ASTM F1987-00a

(Specification)Standard Specification for Multilayer Pipe Type 2 , Compression Fittings, and Compression Joints for Hydronic Heating Systems

Standard Specification for Multilayer Pipe Type 2 , Compression Fittings, and Compression Joints for Hydronic Heating Systems

SCOPE

1.1 This specification covers requirements for multilayer pipe type 2 and compression fittings for hydronic heating systems, with a maximum pressure/temperature range of 1000 kPa (145 psi), at 82°C (180°F).

Note 1—Multilayer Pipe Type 2—Construction-based pressure rated pipe comprising more than one layer in which at least 60 % of the wall thickness is polymeric material.

1.2 Multilayer pipe type 2 is produced using a butt-welded aluminum pipe as a core, with an extruded inside layer of crosslinked polyethylene (PEX). An adhesive layer is used to bond the inside layer to the wall of the aluminum pipe. An outer layer of polyethylene (PE) and an adhesive layer are extruded to the outer wall of the aluminum pipe.

1.3 Multilayer pipe type 2 is produced in Configurations 1 and 2, as shown in Fig. 1.

1.4 This specification includes compression fittings, which are referenced in Fig. 2.

1.5 Specifications for threaded or solder adapters for use with pipe and fittings meeting the requirements of this specification are given in Annex A1 and Annex A2.

1.6 The following safety hazards caveat pertains only to the test method portion of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.7 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.Note 2—Multilayer pipe type 2, configurations 1 and 2, for hydronic heating systems are not compatible for drinking water use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: F 1987 – 00a

Standard Specification for

Multilayer Pipe Type 2, Compression Fittings, and

Compression Joints for Hydronic Heating Systems

This standard is issued under the fixed designation F 1987; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers requirements for multilayer

pipe type 2 and compression fittings for hydronic heating

systems, with a maximum pressure/temperature range of 1000

kPa (145 psi), at 82°C (180°F).

NOTE 1—Multilayer Pipe Type 2—Construction-based pressure rated

pipe comprising more than one layer in which at least 60 % of the wall

thickness is polymeric material.

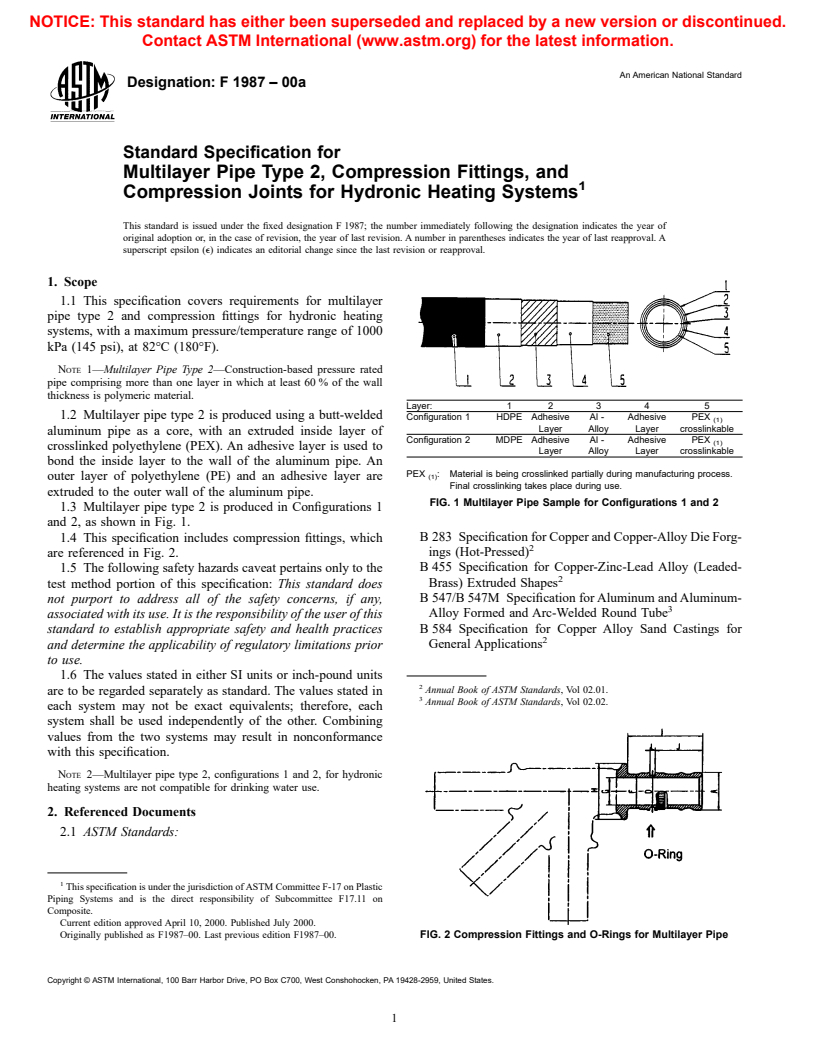

Layer: 1 2 3 4 5

1.2 Multilayer pipe type 2 is produced using a butt-welded

Configuration 1 HDPE Adhesive Al - Adhesive PEX

(1)

Layer Alloy Layer crosslinkable

aluminum pipe as a core, with an extruded inside layer of

Configuration 2 MDPE Adhesive Al - Adhesive PEX

(1)

crosslinked polyethylene (PEX). An adhesive layer is used to

Layer Alloy Layer crosslinkable

bond the inside layer to the wall of the aluminum pipe. An

PEX : Material is being crosslinked partially during manufacturing process.

(1)

outer layer of polyethylene (PE) and an adhesive layer are

Final crosslinking takes place during use.

extruded to the outer wall of the aluminum pipe.

FIG. 1 Multilayer Pipe Sample for Configurations 1 and 2

1.3 Multilayer pipe type 2 is produced in Configurations 1

and 2, as shown in Fig. 1.

B 283 Specification for Copper and Copper-Alloy Die Forg-

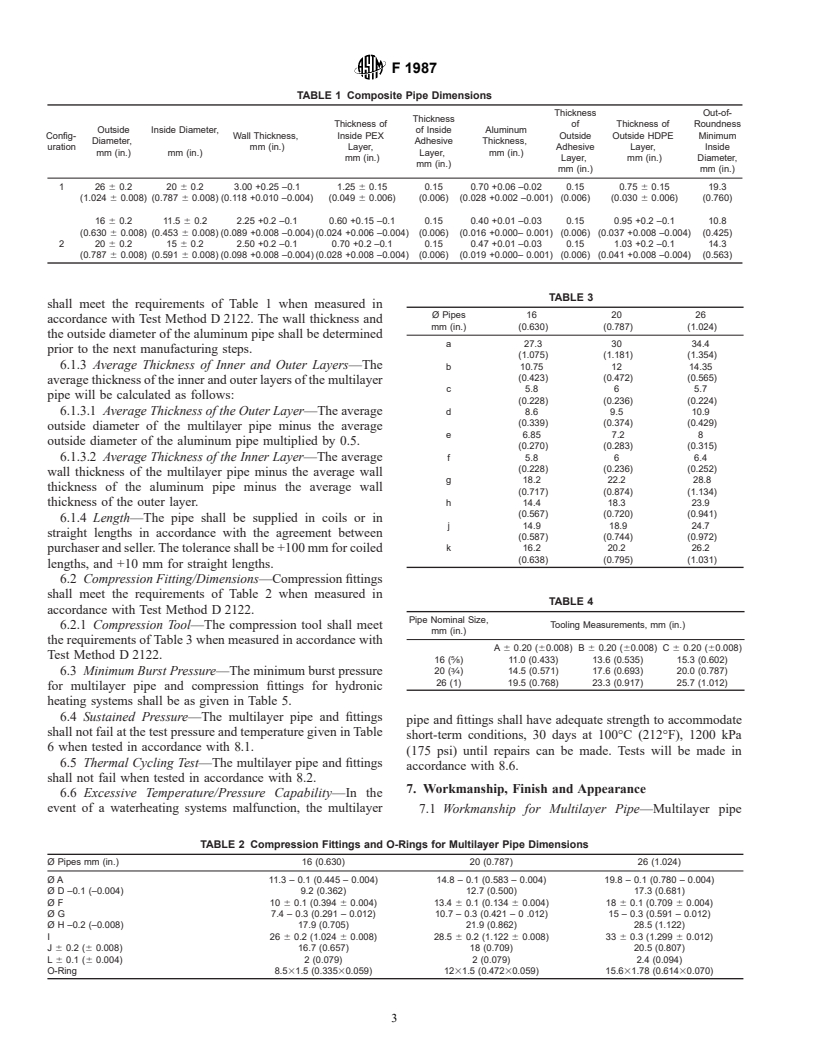

1.4 This specification includes compression fittings, which

are referenced in Fig. 2. ings (Hot-Pressed)

B 455 Specification for Copper-Zinc-Lead Alloy (Leaded-

1.5 The following safety hazards caveat pertains only to the

test method portion of this specification: This standard does Brass) Extruded Shapes

B 547/B 547M Specification for Aluminum and Aluminum-

not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this Alloy Formed and Arc-Welded Round Tube

B 584 Specification for Copper Alloy Sand Castings for

standard to establish appropriate safety and health practices

General Applications

and determine the applicability of regulatory limitations prior

to use.

1.6 The values stated in either SI units or inch-pound units

Annual Book of ASTM Standards, Vol 02.01.

are to be regarded separately as standard. The values stated in

Annual Book of ASTM Standards, Vol 02.02.

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

values from the two systems may result in nonconformance

with this specification.

NOTE 2—Multilayer pipe type 2, configurations 1 and 2, for hydronic

heating systems are not compatible for drinking water use.

2. Referenced Documents

2.1 ASTM Standards:

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.11 on

Composite.

Current edition approved April 10, 2000. Published July 2000.

Originally published as F1987–00. Last previous edition F1987–00. FIG. 2 Compression Fittings and O-Rings for Multilayer Pipe

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1987

D 618 Practice for Conditioning Plastics and Electrical 3.2.3 lot, n—all pipe of the same size produced from one

Insulating Materials for Testing extrusion line during one designated period.

D 1505 Test Method for Density of Plastics by the Density- 3.2.4 multilayer pipe—abbreviation used in this specifica-

Gradient Technique tion for multilayer pipe type 2.

D 1525 Test Method for Vicat Softening Temperature of

4 4. Classification

Plastics

4.1 Multilayer pipe and compression fittings produced un-

D 1598 Test Method for Time-to-Failure of Plastic Pipe

Under Constant Internal Pressure der this specification shall be suitable for hydronic heating

systems at specified pressure ratings and temperatures.

D 1600 Terminology for Abbreviated Terms Relating to

Plastics

4 5. Materials and Manufacture

D 1898 Practice for Sampling of Plastics

5.1 Specification for Material and Manufacture of Multi-

D 2122 Test Method for Determining Dimensions of Ther-

layer Pipe Configurations 1 and 2:

moplastic Pipe and Fittings

5.1.1 Polyethylene (PE), shall meet the requirement pro-

D 3222 Specification for Unmodified Poly(Vinylidene

vided in Specification D 3350 and shall equal or exceed a

Fluoride) (PVDF) Molding Extrusion and Coating Mate-

minimum cell classification of 234233 B or 345442 B. Color

rials

and form of the material shall be in accordance with the

D 3350 Specification for Polyethylene Plastics Pipe and

agreement between purchaser and supplier under Specification

Fittings Materials

D 3350.

D 5033 Guide for the Development of Standards Relating to

5.1.2 Crosslinked Polyethylene (PEX), shall equal or ex-

the Proper Use of Recycled Plastics

ceed a minimum cell classification 344543 A. Form of the

F 412 Terminology Relating to Plastic Piping Systems

material shall be in accordance with the agreement between

F 477 Specification for Elastomeric Seals (Gaskets) for

purchaser and supplier under Specification D 3350.

Joining Plastic Pipe

5.1.3 Adhesive Polymers, shall be modified low molecular

2.2 ISO Standard:

weight PE with a minimum density of 0.915 g/cm and

ISO 10508 Thermoplastics Pipe and Fittings for Hot and

different levels of comonomer for adhesion to aluminum and

Cold Water Systems

other substrates. The melting point shall not be less than 120°C

2.3 ARP Standard:

(248°F). Density shall be determined in accordance with Test

AS 568 A Aerospace Size Standard for O-Rings

Method D 1505 and melting point in accordance with Test

3. Terminology

Method D 1525.

3.1 Definitions—Definitions are in accordance with Termi- 5.1.4 Aluminum Pipe—Mechanical Properties—Minimum

nology F 412, and abbreviations are in accordance with Ter-

tensile strength shall be 80 MPa (11 600 psi), minimum

minology D 1600, unless otherwise specified. elongation shall be 22 % A5, in accordance with Test Method

3.1.1 crosslinkable polyethylene, n—plastic prepared by

B 547/B 547M.

crosslinking (curing) of PE compound partially during manu- 5.1.5 Reusable Material—Reusable material as defined in

facturing process and final crosslinking during use. Guide D 5033 issued from the multilayer pipe manufacturer

3.1.2 crosslinked polyethylene (PEX), n—plastic prepared shall be used for the outside coating of the multilayer pipe.

by crosslinking (curing) of polyethylene compound. 5.2 Specification for Material and Manufacture of Compres-

3.1.3 multilayer pipe type 2, n—pipe consisting of different sion Fittings for Multilayer Pipe:

materials with specific functional purpose to serve as pipe. 5.2.1 Compression fittings made from cast bronze shall

3.1.4 pressure ratings, PR, n—the maximum, continuous

meet the requirements of Specification B 584 UNS copper

water pressure at a specified temperature that is capable of alloy C 83600.

withstanding without failure.

5.2.2 Compression fittings made from brass shall meet the

3.2 Definitions of Terms Specific to This Standard: requirements of Specification B 455, copper alloy C 38500 or

3.2.1 adhesive, n—a low-molecular-weight PE that func-

Specification B 283 copper alloy C 37700.

tions as an adhesive layer and bonds the PEX to aluminum 5.2.3 Compression fittings made from plastic shall be injec-

pipe.

tion molded from virgin material and meet the requirements of

3.2.2 compression fittings for multilayer pipe, n—fittings Specification D 3222, Type II.

developed specially for multilayer pipe in which the aluminum

5.3 Material Specification for O-Rings—The O-ring mate-

core is used as compression sleeve to develop sufficient rial shall be EPDM, with a hardness of 70° IRHD, in

mechanical strength for the connection (see Fig. 2).

accordance with Specification F 477. O-ring dimensions shall

be in accordance with AS 568 A.

Annual Book of ASTM Standards, Vol 08.01.

6. Requirements

Annual Book of ASTM Standards, Vol 08.04.

6.1 Multilayer Pipe Dimensions:

Annual Book of ASTM Standards, Vol 08.02.

Annual Book of ASTM Standards, Vol 08.03.

6.1.1 Outside Diameter—The outside diameter shall meet

Available from American National Standards Institute, 11 West 42nd Street,

the requirements of Table 1, when measured in accordance

13th floor, New York, NY, 10036.

9 with Test Method D 2122.

Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Warrendale, PA 15096. 6.1.2 Wall Thickness—The wall thickness of composite pipe

F 1987

TABLE 1 Composite Pipe Dimensions

Thickness Out-of-

Thickness

Thickness of of Thickness of Roundness

Outside Inside Diameter, of Inside Aluminum

Config- Wall Thickness, Inside PEX Outside Outside HDPE Minimum

Diameter, Adhesive Thickness,

uration mm (in.) Layer, Adhesive Layer, Inside

mm (in.) mm (in.) Layer, mm (in.)

mm (in.) Layer, mm (in.) Diameter,

mm (in.)

mm (in.) mm (in.)

126 6 0.2 20 6 0.2 3.00 +0.25 –0.1 1.25 6 0.15 0.15 0.70 +0.06 –0.02 0.15 0.75 6 0.15 19.3

(1.024 6 0.008) (0.787 6 0.008) (0.118 +0.010 –0.004) (0.049 6 0.006) (0.006) (0.028 +0.002 –0.001) (0.006) (0.030 6 0.006) (0.760)

16 6 0.2 11.5 6 0.2 2.25 +0.2 –0.1 0.60 +0.15 –0.1 0.15 0.40 +0.01 –0.03 0.15 0.95 +0.2 –0.1 10.8

(0.630 6 0.008) (0.453 6 0.008) (0.089 +0.008 –0.004) (0.024 +0.006 –0.004) (0.006) (0.016 +0.000– 0.001) (0.006) (0.037 +0.008 –0.004) (0.425)

220 6 0.2 15 6 0.2 2.50 +0.2 –0.1 0.70 +0.2 –0.1 0.15 0.47 +0.01 –0.03 0.15 1.03 +0.2 –0.1 14.3

(0.787 6 0.008) (0.591 6 0.008) (0.098 +0.008 –0.004) (0.028 +0.008 –0.004) (0.006) (0.019 +0.000– 0.001) (0.006) (0.041 +0.008 –0.004) (0.563)

TABLE 3

shall meet the requirements of Table 1 when measured in

Ø Pipes 16 20 26

accordance with Test Method D 2122. The wall thickness and

mm (in.) (0.630) (0.787) (1.024)

the outside diameter of the aluminum pipe shall be determined

a 27.3 30 34.4

prior to the next manufacturing steps.

(1.075) (1.181) (1.354)

6.1.3 Average Thickness of Inner and Outer Layers—The

b 10.75 12 14.35

(0.423) (0.472) (0.565)

average thickness of the inner and outer layers of the multilayer

c 5.8 6 5.7

pipe will be calculated as follows:

(0.228) (0.236) (0.224)

6.1.3.1 Average Thickness of the Outer Layer—The average

d 8.6 9.5 10.9

(0.339) (0.374) (0.429)

outside diameter of the multilayer pipe minus the average

e 6.85 7.2 8

outside diameter of the aluminum pipe multiplied by 0.5.

(0.270) (0.283) (0.315)

6.1.3.2 Average Thickness of the Inner Layer—The average f 5.8 6 6.4

(0.228) (0.236) (0.252)

wall thickness of the multilayer pipe minus the average wall

g 18.2 22.2 28.8

thickness of the aluminum pipe minus the average wall

(0.717) (0.874) (1.134)

thickness of the outer layer. h 14.4 18.3 23.9

(0.567) (0.720) (0.941)

6.1.4 Length—The pipe shall be supplied in coils or in

j 14.9 18.9 24.7

straight lengths in accordance with the agreement between

(0.587) (0.744) (0.972)

k 16.2 20.2 26.2

purchaser and seller. The tolerance shall be +100 mm for coiled

(0.638) (0.795) (1.031)

lengths, and +10 mm for straight lengths.

6.2 Compression Fitting/Dimensions—Compression fittings

shall meet the requirements of Table 2 when measured in

TABLE 4

accordance with Test Method D 2122.

Pipe Nominal Size,

6.2.1 Compression Tool—The compression tool shall meet Tooling Measurements, mm (in.)

mm (in.)

the requirements of Table 3 when measured in accordance with

A 6 0.20 (60.008) B 6 0.20 (60.008) C 6 0.20 (60.008)

Test Method D 2122.

16 ( ⁄8) 11.0 (0.433) 13.6 (0.535) 15.3 (0.602)

20 ( ⁄4) 14.5 (0.571) 17.6 (0.693) 20.0 (0.787)

6.3 Minimum Burst Pressure—The minimum burst pressure

26 (1) 19.5 (0.768) 23.3 (0.917) 25.7 (1.012)

for multilayer pipe and compression fittings for hydronic

heating systems shall be as given in Table 5.

6.4 Sustained Pressure—The multilayer pipe and fittings

pipe and fittings shall have adequate strength to accommodate

shall not fail at the test pressure and temperature given in Table

short-term conditions, 30 days at 100°C (212°F), 1200 kPa

6 when tested in accordance with 8.1.

(175 psi) until repairs can be made. Tests will be made in

6.5 Thermal Cycling Test—The multilayer pipe and fittings

accordance with 8.6.

shall not fail when tested in accordance with 8.2.

7. Workmanship, Finish and Appearance

6.6 Excessive Temperature/Pressure Capability—In the

event of a waterheating systems malfunction, the multilayer 7.1 Workmanship for Multilayer Pipe—Multilayer pipe

TABLE 2 Compression Fittings and O-Rings for Multilayer Pipe Dimensions

Ø Pipes mm (in.) 16 (0.630) 20 (0.787) 26 (1.024)

Ø A 11.3 – 0.1 (0.445 – 0.004) 14.8 – 0.1 (0.583 – 0.004) 19.8 – 0.1 (0.780 – 0.004)

Ø D –0.1 (–0.004) 9.2 (0.362) 12.7 (0.500) 17.3 (0.681)

ØF 10 6 0.1 (0.394 6 0.004) 13.4 6 0.1 (0.134 6 0.004) 18 6 0.1 (0.709 6 0.004)

Ø G 7.4 – 0.3 (0.291 – 0.012) 10.7 – 0.3 (0.421 – 0 .012) 15 – 0.3 (0.591 – 0.012)

Ø H –0.2 (–0.008) 17.9 (0.705) 21.9 (0.862) 28.5 (1.122)

I26 6 0.2 (1.024 6 0.008) 28.5 6 0.2 (1.122 6 0.008) 33 6 0.3 (1.299 6 0.012)

J 6 0.2 (6 0.008) 16.7 (0.657) 18 (0.709) 20.5 (0.807)

L 6 0.1 (6 0.004) 2 (0.079) 2 (0.079) 2.4 (0.094)

O-Ring 8.531.5 (0.33530.059) 1231.5 (0.47230.059) 15.631.78 (0.61430.070)

F 1987

psi). Each cycle shall comprise 15 min of cold water at 20 6

2°C (68 6 3.6°F) and 15 min of hot water at 90 6 2°C (194

6 3.6°F).

8.3 Water Hammer Test—Multilayer pipe and fittings shall

not fail when subjected to 10 000 cycles. Tests shall be

performed at room temperature, pressure cycles alternating

between 100 6 50 kPa (14.51 6 7.25 psi) and 1500 6 50 kPa

(220 6 7.25 psi) at a rate of 30 6 5 per min. Test in accordance

with ISO 10508, referring to Fig. 5.

8.4 Delamination—Multilayer pipe shall not delaminate

when tested with the adapter tool, as described in Fig. 6. The

depth to which the adapter tool is to be inserted shall be

marked. No delamination of bond shall occur.

8.5 Fusion Line Test—The adapter tool has to be inserted

into the multilayer pipe to the indicated depth (see Fig. 6). No

visible damage shall occur on the fusion line or at any place of

the aluminum section.

FIG. 3 Compression Tools for Multilayer Pipes

8.6 Excessive Temperature/Pressure Capability—Test six

assemblies of multilayer pipe and fittings selected at random in

TABLE 5 Burst Pressure Test for Multilayer Pipe and

accordance with Test Method D 1598, except

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.