ASTM D3632-98(2019)

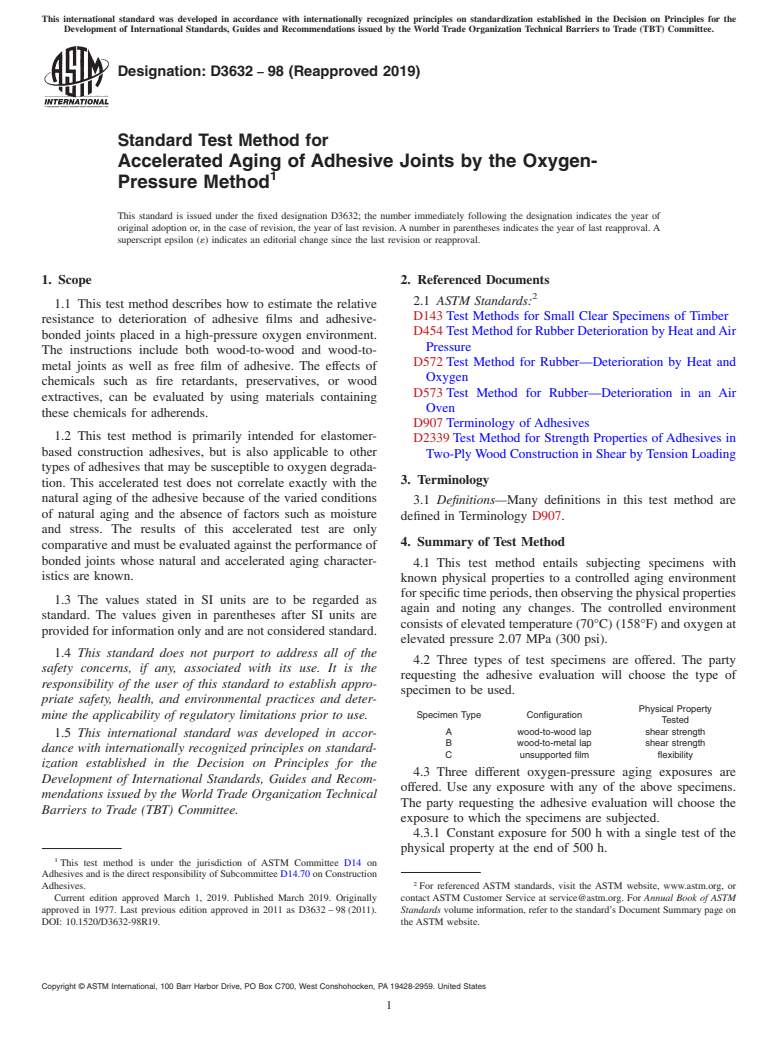

(Test Method)Standard Test Method for Accelerated Aging of Adhesive Joints by the Oxygen-Pressure Method

Standard Test Method for Accelerated Aging of Adhesive Joints by the Oxygen-Pressure Method

SIGNIFICANCE AND USE

5.1 This test method is useful to the adhesive manufacturer in research and development or in manufacturing control. The results are also used for specification acceptance or as a guide in adhesive selection.

5.2 The provisions for testing bonded specimens as well as free films are made for two purposes. First, it is possible for an interaction to occur between oxygen and chemicals or degradation products that may affect the degradation of the bonded joints strength. Second, some increase in strength due to oxidative crosslinking may not be detrimental in a bonded assembly and in fact may be beneficial. Adhesives of this behavior are not satisfactorily tested by a film flexibility test.

5.3 Some users of this test method will be most interested in the performance of the bonded joint; some will be most interested in the performance of the adhesive. In the latter case, it is important to note that the true variance (error mean square) of the strength of the adhesive may be obscured when the tested control specimens or the tested aged specimens show wood failure.

5.4 Conflict of Procedure—If the procedures of this test method conflict with those of detailed product specifications or manufacturer's use instructions for a particular material, then use the latter.

SCOPE

1.1 This test method describes how to estimate the relative resistance to deterioration of adhesive films and adhesive-bonded joints placed in a high-pressure oxygen environment. The instructions include both wood-to-wood and wood-to-metal joints as well as free film of adhesive. The effects of chemicals such as fire retardants, preservatives, or wood extractives, can be evaluated by using materials containing these chemicals for adherends.

1.2 This test method is primarily intended for elastomer-based construction adhesives, but is also applicable to other types of adhesives that may be susceptible to oxygen degradation. This accelerated test does not correlate exactly with the natural aging of the adhesive because of the varied conditions of natural aging and the absence of factors such as moisture and stress. The results of this accelerated test are only comparative and must be evaluated against the performance of bonded joints whose natural and accelerated aging characteristics are known.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3632 − 98 (Reapproved 2019)

Standard Test Method for

Accelerated Aging of Adhesive Joints by the Oxygen-

1

Pressure Method

This standard is issued under the fixed designation D3632; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method describes how to estimate the relative

D143 Test Methods for Small Clear Specimens of Timber

resistance to deterioration of adhesive films and adhesive-

D454 Test Method for Rubber Deterioration by Heat andAir

bonded joints placed in a high-pressure oxygen environment.

Pressure

The instructions include both wood-to-wood and wood-to-

D572 Test Method for Rubber—Deterioration by Heat and

metal joints as well as free film of adhesive. The effects of

Oxygen

chemicals such as fire retardants, preservatives, or wood

D573 Test Method for Rubber—Deterioration in an Air

extractives, can be evaluated by using materials containing

Oven

these chemicals for adherends.

D907 Terminology of Adhesives

1.2 This test method is primarily intended for elastomer-

D2339 Test Method for Strength Properties of Adhesives in

based construction adhesives, but is also applicable to other

Two-Ply Wood Construction in Shear by Tension Loading

types of adhesives that may be susceptible to oxygen degrada-

3. Terminology

tion. This accelerated test does not correlate exactly with the

natural aging of the adhesive because of the varied conditions

3.1 Definitions—Many definitions in this test method are

of natural aging and the absence of factors such as moisture

defined in Terminology D907.

and stress. The results of this accelerated test are only

4. Summary of Test Method

comparative and must be evaluated against the performance of

bonded joints whose natural and accelerated aging character-

4.1 This test method entails subjecting specimens with

istics are known.

known physical properties to a controlled aging environment

forspecifictimeperiods,thenobservingthephysicalproperties

1.3 The values stated in SI units are to be regarded as

again and noting any changes. The controlled environment

standard. The values given in parentheses after SI units are

consists of elevated temperature (70°C) (158°F) and oxygen at

provided for information only and are not considered standard.

elevated pressure 2.07 MPa (300 psi).

1.4 This standard does not purport to address all of the

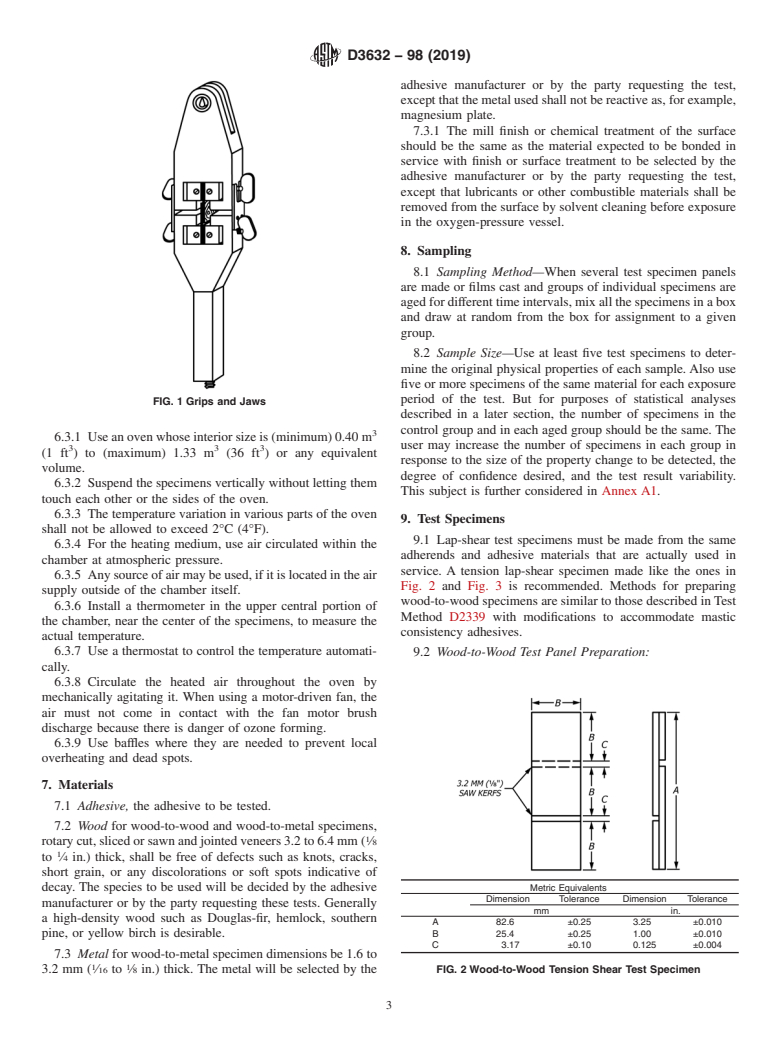

4.2 Three types of test specimens are offered. The party

safety concerns, if any, associated with its use. It is the

requesting the adhesive evaluation will choose the type of

responsibility of the user of this standard to establish appro-

specimen to be used.

priate safety, health, and environmental practices and deter-

Physical Property

Specimen Type Configuration

mine the applicability of regulatory limitations prior to use.

Tested

A wood-to-wood lap shear strength

1.5 This international standard was developed in accor-

B wood-to-metal lap shear strength

dance with internationally recognized principles on standard-

C unsupported film flexibility

ization established in the Decision on Principles for the

4.3 Three different oxygen-pressure aging exposures are

Development of International Standards, Guides and Recom-

offered. Use any exposure with any of the above specimens.

mendations issued by the World Trade Organization Technical

The party requesting the adhesive evaluation will choose the

Barriers to Trade (TBT) Committee.

exposure to which the specimens are subjected.

4.3.1 Constant exposure for 500 h with a single test of the

physical property at the end of 500 h.

1

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

2

Adhesives. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2019. Published March 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1977. Last previous edition approved in 2011 as D3632 – 98 (2011). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D3632-98R19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3632 − 98 (2019)

4.3.2 Constant exposure for 1000 h with a single test of the 6.1.1.2 The sour

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.