ASTM A217/A217M-11

(Specification)Standard Specification for Steel Castings, Martensitic Stainless and Alloy, for Pressure-Containing Parts, Suitable for High-Temperature Service

Standard Specification for Steel Castings, Martensitic Stainless and Alloy, for Pressure-Containing Parts, Suitable for High-Temperature Service

ABSTRACT

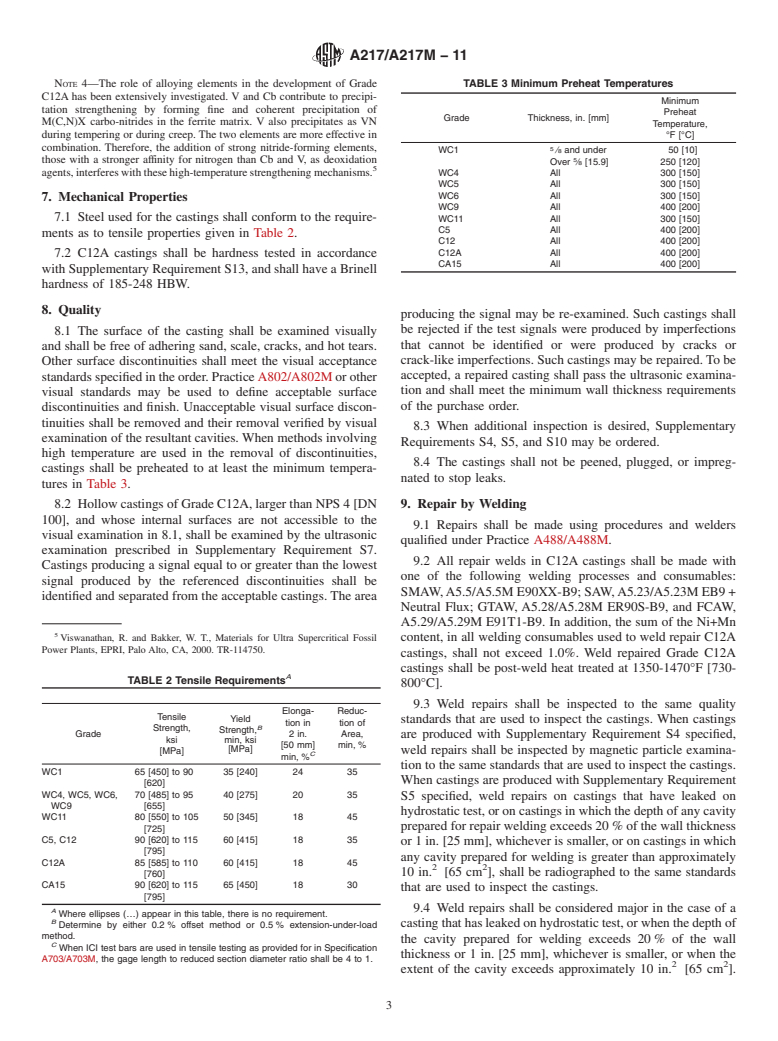

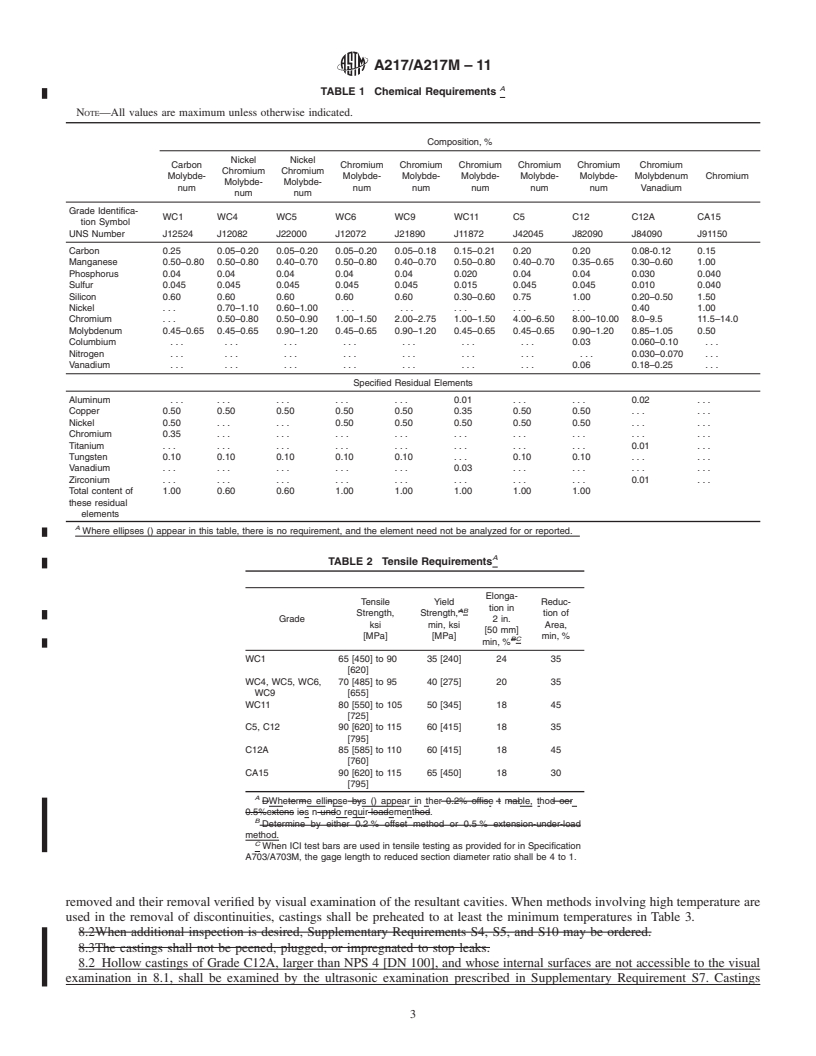

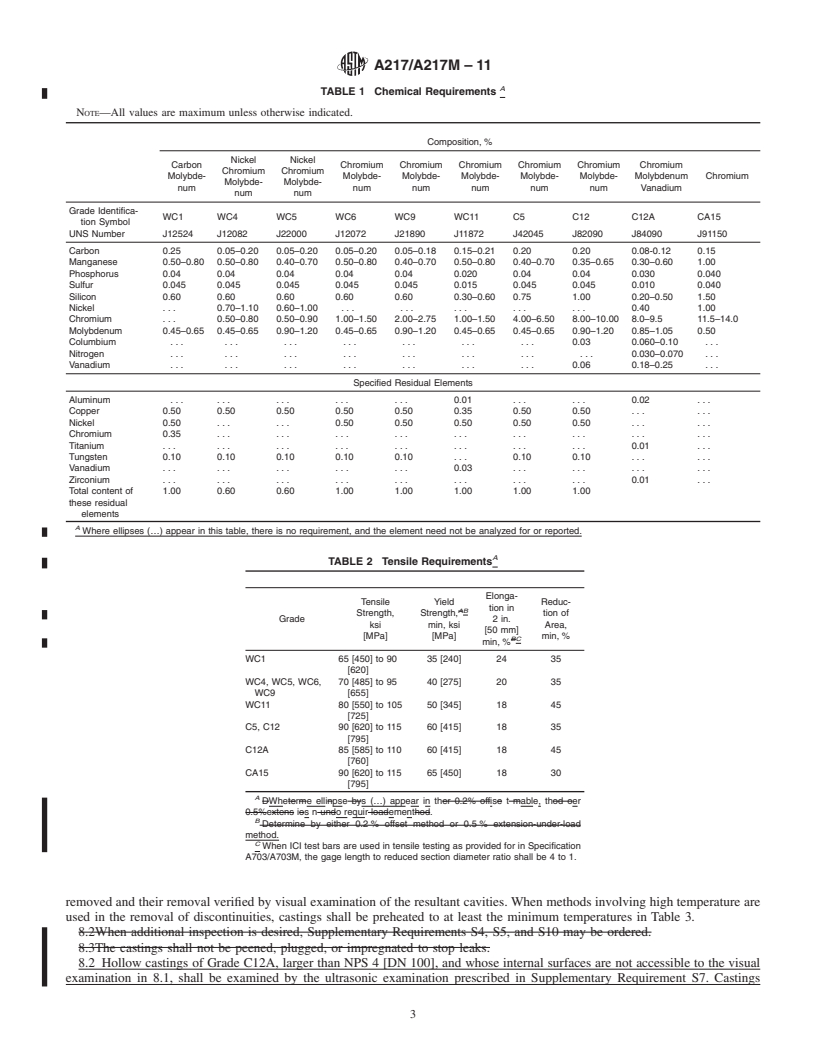

This specification covers steel castings, martensitic stainless steel and alloys steel castings for valves, flanges, fittings, and other pressure-containing parts intended primarily for high-temperature and corrosive service. The grades of steels covered here are: Grade WC1, Grade WC4, Grade WC5, Grade WC6, Grade WC9, Grade WC11, Grade C5, Grade C12, Grade C12A, and Grade CA15. Heat treatment shall consist of normalizing and tempering for Grade C12A and tempering for all other grades. Heat treatments shall be performed after castings have been allowed to cool. Heat and product analyses shall be performed wherein specimens shall conform to required chemical composition of carbon, molybdenum, chromium, nickel, vanadium, manganese, phosphorus, sulfur, silicon, columbium, nitrogen, aluminum, copper, titanium, tungsten, and zirconium. The surface of the casting shall be examined visually and shall be free of adhering sand, scale, cracks and hot tears. Steels shall undergo tension test, and shall conform to the following mechanical requirements: tensile strength, yield strength, elongation, and reduction of area.

SCOPE

1.1 This specification covers martensitic stainless steel and alloy steel castings for valves, flanges, fittings, and other pressure-containing parts (Note 1) intended primarily for high-temperature and corrosive service (Note 2).

1.2 One grade of martensitic stainless steel and nine grades of ferritic alloy steel are covered. Selection will depend on design and service conditions, mechanical properties, and the high-temperature and corrosion-resistant characteristics (Note 3).

Note 1—Carbon steel castings for pressure-containing parts are covered by Specification A216/A216M. Low alloy quench-and-tempered grades equivalent to Specification A217/A217M grades may be found in both Specifications A352/A352M and A487/A487M.

Note 2—The grades covered by this specification represent materials that are generally suitable for assembly with other castings or wrought steel parts by fusion welding. It is not intended to imply that these grades possess equal degrees of weldability; therefore, it is the responsibility of the purchaser to establish for himself a suitable welding technique. Since these grades possess varying degrees of suitability for high-temperature and corrosion-resistant service, it is also the responsibility of the purchaser to determine which grade shall be furnished, due consideration being given to the requirements of the applicable construction codes.

Note 3—The committee formulating this specification has included nine grades of materials that are considered to represent basic types of ferritic alloy steels suitable for valves, flanges, fittings, and other pressure-containing parts. Additional alloy steels that may better fulfill certain types of service will be considered for inclusion in this specification by the committee as the need becomes apparent.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A217/A217M −11 Endorsedby Manufacturers Standardization Society

of the Valve and Fittings Industry

Endorsed by American Foundrymen’s Society

Used in USDOE-NE Standards

Standard Specification for

Steel Castings, Martensitic Stainless and Alloy, for

Pressure-Containing Parts, Suitable for High-Temperature

1

Service

This standard is issued under the fixed designationA217/A217M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* system shall be used independently of the other. Combining

2

values from the two systems may result in non-conformance

1.1 This specification covers martensitic stainless steel and

with the standard.

alloy steel castings for valves, flanges, fittings, and other

pressure-containing parts (Note 1) intended primarily for

2. Referenced Documents

high-temperature and corrosive service (Note 2).

3

1.2 One grade of martensitic stainless steel and nine grades

2.1 ASTM Standards:

of ferritic alloy steel are covered. Selection will depend on

A216/A216M SpecificationforSteelCastings,Carbon,Suit-

design and service conditions, mechanical properties, and the

able for Fusion Welding, for High-Temperature Service

high-temperature and corrosion-resistant characteristics (Note

A352/A352M Specification for Steel Castings, Ferritic and

3).

Martensitic, for Pressure-Containing Parts, Suitable for

Low-Temperature Service

NOTE 1—Carbon steel castings for pressure-containing parts are cov-

ered by Specification A216/A216M. Low alloy quench-and-tempered

A487/A487M Specification for Steel Castings Suitable for

grades equivalent to Specification A217/A217M grades may be found in

Pressure Service

both Specifications A352/A352M and A487/A487M.

A488/A488M Practice for Steel Castings, Welding, Qualifi-

NOTE 2—The grades covered by this specification represent materials

cations of Procedures and Personnel

that are generally suitable for assembly with other castings or wrought

steel parts by fusion welding. It is not intended to imply that these grades

A703/A703M Specification for Steel Castings, General

possess equal degrees of weldability; therefore, it is the responsibility of

Requirements, for Pressure-Containing Parts

the purchaser to establish for himself a suitable welding technique. Since

A802/A802M Practice for Steel Castings, Surface Accep-

these grades possess varying degrees of suitability for high-temperature

tance Standards, Visual Examination

andcorrosion-resistantservice,itisalsotheresponsibilityofthepurchaser

to determine which grade shall be furnished, due consideration being

A985/A985M Specification for Steel Investment Castings

given to the requirements of the applicable construction codes.

General Requirements, for Pressure-Containing Parts

NOTE 3—The committee formulating this specification has included

E165 Practice for Liquid Penetrant Examination for General

nine grades of materials that are considered to represent basic types of

Industry

ferriticalloysteelssuitableforvalves,flanges,fittings,andotherpressure-

containingparts.Additionalalloysteelsthatmaybetterfulfillcertaintypes

E709 Guide for Magnetic Particle Testing

of service will be considered for inclusion in this specification by the

4

2.2 AWS Specifications:

committee as the need becomes apparent.

A5.5/A5.5M LowAlloy Steel Electrodes for Shielded Metal

1.3 The values stated in either SI units or inch-pound units

Arc Welding

are to be regarded separately as standard. The values stated in

A5.23/A5.23M Low-Alloy Steel Electrodes and Fluxes for

each system may not be exact equivalents; therefore, each

Submerged Arc Welding

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

3

A01.18 on Castings. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2011. Published November 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1939. Last previous edition approved in 2010 as A217/A217M – 10. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0217_A0217M-11. the ASTM website.

2 4

For ASME Boiler and Pressure Vessel Code applications, see related Specifi- Available from American Welding Society, 550 NW LeJuene Rd., Miami, FL

cation SA-217/SA 217M in Section II of that code. 33126, http://www.aws.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Har

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Endorsed by Manufacturers Standardization Society

Designation:A217/A217M–10 Designation: A217/A217M – 11 of the Valve and Fittings Industry

Endorsed by American Foundrymen’s Society

Used in USDOE-NE Standards

Standard Specification for

Steel Castings, Martensitic Stainless and Alloy, for

Pressure-Containing Parts, Suitable for High-Temperature

1

Service

This standard is issued under the fixed designationA217/A217M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

2

1.1 This specification covers martensitic stainless steel and alloy steel castings for valves, flanges, fittings, and other

pressure-containing parts (Note 1) intended primarily for high-temperature and corrosive service (Note 2).

1.2 One grade of martensitic stainless steel and nine grades of ferritic alloy steel are covered. Selection will depend on design

and service conditions, mechanical properties, and the high-temperature and corrosion-resistant characteristics (Note 3).

NOTE 1—Carbon steel castings for pressure-containing parts are covered by Specification A216/A216M. Low alloy quench-and-tempered grades

equivalent to Specification A217/A217M grades may be found in both Specifications A352/A352M and A487/A487M.

NOTE 2—The grades covered by this specification represent materials that are generally suitable for assembly with other castings or wrought steel parts

by fusion welding. It is not intended to imply that these grades possess equal degrees of weldability; therefore, it is the responsibility of the purchaser

toestablishforhimselfasuitableweldingtechnique.Sincethesegradespossessvaryingdegreesofsuitabilityforhigh-temperatureandcorrosion-resistant

service, it is also the responsibility of the purchaser to determine which grade shall be furnished, due consideration being given to the requirementsof

the applicable construction codes.

NOTE 3—Thecommitteeformulatingthisspecificationhasincludedninegradesofmaterialsthatareconsideredtorepresentbasictypesofferriticalloy

steels suitable for valves, flanges, fittings, and other pressure-containing parts. Additional alloy steels that may better fulfill certain types of service will

be considered for inclusion in this specification by the committee as the need becomes apparent.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

2. Referenced Documents

3

2.1 ASTM Standards:

A216/A216M Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service

A352/A352M Specification for Steel Castings, Ferritic and Martensitic, for Pressure-Containing Parts, Suitable for Low-

Temperature Service

A487/A487M Specification for Steel Castings Suitable for Pressure Service

A488/A488M Practice for Steel Castings, Welding, Qualifications of Procedures and Personnel

A703/A703M Specification for Steel Castings, General Requirements, for Pressure-Containing Parts

A802/A802M Practice for Steel Castings, Surface Acceptance Standards, Visual Examination

A985/A985M Specification for Steel Investment Castings General Requirements, for Pressure-Containing Parts

E165 Practice for Liquid Penetrant Examination for General Industry

E709 Guide for Magnetic Particle Testing

4

2.2 AWS Specifications:

A5.5/A5.5M Low Alloy Steel Electrodes for Shielded Metal Arc Welding

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.18

on Castings.

Current edition approved MayOct. 1, 2010.2011. Published June 2010.November 2011. Originally approved in 1939. Last previous edition approved in 20082010 as

A217/A217M – 108. DOI: 10.1520/A0217_A0217M-101.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SA-217/SA 217M in Section II of that code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Endorsed by Manufacturers Standardization Society

Designation:A217/A217M–10 Designation: A217/A217M – 11 of the Valve and Fittings Industry

Endorsed by American Foundrymen’s Society

Used in USDOE-NE Standards

Standard Specification for

Steel Castings, Martensitic Stainless and Alloy, for

Pressure-Containing Parts, Suitable for High-Temperature

1

Service

This standard is issued under the fixed designationA217/A217M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

2

1.1 This specification covers martensitic stainless steel and alloy steel castings for valves, flanges, fittings, and other

pressure-containing parts (Note 1) intended primarily for high-temperature and corrosive service (Note 2).

1.2 One grade of martensitic stainless steel and nine grades of ferritic alloy steel are covered. Selection will depend on design

and service conditions, mechanical properties, and the high-temperature and corrosion-resistant characteristics (Note 3).

NOTE 1—Carbon steel castings for pressure-containing parts are covered by Specification A216/A216M. Low alloy quench-and-tempered grades

equivalent to Specification A217/A217M grades may be found in both Specifications A352/A352M and A487/A487M.

NOTE 2—The grades covered by this specification represent materials that are generally suitable for assembly with other castings or wrought steel parts

by fusion welding. It is not intended to imply that these grades possess equal degrees of weldability; therefore, it is the responsibility of the purchaser

toestablishforhimselfasuitableweldingtechnique.Sincethesegradespossessvaryingdegreesofsuitabilityforhigh-temperatureandcorrosion-resistant

service, it is also the responsibility of the purchaser to determine which grade shall be furnished, due consideration being given to the requirementsof

the applicable construction codes.

NOTE 3—Thecommitteeformulatingthisspecificationhasincludedninegradesofmaterialsthatareconsideredtorepresentbasictypesofferriticalloy

steels suitable for valves, flanges, fittings, and other pressure-containing parts. Additional alloy steels that may better fulfill certain types of service will

be considered for inclusion in this specification by the committee as the need becomes apparent.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

2. Referenced Documents

3

2.1 ASTM Standards:

A216/A216M Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service

A352/A352M Specification for Steel Castings, Ferritic and Martensitic, for Pressure-Containing Parts, Suitable for Low-

Temperature Service

A487/A487M Specification for Steel Castings Suitable for Pressure Service

A488/A488M Practice for Steel Castings, Welding, Qualifications of Procedures and Personnel

A703/A703M Specification for Steel Castings, General Requirements, for Pressure-Containing Parts

A802/A802M Practice for Steel Castings, Surface Acceptance Standards, Visual Examination

A985/A985M Specification for Steel Investment Castings General Requirements, for Pressure-Containing Parts

E165 Practice for Liquid Penetrant Examination for General Industry

E709 Guide for Magnetic Particle Testing

4

2.2 AWS Specifications:

A5.5/A5.5M Low Alloy Steel Electrodes for Shielded Metal Arc Welding

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.18

on Castings.

Current edition approved MayOct. 1, 2010.2011. Published June 2010.November 2011. Originally approved in 1939. Last previous edition approved in 20082010 as

A217/A217M – 108. DOI: 10.1520/A0217_A0217M-101.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SA-217/SA 217M in Section II of that code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.