ASTM F788/F788M-97

(Specification)Standard Specification for Surface Discontinuities of Bolts, Screws, and Studs, Inch and Metric Series

Standard Specification for Surface Discontinuities of Bolts, Screws, and Studs, Inch and Metric Series

SCOPE

1.1 This specification establishes allowable limits for the various types of surface discontinuities that may occur during the manufacture and processing of bolts, screws, and studs, including heat-treated machine screws, tapping screws, and sems (the washers of screw-washer assemblies are excluded). This specification covers metric series products with nominal diameters of 4 mm and larger and with specified minimum tensile strengths of 800 MPa and greater; and inch series products with nominal diameters of No. 5 (0.1250 in.) and larger and with specified minimum tensile strengths of 90 000 psi and greater.

1.2 The values stated in either SI (metric) or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents, therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 When the engineering requirements of the application necessitate control of surface discontinuities on bolts, screws, or studs, the purchaser shall specify conformance to ASTM Specification F788/F788M, in the original inquiry and purchase order.

1.3.1 When the engineering requirements of the application necessitate that surface discontinuities on bolts, screws, and studs be controlled within limits closer than those specified in this specification, the purchaser shall specify the applicable limits in the original inquiry and purchase order.

1.4 The allowable limits established in this specification for metric bolts, screws, and studs with nominal diameters from 4 to 24 mm inclusive, are essentially identical with requirements given in ISO/DIS 6157/I. There are no ISO standards for surface discontinuities on metric series bolts, screws, and studs with nominal diameters larger than 24 mm or on any inch-series products.

General Information

Relations

Standards Content (Sample)

Designation: F 788/F 788M – 97

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Surface Discontinuities of Bolts, Screws, and Studs, Inch

1

and Metric Series

This standard is issued under the fixed designation F 788/F 788M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense. Consult the DoD Index of Specifications and

Standards for the specific year of issue which has been adopted by the Department of Defense.

2

1. Scope * E 340 Test Method for Macroetching Metals and Alloys

3

2.2 ISO Standard:

1.1 This specification establishes allowable limits for the

ISO 6157/I Fasteners, Surface Discontinuities on Bolts,

various types of surface discontinuities that may occur during

Screws and Studs

the manufacture and processing of bolts, screws, and studs,

including heat-treated machine screws, tapping screws, and

3. Ordering Information

sems (the washers of screw-washer assemblies are excluded).

3.1 Orders for bolts, screws, and studs requiring disconti-

This specification covers metric series products with nominal

nuity control shall include the following:

diameters of 4 mm and larger and with specified minimum

3.1.1 ASTM designation and date of issue of this specifica-

tensile strengths of 800 MPa and greater; and inch series

tion.

products with nominal diameters of No. 5 (0.1250 in.) and

3.1.2 Special requirements, for example, closer discontinu-

larger and with specified minimum tensile strengths of 90 000

ity limits (1.3.1) and inspection sampling plan (6.2).

psi and greater.

1.2 The values stated in either SI (metric) or inch-pound

4. Types of Surface Discontinuities

units are to be regarded separately as standard. The values

4.1 Crack—A crack is a clean (crystalline) fracture passing

stated in each system are not exact equivalents, therefore, each

through or across the grain boundaries and may possibly follow

system must be used independently of the other. Combining

inclusions of foreign elements. Cracks are normally caused by

values from the two systems may result in nonconformance

overstressing the metal during forging or other forming opera-

with the specification.

tions, or during heat treatment. Where parts are subjected to

1.3 When the engineering requirements of the application

significant reheating, cracks usually are discolored by scale.

necessitate control of surface discontinuities on bolts, screws,

4.1.1 Quench Cracks—Quench cracks may occur due to

or studs, the purchaser shall specify conformance to ASTM

excessively high thermal and transformation stresses during

Specification F 788/F 788M, in the original inquiry and pur-

heat treatment. Quench cracks usually traverse an irregular and

chase order.

erratic course on the surface of the fastener. Typical quench

1.3.1 When the engineering requirements of the application

cracks are shown in Fig. 1. Limits are specified in 5.2.

necessitate that surface discontinuities on bolts, screws, and

4.1.2 Forging Cracks—Forging cracks may occur during

studs be controlled within limits closer than those specified in

the cutoff or forging operations and are located on the top of

this specification, the purchaser shall specify the applicable

the head and on the raised periphery of indented head bolts and

limits in the original inquiry and purchase order.

screws. Typical forging cracks are shown in Fig. 2. Limits are

1.4 The allowable limits established in this specification for

specified in 5.3.

metric bolts, screws, and studs with nominal diameters from 4

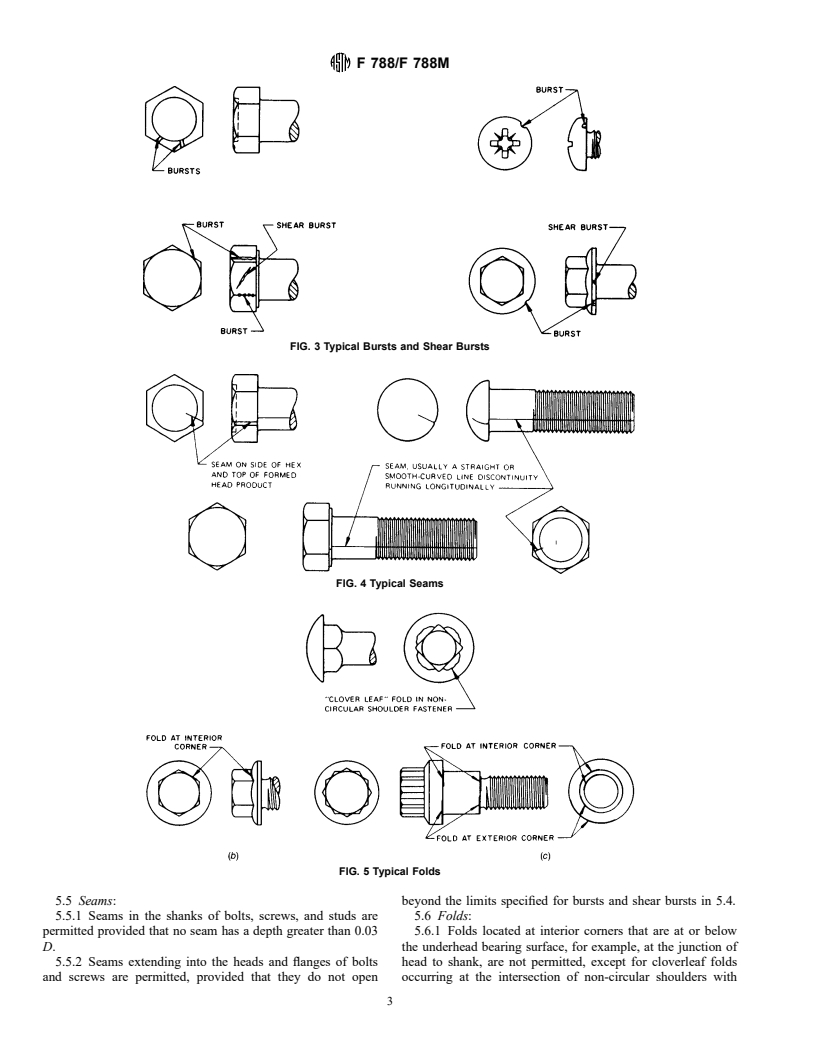

4.2 Burst—A burst is an open break in the metal. Bursts

to 24 mm inclusive, are essentially identical with requirements

occur during the forging operation and are located on the flats

given in ISO 6157/I. There are no ISO standards for surface

or corners of heads or at the periphery of flanged or circular

discontinuities on any inch-series products.

head products or on the raised periphery of indented head bolts

and screws. Typical bursts are shown in Fig. 3. Limits are

2. Referenced Documents

specified in 5.4.

2.1 ASTM Standards:

4.2.1 Shear Burst—A shear burst is an open break in the

metal located at approximately a 45° angle to the product axis.

1

This specification is under the jurisdiction of ASTM Committee F-16 on

Fasteners and is the direct responsibility of Subcommittee F16.93 on Quality

2

Assurance Provisions for Fasteners. Annual Book of ASTM Standards, Vol 03.01.

3

Current edition approved Feb. 10, 1997. Published August 1997. Originally Available from American National Standards Institute, 11 West 42nd Street,

published as F 788/F 788M – 82. Last previous editio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.