ASTM C614-10

(Test Method)Standard Test Method for Alkali Resistance of Porcelain Enamels

Standard Test Method for Alkali Resistance of Porcelain Enamels

SIGNIFICANCE AND USE

This test method is intended specifically for testing the resistance to alkaline attack of porcelain enamels to be used as a final finish on washing machines, dishwashers, combination washer-dryers, and similar appliances where the surface is normally exposed to an alkaline environment at elevated temperatures.

SCOPE

1.1 This test method covers the measurement of the resistance of a porcelain enamel to a hot solution of tetrasodium pyrophosphate. Although the specific alkali mentioned herein is tetrasodium pyrophosphate the equipment and techniques are equally applicable to other alkali solutions.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C614–10

Standard Test Method for

1

Alkali Resistance of Porcelain Enamels

This standard is issued under the fixed designation C614; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Although all porcelain enamels are highly resistant to atttack by cold alkaline solutions, some

compositions are affected by hot solutions of the type encountered in automatic laundry and

dishwashing equipment. Tests to eliminate porcelain enamels of poor resistance have been developed

and used by various laboratories. In general, these tests consist of subjecting specimens to a boiling

solution of either sodium pyrophosphate or sodium hydroxide for a period of two or more hours. The

specimens are weighed before and after exposure to the test treatment and the loss-in-weight is taken

as a measure of alkali attack. In some tests representing milder exposure conditions, the 45 degree

specularglossismeasuredbeforeandafterexposureandthepercentageofinitialglossretainedisused

as an indicator of alkali resistance. While such tests have served a useful purpose in developing more

resistant porcelain enamel compositions and in manufacturing control operations, agreement between

laboratories has left something to be desired. The present test was designed to provide the

reproducibility between laboratories that is so essential to any standard test procedure.

1. Scope washer-dryers, and similar appliances where the surface is

2

normally exposed to an alkaline environment at elevated

1.1 This test method covers the measurement of the resis-

temperatures.

tance of a porcelain enamel to a hot solution of tetrasodium

pyrophosphate. Although the specific alkali mentioned herein

3. Apparatus

istetrasodiumpyrophosphatetheequipmentandtechniquesare

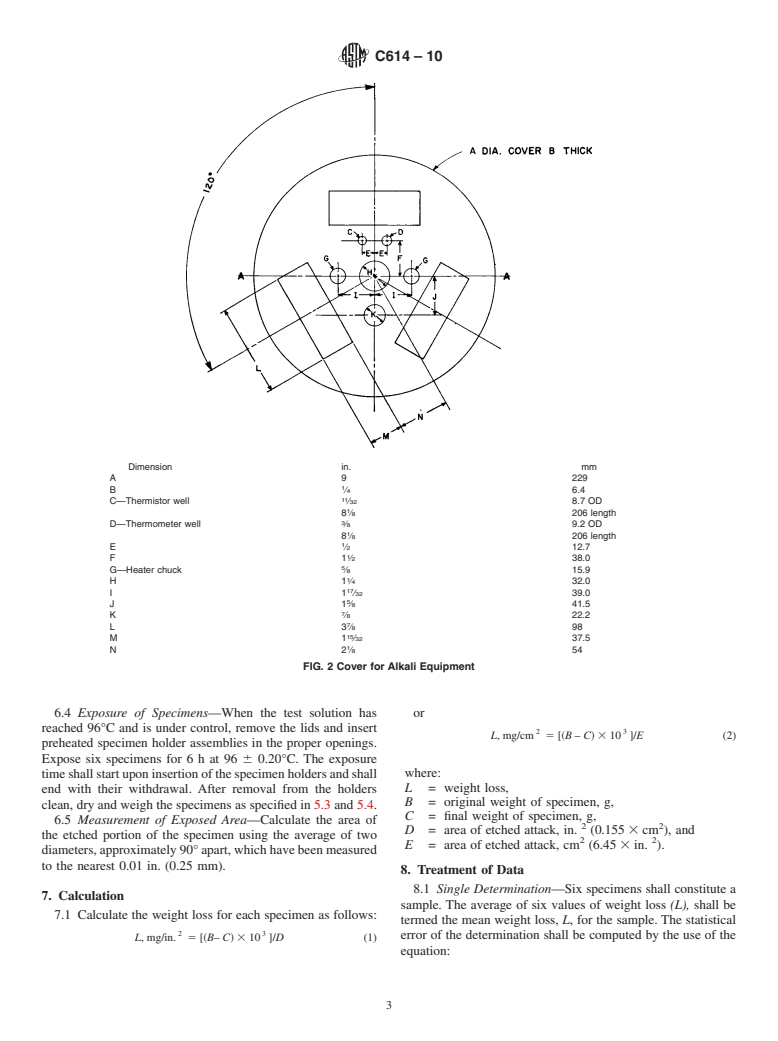

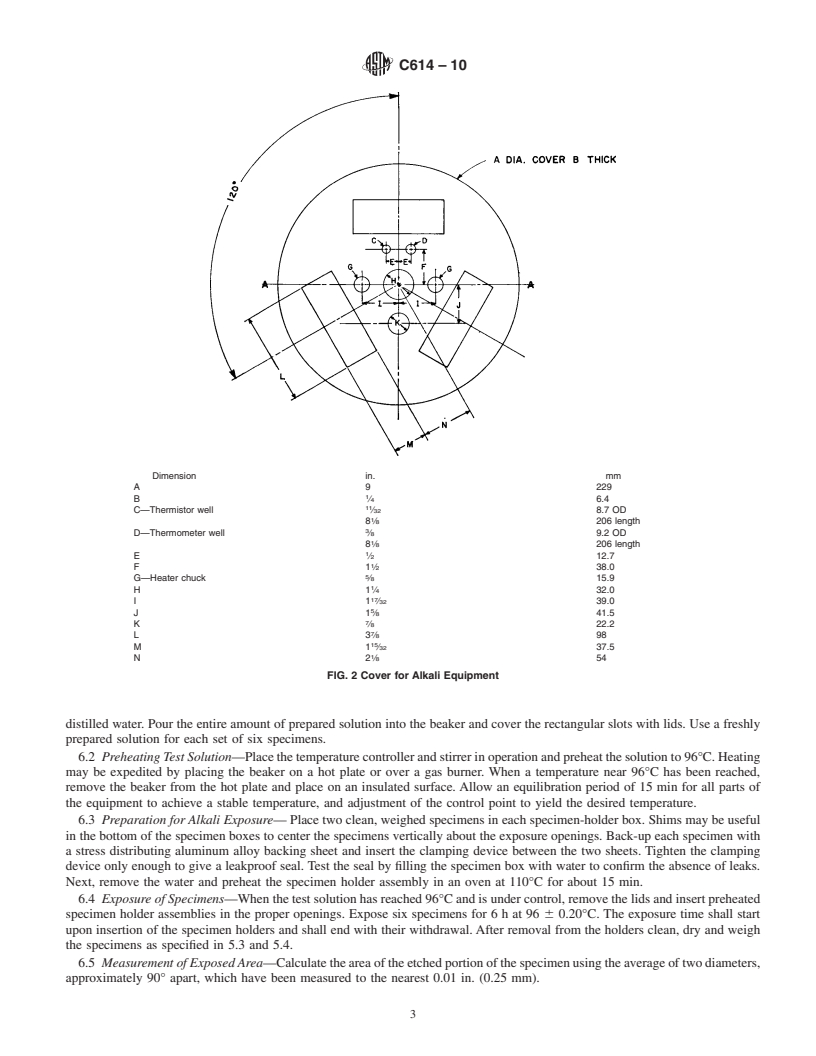

3.1 Test Chamber, of a type illustrated in Fig. 1, Fig. 3, and

equally applicable to other alkali solutions.

Fig. 6. This part of the equipment consists of a stainless steel

1.2 The values stated in inch-pound units are to be regarded

beaker fitted with an O-ring sealed cover which supports an

as standard. The values given in parentheses are mathematical

immersion heater, a stirring device, thermometer and thermis-

conversions to SI units that are provided for information only

tor wells; three specimen holders; a reflux condenser; a flow

and are not considered standard.

channeling shield to slide over and be supported by the

1.3 This standard does not purport to address all of the

3

immersion heater; and a stirring motor. The beaker, heater

safety concerns, if any, associated with its use. It is the

sheath, stirring device, thermometer and thermistor wells,

responsibility of the user of this standard to establish appro-

specimenholders,andtheflowchannelingshieldshallbemade

priate safety and health practices and determine the applica-

from stainless steel alloys from the AISI 300 Series.

bility of regulatory limitations prior to use.

3.2 Temperature Controller, thermistor-actuated, capable of

2. Significance and Use maintaining the temperature of the alkali solution in the beaker

at 96.00 6 0.20°C.

2.1 This test method is intended specifically for testing the

3.3 Thermometer, calibrated, approximately 15 in. (380

resistance to alkaline attack of porcelain enamels to be used as

9

mm) long and ⁄32 in. (7.1 mm) in diameter, with 0.1° divisions.

a final finish on washing machines, dishwashers, combination

3.4 Drying Oven, electrically heated.

3.5 Balance,havingasensitivityof0.1mgandacapacityof

not less than 200 g.

1

This test method is under the jurisdiction ofASTM Committee B08 on Metallic

3.6 Desiccator.

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.12 on

3.7 Hot Plate, or burner suitable for heating the test solu-

Materials for Porcelain Enamel and Ceramic-Metal Systems.

tion.

Current edition approved Nov. 1, 2010. Published November 2010. Originally

approved in 1968. Last previous edition approved in 2005 as C614 – 74 (2005).

DOI: 10.1520/C0614-10.

2 3

This test was developed at the National Bureau of Standards under the See the appendix for drawings of the equipment. This equipment may be

sponsorship of The Porcelain Enamel Institute, Inc., and published as P. E. I. purchased from the Hoover Instrument Service, Inc., 401 N. Home Rd.,Mansfield,

Bulletin T-25. OH 44906.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C614–10

NOTE 1—Test solution is in stainless steel beaker.

FIG. 1 Alkali Equipment in Operation

3.8 Sponge, soft, c

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C614–74 (Reapproved 2005) Designation:C614–10

Standard Test Method for

1

Alkali Resistance of Porcelain Enamels

This standard is issued under the fixed designation C614; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Although all porcelain enamels are highly resistant to atttack by cold alkaline solutions, some

compositions are affected by hot solutions of the type encountered in automatic laundry and

dishwashing equipment. Tests to eliminate porcelain enamels of poor resistance have been developed

and used by various laboratories. In general, these tests consist of subjecting specimens to a boiling

solution of either sodium pyrophosphate or sodium hydroxide for a period of two or more hours. The

specimens are weighed before and after exposure to the test treatment and the loss-in-weight is taken

as a measure of alkali attack. In some tests representing milder exposure conditions, the 45 degree

specularglossismeasuredbeforeandafterexposureandthepercentageofinitialglossretainedisused

as an indicator of alkali resistance. While such tests have served a useful purpose in developing more

resistant porcelain enamel compositions and in manufacturing control operations, agreement between

laboratories has left something to be desired. The present test was designed to provide the

reproducibility between laboratories that is so essential to any standard test procedure.

1. Scope

2

1.1 This test method covers the measurement of the resistance of a porcelain enamel to a hot solution of tetrasodium

pyrophosphate. Although the specific alkali mentioned herein is tetrasodium pyrophosphate the equipment and techniques are

equally applicable to other alkali solutions.

1.2

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Significance and Use

2.1 This test method is intended specifically for testing the resistance to alkaline attack of porcelain enamels to be used as a final

finish on washing machines, dishwashers, combination washer-dryers, and similar appliances where the surface is normally

exposed to an alkaline environment at elevated temperatures.

3. Apparatus

3.1 TestChamber, of a type illustrated in Fig. 1, Fig. 3, and Fig. 6.This part of the equipment consists of a stainless steel beaker

fitted with an O-ring sealed cover which supports an immersion heater, a stirring device, thermometer and thermistor wells; three

specimen holders; a reflux condenser; a flow channeling shield to slide over and be supported by the immersion heater; and a

3

stirring motor. The beaker, heater sheath, stirring device, thermometer and thermistor wells, specimen holders, and the flow

channeling shield shall be made from stainless steel alloys from the AISI 300 Series.

1

This test method is under the jurisdiction of ASTM Committee B08 on Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee B08.12 on

Materials for Porcelain Enamel and Ceramic-Metal Systems.

Current edition approved Sept. 15, 2005. Published September 2005. Originally approved in 1968. Last previous edition approved in 1999 as C614–74 (1999). DOI:

10.1520/C0614-74R05.

Current edition approved Nov. 1, 2010. Published November 2010. Originally approved in 1968. Last previous edition approved in 2005 as C614 – 74 (2005). DOI:

10.1520/C0614-10.

2

This test was developed at the National Bureau of Standards under the sponsorship of The Porcelain Enamel Institute, Inc., and published as P. E. I. Bulletin T-25.

3

See the appendix for drawings of the equipment. This equipment may be purchased from the Hoover Instrument Service, Inc., 401 N. Home Rd.,Mansfield, OH 44906.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C614–10

NOTE 1—Test solution is in stainless steel beaker.

FIG. 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.