ASTM D4067-03

(Classification)Standard Classification System for Reinforced and Filled Poly(Phenylene Sulfide) (PPS) Injection Molding and Extrusion Materials Using ASTM Methods

Standard Classification System for Reinforced and Filled Poly(Phenylene Sulfide) (PPS) Injection Molding and Extrusion Materials Using ASTM Methods

ABSTRACT

This classification system covers reinforced and filled poly(phenylene sulfide) (PPS) materials suitable for injection molding and extrusion. This classification system is not intended for the selection of materials, but only as a means to call out plastic materials to be used for the manufacture of parts. The physical properties of the materials must meet the required tensile strength, flexural modulus, Izod impact strength, flexural strength, and density.

SCOPE

1.1 This classification system covers reinforced and filled poly(phenylene sulfide) materials suitable for injection molding and extrusion.

1.2 This classification system is not intended for the selection of materials, but only as a means to call out plastic materials to be used for the manufacture of parts. The selection of these materials shall be made by personnel with expertise in the plastics field where the environment, inherent properties of the materials, performance of the parts, part design, manufacturing process, and economics are considered.

1.3 The properties included in this classification system are those required to identify the compositions covered. If necessary, other requirements identifying particular characteristics important to specific applications shall be designated by using the suffixes given in Section 5 or Classification System D 4000.

1.4 The values stated in SI units are to be regarded as the standard.

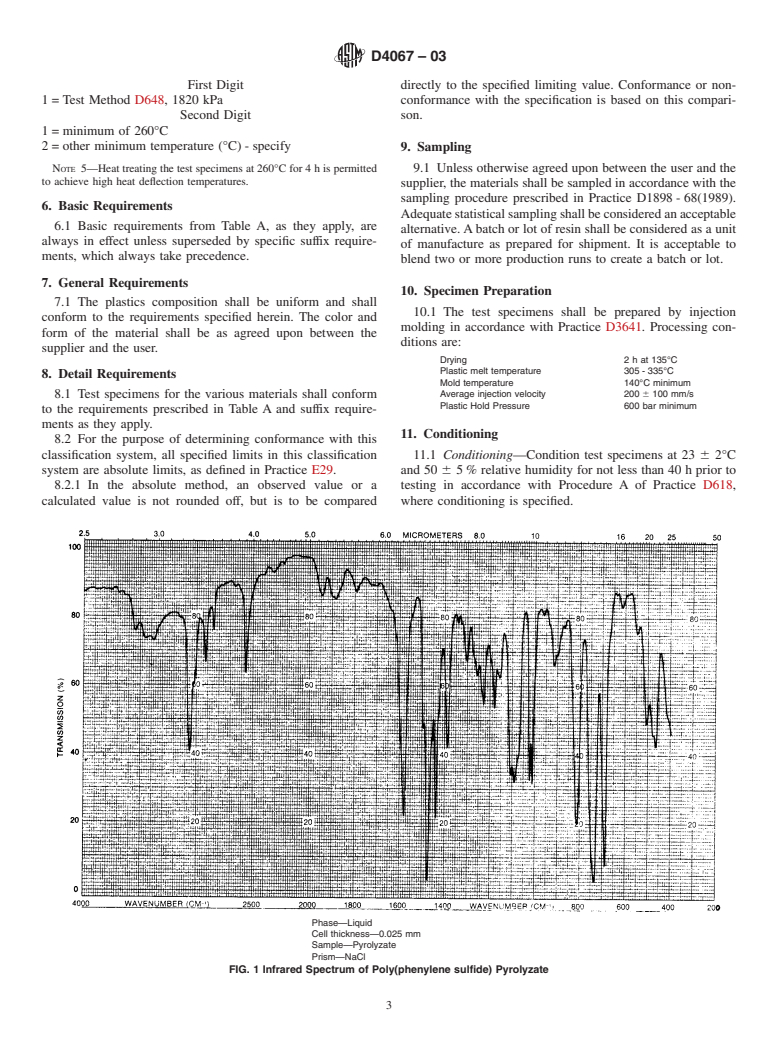

1.5 This precautionary statement pertains only to the test method portion of this classification system, Section 12. This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no known ISO equivalent to this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4067 – 03

Standard Classification System for

Reinforced and Filled Poly(Phenylene Sulfide) (PPS)

Injection Molding and Extrusion Materials Using ASTM

1

Methods

This standard is issued under the fixed designation D4067; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 This classification system covers reinforced and filled 2.1 ASTM Standards:

poly(phenylene sulfide) materials suitable for injection mold- D256 Test Methods for Determining the Izod Pendulum

ing and extrusion. Impact Resistance of Plastics

1.2 This classification system is not intended for the selec- D618 Practice for Conditioning Plastics for Testing

tion of materials, but only as a means to call out plastic D638 Test Method for Tensile Properties of Plastics

materials to be used for the manufacture of parts.The selection D648 Test Method for Deflection Temperature of Plastics

of these materials shall be made by personnel with expertise in Under Flexural Load in the Edgewise Position

the plastics field where the environment, inherent properties of D790 Test Methods for Flexural Properties of Unreinforced

the materials, performance of the parts, part design, manufac- and Reinforced Plastics and Electrical Insulating Materials

turing process, and economics are considered. D792 Test Methods for Density and Specific Gravity (Rela-

1.3 The properties included in this classification system are tive Density) of Plastics by Displacement

those required to identify the compositions covered. If neces- D883 Terminology Relating to Plastics

sary, other requirements identifying particular characteristics D1238 Test Method for Melt Flow Rates of Thermoplastics

important to specific applications shall be designated by using by Extrusion Plastometer

the suffixes given in Section 5 or Classification System D4000. D1600 Terminology for Abbreviated Terms Relating to

1.4 The values stated in SI units are to be regarded as the Plastics

standard. D3418 Test Method for Transition Temperatures and En-

1.5 This precautionary statement pertains only to the test thalpies of Fusion and Crystallization of Polymers by

method portion of this classification system, Section 12. This Differential Scanning Calorimetry

standard does not purport to address all of the safety concerns D3641 Practice for Injection Molding Test Specimens of

associated with its use. It is the responsibility of the user of this Thermoplastic Molding and Extrusion Materials

standard to establish appropriate safety and health practices D3835 Test Method for Determination of Properties of

and determine the applicability of regulatory limitations prior Polymeric Materials by Means of a Capillary Rheometer

to use. D3892 Practice for Packaging/Packing of Plastics

D4000 Classification System for Specifying Plastic Materi-

NOTE 1—There is no known ISO equivalent to this standard.

als

D5630 Test Method for Ash Content in Plastics

1

ThisclassificationsystemisunderthejurisdictionofASTMCommitteeD20on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

2

Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 10, 2003. Published November 2003. Originally contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

approved in 1982. Last previous edition approved in 1996 as D4067 – 96. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D4067-03. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4067 – 03

3

E29 Practice for Using Significant Digits in Test Data to 2.2 Military Standards:

Determine Conformance with Specifications MIL-P-46174 (MR) Plastic Molding Material, Polyphe-

E595 Test Method for Total Mass Loss and Collected nylene Sulfide, Glass Fiber Reinforced

Volatile Condensable Materials from Outgassing in a

Vacuum Environment

3

E662 Test Method for Specific Optical Density of Smoke

Available from Standardization Documents, Order Desk, Bldg. 4 Section D,

Generated by Solid Materials 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

TABLE A Physical Property Requirements

Designation Property/ASTM Test

Units0 1 23 456 7 8 9

Order Method

A BC D

1 Tensile strength, min D638 MPa 60 80 110 120 130 160 180 200

E BC D

2 Flexural modulus

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.