using Sieve

Analysis

This standard is issued under the fixed designation D6913; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Although this test method has been used for many years, there are vast testing variations required

due to soil types and conditions. The test is more complicated and complex than would be expected.

Multiple procedures are being presented along with new terminology.Although these procedures are

not new, they will now be defined and explained. Some examples of these new terms are composite

sieving, designated separating sieve and subspecimen. This test method outlines the majority of

conditions and procedures but does not cover every conceivable variation or contingency. The table

of contents in the Scope section is added to enable the user to easily find a specific topic or

requirement.Onlysections/subsectionswithtitlesarepresented.Therefore,numberedsubsectionswill

not be continuous in some cases, as indicated in the Scope section.

1. Scope sieving is applicable. Finally, if the maximum particle size is

equal to or greater than 19.0 mm ( ⁄4-in sieve), composite

1.1 Soils consist of particles with various shapes and sizes.

sieving is applicable. For special conditions see 10.3.

This test method is used to separate particles into size ranges

and to determine quantitatively the mass of particles in each

1.6 Two test methods are provided in this standard. The

range. These data are combined to determine the particle-size

methods differ in the significant digits recorded and the size of

distribution (gradation). This test method uses a square open-

the specimen (mass) required. The method to be used may be

ingsievecriterionindeterminingthegradationofsoilbetween

specifiedbytherequestingauthority;otherwiseMethodAshall

the 3-in. (75-mm) and No. 200 (75-µm) sieves.

be performed.

1.6.1 Method A—The percentage (by mass) passing each

1.2 The terms, soils and material, are used interchangeably

sieve size is recorded to the nearest 1%. This method must be

throughout the standard.

used when performing composite sieving. For cases of

1.3 Incaseswherethegradationofparticleslargerthan3in.

disputes, Method A is the referee method.

(75 mm) sieve is required, Test Method D5519 may be used.

1.6.2 Method B—The percentage (by mass) passing each

1.4 In cases where the gradation of particles smaller than

sievesizeisrecordedtothenearest0.1%.Thismethodisonly

No. 200 (75-µm) sieve is required,Test Method D422 may be

applicable for single sieve-set sieving and when the maximum

used.

particle size is equal to or less than the No. 4 (4.75-mm) sieve.

1.5 Typically, if the maximum particle size is equal to or

1.7 This test method does not cover, in any detail, procure-

less than 4.75 mm (No. 4 sieve), then single-set sieving is

ment of the sample. It is assumed that the sample is obtained

applicable. Furthermore, if the maximum particle size is

using appropriate methods and is representative.

greaterthan4.75mm(No.4sieve)andequaltoorlessthan9.5

1.8 Sample Processing—Three procedures (moist, air dry,

mm ( ⁄8-in sieve), then either single-set sieving or composite

and oven dry) are provided to process the sample to obtain a

specimen. The procedure selected will depend on the type of

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

sample, the maximum particle-size in the sample, the range of

Rock andisthedirectresponsibilityofSubcommitteeD18.03onTexture, Plasticity

particle sizes, the initial conditions of the material, the plastic-

and Density Characteristics of Soils.

Current edition approved July 1, 2009. Published August 2009. Originally

ity of the material, the efficiency, and the need for other testing

ε2

approved in 2004. Last previous edition approved in 2004 as D6913–04 . DOI:

on the sample. The procedure may be specified by the

10.1520/D6913-04R09.

2 requesting authority; otherwise the guidance given in Section

Currently Subcommittee D18.03 is preparing a new test method (Hydrometer

Analysis or Combined Sieve and Hydrometer Analysis) to replace D422. 10 shall be followed.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6913−04 (2009)

1.9 This test method typically requires two or three days to 1.15 Asummary of the symbols used in this test method is

complete, depending on the type and size of the sample and given in Annex A1.

soil type.

1.16 This standard does not purport to address all of the

1.10 This test method is not applicable for the following safety concerns, if any, associated with its use. It is the

soils:

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.10.1 Soils containing fibrous peat that will change in

particle size during the drying, washing, or sieving procedure. bility of regulatory limitations prior to use.

1.10.2 Soils containing extraneous matter, such as organic

1.17 Table of Contents—All tables and figures appear at the

solvents, oil, asphalt, wood fragments, or similar items. Such

end of this standard.

extraneous matter can affect the washing and sieving proce-

Section

dures. Scope 1

Method A 1.6.1

1.10.3 Materials that contain cementitious components,

Method B 1.6.2

suchascement,flyash,lime,orotherstabilizationadmixtures.

Sample Processing 1.8

Units 1.14

1.11 This test method may not produce consistent test

Referenced Documents 2

ASTM Standards 2.1

results within and between laboratories for the following soils

Terminology 3

and the precision statement does not apply to them.

General 3.1

1.11.1 Friable soils in which the sieving processes change

Definitions 3.2

Definitions of Terms Specific to This 3.3

the gradation of the soil. Typical examples of these soils are

Standard

some residual soils, most weathered shales and some weakly

Summary of Test Method 4

cemented soils such as hardpan, caliche or coquina.

Significance and Use 5

Apparatus 6

1.11.2 Soilsthatwillnotreadilydispersesuchasglauconitic

Sieves 6.1

clays or some dried plastic clays.

Standard Sieve Set 6.1.1

Washing Sieve, No. 200 (75-µm) 6.1.2

1.11.3 To test these soils, this test method must be adapted,

Designated Separating Sieve 6.1.3

oraltered,andthesealterationsdocumented.Dependingonthe

Washing Sink with Spray Nozzle 6.2

design considerations, a specialized gradation-testing program

Mechanical Sieve Shaker 6.3

Balances 6.4

could be performed. The alterations could require the washing

Drying Oven 6.5

and sieving procedures to be standardized such that each

Sieving Containers 6.6

specimen would be processed in a similar manner.

Specimen Containers 6.6.1

Collection/Transfer Device 6.6.2

1.12 Some materials that are not soils, but are made up of

Cumulative Mass Container 6.6.3

Sieve Brushes 6.7

particles may be tested using this method. However, the

Miscellaneous Items 6.8

applicable sections above should be used in applying this

Splitter or Riffle Box (optional) 6.9

standard.

Quartering Accessories (optional) 6.10

Mortar and Rubber-Covered Pestle 6.11

1.13 Allobservedandcalculatedvaluesshallconformtothe

(optional)

Low Temperature Drying Oven 6.12

guidelines for significant digits and rounding established in

(optional)

Practice D6026, unless superseded by this test method.

Ultrasonic Water Bath (optional) 6.13

1.13.1 The procedures used to specify how data are Dispersion Shaker (optional) 6.14

Reagents 7

collected/recorded and calculated in this standard are regarded

Dispersant 7.1

as the industry standard. In addition, they are representative of

Dry Addition 7.1.1.1

the significant digits that generally should be retained. The Solution 7.1.1.2

Preparation of Apparatus 8

proceduresuseddonotconsidermaterialvariation,purposefor

Verification of Sieves 8.1

obtaining the data, special purpose studies, or any consider-

Verification Interval 8.1.1

ations for the user’s objectives; and it is common practice to

Verification of Mechanical Sieve Shaker 8.2

and

increase or reduce significant digits of reported data to be

Standard Shaking Period

commensuratewiththeseconsiderations.Itisbeyondthescope

Large Mechanical Sieve Shaker 8.2.1

of these test methods to consider significant digits used in Verification Interval 8.2.2

Hand Sieve Shaking Procedure 8.2.3

analysis methods for engineering design.

Sampling 9

General 9.1

1.14 Units—ThedimensionalvaluesstatedineitherSIunits

Sample Sources 9.2

or inch-pound units are to be regarded as standard, such as

Bulk Samples 9.2.1

200-mmor8-in.diametersieve.Except,thesievedesignations Jar and Small Bag Samples 9.2.2

Undisturbed Tube Samples 9.2.3

are typically identified using the “alternative” system in

Samples from Prior Testing 9.2.4

accordance with Practice E11, such as 3 in. and No. 200,

Specimen 10

instead of the “standard” system of 75 mm and 75 µm, General 10.1

Minimum Mass Requirement 10.2

respectively. Only the SI units are used for mass

Selection of Sieving Procedure 10.3

determinations, calculations, and reported results. However,

Single Sieve-Set Sieving 10.3.1

Composite Sieving 10.3.2

the use of balances or scales recording pounds of mass (lbm)

Specimen Procurement 10.4

shall not be regarded as nonconformance with this standard.

D6913−04 (2009)

Moist Procedure 10.4.1 Percent Passing, Specimen 12.5.2.1

Air-Dried Procedure 10.4.2 (combined

Oven-Dried Procedure 10.4.3 coarser and finer portions)

Discussion on Segregating Soils 10.4.4 Subspecimen, Acceptable 12.5.2.2

Fractional

Specimen Procurement and Processing 10.5

Requirements Percent Retained

Percent Passing, Acceptance 12.5.2.3

Moist Procedure, Single Sieve-Set 10.5.1

Sieving Criterion

Finer Portion, Percent Passing 12.5.3

Moist Procedure, Composite Sieving 10.5.2

Coarse Portion Acceptable Loss 10.5.2.3 (optional)

Composite Sieving, Double Separation 12.6

(CP )

L

st

Air-Dried Procedure, General 10.5.3 1 Coarser Portion 12.6.1

st

Air-Dried Procedure, Single Sieve- 10.5.4 1 Subspecimen 12.6.2

nd

Set Sieving Percent Passing, 2 Coarser 12.6.2.1

Air-Dried Procedure, Composite 10.5.5 Portion

nd

Sieving 2 Coarser Portion, Composite 12.6.2.2

Oven-Dried Procedure, General 10.5.6 Sieving

nd

Oven-Dried Procedure, Single Sieve- 10.5.7 Correction Factor (2 CSCF)

nd

Set Sieving 2 Coarser Portion, Acceptable 12.6.2.3

Loss on

Oven-Dried Procedure, Composite 10.5.8

Sieving Sieving and Washing

nd

2 Coarser Portion, Acceptable 12.6.2.4

Procedure (Sieving) 11

General 11.1 Fractional

Percent Retained

Mass Measurements 11.2

Sieve Overloading 11.3 Percent Passing, Acceptance 12.6.2.5

Criterion

Single Sieve-Set Sieving 11.4

nd

Specimen Mass 11.4.1 2 Subspecimen 12.6.3

nd

Percent Passing, 2 Subspecimen 12.6.3.1

Specimen Dispersion 11.4.2

nd

Soaking without a Dispersant 11.4.2.1 2 Subspecimen, Acceptable 12.6.3.2

Fractional

Soaking with a Dispersant 11.4.2.2

Percent Retained

Using an Ultrasonic Water Bath 11.4.2.3

Percent Passing, Acceptance 12.6.3.3

Washing Specimen 11.4.3

Criterion

General Precautions 11.4.3.1

st

1 Finer Portion, Percent Passing 12.6.4

Transfer Specimen 11.4.3.2

(optional)

Washing 11.4.3.3

nd

Transfer Washed Specimen 11.4.3.4 2 Finer Portion, Composite 12.6.4.1

Sieving

Dry Sieving 11.4.4

Correction Factor (optional)

Sieve Set 11.4.4.1

nd

2 Finer Portion, Percent Passing 12.6.4.2

Mechanical Shaking 11.4.4.2

for

Cumulative Material/Mass Retained 11.4.5

nd

2 Subspecimen (optional)

First Sieve 11.4.5.1

Report: Test Data Sheet(s)/Form(s) 13

Remaining Sieves 11.4.5.2

Precision and Bias 14

Composite Sieving, Single Separation 11.5

Precision 14.1

Coarser Portion 11.5.1

Precision Data Analysis 14.1.1

Dispersing and Washing 11.5.1.1

Calculation of Precision 14.1.2

Dry Sieving Coarser Portion 11.5.1.3

Acceptance Criterion 14.1.2.4

Subspecimen from Finer Portion 11.5.2

Triplicate Test Precision Data (TTPD) 14.1.3

Dispersing and Washing 11.5.2.1

TTPD Method A Repeatability 14.1.3.1

Subspecimen

TTPD -Method A Reproducibility 14.1.3.2

Dry Sieving Subspecimen 11.5.2.2

TTPD -Method B Repeatability 14.1.3.3

Composite Sieving, Double Separation 11.6

st

TTPD -Method B Reproducibility 14.1.3.4

Separating 1 Subspecimen 11.6.1

nd

Single Test Precision Data (STPD) 14.1.4

Dispersing and Washing 2 Coarser 11.6.2

STPD -Method A Reproducibility 14.1.4.1

Portion

nd

STPD -Method B Reproducibility 14.1.4.2

Dry Sieving 2 Coarser Portion 11.6.3

nd

Soils Type 14.1.5

2 Subspecimen 11.6.4

nd

Discussion on Precision 14.1.6

Dispersing and Washing 2 11.6.4.1

Subspecimen Bias 14.2

nd

Keywords 15

Dry Sieving 2 Subspecimen 11.6.4.2

ANNEXES

Calculations 12

Symbols Annex A1

General 12.1

Sample to Specimen Splitting/Reduction Annex A2

Sieve Overloading 12.2

Methods

Single Sieve-Set Sieving, Percent 12.3

General A2.1

Passing

Mechanical Splitting A2.1.1

Composite Sieving, Mass of Specimen 12.4

Quartering A2.1.2

Composite Sieving, Single Separation 12.5

Composite Sieving, Coarser Portion 12.5.1 Miniature Stockpile Sampling A2.1.3

Sample Processing Recommendation A2.2

(CP)

Based

CP, Percent Passing 12.5.1.1

on Soil Type

CP, Composite Sieving Correction 12.5.1.2

Clean Gravel (GW, GP) and Clean A2.2.1

Factor (CSCF)

Sand

CP, Acceptable Loss During 12.5.1.3

(SW, SP)

Washing

Gravel with Fines (GM, GC, GC-GM, A2.2.2

and Sieving

GW-GM, GP-GM, GP-GC)

Composite Sieving, Subspecimen 12.5.2

(finer

portion)

D6913−04 (2009)

E691Practice for Conducting an Interlaboratory Study to

Sand with Silt Fines (SW-SM, SP- A2.2.3

SM,

Determine the Precision of a Test Method

SM)

Sand with Clay and Silt Fines or Clay A2.2.4

Fines (SW-SC, SP-SC, SC, SC- 3. Terminology

SM)

3.1 General:

Silts with Sand or Gravel, or Both A2.2.5

(ML,

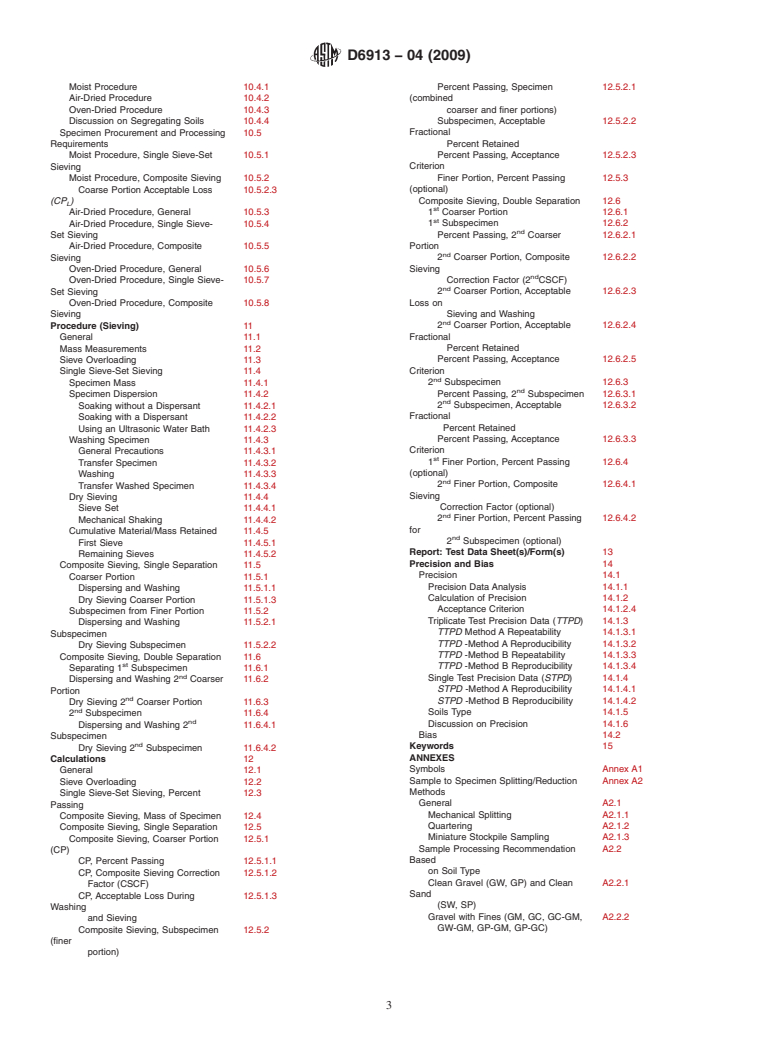

3.1.1 An overview of terms used in the sieving processes is

MH)

presented in Fig. 1(a) using a tabular format and in Fig. 1(b)

Organic Soils with Sand or Gravel, or A2.2.6

Both (OL, OH)

using a flowchart format. In addition, Fig. 1(a) includes

APPENDIXES

symbols used in the sieving processes.

Example Test Data Sheets/Forms Appendix X1

3.1.2 There are two types of definitions in the following

General X1.1

Precision: Example Calculations Appendix X2

sections. There are definitions that are general (see 3.2) and

General X2.1

others that are specific to this standard (see 3.3). To locate a

TABLES and FIGURES

definition, it may be necessary to review both sections. The

definitions are in alphabetical order.

2. Referenced Documents

3.2 Definitions:

2.1 AST

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.