ASTM D3916-08

(Test Method)Standard Test Method for Tensile Properties of Pultruded Glass-Fiber-Reinforced Plastic Rod

Standard Test Method for Tensile Properties of Pultruded Glass-Fiber-Reinforced Plastic Rod

SIGNIFICANCE AND USE

The high axial-tensile strength and the low transverse-compressive strength of pultruded rod combine to present some unique problems in determining the tensile strength of this material with conventional test grips. The high transverse-compressive forces generated in the conventional method of gripping tend to crush the rod, thereby causing premature failure. In this test method, aluminum-alloy tabs contoured to the shape of the rod reduce the compressive forces imparted to the rod, thus overcoming the deleterious influence of conventional test grips.

Tensile properties are influenced by specimen preparation, strain rate, thermal history, and the environmental conditions at the time of testing. Consequently, where precise comparative results are desired, these factors must be carefully controlled.

Tensile properties provide useful data for many engineering design purposes. However, due to the high sensitivity of these properties to strain rate, temperature, and other environmental conditions, data obtained by this test method should not, by themselves, be considered for applications involving load-time scales or environmental conditions that differ widely from the test conditions. In cases where such dissimilarities are apparent, the sensitivities to strain rate, including impact and creep, as well as to environment, should be determined over a wide range of conditions as dictated by the anticipated service requirements.

SCOPE

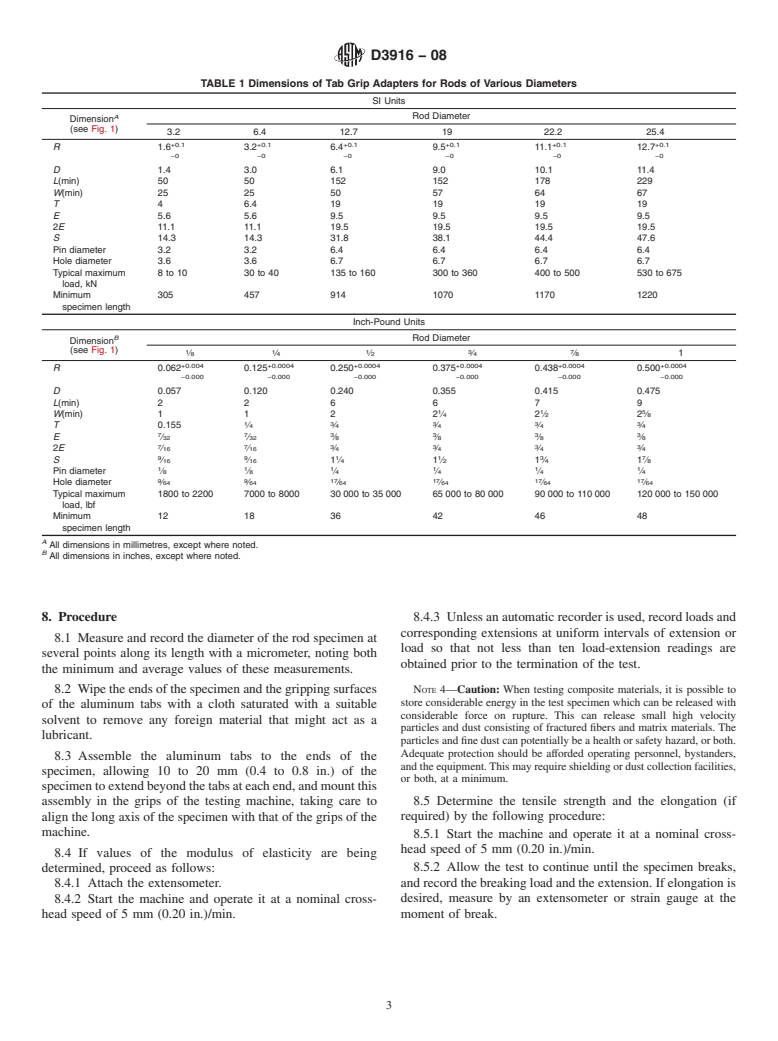

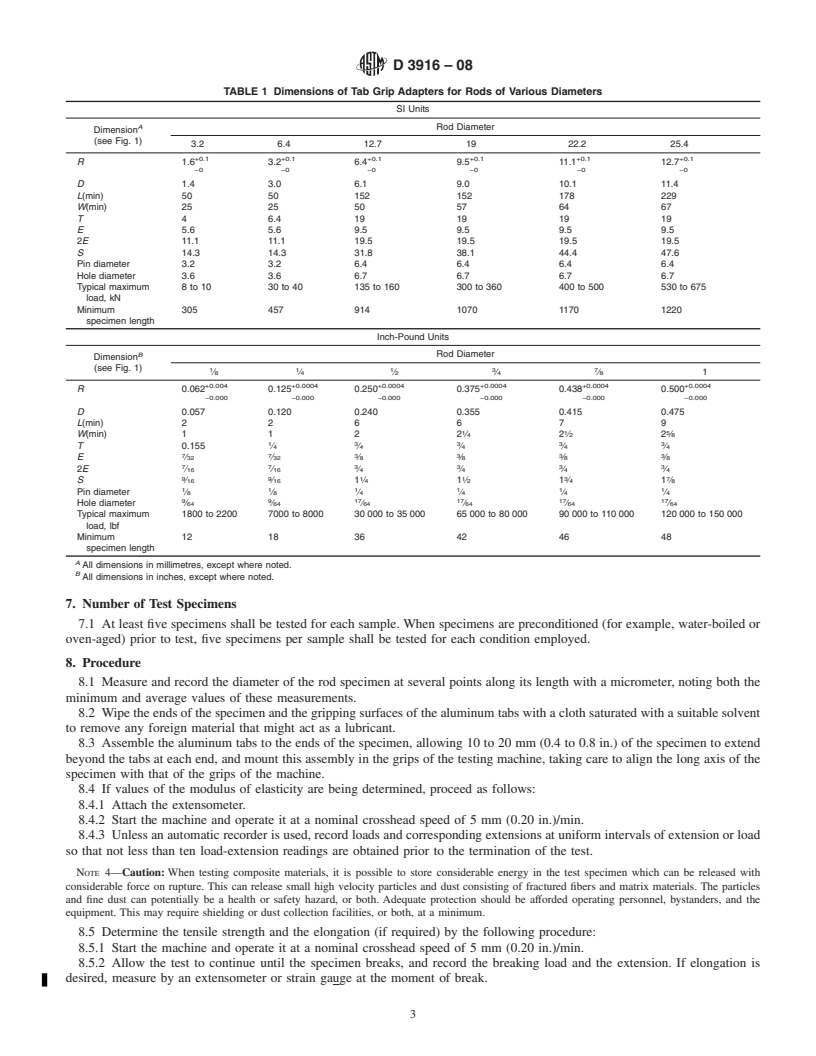

1.1 This test method describes a procedure for determining the tensile properties of pultruded, glass-fiber-reinforced thermosetting plastic rod of diameters ranging from 3.2 mm (1/8 in.) to 25.4 mm (1 in.). Little test specimen preparation is required; however, reusable aluminum tab grip adapters (Fig. 1) of appropriate size are required to prevent premature failure of the specimens at the grips.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Note 3 and Note 4.

Note 1—There is no known ISO equivalent to this test method.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3916 − 08

StandardTest Method for

Tensile Properties of Pultruded Glass-Fiber-Reinforced

1

Plastic Rod

This standard is issued under the fixed designation D3916; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* unique problems in determining the tensile strength of this

material with conventional test grips. The high transverse-

1.1 This test method describes a procedure for determining

compressive forces generated in the conventional method of

the tensile properties of pultruded, glass-fiber-reinforced ther-

gripping tend to crush the rod, thereby causing premature

1

mosettingplasticrodofdiametersrangingfrom3.2mm( ⁄8in.)

failure. In this test method, aluminum-alloy tabs contoured to

to25.4mm(1in.).Littletestspecimenpreparationisrequired;

the shape of the rod reduce the compressive forces imparted to

however, reusable aluminum tab grip adapters (Fig. 1)of

the rod, thus overcoming the deleterious influence of conven-

appropriatesizearerequiredtopreventprematurefailureofthe

tional test grips.

specimens at the grips.

3.2 Tensile properties are influenced by specimen

1.2 The values stated in SI units are to be regarded as the

preparation, strain rate, thermal history, and the environmental

standard. The values given in parentheses are for information

conditions at the time of testing. Consequently, where precise

only.

comparative results are desired, these factors must be carefully

1.3 This standard does not purport to address all of the

controlled.

safety concerns, if any, associated with its use. It is the

3.3 Tensile properties provide useful data for many engi-

responsibility of the user of this standard to establish appro-

neering design purposes. However, due to the high sensitivity

priate safety and health practices and determine the applica-

of these properties to strain rate, temperature, and other

bility of regulatory limitations prior to use. Specific hazards

environmental conditions, data obtained by this test method

statements are given in Note 3 and Note 4.

should not, by themselves, be considered for applications

NOTE 1—There is no known ISO equivalent to this test method.

involving load-time scales or environmental conditions that

differ widely from the test conditions. In cases where such

2. Referenced Documents

dissimilarities are apparent, the sensitivities to strain rate,

2

2.1 ASTM Standards:

including impact and creep, as well as to environment, should

D618Practice for Conditioning Plastics for Testing

be determined over a wide range of conditions as dictated by

D638Test Method for Tensile Properties of Plastics

the anticipated service requirements.

E4Practices for Force Verification of Testing Machines

E83Practice for Verification and Classification of Exten-

4. Apparatus

someter Systems

4.1 Water-Cooled Diamond or Tungsten-Carbide Saw, for

cutting rod to size.

3. Significance and Use

4.2 Micrometer, reading to at least 0.025 6 0.000 mm

3.1 The high axial-tensile strength and the low transverse-

(0.001 6 0.000 in.), for measuring the width and thickness of

compressivestrengthofpultrudedrodcombinetopresentsome

the test specimens. The thickness of nonrigid plastics (rein-

forcedpultrudedproductsarerigid)shouldbemeasuredwitha

dial micrometer that exerts a pressure of 25 6 kPa (3.6 6 0.7

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

psi) on the specimen and measures the thickness to within

and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermoset-

ting Plastics.

0.025 mm (0.001 in.). The anvil of the micrometer shall be at

Current edition approved March 1, 2008. Published March 2008. Originally

least 30 mm (1.4 in.) in diameter and parallel to the face of the

approved in 1980. Last previous edition approved in 2002 as D3916-02. DOI:

contact foot.

10.1520/D3916-08.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.3 Universal Testing Machine, verified in accordance with

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Practices E4, having a capacity of at least 530 kN (120 000

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. lbf) to permit the testing of 25.4 mm (1 in.) diameter rod.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3916 − 08

NOTE 1—Sandblast

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3916–02 Designation:D3916–08

Standard Test Method for

Tensile Properties of Pultruded Glass-Fiber-Reinforced

1

Plastic Rod

This standard is issued under the fixed designation D 3916; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This test method describes a procedure for determining the tensile properties of pultruded, glass-fiber-reinforced

1

thermosetting plastic rod of diameters ranging from 3.2 mm ( ⁄8 in.) to 25.4 mm (1 in.). Little test specimen preparation is required;

however, reusable aluminum tab grip adapters (Fig. 1) of appropriate size are required to prevent premature failure of the

specimens at the grips.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific hazards statements are given in Note 3 and Note 4.

NOTE 1—There is no known ISO equivalent to this test method.

2. Referenced Documents

2

2.1 ASTM Standards:

D 618 Practice for Conditioning Plastics for Testing

D 638 Test Method for Tensile Properties of Plastics

E 4 Practices for Force Verification of Testing Machines

E 83 Practice for Verification and Classification of Extensometer Systems

3. Significance and Use

3.1 The high axial-tensile strength and the low transverse-compressive strength of pultruded rod combine to present some

unique problems in determining the tensile strength of this material with conventional test grips. The high transverse-compressive

forces generated in the conventional method of gripping tend to crush the rod, thereby causing premature failure. In this test

method,aluminum-alloytabscontouredtotheshapeoftherodreducethecompressiveforcesimpartedtotherod,thusovercoming

the deleterious influence of conventional test grips.

3.2 Tensile properties are influenced by specimen preparation, strain rate, thermal history, and the environmental conditions at

the time of testing. Consequently, where precise comparative results are desired, these factors must be carefully controlled.

3.3 Tensile properties provide useful data for many engineering design purposes. However, due to the high sensitivity of these

properties to strain rate, temperature, and other environmental conditions, data obtained by this test method should not, by

themselves, be considered for applications involving load-time scales or environmental conditions that differ widely from the test

conditions. In cases where such dissimilarities are apparent, the sensitivities to strain rate, including impact and creep, as well as

to environment, should be determined over a wide range of conditions as dictated by the anticipated service requirements.

4. Apparatus

4.1 Water-Cooled Diamond or Tungsten-Carbide Saw, for cutting rod to size.

4.2 Micrometer, reading to at least 0.025 6 0.000 mm (0.001 6 0.000 in.), for measuring the width and thickness of the test

specimens. The thickness of nonrigid plastics (reinforced pultruded products are rigid) should be measured with a dial micrometer

that exerts a pressure of 25 6 kPa (3.6 6 0.7 psi) on the specimen and measures the thickness to within 0.025 mm (0.001 in.).

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermosetting

Plastics.

Current edition approved March 10, 2002. Published May 2002. Originally published as D3916–80. Last previous edition D3916–94.

Current edition approved March 1, 2008. Published March 2008. Originally approved in 1980. Last previous edition approved in 2002 as D3916 - 02.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 08.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.