ASTM E238-17a

(Test Method)Standard Test Method for Pin-Type Bearing Test of Metallic Materials

Standard Test Method for Pin-Type Bearing Test of Metallic Materials

SIGNIFICANCE AND USE

4.1 The data obtained from the bearing test are the bearing ultimate and yield strength. The data provide a measure of the load-carrying capacity of a material edge loaded with a close-fitting cylindrical pin through a hole located a specific distance from the specimen edge.

4.2 Bearing properties are useful in the comparison of materials and design of structures under conditions where the pin is not restricted.

SCOPE

1.1 This test method covers a pin-type bearing test of metallic materials to determine bearing yield strength and bearing strength.

Note 1: The presence of incidental lubricants on the bearing surfaces may significantly lower the value of bearing yield strength obtained by this method.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E238 − 17a

Standard Test Method for

1

Pin-Type Bearing Test of Metallic Materials

This standard is issued under the fixed designation E238; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

3.1 Definitions:

1.1 This test method covers a pin-type bearing test of

3.1.1 bearing area—the product of the pin diameter and

metallic materials to determine bearing yield strength and

specimen thickness.

bearing strength.

3.1.2 bearing stress—the force per unit of bearing area.

NOTE 1—The presence of incidental lubricants on the bearing surfaces

may significantly lower the value of bearing yield strength obtained by

3.1.3 bearing strain—theratioofthebearingdeformationof

this method.

the bearing hole, in the direction of the applied force, to the pin

diameter.

1.2 Units—The values stated in inch-pound units are to be

regarded as standard. The values given in parentheses are

3.1.4 bearing yield strength—the bearing stress at which a

mathematical conversions to SI units that are provided for

material exhibits a specified limiting deviation from the pro-

information only and are not considered standard.

portionality of bearing stress to bearing strain.

1.3 This standard does not purport to address all of the

3.1.5 bearing strength—the maximum bearing stress which

safety concerns, if any, associated with its use. It is the

a material is capable of sustaining.

responsibility of the user of this standard to establish appro-

3.1.6 edge distance—thedistancefromtheedgeofabearing

priate safety and health practices and determine the applica-

specimen to the center of the hole in the direction of applied

bility of regulatory limitations prior to use.

force (Fig. 1).

1.4 This international standard was developed in accor-

3.1.7 edge distance ratio—the ratio of the edge distance to

dance with internationally recognized principles on standard-

the pin diameter.

ization established in the Decision on Principles for the

3.1.8 For definitions of other terms see Terminology E6.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4. Significance and Use

Barriers to Trade (TBT) Committee.

4.1 The data obtained from the bearing test are the bearing

ultimate and yield strength. The data provide a measure of the

2. Referenced Documents

load-carrying capacity of a material edge loaded with a

2

2.1 ASTM Standards:

close-fitting cylindrical pin through a hole located a specific

E4 Practices for Force Verification of Testing Machines

distance from the specimen edge.

E6 Terminology Relating to Methods of Mechanical Testing

4.2 Bearing properties are useful in the comparison of

E83 Practice for Verification and Classification of Exten-

materials and design of structures under conditions where the

someter Systems

pin is not restricted.

B769 Test Method for Shear Testing of Aluminum Alloys

B831 Test Method for Shear Testing of Thin Aluminum

5. Apparatus

Alloy Products

5.1 Testing Machines—Machines used for bearing testing

shall conform to the requirements of Practices E4.

5.2 Gripping Devices—Various types of gripping devices

1

This test method is under the jurisdiction of ASTM Committee E28 on

may be used to transmit the measured load applied by the

Mechanical Testing and is the direct responsibility of Subcommittee E28.04 on

Uniaxial Testing.

testing machine to the test specimens.Any grips considered to

Current edition approved April 1, 2017. Published April 2017. Originally

apply the load axially for tension testing, such as pin connec-

approved in 1964. Last previous edition approved in 2017 as E238 – 17. DOI:

tions or wedge grips, are satisfactory for use in bearing testing.

10.1520/E0238-17A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

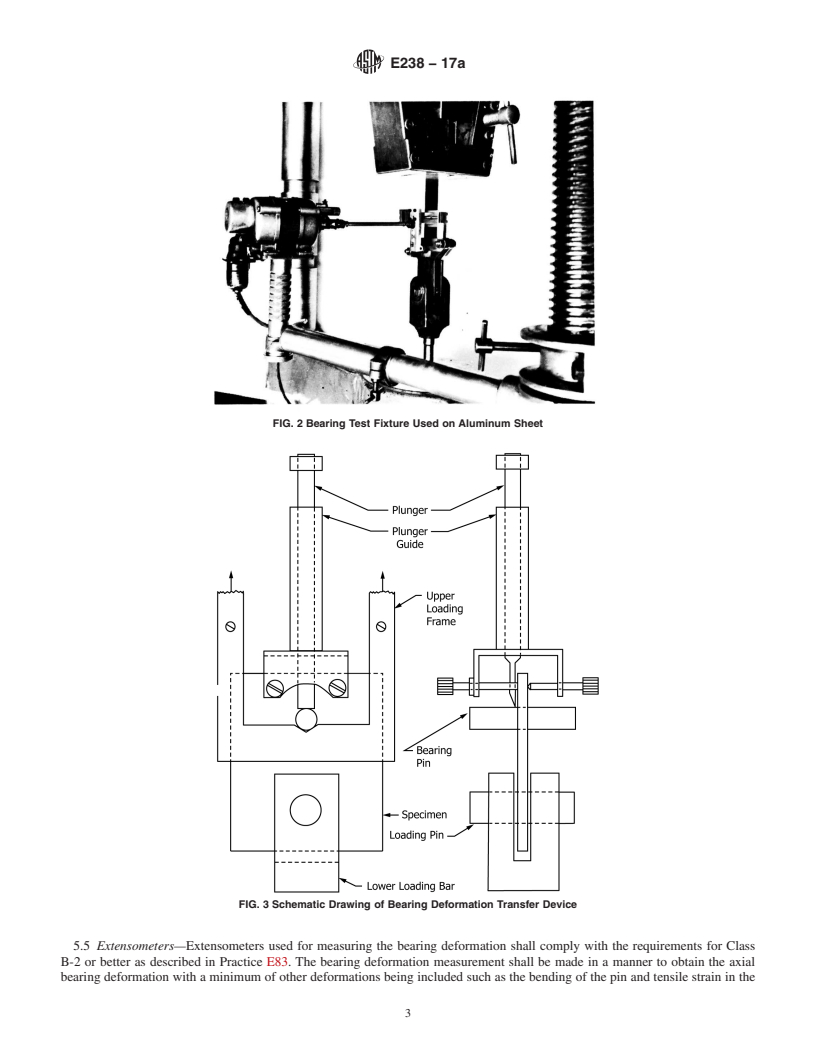

5.3 Pin—The bearing load is generally applied to the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

specimen through a close-fitting cylindrical pin. The pin shall

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. be harder and stronger than the material being tested. Restraint

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E238 − 17a

ofmovementofthespecimenwhereitisi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E238 − 12 E238 − 17a

Standard Test Method for

1

Pin-Type Bearing Test of Metallic Materials

This standard is issued under the fixed designation E238; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers a pin-type bearing test of metallic materials to determine bearing yield strength and bearing

strength.

NOTE 1—The presence of incidental lubricants on the bearing surfaces may significantly lower the value of bearing yield strength obtained by this

method.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

E6 Terminology Relating to Methods of Mechanical Testing

E83 Practice for Verification and Classification of Extensometer Systems

B769 Test Method for Shear Testing of Aluminum Alloys

B831 Test Method for Shear Testing of Thin Aluminum Alloy Products

3. Terminology

3.1 Definitions:

3.1.1 bearing area—the product of the pin diameter and specimen thickness.

3.1.2 bearing stress—the force per unit of bearing area.

3.1.3 bearing strain—the ratio of the bearing deformation of the bearing hole, in the direction of the applied force, to the pin

diameter.

3.1.4 bearing yield strength—the bearing stress at which a material exhibits a specified limiting deviation from the

proportionality of bearing stress to bearing strain.

3.1.5 bearing strength—the maximum bearing stress which a material is capable of sustaining.

3.1.6 edge distance—the distance from the edge of a bearing specimen to the center of the hole in the direction of applied force

(Fig. 1).

3.1.7 edge distance ratio—the ratio of the edge distance to the pin diameter.

3.1.8 For definitions of other terms see Terminology E6.

1

This test method is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.04 on Uniaxial Testing.

Current edition approved June 1, 2012April 1, 2017. Published August 2012April 2017. Originally approved in 1964. Last previous edition approved in 20082017 as

E238 – 84 (2008).E238 – 17. DOI: 10.1520/E0238-12.10.1520/E0238-17A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E238 − 17a

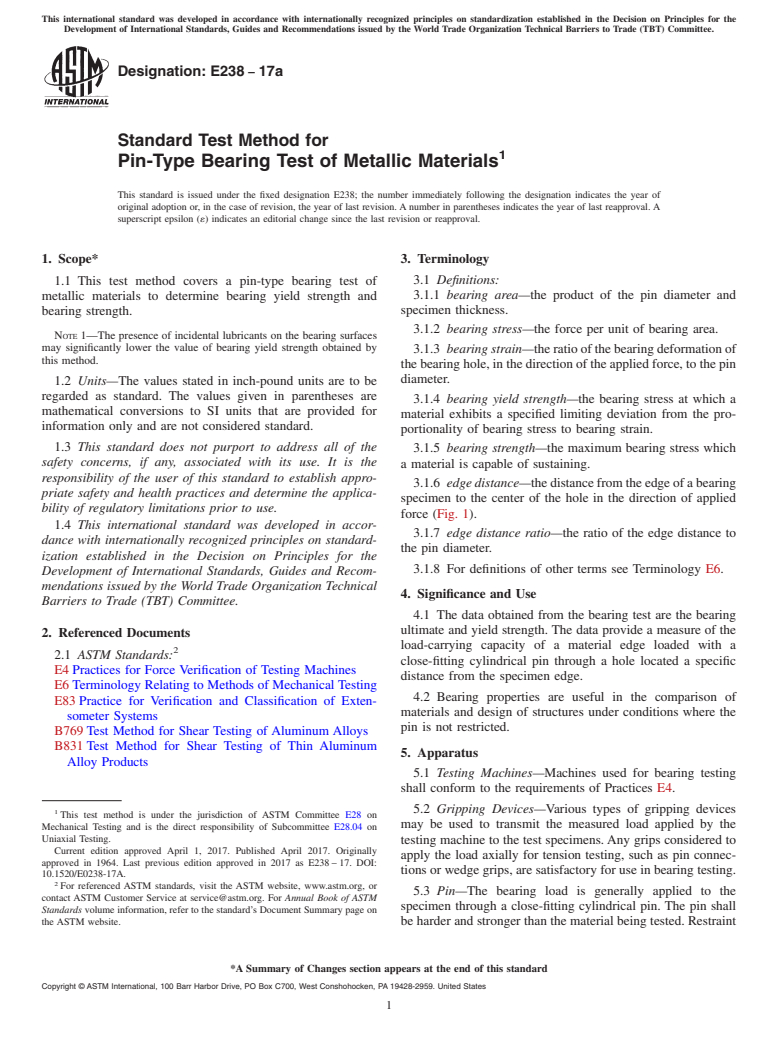

FIG. 1 Bearing Test Specimen

TABLE 1 Characteristics of Pin for Various Materials Tested

Rockwell Surface Roughness,

Material Tested Material

Hardness μ in. (μm) (avg)

Aluminum alloys hardened steel C60 to 64 4 to 8 (0.1 to 0.2 μm)

Beryllium alloys hardened steel C60 to 64 4 to 8 (0.1 to 0.2 μm)

Copper alloys hardened steel C60 to 64 4 to 8 (0.1 to 0.2μ m)

Magnesium alloys hardened steel C60 to 64 4 to 8 (0.1 to 0.2 μm)

Zinc alloys hardened steel C60 to 64 4 to 8 (0.1 to 0.2μ m)

4. Significance and Use

4.1 The data obtained from the bearing test are the bearing ultimate and yield strength. The data provide a measure of the

load-carrying capacity of a material edge loaded with a close-fitting cylindrical pin through a hole located a specific distance from

the specimen edge.

4.2 Bearing properties are useful in the comparison of materials and design of structures under condit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.