ASTM D6611-00

(Test Method)Standard Test Method for Wet and Dry Yarn-on-Yarn Abrasion Resistance

Standard Test Method for Wet and Dry Yarn-on-Yarn Abrasion Resistance

SIGNIFICANCE AND USE

This test method is intended for testing dry and wet abrasion resistance of manufactured fiber yarns. This test method is especially useful for ropes intended for use in the marine environment. The test method has been used with yarns having linear densities ranging from 70 to 300 tex, but may be used with yarns outside these ranges.

Limited interlaboratory correlation testing has been conducted to date. Single-laboratory testing, in accordance with ASTM practices, has now been conducted. Additional interlaboratory testing, in accordance with ASTM practices, will be conducted after approval of a definitive test method. Test results should be used with caution pending completion of interlaboratory testing.

This test method is not recommended for acceptance testing of commercial shipments in the absence of reliable information on between-laboratory precision.

If there are differences of practical significance between reported test results for two or more laboratories, comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum the test samples used should be as homogeneous as possible, be drawn from the material from which the disparate test results were obtained, and be randomly assigned in equal numbers to each laboratory for testing. Other materials with established test values may be used for this purpose. The test results from the two or more laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to testing. If a bias is found, either its cause must be found and corrected, or future test results must be adjusted in consideration of the known bias.

This test method is conducted at one or several applied tensions that may depend upon the yarn material and size. The number and magnitudes of applied tensions and the number of eight specimen sets generally are agreed upon in a material specification or contract order...

SCOPE

1.1 This test method describes the measurement of abrasion resistance properties for manufactured fiber yarns in dry and wet conditions.

1.2 This test method applies to manufactured yarns used in rope making.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6611–00

Standard Test Method for

Wet and Dry Yarn-on-Yarn Abrasion Resistance

This standard is issued under the fixed designation D6611; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope effects. The tension at any point in the interwrapped yarn

regionandatanytimemaydiffersubstantiallyfromtheapplied

1.1 This test method describes the measurement of abrasion

tension but is a function of that applied tension.

resistance properties for manufactured fiber yarns in dry and

3.1.4 cycles to failure, CTF, n—inyarnabrasiontesting,the

wet conditions.

number of cycles applied to the yarn before it fails due to

1.2 This test method applies to manufactured yarns used in

abrasion.

rope making.

3.1.4.1 Discussion—Failureisconsideredtooccurwhenthe

1.3 The values stated in SI units are to be regarded as

yarn is completely separated.

standard. The values given in parentheses are provided for

3.1.5 dry, adj—the state of a yarn which has not been

information only.

exposed to excessive moisture.

1.4 This standard does not purport to address all of the

3.1.6 rope, n—a compact and flexible, generally torsionally

safety concerns, if any, associated with its use. It is the

balanced continuous structure, greater than 4-mm ( ⁄32-in.)

responsibility of the user of this standard to establish appro-

diameter, capable of applying or transmitting tension between

priate safety and health practices and determine the applica-

two points.

bility of regulatory limitations prior to use.

3.1.7 wet, adj—the state of a yarn which has been exposed

2. Referenced Documents to excessive moisture.

3.2 For definitions of other textile terms used in this test

2.1 ASTM Standards:

method, refer to Terminology D123.

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning Textiles for Testing

4. Summary of Test Method

D2904 PracticeforInterlaboratoryTestingofaTextileTest

4.1 A length of yarn is interwrapped in contact with itself

Method that Produces Normally Distributed Data

betweenthreepulleysthatarepositionedinadefinedgeometry

3. Terminology

toproduceaspecificintersectionangle.Aweightisattachedto

oneendoftheyarntoapplyaprescribedtension.Theotherend

3.1 Definitions:

is drawn back and forth through a defined stroke at a defined

3.1.1 abrasion, n—the wearing away of any part of a

speed until the yarn fails due to abrasion upon itself within the

material by rubbing against another surface.

interwrapped region. The yarn abrasion test can be conducted

3.1.2 apex angle, n—the angle formed between the incom-

in either the dry state or the wet state.

ing and outgoing yarn at the top (and bottom) of the inter-

wrapped yarn area in the static condition (see Annex A1).

5. Significance and Use

3.1.2.1 Discussion—In yarn abrasion testing, the state of a

5.1 This test method is intended for testing dry and wet

yarn, which has been soaked for a prescribed period of time in

abrasion resistance of manufactured fiber yarns. This test

water before testing and then immersed in water during the

method is especially useful for ropes intended for use in the

abrasion test.

marineenvironment.Thetestmethodhasbeenusedwithyarns

3.1.3 applied tension, n—in yarn abrasion testing, the static

having linear densities ranging from 70 to 300 tex, but may be

tension exerted on the weighted end of the yarn by the applied

used with yarns outside these ranges.

weight.

5.2 Limited interlaboratory correlation testing has been

3.1.3.1 Discussion—Tension in the yarn varies along its

conducted to date. Single-laboratory testing, in accordance

length during each cycle because of friction and dynamic

with ASTM practices, has now been conducted. Additional

interlaboratory testing, in accordance with ASTM practices,

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextiles

will be conducted after approval of a definitive test method.

and is the direct responsibility of Subcommittee D13.16 on Rope and Cordage.

Testresultsshouldbeusedwithcautionpendingcompletionof

Current edition approved Nov. 10, 2000. Published February 2001.

interlaboratory testing.

Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6611–00

5.3 This test method is not recommended for acceptance 10.8 radians (34°). Other spacings may be used which produce

testing of commercial shipments in the absence of reliable the same apex angle, when analyzed by the procedure given in

information on between-laboratory precision. Annex A1.

5.4 If there are differences of practical significance between 6.4 Wet Testing Arrangement—For wet testing, the lower

reported test results for two or more laboratories, comparative pulleyisplacedonabarextendingdownfromasupportframe,

tests should be performed to determine if there is a statistical such that a beaker of water can be placed around it to immerse

bias between them, using competent statistical assistance.As a the interwrapped portion of the yarn. The lower pulley has a

minimum the test samples used should be as homogeneous as bushing-type bearing suitable for prolonged service immersed

possible, be drawn from the material from which the disparate in water.

test results were obtained, and be randomly assigned in equal 6.5 Drive Motor—An eccentric crank driven by a gear

numbers to each laboratory for testing. Other materials with motor is arranged in alignment with one of the upper pulleys.

established test values may be used for this purpose. The test The crank is offset by 25 6 2 mm from the drive motor shaft

results from the two or more laboratories should be compared to create a yarn stroke of 50 6 4 mm. The gear motor drives

using a statistical test for unpaired data, at a probability level the crank at between 60 and 70 revolutions/min. Other drive

chosen prior to testing. If a bias is found, either its cause must arrangements, which accomplish the specified stroke and drive

be found and corrected, or future test results must be adjusted speed may alternatively be used.

in consideration of the known bias. 6.6 Multi-Station Tester—Several test stations may be ar-

5.5 This test method is conducted at one or several applied ranged on a support frame and driven by the same motor.

tensions that may depend upon the yarn material and size.The 6.7 Cycle Counter Arrangement—A means of counting the

number and magnitudes of applied tensions and the number of number of yarn abrasion strokes to failure is provided. This

eight specimen sets generally are agreed upon in a material may be a counter directly connected to the drive motor or a

specification or contract order. Guidance on determining the counter, which is indexed by each revolution of the crank or

appropriate number and magnitudes of applied tensions is directly by each stroke of the yarn. This counter is arranged to

given in Annex A2. stopcountingwhentheyarnbreaksandtoretainacountofthe

numberofstrokesuntilitisreset.Formultistationtesters,such

6. Apparatus

a counter is provided for each yarn station.

6.8 Yarn Twist Control—If the yarn has pronounced twist,

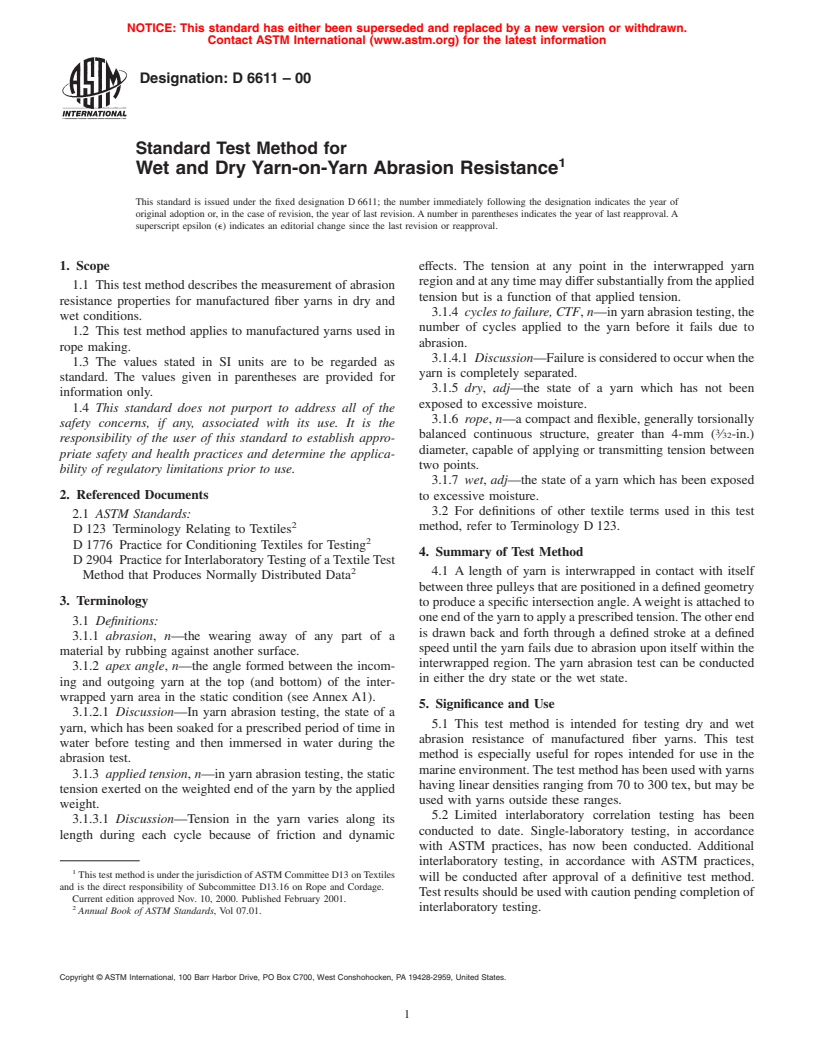

6.1 The Yarn-on-Yarn Abrasion Test Apparatus is shown

or if the yarn tends to twist or untwist during testing, a means

schematically in Fig. 1 and consists of the following:

should be provided to control yarn twist, such as an extension

6.2 Yarn Guide Pulleys—Three pulleys are arranged on a

arm on the applied weight which follows a guide.

vertical frame with the centerline spacing indicated.All of the

pulleys have the same diameter. The pulleys have low-friction

7. Sampling and Test Specimens

bearings.

6.3 Arrangement of Guide Pulleys—The upper pulley cen- 7.1 Primary Sampling Unit—Consider spools or beams to

terlines are separated by 140 6 2 mm. The lower pulley be the primary sampling unit.

centerline is 254 6 2 mm below a line connecting the upper 7.2 Laboratory Sampling Unit—As a laboratory sampling

pulleycenterlines.Thisarrangementproducesanapexangleof unit take from the primary sampling unit a total length of yarn

FIG. 1 General Arrangement of the Yarn-on-Yarn Abrasion Test Apparatus

D6611–00

that will provide eight test specimens for each of the applied yarn mounted on the test machine prior to beginning testing. If

tensions as determined in Annex A2. a separate bath is used, care must be taken to avoid damaging

7.2.1 Determinethespecimenlengthsufficienttoaccommo- the yarn while mounting the yarn for testing.

datethedistanceneededtosecuretheyarntothetestapparatus

NOTE 1—The yarn test specification may give a different soak time for

motorcrank,throughthepulleyarrangementandtotheapplied

testing, with agreement of the interested parties. The yarn should not be

weight,allowingformovementofthecrankandweightduring

soaked for more than the specified time, as the abrasion resistance

the test.Add to this a suitable allowance for the length needed

properties of some yarns is sensitive to the length of soak.

to attach the yarn to the crank and to the weight.

9. Procedure

7.2.2 Determine the number and magnitudes of applied

tensions as directed in Annex A2.

9.1 Handle the test specimen carefully to avoid altering the

7.2.3 Remove sufficient yarn from the primary sample prior

natural state of the yarn, including the level of twist.

to taking the laboratory sample to assure the test yarn has not

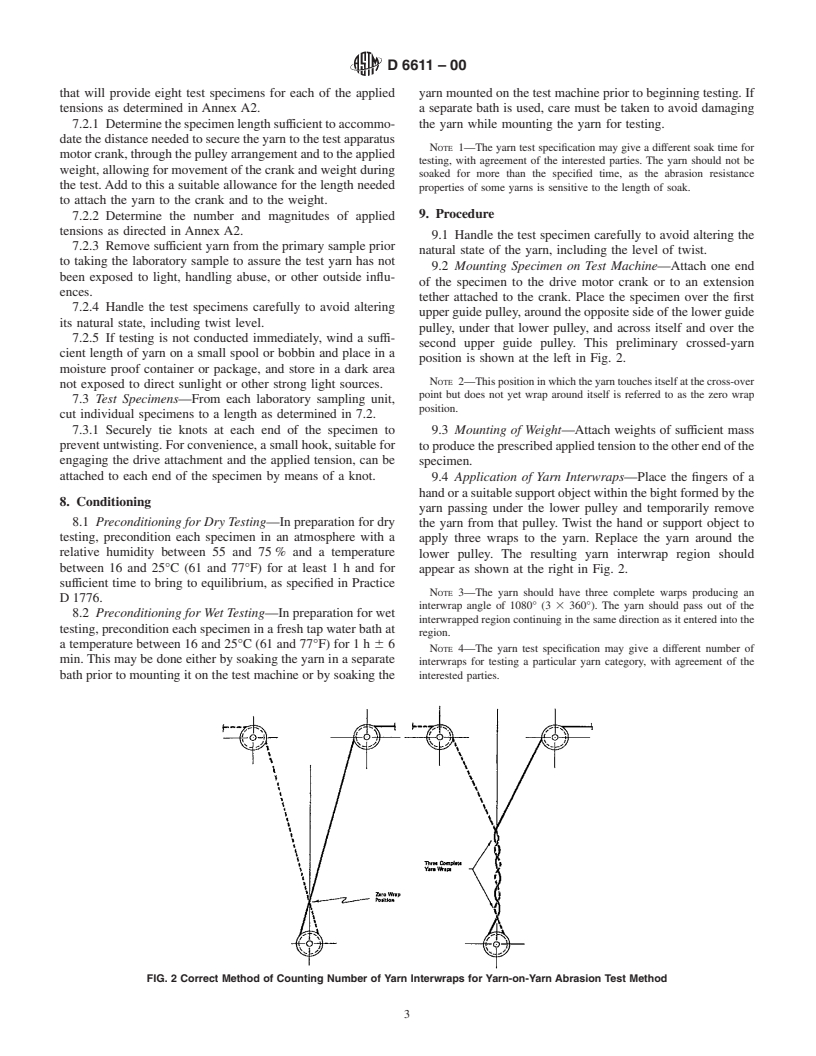

9.2 Mounting Specimen on Test Machine—Attach one end

been exposed to light, handling abuse, or other outside influ-

of the specimen to the drive motor crank or to an extension

ences.

tether attached to the crank. Place the specimen over the first

7.2.4 Handle the test specimens carefully to avoid altering

upperguidepulley,aroundtheoppositesideofthelowerguide

its natural state, including twist level.

pulley, under that lower pulley, and across itself and over the

7.2.5 If testing is not conducted immediately, wind a suffi-

second upper guide pulley. This preliminary crossed-yarn

cient length of yarn on a small spool or bobbin and place in a

position is shown at the left in Fig. 2.

moisture proof container or package, and store in a dark area

NOTE 2—Thispositioninwhichtheyarntouchesitselfatthecross-over

not exposed to direct sunlight or other strong light sources.

point but does not yet wrap around itself is referred to as the zero wrap

7.3 Test Specimens—From each laboratory sampling unit,

position.

cut individual specimens to a length as determined in 7.2.

7.3.1 Securely tie knots at each end of the specimen to 9.3 Mounting of Weight—Attach weights of sufficient mass

preventuntwisting.Forconvenience,asmallhook,suitablefor

toproducetheprescribedappliedtensiontotheotherendofthe

engaging the drive attachment and the applied tension, can be specimen.

attached to each end of the specimen by means of a knot.

9.4 Application of Yarn Interwraps—Place the fingers of a

handorasuitablesupportobjectwithinthebightformedbythe

8. Conditioning

yarn passing under the lower pulley and temporarily remove

8.1 Preconditioning for Dry Testing—In preparation for dry

the yarn from that pulley. Twist the hand or support object to

testing, precondition each specimen in an atmosphere with a

apply three wraps to the yarn. Replace the yarn around the

relative humidity between 55 and 75% and a temperature

lower pulley. The resulting yarn interwrap region should

between 16 and 25°C (61 and 77°F) for at least 1 h and for

appear as shown at the right in Fig. 2.

sufficient time to bring to equilibrium, as specified in Practice

NOTE 3—The yarn should have three complete warps producing an

D1776.

interwrap angle of 1080° (3 3 360°). The yarn should pass out of the

8.2 Preconditioning for Wet Testing—In preparation for wet

interwrappedregioncontinuinginthesamedirectionasitenteredintothe

testing,preconditioneachspecimeninafreshtapwaterbathat

region.

a temperature between 16 and 25°C (61 and 77°F) for 1 h 6 6

NOTE 4—The yarn test specification may give a different number of

min.This may be done either by soaking the yarn in a separate

interwraps for testing a particular yarn category, with agreement of the

bath prior to mounting it on the test machine or by soaking the interested parties.

FIG. 2 Correct Method of Counting Number of Yarn Interwraps for Yarn-on-Yarn Abrasion Test Method

D6611–00

9.4.1 Relation of Direction of Twist to Direction of 11. Report

Interwrap—If the yarn has a pronounced twist, the interwrap

11.1 Report that the yarn-on-yarn abrasion resistance was

should be applied in the same direction as the twist, unless the

determined as directed in Test Method D6611.

yarn test specification gives different instructions.

11.2 Report the following information for the laboratory

9.5 Dry Testing—For dry testing, conduct the test in an

sampling unit and for the lot as applicable to a material

atmosphere with a relative humidity between 55 and 75% and

specification or contract order:

a temperature between 16 and 25°C (61 and 77°F).

11.2.1 Descriptionofspecimens,thatis,yarnmaterial,type,

9.6 Wet Testing—Forwettesting,placeabeakeroffreshtap

source, size, tenacity, etc.

water at a temperature of between 16 and 25°C (61 and 77°F)

11.2.2 Condition of Specimens, wet or dry, including soak

around the yarn such that the interwrapped region of the yarn

time if this differed from above specified value.

is completely immersed.

11.2.3 Appliedtension,inmN/tex(g/denier)foreachseries.

9.7 Start of Test—Reset the counter(s) to zero. Start the

11.2.4 Mean cycles to failure, M at each applied tension.

drive motor.

11.2.5 Ln standard deviation of cycles to failure, Ln s at

9.8 ConductofTest—Carryoutthetestuntiltheyarn(s)fails

each applied tension.

due to interyarn abrasion at the applied tension.

11.3 If testing was conducted at more than two applied

9.9 Conclusion of Test—After the yarn(s) fails, shut off the

tensions, plot and report the following information:

drive motor. Record the number(s) of Cycles to Failure (CTF)

11.3.1 Plot the mean cycles to failure M on the log scale

for each specimen.

against applied tension on the normal scale on a semi-log

9.10 Testeightyarnspecimensasdirectedinthissectionfor

graph.

−1

each designated applied tension and for each set of test

11.3.2 PlottheLn (Ln M+2Ln s)foreachappliedweight

conditions.

on the same semi-log graph.

−1

11.3.3 Plot the Ln (Ln M −2Ln s) for each applied

10. Calculation

tension on the same semi-log graph.

10.1 Mean Cycles to Failure—Calculate mean cycles to

11.4 Further guidance on presenti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.