ASTM C1618-13

(Test Method)Standard Test Method for Concrete Sanitary Sewer Pipe by Negative (Vacuum) or Positive Air Pressure

Standard Test Method for Concrete Sanitary Sewer Pipe by Negative (Vacuum) or Positive Air Pressure

SIGNIFICANCE AND USE

5.1 This is a quality control test performed at the manufacturing plant to establish that the finished, shippable pipe meets the leakage limits stated in the specifications.

SCOPE

1.1 This test method covers procedures for testing of precast concrete pipe sections, prior to delivery, where maximum field leakage rates are specified.

1.2 Tests described in this standard are intended to be used at the point of manufacture of the concrete pipe and are not intended for testing installed pipe (for field tests see Practices C924, C969, and C1214). The user of this specification is advised that individual or multiple pipe sections may be tested for the purpose of testing the pipe barrel and additionally the joints in straight alignment when multiple pipe sections are tested.

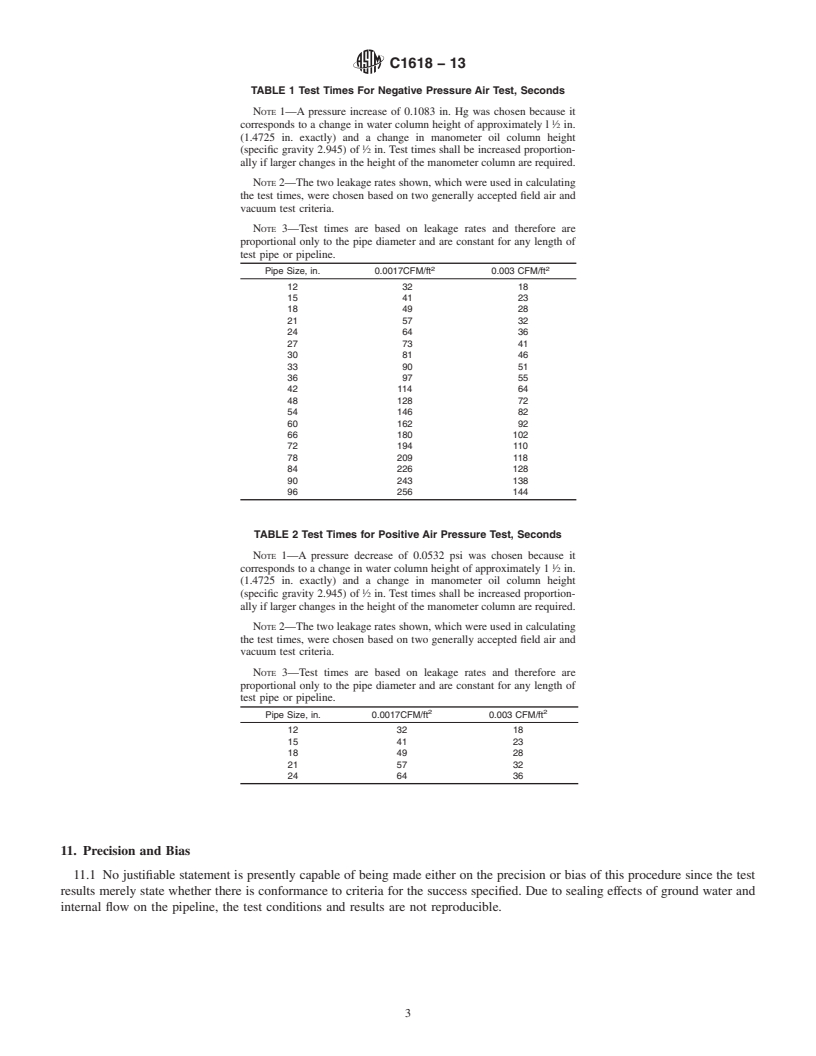

1.3 Test times are based on leakage rates and therefore are proportional only to the pipe diameter and are constant for any length of test pipe or pipeline.

1.4 Test times tabulated and the rate of air loss in this standard are based on successful testing of installed pipelines. However, since air and water have different physical properties, retests of some pipelines not meeting field air tests have been successful when tested with water. The leakage rates of 0.0017 CFM/ft2 and 0.0003 CFM/ft2, were determined empirically as the maximums for pipe to meet the 50 and 200 gal/(in. of internal diameter) (mile of sewer) (24h) test rates, respectively.

1.5 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.Note 1—The availability of this test procedure for concrete pipe varies from location to location. Check with local supplier(s) for availability and recommendations.

1.6 This standard does not purport to address all the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish the appropriate safety and health practices and to determine the applicability of regulatory limitations prior to its use. See Section 6 for specific safety precautions.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1618 − 13

Standard Test Method for

Concrete Sanitary Sewer Pipe by Negative (Vacuum) or

1

Positive Air Pressure

This standard is issued under the fixed designation C1618; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope and health practices and to determine the applicability of

regulatory limitations prior to its use.SeeSection6forspecific

1.1 Thistestmethodcoversproceduresfortestingofprecast

safety precautions.

concrete pipe sections, prior to delivery, where maximum field

leakage rates are specified.

2. Referenced Documents

2

1.2 Tests described in this standard are intended to be used

2.1 ASTM Standards:

at the point of manufacture of the concrete pipe and are not

C822 Terminology Relating to Concrete Pipe and Related

intended for testing installed pipe (for field tests see Practices

Products

C924, C969, and C1214). The user of this specification is

C924 Practice for Testing Concrete Pipe Sewer Lines by

advised that individual or multiple pipe sections may be tested

Low-Pressure Air Test Method

for the purpose of testing the pipe barrel and additionally the

C969 Practice for Infiltration and Exfiltration Acceptance

joints in straight alignment when multiple pipe sections are

Testing of Installed Precast Concrete Pipe Sewer Lines

tested.

C1214 Test Method for Concrete Pipe Sewerlines by Nega-

tive Air Pressure (Vacuum) Test Method

1.3 Test times are based on leakage rates and therefore are

proportional only to the pipe diameter and are constant for any

3. Terminology

length of test pipe or pipeline.

3.1 Definitions—For definitions of terms related to precast

1.4 Test times tabulated and the rate of air loss in this

concrete pipe, see Terminology C822.

standard are based on successful testing of installed pipelines.

However, since air and water have different physical

4. Summary of Test Method

properties, retests of some pipelines not meeting field air tests

4.1 The pipe to be tested shall be sealed at the outer ends

have been successful when tested with water.The leakage rates

withsuitableairtightbulkheads.Themanufacturershallchoose

2 2

of 0.0017 CFM/ft and 0.0003 CFM/ft , were determined

to use either low-pressure air or negative pressure air (vacuum)

empirically as the maximums for pipe to meet the 50 and 200

test methods to evaluate the condition of the pipe before

gal/(in. of internal diameter) (mile of sewer) (24h) test rates,

delivery. The change in the internal pressure during a specified

respectively.

time is used to determine the acceptability of the pipe.

1.5 The values stated in inch-pound units are to be regarded

5. Significance and Use

as standard. No other units of measurement are included in this

standard. 5.1 This is a quality control test performed at the manufac-

turing plant to establish that the finished, shippable pipe meets

NOTE 1—The availability of this test procedure for concrete pipe varies

the leakage limits stated in the specifications.

from location to location. Check with local supplier(s) for availability and

recommendations.

6. Safety Precautions

1.6 This standard does not purport to address all the safety

6.1 Theuserofthisspecificationisadvisedofthefollowing:

concerns, if any, associated with its use. It is the responsibility

6.1.1 This test may be dangerous if a pipe is not prepared

of the user of this standard to establish the appropriate safety

properly and proper procedures are not followed.

6.1.2 No one should be allowed near the ends of the pipe or

test bulkheads during the test.

1

This test method is under the jurisdiction of ASTM Committee C13 on

Concrete Pipe and is the direct responsibility of Subcommittee C13.09 on Methods

2

of Test. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2013. Published December 2013. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2005. Last previous edition approved in 2013 as C1618 – 05(2013). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/C1618-13. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1618 − 13

TABLE 1 Test Times For Negative Pressure Air Test, Seconds

7. Apparatus

NOTE 1—A pressure increase of 0.1083 in. Hg was chosen because it

7.1 For positive air pressure test, one bulkhead shall include

l

corresponds to a change in water column height of approximately l ⁄2 in.

a remote controlled valve that will release the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1618 − 05 (Reapproved 2013) C1618 − 13

Standard Test Method for

Concrete Sanitary Sewer Pipe by Negative (Vacuum) or

1

Positive Air Pressure

This standard is issued under the fixed designation C1618; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers procedures for testing of precast concrete pipe sections, prior to delivery, where maximum field

leakage rates are specified.

1.2 Tests described in this standard are intended to be used at the point of manufacture of the concrete pipe and are not intended

for testing installed pipe (for field tests see Practices C924, C969, and C1214). The user of this specification is advised that

individual or multiple pipe sections may be tested for the purpose of testing the pipe barrel and additionally the joints in straight

alignment when multiple pipe sections are tested.

1.3 The two leakage rates shown, which were used in calculating the test times, were chosen based on two generally accepted

field air and vacuum test criteria. Test times are based on leakage rates and therefore are proportional only to the pipe diameter

and are constant for any length of test pipe or pipeline.

1.4 Test times tabulated and the rate of air loss in this standard are based on successful testing of installed pipelines. However,

since air and water have different physical properties, retests of some pipelines not meeting field air tests have been successful

2 2

when tested with water. The leakage rates of 0.0017 CFM/ft and 0.0003 CFM/ft , were determined empirically as the maximums

for pipe to meet the 50 and 200 gal/(in. of internal diameter) (mile of sewer) (24h) test rates, respectively.

1.5 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this

standard.

NOTE 1—The availability of this test procedure for concrete pipe varies from location to location. Check with local supplier(s) for availability and

recommendations.

1.6 This standard does not purport to address all the safety concerns, if any, associated with its use. It is the responsibility of

the user of this standard to establish the appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to its use. See Section 6 for specific safety precautions.

2. Referenced Documents

2

2.1 ASTM Standards:

C822 Terminology Relating to Concrete Pipe and Related Products

C924 Practice for Testing Concrete Pipe Sewer Lines by Low-Pressure Air Test Method

C969 Practice for Infiltration and Exfiltration Acceptance Testing of Installed Precast Concrete Pipe Sewer Lines

C1214 Test Method for Concrete Pipe Sewerlines by Negative Air Pressure (Vacuum) Test Method

3. Terminology

3.1 Definitions—For definitions of terms related to precast concrete pipe, see Terminology C822.

4. Summary of Test Method

4.1 The pipe to be tested shall be sealed at the outer ends with suitable airtight bulkheads. The manufacturer shall choose to

use either low-pressure air or negative pressure air (vacuum) test methods to evaluate the condition of the pipe before delivery.

The change in the internal pressure during a specified time is used to determine the acceptability of the pipe.

1

This test method is under the jurisdiction of ASTM Committee C13 on Concrete Pipe and is the direct responsibility of Subcommittee C13.09 on Methods of Test.

Current edition approved Feb. 1, 2013July 1, 2013. Published February 2013December 2013. Originally approved in 2005. Last previous edition approved in 20052013

as C1618 – 05.C1618 – 05(2013). DOI: 10.1520/C1618-05R13.10.1520/C1618-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1618 − 13

5. Significance and Use

5.1 This is a quality control test performed at the manufacturing plant to establish that the finished, shippable pipe meets the

leakage limits stated in the specifications.

6. Safety Precautions

6.1 The user of this specification is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.