ASTM D4567-03

(Test Method)Standard Test Method for Single-Point Determination of Specific Surface Area of Catalysts and Catalyst Carriers Using Nitrogen Adsorption by Continuous Flow Method

Standard Test Method for Single-Point Determination of Specific Surface Area of Catalysts and Catalyst Carriers Using Nitrogen Adsorption by Continuous Flow Method

SIGNIFICANCE AND USE

This test method is useful for determining the specific surface area of catalysts and catalyst carriers for material specifications, manufacturing control, and research and development in the evaluation of catalysts.

SCOPE

1.1 This test method covers the single-point determination of the surface area of catalysts and catalyst carriers that exhibit Type II or Type IV nitrogen adsorption isotherms using a nitrogen-helium flowing gas mixture. This test method is applicable for the determination of total surface areas from 0.1 to 300 m2, where rapid surface area determinations are desired.

1.2 Because the single-point method uses an approximation of the BET equation, the multipoint BET method (Test Method D 3663) is preferred to the single-point method.

Note 1—This is particularly true when testing microporous materials.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4567 – 03

Standard Test Method for

Single-Point Determination of Specific Surface Area of

Catalysts and Catalyst Carriers Using Nitrogen Adsorption

1

by Continuous Flow Method

This standard is issued under the fixed designation D4567; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the single-point determination

ofthesurfaceareaofcatalystsandcatalystcarriersthatexhibit

3. Terminology

Type II or Type IV nitrogen adsorption isotherms using a

3.1 Definitions—See Terminology D3766.

nitrogen-helium flowing gas mixture. This test method is

3.2 Symbols:

applicable for the determination of total surface areas from 0.1

2

to300m ,whererapidsurfaceareadeterminationsaredesired.

1.2 Because the single-point method uses an approximation −20 2

A = cross-sectional area of nitrogen, 16.2 310 m .

cs

oftheBETequation,themultipointBETmethod(TestMethod

C = integrator counts.

I

T

D3663) is preferred to the single-point method.

C a = integrator counts corrected for ambient tempera-

I

ture.

NOTE 1—This is particularly true when testing microporous materials.

P

C a = integrator counts corrected for ambient pressure.

I

23

1.3 The values stated in SI units are to be regarded as the

N = Avogadro’s number, 6.02 310 , molecules/mole.

standard. The values given in parentheses are for information

P = partial pressure of nitrogen, torr.

only.

P = ambient pressure, torr.

a

1.4 This standard does not purport to address all of the

P = saturated equilibrium vapor pressure of liquid ni-

o

safety concerns, if any, associated with its use. It is the

trogen, torr.

3

responsibility of whoever uses this standard to consult and

R = gas constant, 82.1 cm atm/K mole.

establish appropriate safety and health practices and deter- T = ambient temperature, K.

a

V = volume of nitrogen adsorbed at ambient tempera-

mine the applicability of regulatory limitations prior to use.

3

ture and pressure, cm .

2. Referenced Documents

W = tare of sample cell, g.

1

2

W = sample mass+tare of sample cell after analysis, g.

2.1 ASTM Standards: 2

W = mass of sample, g.

D3663 Test Method for Surface Area of Catalysts s

D3766 Terminology Relating to Catalysts and Catalysis

4. Summary of Test Method

E177 Practice for Use of the Terms Precision and Bias in

4.1 The sample is degassed by heating in a flow of inert gas

ASTM Test Methods

to remove adsorbed vapors from the surface. The sample is

E456 Terminology Relating to Quality and Statistics

then immersed in a liquid nitrogen bath causing adsorption of

nitrogen from a flowing mixture of a fixed concentration of

1

This test method is under the jurisdiction of Committee D32 on Catalysts and

nitrogeninhelium.Whenadsorptioniscomplete,thesampleis

is the direct responsibility of Subcommittee D32.01 on Physical-Chemical Proper-

allowed to warm to room temperature causing desorption,

ties.

whichresultsinanincreaseinthenitrogenconcentrationinthe

Current edition approved Oct. 1, 2003. Published October 2003. Originally

flowing mixture. The quantity of nitrogen gas desorbed is

approved in 1986. Last previous edition approved in 1999 as D4567–99.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

determined by sensing the change in thermal conductivity.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2 Calculation of the surface area is based on a modified

Standards volume information, refer to the standard’s Document Summary page on

form of the BET equation.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4567–03

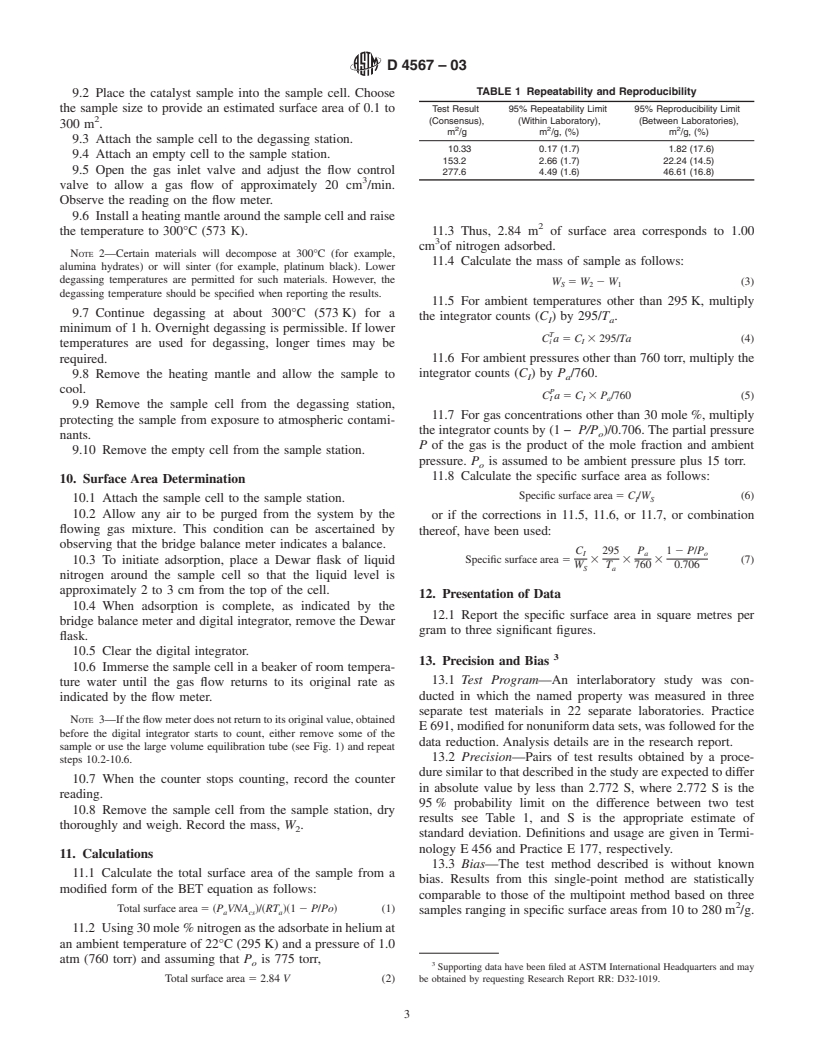

FIG. 1 Apparatus

5. Significance and Use 6.1.11 Cold Trap, for removal of impurities in the gas

mixture.

5.1 This test method is useful for determining the specific

6.1.12 Thermal Equilibration Tube,toallowtheflowinggas

surface area of catalysts and catalyst carriers for material

mixture to reach temperature and pressure equilibration before

specifications, manufacturing control, and research and devel-

reaching detector (A).

opment in the evaluation of catalysts.

6.2 Heating Mantle.

6. Apparatus 6.3 Dewar Flasks.

−7

6.4 Laboratory Balance with 0.1 mg (10 kg) sensitivity.

6.1 AschematicdiagramoftheapparatusisshowninFig.1.

3

6.5 Gas-Tight Syringe or Gas Sampling Loop, 1.00 cm .

The apparatus may be constructed of glass or metal tubing. It

has the following features:

7. Reagents

6.1.1 Different

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.