ASTM D5011-92(1997)e1

(Practice)Standard Practices for Calibration of Ozone Monitors Using Transfer Standards

Standard Practices for Calibration of Ozone Monitors Using Transfer Standards

SCOPE

1.1 These practices describe means for calibrating ambient, workplace or indoor ozone monitors, using transfer standards.

1.2 These practices describe five types of transfer standards: (A) Analytical instruments (B) Boric acid potassium iodide (BAKI) manual analytical procedure (C) Gas phase titration with excess nitric oxide (D) Gas phase titration with excess ozone (E) Ozone generator device.

1.3 These practices describe procedures to establish the authority of transfer standards: qualification, certification, and periodic recertification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section 8 for specific precautionary statements.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 5011 – 92 (Reapproved 1997)

Standard Practices for

1,2

Calibration of Ozone Monitors Using Transfer Standards

This standard is issued under the fixed designation D 5011; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Footnote 10 was deleted editorially in September 1997.

1. Scope D 5110 Practice for Calibration of Ozone Monitors and

Certification of Ozone Transfer Standards Using Ultravio-

1.1 These practices describe means for calibrating ambient,

let Photometry

workplace or indoor ozone monitors, using transfer standards.

E 591 Practice for Safety and Health Requirements Relating

1.2 These practices describe five types of transfer standards:

to Occupational Exposure to Ozone

(A) Analytical instruments

2.2 Other Documents:

(B) Boric acid potassium iodide (BAKI) manual analytical

40 CFR Part 50, Environmental Protection Agency Regula-

procedure

tions on Ambient Air Monitoring Reference Methods

(C) Gas phase titration with excess nitric oxide

(D) Gas phase titration with excess ozone

3. Terminology

(E) Ozone generator device.

3.1 For definitions of terms used in this standard, see

1.3 These practices describe procedures to establish the

Terminology D 1356.

authority of transfer standards: qualification, certification, and

3.2 Definitions of Terms Specific to This Standard:

periodic recertification.

3.2.1 primary standard—a standard directly defined and

1.4 This standard does not purport to address all of the

established by some authority, against which all secondary

safety concerns, if any, associated with its use. It is the

standards are compared.

responsibility of the user of this standard to establish appro-

3.2.2 secondary standard—a standard used as a means of

priate safety and health practices and determine the applica-

comparison, but checked against a primary standard.

bility of regulatory limitations prior to use. See Section 8 for

3.2.3 standard—an accepted reference sample or device

specific precautionary statements.

used for establishing measurement of a physical quantity.

2. Referenced Documents 3.2.4 transfer standard—a type of secondary standard. It is

a transportable device or apparatus, which, together with

2.1 ASTM Standards:

operational procedures, is capable of reproducing pollutant

D 1071 Test Methods for Volumetric Measurement of Gas-

concentration or producing acceptable assays of pollutant

eous Fuel Samples

concentrations.

D 1193 Specification for Reagent Water

3.2.5 zero air—purified air that does not contain ozone and

D 1356 Terminology Relating to Sampling and Analysis of

5 does not contain any other component that may interfere with

Atmospheres

the measurement. See 7.1.

D 3195 Practice for Rotameter Calibration

3.3 Symbols:

D 3249 Practice for General Ambient Air Analyzer Proce-

dures

D 3631 Test Methods for Measuring Surface Atmospheric

b = Spectrophotometer cell path length, cm. See

Pressure

Annex A2.

d = Average of discrete single point compari-

avg

These practices are under the jurisdiction of ASTM Committee D-22 on sons. See Annex A1.

Sampling and Analysis of Atmospheresand are the direct responsibility of Subcom-

d = Single point comparison. See Annex A1.

i

mittee D22.03on Ambient Atmospheres and Source Emissions.

F = Diluent air flow, mL/min.

D

Current edition approved Aug. 15, 1992. Published October 1992. Originally

F 8 = New diluent air flow, mL/min.

D

published as D 5011 – 89. Last previous edition D 5011 – 89.

F = NO flow, mL/min.

These practices are adapted from EPA-4-79-056, September 1979;“ Transfer NO

Standards for Calibration of Air Monitoring Analyzers for Ozone. Technical

Assistant Document” by F. F. McElroy, available from the National Technical

Information Service, Springfield, VA 22161.

3 6

Annual Book of ASTM Standards, Vol 05.05. Discontinued; see 1990 Annual Book of ASTM Standards, Vol 11.03.

4 7

Annual Book of ASTM Standards, Vol 11.01. Available from the Superintendent of Documents, U.S. Government Printing

Annual Book of ASTM Standards, Vol 11.03. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5011

F = Flow through the O generator, mL/min. P = Barometric pressure at sampling conditions,

O 3 S

F = Flowrate corrected to reference conditions kPa. See Annex A2.

R

(25°C and 101.3 kPa), mL/min. See Annex S = Slope of KI calibration curve, mL/mol/cm.

c

A2. See Annex A2.

F = Flowrate at sampling conditions, mL/min. s = Standard deviation of single point compari-

S d

See Annex A2. sons. See Annex A1.

F = The total flow required at the output mani- s = Relative standard deviation of the six inter-

T i

fold (monitors demand plus 10 to 50 % cepts. See Annex A1.

s = Relative standard deviation of the six slopes.

excess), mL/min.

m

I = The intensity of light which passes through See Annex A1.

t = Residence time in reaction chamber, min.

the photometer absorption cell and is sensed

R

t = Sampling time, min. See Annex A2.

by the detector when the cell contains an O

s

T = Temperature at sampling conditions, °C. See

sample. See Annex A4. S

Annex A2

[I ] = Concentration of each I standard, mol I /L.

2 i 2 2

URL = Upper range limit of O or NO monitor, ppm.

See Annex A2. 3

V = Volume of I solution, mL. See Annex A2

I = Average intercept. See Annex A1. i 2

avg

VO = Volume of O absorbed, μL. See Annex A2.

I = Individual intercepts. See Annex A1. 3 3

i

V = Volume of air sampled, corrected to 25°C

I = The intensity of light which passes through R

O

and 101.3 kPa (1 atm), mL. See Annex A2.

the photometer absorption cell and is sensed

V = Volume of the reaction chamber, mL.

RC

by the detector when the cell contains zero

y =O concentration indicated by the transfer

i 3

air. See Annex A4.

standard, ppm. See 10.6.2.

m = Average slope. See Annex A1.

avg

Z = Recorder response with zero air, % scale.

m = Individual slopes. See Annex A1.

i

mol I =I released, mols. See Annex A2.

2 2

4. Summary of Practices

N = Normality of KIO , equivalent/L. See Annex

KIO 3

4.1 These practices describe the procedures necessary to

A2.

[NO] = Diluted NO concentration, ppm. See Annex establish the authority of ozone transfer standards: qualifica-

A4. tion, certification, and periodic recertification. Qualification

[NO] = Original NO concentration, ppm. See Annex

consists of demonstrating that a candidate transfer standard is

ORIG

A3.

sufficiently stable (repeatable) to be useful as a transfer

[NO] = Highest NO concentration required at the

OUT standard. Repeatability is necessary over a range of variables

output manifold, ppm. It is approximately

(such as temperature, line voltage, barometric pressure, elapsed

equal to 90 % of the upper range limit of the

time, operator adjustments, relocation, etc.), any of which may

O concentration to be determined. See An-

be encountered during use of the transfer standard. Tests and

nex A3.

possible compensation techniques for several such common

[NO] = NO concentration (approximate) in the reac-

RC variables are described. Detailed certification procedures are

tion chamber, ppm. See Annex A3.

provided, and the quantitative specifications necessary to

[NO] = NO concentration remaining after addition of

REM

maintain continuous certification of the transfer standard are

O , ppm. See Annex A3.

3 also provided.

[NO] = Concentration of the undiluted NO standard,

STD

4.2 Method A—A dedicated ozone monitor is tested as

ppm.

described in 4.1 to demonstrate its authority as a transfer

n = Number of comparisons. See Eq 4

standard.

[O ] = Certified O concentration, ppm.

3 CERT 3 8

4.3 Method B—This method (1) is based on the reaction

[O ] = Diluted certified O concentration, ppm.

3 CERT8 3

between ozone (O ) and potassium iodide (KI) to release

[O ] =O concentration produced by the O genera-

3 GEN 3 3

iodine (I ) in accordance with the following stoichiometric

tor, ppm. See Annex A4.

equation (2):

[O ] = Indicated O concentration, ppm. See Annex

3 OUT 3

2 1

A2.

O 1 2I 1 2H 5 I 1 H O 1 O (1)

3 2 2 2

[O ] = Diluted O concentration, ppm.

3 OUT8 3

The stoichiometry is such that the amount of I released is

[O ] =O concentration (approximate) at the output

3 RC 3

equal to the amount of O absorbed. Ozone is absorbed in a 0.1

manifold, ppm.

N boric acid solution containing 1 % KI, and the I released

P = Vapor pressure of HOat T , kPa, wet

H O 2 S − −

reacts with excess iodide ion (I ) to form triiodide ion (I ),

volume standard. (For a dry standard,

which is measured spectrophotometrically at a wavelength of

P = 0.) (See Test Method D 4230 for

H O

352 nm. The output of a stable O generator is assayed in this

tables of saturation vapor pressure of water.)

manner, and the O generator is immediately used to calibrate

See Annex A2.

the O monitor.

P = Dynamic specification, determined empiri-

R

cally, to ensure complete reaction of O or

NO, ppm/min.

The boldface numbers in parentheses refer to the references at the end of these

practices.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5011

4.4 Method C—This procedure is based on the rapid gas 5. Significance and Use

phase reaction between nitric oxide (NO) and O , as described

5.1 The reactivity and instability of O precludes the storage

by the following equation (3):

of O concentration standards for any practical length of time,

NO 1 O 5 NO 1 O (2)

and precludes direct certification of O concentrations as

3 2

SRM’s. Moreover, there is no available SRM that can be

When O is added to excess NO in a dynamic system, the

readily and directly adapted to the generation of O standards

decrease in NO response is equivalent to the concentration of

analogous to permeation devices and standard gas cylinders for

O added. The NO is obtained from a standard NO cylinder,

sulfur dioxide and nitrogen oxides. Dynamic generation of O

and the O is produced by a stable O generator. A chemilu-

3 3

concentrations is relatively easy with a source of ultraviolet

minescence NO analyzer is used to measure the change in NO

(UV) radiation. However, accurately certifying an O concen-

concentration. The concentration of O added may be varied to

tration as a primary standard requires assay of the concentra-

obtain calibration concentrations over the range desired. The

tion by a comprehensively specified analytical procedure,

dynamic system is designed to produce locally high concen-

which must be performed every time a standard is needed.

trations of NO and O in the reaction chamber, with subsequent

5.2 The primary UV standard photometers, which are usu-

dilution, to effect complete O reaction with relatively small

ally used at a fixed location under controlled conditions, are

chamber volumes.

used to certify transfer standards that are then transported to the

4.5 Method D—This procedure is based on the rapid gas

field sites where the ambient ozone monitors are being used.

phase reaction between O and nitric oxide (NO) as described

See Practice D 5110.

by the following equation (3):

5.3 The advantages of this procedure are:

NO 1 O 5 NO 1 O (3)

3 2 2

5.3.1 All O monitors in a given network or region may be

When NO is added to excess O in a dynamic system, the

traced to a single primary standard.

decrease in O response observed on an uncalibrated O

3 3

5.3.2 The primary standard is used at only one location,

monitor is equivalent to the concentration of NO added. By

under controlled conditions.

measuring this decrease in response and the initial response,

5.3.3 Transfer standards are more rugged and more easily

the O concentration can be determined. Additional O con-

3 3

portable than primary standards.

centrations are generated by dilution. The gas phase titration

5.3.4 Transfer standards may be used to intercompare vari-

(GPT) system is used under predetermined flow conditions to

ous primary standards.

insure that the reaction of NO is complete and that further

reaction of the resultant nitrogen dioxide (NO ) with residual

6. Apparatus

O is negligible.

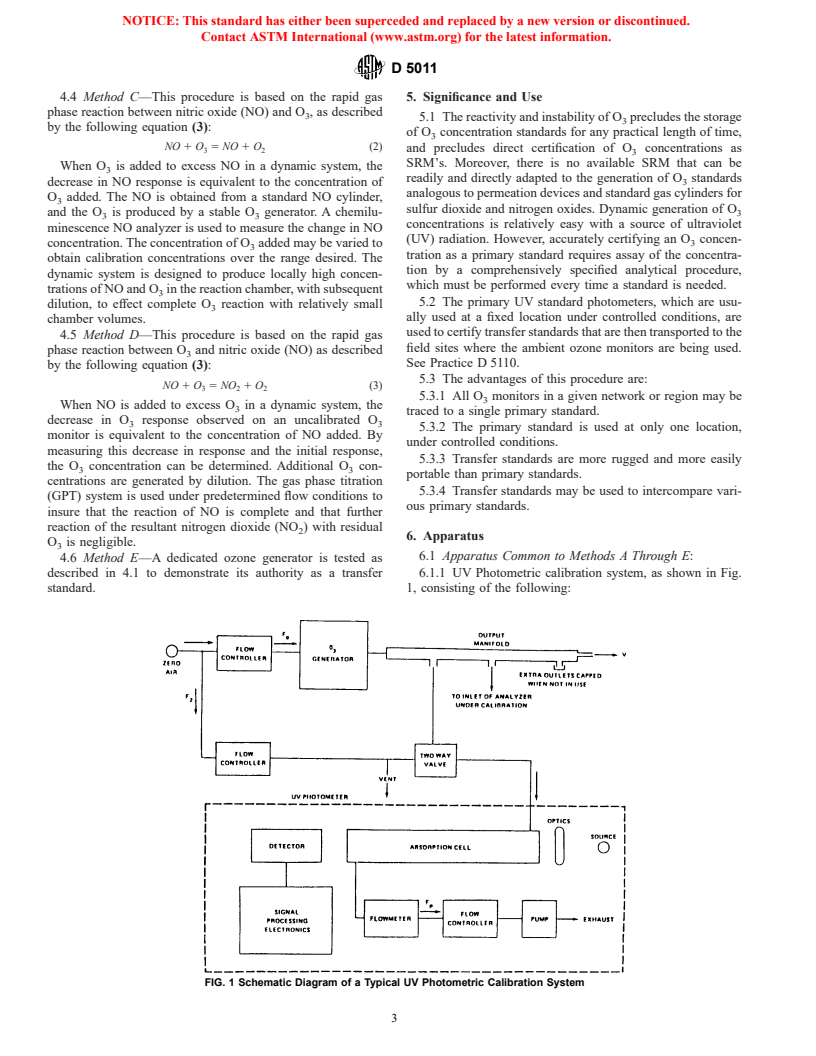

6.1 Apparatus Common to Methods A Through E:

4.6 Method E—A dedicated ozone generator is tested as

described in 4.1 to demonstrate its authority as a transfer 6.1.1 UV Photometric calibration system, as shown in Fig.

standard. 1, consisting of the following:

FIG. 1 Schematic Diagram of a Typical UV Photometric Calibration System

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5011

6.1.1.1 Primary Ozone Standard—a UV photometer, con- a pressure correction. Most photometer cells operate at atmo-

sisting of a low-pressure mercury discharge lamp, collimation spheric pressure. If there are no restrictions between the cell

optics (optional), an absorption cell, a detector, and signal- and the output manifold, the cell pressure should be very nearly

processing electronics. It shall be capable of measuring the the same as the local barometric pressure. A certified local

transmittance, I/I , at a wavelength of 253.7 nm with sufficient barometric pressure reading can then be used for the pressure

precision that the standard deviation of the concentration correction. If the cell pressure is different than the local

measurements does not exceed the greater of 0.005 ppm or 3 % barometric pressure, some means of accurately measuring the

of the concentration. It shall incorporate means to assure that cell pressure (manometer, pressure gage, or pressure trans-

no O is generated in the cell by the UV lamp. This is generally ducer) is required. This device shall be calibrated against a

accomplished by filtering out the 184.9 nm Hg line with a high suitable pressure standard, in accordance with Test Methods

silica filter. In addition, at least 99.5 % of the radiation sensed D 3631.

by the detector shall be 253.7 nm. This is usually accomplished 6.1.2 Output Indicating Device, such as Continuous Strip

by using a solar blind photodiode tube. The length of the light Chart Recorder or Digital Volt Meter—If a recorder is used, it

path through the absorption cell shall be kno

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.