ASTM C623-92(2010)

(Test Method)Standard Test Method for Young's Modulus, Shear Modulus, and Poisson's Ratio for Glass and Glass-Ceramics by Resonance

Standard Test Method for Young's Modulus, Shear Modulus, and Poisson's Ratio for Glass and Glass-Ceramics by Resonance

SIGNIFICANCE AND USE

This test system has advantages in certain respects over the use of static loading systems in the measurement of glass and glass-ceramics:

Only minute stresses are applied to the specimen, thus minimizing the possibility of fracture.

The period of time during which stress is applied and removed is of the order of hundreds of microseconds, making it feasible to perform measurements at temperatures where delayed elastic and creep effects proceed on a much-shortened time scale, as in the transformation range of glass, for instance.

The test is suitable for detecting whether a material meets specifications, if cognizance is given to one important fact: glass and glass-ceramic materials are sensitive to thermal history. Therefore the thermal history of a test specimen must be known before the moduli can be considered in terms of specified values. Material specifications should include a specific thermal treatment for all test specimens.

SCOPE

1.1 This test method covers the determination of the elastic properties of glass and glass-ceramic materials. Specimens of these materials possess specific mechanical resonance frequencies which are defined by the elastic moduli, density, and geometry of the test specimen. Therefore the elastic properties of a material can be computed if the geometry, density, and mechanical resonance frequencies of a suitable test specimen of that material can be measured. Young's modulus is determined using the resonance frequency in the flexural mode of vibration. The shear modulus, or modulus of rigidity, is found using torsional resonance vibrations. Young's modulus and shear modulus are used to compute Poisson's ratio, the factor of lateral contraction.

1.2 All glass and glass-ceramic materials that are elastic, homogeneous, and isotropic may be tested by this test method. The test method is not satisfactory for specimens that have cracks or voids that represent inhomogeneities in the material; neither is it satisfactory when these materials cannot be prepared in a suitable geometry.

Note 1—Elastic here means that an application of stress within the elastic limit of that material making up the body being stressed will cause an instantaneous and uniform deformation, which will cease upon removal of the stress, with the body returning instantly to its original size and shape without an energy loss. Glass and glass-ceramic materials conform to this definition well enough that this test is meaningful.

Note 2—Isotropic means that the elastic properties are the same in all directions in the material. Glass is isotropic and glass-ceramics are usually so on a macroscopic scale, because of random distribution and orientation of crystallites.

1.3 A cryogenic cabinet and high-temperature furnace are described for measuring the elastic moduli as a function of temperature from −195°C to 1200°C.

1.4 Modification of the test for use in quality control is possible. A range of acceptable resonance frequencies is determined for a piece with a particular geometry and density. Any specimen with a frequency response falling outside this frequency range is rejected. The actual modulus of each piece need not be determined as long as the limits of the selected frequency range are known to include the resonance frequency that the piece must possess if its geometry and density are within specified tolerances.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C623 − 92(Reapproved 2010)

Standard Test Method for

Young’s Modulus, Shear Modulus, and Poisson’s Ratio for

Glass and Glass-Ceramics by Resonance

This standard is issued under the fixed designation C623; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 Modification of the test for use in quality control is

possible. A range of acceptable resonance frequencies is

1.1 This test method covers the determination of the elastic

determined for a piece with a particular geometry and density.

properties of glass and glass-ceramic materials. Specimens of

Any specimen with a frequency response falling outside this

thesematerialspossessspecificmechanicalresonancefrequen-

frequency range is rejected. The actual modulus of each piece

cies which are defined by the elastic moduli, density, and

need not be determined as long as the limits of the selected

geometry of the test specimen. Therefore the elastic properties

frequency range are known to include the resonance frequency

of a material can be computed if the geometry, density, and

that the piece must possess if its geometry and density are

mechanical resonance frequencies of a suitable test specimen

within specified tolerances.

of that material can be measured. Young’s modulus is deter-

1.5 The values stated in SI units are to be regarded as

mined using the resonance frequency in the flexural mode of

standard. No other units of measurement are included in this

vibration. The shear modulus, or modulus of rigidity, is found

standard.

using torsional resonance vibrations. Young’s modulus and

shear modulus are used to compute Poisson’s ratio, the factor

1.6 This standard does not purport to address all of the

of lateral contraction.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1.2 All glass and glass-ceramic materials that are elastic,

priate safety and health practices and determine the applica-

homogeneous,andisotropicmaybetestedbythistestmethod.

bility of regulatory limitations prior to use.

The test method is not satisfactory for specimens that have

cracks or voids that represent inhomogeneities in the material;

2. Summary of Test Method

neither is it satisfactory when these materials cannot be

2.1 This test method measures the resonance frequencies of

prepared in a suitable geometry.

test bars of suitable geometry by exciting them at continuously

NOTE 1—Elastic here means that an application of stress within the

variable frequencies. Mechanical excitation of the specimen is

elastic limit of that material making up the body being stressed will cause

provided through use of a transducer that transforms an initial

aninstantaneousanduniformdeformation,whichwillceaseuponremoval

electrical signal into a mechanical vibration. Another trans-

ofthestress,withthebodyreturninginstantlytoitsoriginalsizeandshape

without an energy loss. Glass and glass-ceramic materials conform to this

ducer senses the resulting mechanical vibrations of the speci-

definition well enough that this test is meaningful.

men and transforms them into an electrical signal that can be

NOTE 2—Isotropic means that the elastic properties are the same in all

displayed on the screen of an oscilloscope to detect resonance.

directionsinthematerial.Glassisisotropicandglass-ceramicsareusually

The reasonance frequencies, the dimensions, and the mass of

so on a macroscopic scale, because of random distribution and orientation

the specimen are used to calculate Young’s modulus and the

of crystallites.

shear modulus.

1.3 A cryogenic cabinet and high-temperature furnace are

described for measuring the elastic moduli as a function of

3. Significance and Use

temperature from−195°C to 1200°C.

3.1 This test system has advantages in certain respects over

the use of static loading systems in the measurement of glass

and glass-ceramics:

This test method is under the jurisdiction of ASTM Committee C14 on Glass

3.1.1 Only minute stresses are applied to the specimen, thus

and Glass Products and is the direct responsibility of Subcommittee C14.04 on

minimizing the possibility of fracture.

Physical and Mechanical Properties.

3.1.2 The period of time during which stress is applied and

Current edition approved April 1, 2010. Published May 2010. Originally

approved in 1969. Last previous edition approved in 2005 as C623–92(2005).

removed is of the order of hundreds of microseconds, making

DOI: 10.1520/C0623-92R10.

it feasible to perform measurements at temperatures where

Spinner, S., and Tefft, W. E., “A Method for Determining Mechanical

delayed elastic and creep effects proceed on a much-shortened

Resonance Frequencies and for Calculating Elastic Moduli from These

Frequencies,” Proceedings, ASTM, 1961, pp. 1221–1238. timescale,asinthetransformationrangeofglass,forinstance.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C623 − 92 (2010)

FIG. 1 Block Diagram of Apparatus

3.2 The test is suitable for detecting whether a material or other similar device, depending on the type of coupling

meets specifications, if cognizance is given to one important chosen for use between the transducer and the specimen. The

fact: glass and glass-ceramic materials are sensitive to thermal other transducer, used as a detector, may be a crystal or

history. Therefore the thermal history of a test specimen must magneticreluctancetypeofphonographcartridge.Acapacitive

be known before the moduli can be considered in terms of pickup may be used if desired. The frequency response of the

specified values. Material specifications should include a transducer shall be as good as possible with at least a 6.5-kHz

specific thermal treatment for all test specimens. bandwidth before 3-dB power loss occurs.

4.5 Power Amplifier, in the detector circuit shall be imped-

4. Apparatus

ance matched with the type of detector transducer selected and

4.1 The test apparatus is shown in Fig. 1. It consists of a

shall serve as a prescope amplifier.

variable-frequency audio oscillator, used to generate a sinusoi-

4.6 Cathode-Ray Oscilloscope, shall be any model suitable

dal voltage, and a power amplifier and suitable transducer to

for general laboratory work.

convert the electrical signal to a mechanical driving vibration.

4.7 Frequency Counter,shallbeabletomeasurefrequencies

A frequency meter monitors the audio oscillator output to

to within 61 Hz.

provide an accurate frequency determination. A suitable

suspension-coupling system cradles the test specimen, and

4.8 If data at elevated temperature are desired, a furnace

another transducer acts to detect mechanical resonance in the

shall be used that is capable of controlled heating and cooling.

specimen and to convert it into an electrical signal which is

It shall have a specimen zone 180 mm in length, which will be

passedthroughanamplifieranddisplayedontheverticalplates

uniform in temperature within 65°C throughout the range of

ofanoscilloscope.IfaLissajousfigureisdesired,theoutputof

temperatures encountered in testing.

the oscillator is also coupled to the horizontal plates of the

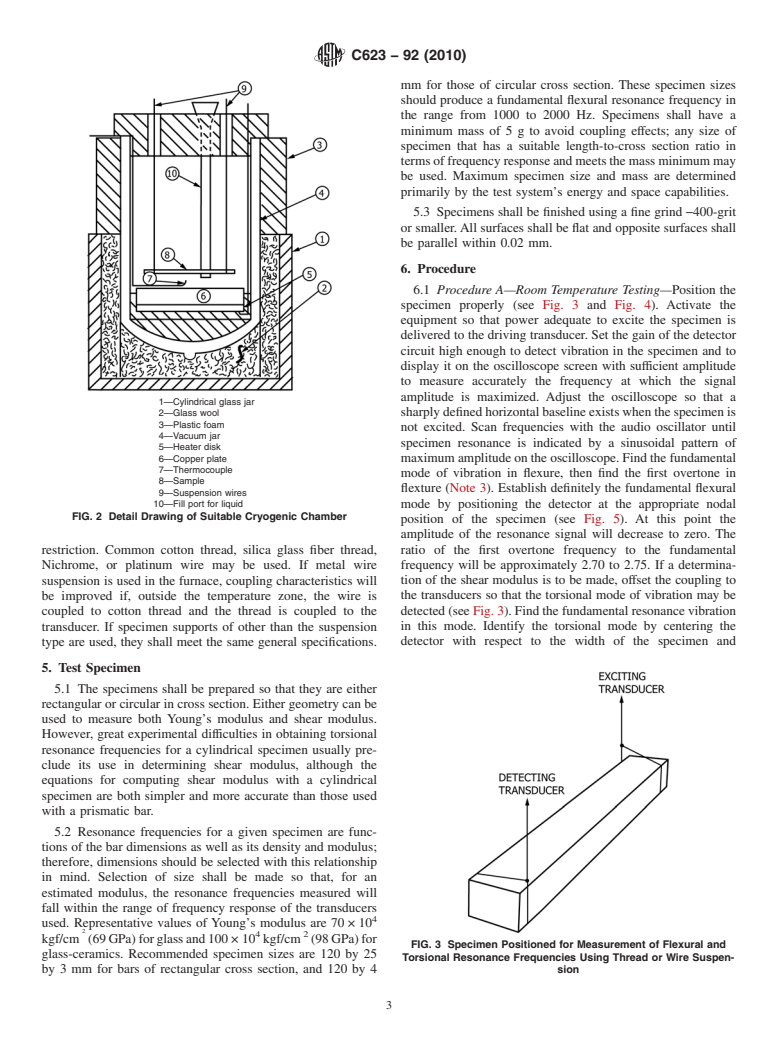

4.9 For data at cryogenic temperatures, any chamber shall

oscilloscope. If temperature-dependent data are desired, a

suffice that shall be capable of controlled heating, frost-free,

suitable furnace or cryogenic chamber is used. Details of the

anduniformintemperaturewithin 65°Coverthelengthofthe

equipment are as follows:

specimen at any selected temperature. A suitable cryogenic

4.2 Audio Oscillator, having a continuously variable fre-

chamber is shown in Fig. 2.

quencyoutputfromabout100Hztoatleast20kHz.Frequency

4.10 Any method of specimen suspension shall be used that

drift shall not exceed 1 Hz/min for any given setting.

shall be adequate for the temperatures encountered in testing

4.3 Audio Amplifier, having a power output sufficient to

and that shall allow the specimen to vibrate without significant

ensurethatthetypeoftransducerusedcanexciteanyspecimen

the mass of which falls within a specified range.

Smith, R. E., and Hagy, H. E., “A Low Temperature Sonic Resonance

4.4 Transducers—Two are required: one used as a driver

Apparatus for Determining Elastic Properties of Solids,” Internal Report 2195,

maybeaspeakerofthetweetertypeoramagneticcuttinghead Corning Glass Works, April, 1961.

C623 − 92 (2010)

mm for those of circular cross section. These specimen sizes

should produce a fundamental flexural resonance frequency in

the range from 1000 to 2000 Hz. Specimens shall have a

minimum mass of 5 g to avoid coupling effects; any size of

specimen that has a suitable length-to-cross section ratio in

termsoffrequencyresponseandmeetsthemassminimummay

be used. Maximum specimen size and mass are determined

primarily by the test system’s energy and space capabilities.

5.3 Specimens shall be finished using a fine grind−400-grit

or smaller.All surfaces shall be flat and opposite surfaces shall

be parallel within 0.02 mm.

6. Procedure

6.1 Procedure A—Room Temperature Testing—Position the

specimen properly (see Fig. 3 and Fig. 4). Activate the

equipment so that power adequate to excite the specimen is

delivered to the driving transducer. Set the gain of the detector

circuit high enough to detect vibration in the specimen and to

display it on the oscilloscope screen with sufficient amplitude

to measure accurately the frequency at which the signal

amplitude is maximized. Adjust the oscilloscope so that a

1—Cylindrical glass jar

2—Glass wool sharplydefinedhorizontalbaselineexistswhenthespecimenis

3—Plastic foam

not excited. Scan frequencies with the audio oscillator until

4—Vacuum jar

specimen resonance is indicated by a sinusoidal pattern of

5—Heater disk

6—Copper plate maximumamplitudeontheoscilloscope.Findthefundamental

7—Thermocouple

mode of vibration in flexure, then find the first overtone in

8—Sample

flexture (Note 3). Establish definitely the fundamental flexural

9—Suspension wires

10—Fill port for liquid

mode by positioning the detector at the appropriate nodal

FIG. 2 Detail Drawing of Suitable Cryogenic Chamber

position of the specimen (see Fig. 5). At this point the

amplitude of the resonance signal will decrease to zero. The

ratio of the first overtone frequency to the fundamental

restriction. Common cotton thread, silica glass fiber thread,

Nichrome, or platinum wire may be used. If metal wire frequency will be approximately 2.70 to 2.75. If a determina-

tion of the shear modulus is to be made, offset the coupling to

suspension is used in the furnace, coupling characteristics will

be improved if, outside the temperature zone, the wire is the transducers so that the torsional mode of vibration may be

detected(seeFig.3).Findthefundamentalresonancevibration

coupled to cotton thread and the thread is coupled to the

transducer. If specimen supports of other than the suspension in this mode. Identify the torsional mode by centering the

detector with respect to the width of the specimen and

type are used, they shall meet the same general specifications.

5. Test Specimen

5.1 The specimens shall be prepared so that they are either

rectangular or circular in cross section. Either geometry can be

used to measure both Young’s modulus and shear modulus.

However, great experimental difficulties in obtaining torsional

resonance frequencies for a cylindrical specimen usually pre-

clude its use in determining shear modulus, although the

equations for computing shear modulus with a cylindrical

specimen are both simpler and more accurate than those used

with a prismatic bar.

5.2 Resonance frequencies for a given specimen are func-

tions of the bar dimensions as well as its density and modulus;

therefore, dimensions should be selected with this relationship

in mind. Selection of size shall be made so that, for an

estimated modulus, the resonance frequencies measured will

fall within the range of frequency response of the transducers

used. Representative values of Young’s modulus are 70×10

4 2

kgf/cm (69GPa)forglassand100×10 kgf/cm (98GPa)for

FIG. 3 Specimen Positioned for Measurement of Flexural and

glass-ceramics. Recommended specimen sizes are 120 by 25

Torsional Resonance Frequencies Using Thread or Wire Suspen-

by 3 mm for bars of rectangular cross section, and 120 by 4 sion

C623 − 92 (2010)

The fundamental and overtone are properly identified by showing them to

be in the correct numerical ratio, and by demonstrating the proper

locations of the nodes for each. Spinner and Tefft recommended using

only the fundamental in flexure when computing Young’s modulus for a

rectangular bar because of the approximate nature of Pickett’s theory.

However, for the nominal size of bar specified, the values of Young’s

modulus computed using Eq 1 and Eq 2 will agree within 1%. When the

correction factor, T , is greater than 2%, Eq 2 should not be used.

6.2 Procedure B—Elevated Temperature Testing—

Determine the mass, dimensions, and frequencies at room

temperature in air as outlined in 6.1. Place the specimen in the

furnace and adjust the driver-detector system so that all the

frequencies to be measured can be detected without further

adjustment. Determine the resonant frequencies at room tem-

perature in the furnace cavity with the furnace doors closed,

etc., as will be the case at elevated temperatures. Heat the

furnace at a controlled rate that does not exceed 150°C/h.Take

data at 25° intervals or at 15-min intervals as dictated by

heating rate and specimen composition. Follow the change in

resonance frequencies with time closely to avoid losing the

FIG. 4 Specimen Positioned for Measurement of Flexural and

identity of each frequency. (The overtone in flexure and the

Torsional Resonance Frequencies Using “Tweeter” Exciter

fundamental in torsion may be difficult to differentiate if not

followed closely; spurious frequencies inherent in the system

may also appear at temperatures above 600°C using certain

types of suspensions, particularly wire.) If desired, data may

alsobetakenoncooling;itmustberemembered,however,that

high temperatures may damage the specimen, by serious

warping for example, making subsequent determinations of

doubtful value.

6.3 Procedure C—Cryogenic Temperature Testing—

Determine the weight, dimensions, and resonance frequencies

in air at room temperature. Measure the resonance frequencies

at room temperature in the cryogenic chamber. Take the

ch

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.