ASTM D7616/D7616M-11

(Test Method)Standard Test Method for Determining Apparent Overlap Splice Shear Strength Properties of Wet Lay-Up Fiber-Reinforced Polymer Matrix Composites Used for Strengthening Civil Structures

Standard Test Method for Determining Apparent Overlap Splice Shear Strength Properties of Wet Lay-Up Fiber-Reinforced Polymer Matrix Composites Used for Strengthening Civil Structures

SIGNIFICANCE AND USE

Overlap splices are used in field applications of FRP composites when site conditions prohibit continuous access to a structural element or when the specified length of the FRP composite is such that saturation and placement of the entire length would be cumbersome. This method can be used as a quality control mechanism for ensuring that overlap splices constructed under field conditions meet or exceed the requirements established by the design engineer or FRP system manufacturer. Both the saturant mixing and fiber saturation method can be verified for wet-layup FRP systems.

Caution is recommended when interpreting apparent shear strength results obtained from this method. Single shear lap splices develop non-uniform shear stress distributions within the overlap splice region during testing. Additional guidance on the interpretation and use of results obtained from lap shear testing is found in D4896.

This test method focuses on the FRP material itself, irrespective of gripping method. Therefore, strengths resulting from failure or pullout at either grip are disregarded. The strength measurements are based solely on test specimens that fail in the gage section (away from the grips) or at the splice.

SCOPE

1.1 This test method describes the requirements for sample preparation and tensile testing of single-lap shear splices formed with fiber-reinforced polymer (FRP) composite materials commonly used for strengthening of structures made of materials such as metals, timber, masonry, and reinforced concrete. The objective of this method is to determine the apparent shear strength of an overlap splice joint through the application of a far-field tensile force. The method applies to wet lay-up FRP material systems fabricated on site or in a laboratory setting. The FRP composite may be of either unidirectional (0°) or cross-ply (0/90 type) reinforcement. For cross-ply laminates, the construction may be achieved using multiple-layers of unidirectional fibers at either 0 or 90°, or one or more layers of stitched or woven 0/90 fabrics. The composite material forms are limited to continuous fiber or discontinuous fiber-reinforced composites in which the laminate is balanced and symmetric with respect to the test direction. The method is often used to determine the length of the overlap splice needed to ensure that a tension failure occurs in the material away from the splice rather than the splice connection itself.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.2.1 Within the text, the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7616/D7616M − 11

Standard Test Method for

Determining Apparent Overlap Splice Shear Strength

Properties of Wet Lay-Up Fiber-Reinforced Polymer Matrix

Composites Used for Strengthening Civil Structures

This standard is issued under the fixed designation D7616/D7616M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method describes the requirements for sample 2.1 ASTM Standards:

preparation and tensile testing of single-lap shear splices D883Terminology Relating to Plastics

formed with fiber-reinforced polymer (FRP) composite mate- D3039/D3039MTest Method forTensile Properties of Poly-

rials commonly used for strengthening of structures made of mer Matrix Composite Materials

materials such as metals, timber, masonry, and reinforced D3878Terminology for Composite Materials

concrete. The objective of this method is to determine the D4896Guide for Use ofAdhesive-Bonded Single Lap-Joint

apparent shear strength of an overlap splice joint through the Specimen Test Results

application of a far-field tensile force. The method applies to D5229/D5229MTestMethodforMoistureAbsorptionProp-

wet lay-up FRP material systems fabricated on site or in a erties and Equilibrium Conditioning of Polymer Matrix

laboratory setting. The FRP composite may be of either Composite Materials

unidirectional (0°) or cross-ply (0/90 type) reinforcement. For D5687/D5687MGuide for Preparation of Flat Composite

cross-ply laminates, the construction may be achieved using Panels with Processing Guidelines for Specimen Prepara-

multiple-layersofunidirectionalfibersateither0or90°,orone tion

or more layers of stitched or woven 0/90 fabrics. The compos- D7565/D7565MTest Method for DeterminingTensile Prop-

ite material forms are limited to continuous fiber or discon- erties of Fiber Reinforced Polymer Matrix Composites

tinuous fiber-reinforced composites in which the laminate is Used for Strengthening of Civil Structures

balanced and symmetric with respect to the test direction. The E6Terminology Relating to Methods of Mechanical Testing

method is often used to determine the length of the overlap E122PracticeforCalculatingSampleSizetoEstimate,With

splice needed to ensure that a tension failure occurs in the Specified Precision, the Average for a Characteristic of a

material away from the splice rather than the splice connection Lot or Process

itself. E177Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.2 The values stated in either SI units or inch-pound units

E456Terminology Relating to Quality and Statistics

are to be regarded separately as standard. The values stated in

2.2 Other Standards:

each system may not be exact equivalents; therefore, each

DOT/FAA/AR-01/33InvestigationofThickBondlineAdhe-

system shall be used independently of the other. Combining

sive Joints, June 2001

values from the two systems may result in non-conformance

DOT/FAA/AR-02/97Shear Stress-Strain Data for Structural

with the standard.

Adhesives, November 2002

1.2.1 Within the text, the inch-pound units are shown in

brackets.

3. Terminology

1.3 This standard does not purport to address all of the

3.1 Definitions—Terminology D3878 defines terms relating

safety concerns, if any, associated with its use. It is the

to high-modulus fibers and their composites. Terminology

responsibility of the user of this standard to establish appro-

D883definestermsrelatingtoplastics.TerminologyE6defines

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This test method is under the jurisdiction of ASTM Committee D30 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Composite Materials and is the direct responsibility of Subcommittee D30.10 on Standards volume information, refer to the standard’s Document Summary page on

Composites for Civil Structures. the ASTM website.

Current edition approved March 1, 2011. Published May 2011. DOI: 10.1520/ Available at the Federal Aviation Administration William J. Hughes Technical

D7616_D7616M-11. Center Full-Text Technical Reports page: http://207.67.203.68/F10011.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7616/D7616M − 11

terms relating to mechanical testing. Terminology E456 and testing in single shear, two thin, flat strips of material having a

Practice E177 define terms relating to statistics. In the event of nominally constant cross section are joined together with a

a conflict between terms, Terminology D3878 shall have specified overlap and allowed to cure. The cured specimen is

precedence over the other standards. mounted in the grips of a mechanical testing machine and

monotonically loaded in tension while force is recorded. The

3.2 Definitions of Terms Specific to This Standard:

following items are reported for each specimen: ultimate force

3.2.1 nominal value, n—a value, existing in name only,

atfailure,failuremode,andtheapparentshearstrengthperunit

assigned to a measurable property for the purpose of conve-

width at failure.

nient designation. Tolerances may be applied to a nominal

value to define an acceptable range for the property.

5. Significance and Use

3.2.2 screed, v—to move a flat rule along the top of a

5.1 Overlap splices are used in field applications of FRP

saturated laminate to level the top of the laminate and

composites when site conditions prohibit continuous access to

simultaneously remove excess resin.

a structural element or when the specified length of the FRP

3.2.3 wet lay-up FRP composite, n—an FRP composite

composite is such that saturation and placement of the entire

material fabricated by manually impregnating dry fibers with a

length would be cumbersome. This method can be used as a

matrix of polymeric resin. Semi-automated processes such as

quality control mechanism for ensuring that overlap splices

machine-aided wetting of fabrics before placement or vacuum

constructed under field conditions meet or exceed the require-

aidedimpregnationoflaminatesafterplacementareconsidered

ments established by the design engineer or FRP system

part of wet lay-up FRP. For civil infrastructure strengthening

manufacturer. Both the saturant mixing and fiber saturation

applications,thedegreeofcontroloverthevolumefractionsof

method can be verified for wet-layup FRP systems.

fibers, matrix, and voids as well as the overall cross-sectional

5.2 Caution is recommended when interpreting apparent

geometry in wet lay-up FRP composites may be less than that

shear strength results obtained from this method. Single shear

for shop manufactured FRP composites on account of the

lap splices develop non-uniform shear stress distributions

manual process. For strengthening applications, wet lay-up

within the overlap splice region during testing. Additional

FRP composites are typically applied to the substrate at the

guidance on the interpretation and use of results obtained from

sametimethedryfiberisimpregnated.Theimpregnatingresin

lap shear testing is found in D4896.

may act as the saturant for the FRP composite as well as the

bonding agent between the composite reinforcement and the

5.3 This test method focuses on the FRP material itself,

substrate. Wet lay-up specimens may be fabricated in either a

irrespective of gripping method. Therefore, strengths resulting

field or a laboratory setting.

from failure or pullout at either grip are disregarded. The

strength measurements are based solely on test specimens that

3.3 Symbols:

fail in the gage section (away from the grips) or at the splice.

3.3.1 F*—strength of FRP laminate per unit width.

3.3.2 h —laminate thickness measured outside of the over-

6. Interferences

lap splice on the bottom (flat) laminate.

6.1 A summary of the interferences, specifically material

3.3.3 h —laminate thickness measured outside of the over-

and specimen preparation, gripping, system alignment, and

lap splice on the top (kinked) laminate.

edge effects in cross-ply laminates, are presented in D3039/

3.3.4 h —laminate thickness measured within the overlap

D3039M.

splice region.

6.2 Additional interferences may arise from lack of control

3.3.5 h' —the reference thickness of a fiber, fabric or

in wet lay-up specimen preparation procedures outlined in

preform layer without resin, measured outside of the overlap

8.3.1. Specimen variations in resin content, ply thickness, void

splice.

content and degree of cure may contribute to variability in test

3.3.6 L—entire length of the overlap splice specimen in-

results.

cluding the portion dedicated to gripping.

6.3 Construction of single lap-splice samples using wet-lay

3.3.7 L'—length of the overlap splice region

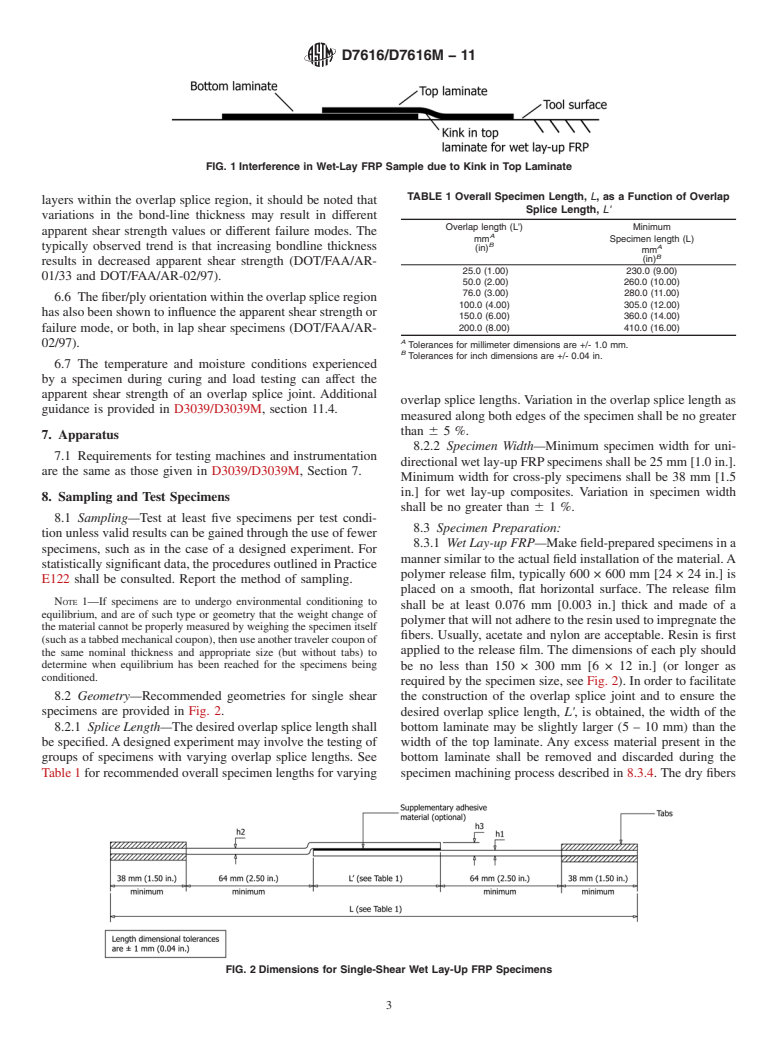

FRP will result in kinked fibers for the top laminate (see Fig.

1). The effects of this kink on lap shear results will be

3.3.8 n—number of specimens.

magnified as the thickness, h and h , of the FRP increases.

1 2

3.3.9 P—force carried by test specimen.

This kink may also result in laminate failure outside the region

max

3.3.10 P —maximum tensile force.

ofthebondlineandtheseverityofthekinkcanimpartmoment

3.3.11 w—coupon width. loading to the bonded joint.

3.3.12 V*—apparent shear strength of the overlap splice per

6.4 Overlapsplicelength, L’,isidentifiedinD4896,section

unit width for the L' under consideration.

5.3.2 as a geometric parameter which affects apparent shear

strength properties obtained from overlap splice tests. The

4. Summary of Test Method

resultsobtainedusingthistestmethodarevalidexclusivelyfor

the overlap splice length under consideration.

4.1 Overlap splice specimens are prepared using a wet

lay-up procedure. Wet lay-up material may be prepared in a 6.5 If a supplementary adhesive material (e.g., thickened

laboratory or field setting, as the testing objectives dictate. For epoxy tack coat) is used to promote bond between composite

D7616/D7616M − 11

FIG. 1 Interference in Wet-Lay FRP Sample due to Kink in Top Laminate

TABLE 1 Overall Specimen Length, L, as a Function of Overlap

layers within the overlap splice region, it should be noted that

Splice Length, L'

variations in the bond-line thickness may result in different

Overlap length (L') Minimum

apparent shear strength values or different failure modes. The

A

mm Specimen length (L)

B

typically observed trend is that increasing bondline thickness A

(in)

mm

B

(in)

results in decreased apparent shear strength (DOT/FAA/AR-

25.0 (1.00) 230.0 (9.00)

01/33 and DOT/FAA/AR-02/97).

50.0 (2.00) 260.0 (10.00)

76.0 (3.00) 280.0 (11.00)

6.6 Thefiber/plyorientationwithintheoverlapspliceregion

100.0 (4.00) 305.0 (12.00)

hasalsobeenshowntoinfluencetheapparentshearstrengthor

150.0 (6.00) 360.0 (14.00)

200.0 (8.00) 410.0 (16.00)

failure mode, or both, in lap shear specimens (DOT/FAA/AR-

A

02/97).

Tolerances for millimeter dimensions are +/- 1.0 mm.

B

Tolerances for inch dimensions are +/- 0.04 in.

6.7 The temperature and moisture conditions experienced

by a specimen during curing and load testing can affect the

apparent shear strength of an overlap splice joint. Additional

overlap splice lengths.Variation in the overlap splice length as

guidance is provided in D3039/D3039M, section 11.4.

measured along both edges of the specimen shall be no greater

than 65%.

7. Apparatus

8.2.2 Specimen Width—Minimum specimen width for uni-

7.1 Requirements for testing machines and instrumentation

directionalwetlay-upFRPspecimensshallbe25mm[1.0in.].

are the same as those given in D3039/D3039M, Section 7.

Minimum width for cross-ply specimens shall be 38 mm [1.5

in.] for wet lay-up composites. Variation in specimen width

8. Sampling and Test Specimens

shall be no greater than 61%.

8.1 Sampling—Test at least five specimens per test condi-

8.3 Specimen Preparation:

tionunlessvalidresultscanbegainedthroughtheuseoffewer

8.3.1 Wet Lay-up FRP—Makefield-preparedspecimensina

specimens, such as in the case of a designed experiment. For

mannersimilartotheactualfieldinstallationofthematerial.A

statisticallysignificantdata,theproceduresoutlinedinPractice

polymer release film, typically 600 × 600 mm [24 × 24 in.] is

E122 shall be consulted. Report the method of sampling.

placed on a smooth, flat horizontal surface. The release film

NOTE 1—If specimens are to undergo environmental conditioning to

shall be at least 0.076 mm [0.003 in.] thick and made of a

equilibrium, and are of such type or geometry that the weight change of

polymerthatwillnotadheretotheresinusedtoimpregnatethe

the material cannot be properly measured by weighing the specimen itself

fibers. Usually, acetate and nylon are acceptable. Resin is first

(suchasatabbedmechanicalcoupon),thenuseanothertravelercouponof

applied to the release film. The dimensions of each ply should

the same nominal thickness and appropriate size (but without tabs) to

determine when equilibrium has been reached for the specimens being

be no less than 150 × 300 mm [6 × 12 in.] (or longer as

conditioned.

required by the specimen size, see Fig. 2). In order to facilitate

8.2 Geometry—Recommended geometries for single shear the construction of the overlap splice joint and to ensure the

specimens are provided in Fig. 2. desired overlap splice length, L', is obtained, the width of the

8.2.1 Splice Length—Thedesiredoverlapsplicelengthshall bottom laminate may be slightly larger (5 – 10 mm) than the

be specified.Adesigned experiment may involve the testing of width of the top laminate. Any excess material present in the

groups of specimens with varying overlap splice lengths. See bottom laminate shall be removed and discarded during the

Table1forrecommendedoverallspecimenlengthsforvarying specimen machining process described in 8.3.4. The dry fibers

FIG. 2 Dimensions for Single-Shear Wet Lay-Up FRP Specimens

D7616/D7616M − 11

are saturated or coated with the specified amount of resin and 8.3.4 Machining Methods—Specimen preparation is ex-

placed on the release film. This can be done using a properly tremely important for this test method. If specimens are cut

calibrated saturator machine or using a manufacturer-specified from plates, take precautions to avoid notches, undercuts,

fiber to resin weight ratio. The specified number of plies at the rough or uneven surfaces, or delaminations caused by inappro-

priate machining methods. Obtain final dimensions by water-

specifiedangles(

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.