ASTM D7294-06

(Guide)Standard Guide for Collecting Treatment Process Design Data at a Contaminated Site-A Site Contaminated With Chemicals of Interest

Standard Guide for Collecting Treatment Process Design Data at a Contaminated Site-A Site Contaminated With Chemicals of Interest

SCOPE

1.1 This guide lists the physical and chemical treatment processes design data needed to evaluate, select, and design treatment processes for remediation of contaminated sites. This data is listed in . Much of these data can be obtained and analyzed at the site with instruments and test kits.

1.2 It is recommended that this guide be used in conducting environmental site assessments and Remedial Investigations/Feasibility Studies (RI/FS) and selections of remedy in U.S. Code of Federal Regulations 40 CFR 300.430.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7294 − 06

StandardGuide for

Collecting Treatment Process Design Data at a

Contaminated Site—A Site Contaminated With Chemicals of

Interest

This standard is issued under the fixed designation D7294; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3152 Test Method for Capillary-Moisture Relationships

for Fine-Textured Soils by Pressure-MembraneApparatus

1.1 This guide lists the physical and chemical treatment

(Withdrawn 2007)

processes design data needed to evaluate, select, and design

D3590 Test Methods for Total Kjeldahl Nitrogen in Water

treatmentprocessesforremediationofcontaminatedsites.This

D3921 Test Method for Oil and Grease and Petroleum

data is listed in Tables 1 and 2. Much of these data can be

Hydrocarbons in Water

obtained and analyzed at the site with instruments and test kits.

D4327 Test Method for Anions in Water by Suppressed Ion

1.2 It is recommended that this guide be used in conducting

Chromatography

environmental site assessments and Remedial Investigations/

D4564 Test Method for Density and Unit Weight of Soil in

Feasibility Studies (RI/FS) and selections of remedy in U.S.

Place by the Sleeve Method

Code of Federal Regulations 40 CFR 300.430.

D4611 Test Method for Specific Heat of Rock and Soil

1.3 This standard does not purport to address all of the D4943 Test Method for Shrinkage Factors of Soils by the

safety concerns, if any, associated with its use. It is the

Wax Method

responsibility of the user of this standard to establish appro- D4972 Test Method for pH of Soils

priate safety and health practices and determine the applica-

D5084 Test Methods for Measurement of Hydraulic Con-

bility of regulatory limitations prior to use. ductivity of Saturated Porous Materials Using a Flexible

Wall Permeameter

2. Referenced Documents

D5334 Test Method for Determination of Thermal Conduc-

tivity of Soil and Soft Rock by Thermal Needle Probe

2.1 ASTM Standards:

Procedure

D422 Test Method for Particle-Size Analysis of Soils

D5463 Guide for Use of Test Kits to Measure Inorganic

D1067 Test Methods for Acidity or Alkalinity of Water

Constituents in Water

D1293 Test Methods for pH of Water

D5730 Guide for Site Characterization for Environmental

D1498 Test Method for Oxidation-Reduction Potential of

Purposes With Emphasis on Soil, Rock, the Vadose Zone

Water

and Groundwater

D2216 Test Methods for Laboratory Determination of Water

D6836 Test Methods for Determination of the Soil Water

(Moisture) Content of Soil and Rock by Mass

Characteristic Curve for Desorption Using Hanging

D2325 Test Method for Capillary-Moisture Relationships

Column, Pressure Extractor, Chilled Mirror Hygrometer,

for Coarse- and Medium-Textured Soils by Porous-Plate

or Centrifuge

Apparatus (Withdrawn 2007)

E953 Test Method for Fusibility of Refuse-Derived Fuel

D2434 Test Method for Permeability of Granular Soils

(RDF) Ash

(Constant Head)

2.2 Other Documents:

Remediation Technologies Screening Matrix and Reference

This guide is under the jurisdiction of ASTM Committee D34 on Waste 4

Guide

Management and is the direct responsibility of Subcommittee D34.01.01 on

U.S. Code of Federal Regulations 40 CFR 300.430

Planning for Sampling.

Current edition approved Oct. 1, 2006. Published November 2006. DOI:

10.1520/D7294-06. 3. Terminology

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1 Definitions:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on Available at http://www.frtr.gov

www.astm.org. Available at http://www.gpoaccess.gov/cfr/index.html

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7294 − 06

A

TABLE 1 Water Parameters

B

Technology

IN SITU TREATMENT

H

Phytoremediation XX X X X O O X O O O X

Permeable Reactive Barriers X X O X O X X O O X X O X X O X X O O X

Monitored Natural Attenuation X X X O O O XXXX X O X O O X XX O X

Enhanced Bioremediation X X X OOOO X X X X O X O O X X X O X

Air Sparging X X X O X X X O O X X O O X O O O X

Hot Water or Steam Flush/Strip See Soil, Sediment & Sludge Parameters—thermally enhanced SVE

Slurry Walls See Soil, Sediment & Sludge Parameters

I

Bioslurping XX X X X X X X

J

Dual (multiphase) Phase Extraction XX X X X

Chemical oxidation X X X O O X X O X O O O X O O X

In Well Air Stripping Same parameters as air sparging

Free Product Recovery See Dual (multiphase) Phase Extraction

EX SITU TREATMENT

Advanced Oxidation (UV) X X O X O X X X O X O O X X X O X O O

Bioreactor X X O X O X X X O X O O O X O O O O O O

Air Stripping X X X X X O X O X X O X

Ion Exchange X X O X X X O X X O O O X O O O

Adsorption (carbon) X X O X O X X O X O O O X O O O

Precipitation/Coagulation/Flocculation X X O X X X O X O X O O O O

Constructed Wetlands X X O X O X X O O O X O O X O O O O O

A

This table was developed jointly by the U.S. Army Corps of Engineers, Hazardous, Toxic, and Radioactive Waste Center of Expertise and the U.S. Environmental Project—Engineering Forum.

B

See Treatment Technology Profiles in www.frtr.gov for a description of the technology.

C

Quality of sampling indicators.

D

If these cations are to be analyzed in an offsite laboratory, evaluate analyzing all metal as the cost may be the same.

E

Conductivity is a good indicator of Total Dissolved Solids (TDS).

F +2 +2

Analyze for Fe in the field or total iron in the laboratory and estimate Fe from turbidity, etc.

G

Estimate of soil hydraulic properties in the aquifer where the samples were taken. This information may already be available.

H

See soil parameaters for vadose zone.

I

Easily converted to conventional bio venting system or SVE after free product is removed to complete the remediation. Include bio/SVE parameters.

J

Dual (multiphase) extraction is generally combined with technologies such as bioremediation, air sparging, bioventing and soil vapor extraction. Include parameters for these technologies if they are being considered

NOTE 1—“X” parameters are recommended during early site investigations before any treatment is being considered or has been selected.

NOTE 2—“O” parameters are recommended in addition to “X” if the technology is being considered or has been selected.

DO (field)

Temperature (field)

Total Suspended Solids (TSS)

C

Turbidity

CO

H S

Dissolved H

Methane, Ethane and Ethene

pH (field)

ORP (field)

Chloride (Cl-)

Fluoride (Fl-)

+2 +2 +2 + +D

Ca ,Mg ,Mn ,Na ,K

TOC

COD

DOC

Total Dissolved Solids (TDS)

- -2

Alkalinity HCO , CO3

E

Conductivity (field)

Volatile Fatty Acids

Biological Oxygen Demand (5-day BOD)

Oil/Grease

Ammonia (NH )

Phosphorous (total)

+2F

Ferrous Iron Fe

+2 +3D

Total Iron Fe +Fe

Sulfate/sulfite (SO =/SO =)

4 3

Nitrate/nitrite (NO -/NO -)

3 2

Kjeldahl Nitrogen

G

Sieve Analysis

D7294 − 06

A

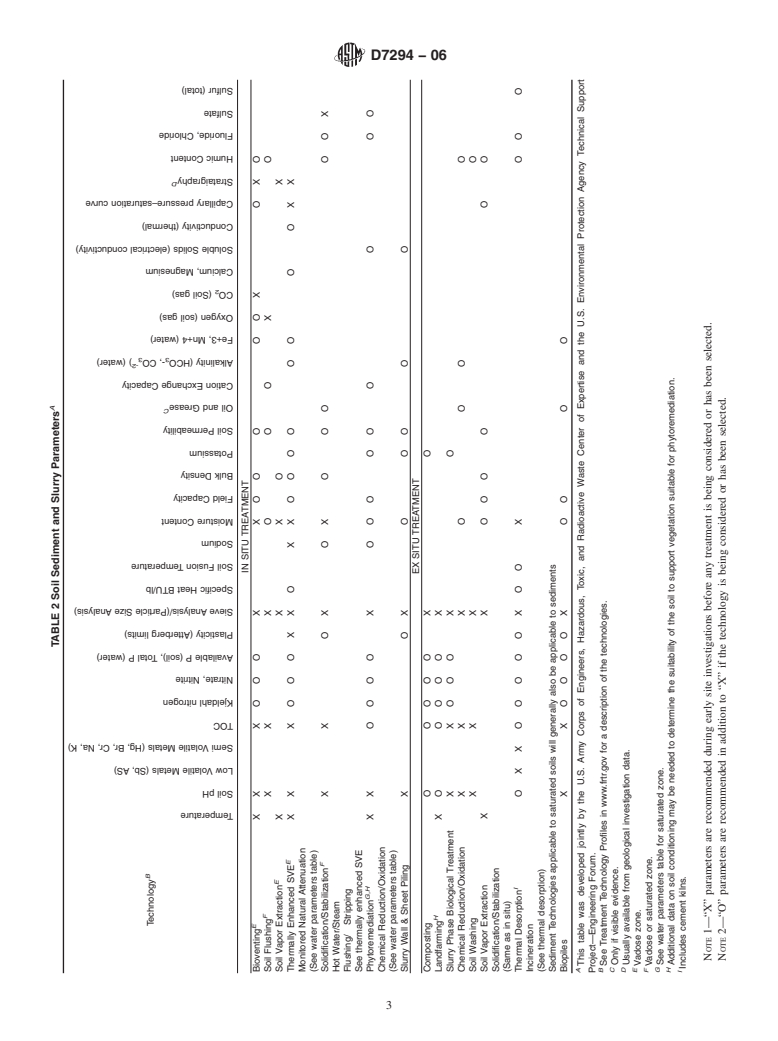

TABLE 2 Soil Sediment and Slurry Parameters

B

Technology

IN SITU TREATMENT

E

Bioventing X X X OOO X X OO O O O X O X O

F

Soil Flushing XX X O O O X O

E

Soil Vapor ExtractionXXXO X

E

Thermally Enhanced SVE X X X OOO X X O X X OOOO OO O O X X

Monitored Natural Attenuation

(See water parameters table)

F

Solidification/Stabilization X X OX OX O O O O OX

Hot Water/Steam

Flushing/ Stripping

See thermally enhanced SVE

G,H

Phytoremediation X X OOOO X OOO OO O O OO

Chemical Reduction/Oxidation

(See water parameters table)

Slurry Wall & Sheet Piling X O X O O O O O

EX SITU TREATMENT

Composting O OOOO X O

H

Landfarming X O OOOO X

Slurry Phase Biological Treatment X X O O O X O

Chemical Reduction/Oxidation X X X O O O O

Soil Washing X X X O

Soil Vapor Extraction X X O O O O O O

Solidification/Stabilization

(Same as in situ)

I

Thermal Desorption O X X OOOOO X O O X OO O

Incineration

(See thermal desorption)

Sediment Technologies applicable to saturated soils will generally also be applicable to sediments

Biopiles X X OOOO X O O O O

A

This table was developed jointly by the U.S. Army Corps of Engineers, Hazardous, Toxic, and Radioactive Waste Center of Expertise and the U.S. Environmental Protection Agency Technical Support

Project—Engineering Forum.

B

See Treatment Technology Profiles in www.frtr.gov for a description of the technologies.

C

Only if visible evidence.

D

Usually available from geological investigation data.

E

Vadose zone.

F

Vadose or saturated zone.

G

See water parameters table for saturated zone.

H

Additional data on soil conditioning may be needed to determine the suitability of the soil to support vegetation suitable for phytoremediation.

I

Includes cement kilns.

NOTE 1—“X” parameters are recommended during early site investigations before any treatment is being considered or has been selected.

NOTE 2—“O” parameters are recommended in addition to “X” if the technology is being considered or has been selected.

Temperature

Soil pH

Low Volatile Metals (Sb, AS)

Semi Volatile Metals (Hg, Br, Cr, Na, K)

TOC

Kjeldahl nitrogen

Nitrate, Nitrite

Available P (soil), Total P (water)

Plasticity (Atterberg limits)

Sieve Analysis/(Particle Size Analysis)

Specific Heat BTU/lb

Soil Fusion Temperature

Sodium

Moisture Content

Field Capacity

Bulk Density

Potassium

Soil Permeability

C

Oil and Grease

Cation Exchange Capacity

-2

Alkalinity (HCO -, CO ) (water)

3 3

Fe+3, Mn+4 (water)

Oxygen (soil gas)

CO (Soil gas)

Calcium, Magnesium

Soluble Solids (electrical conductivity)

Conductivity (thermal)

Capillary pressure–saturation curve

D

Strataigraphy

Humic Content

Fluoride, Chloride

Sulfate

Sulfur (total)

D7294 − 06

3.1.1 remedial treatment process, n— as used in this guide, 4.6 This guide does not address sampling for contaminants

physical, chemical and biological technologies used to destroy, and sampling locations. See EM 200-1-2 Technical Project

contain or remove contaminants of concern at contaminated

Planning (TPP) under Engineering Manuals for information

sites.

on sampling contaminants of concern. It is recommended that

the treatment process design sampling be coordinated with the

3.1.2 treatment process design data, n—as used in this

sampling for chemicals of concern to minimize duplicate

guide, physical and chemical data that are needed, in addition

to data on contaminants of concern, characterization of the sampling and trips to the site.

subsurface, and major factors affecting the surface and subsur-

4.7 This guide does not address physical and chemical

face environment that are addressed in Guide D5730 to

propertiesrelatedtocontaminanttransport.Thisisaddressedin

evaluate and design treatment processes for remediation of

Guide D5730.

contaminated sites. Examples are cations and anions com-

monly present in water such as calcium, iron, carbonate/

4.8 This guide does not address why the data is needed to

bicarbonate, Total Organic Carbon (TOC), pH, temperature,

evaluate each treatment technology. This information is ad-

and sieve analysis. See Tables 1 and 2 for the complete list.

dressed in the Federal Remediation Technologies Roundtable

(FRTF) site at http://www.frtr.gov in the U.S. Army Corps of

4. Significance and Use

Engineers guidance documents at http://www.usace.army.mil/

4.1 This guide allows the decision maker to determine

inet/usace-docs/ and the United Facilities Guide Specifications

which remedial treatment processes are and are not applicable

(UFGS) available at http://www.ccb.org/.

to remediate an area of soil, surface water or ground water that

contains contaminants of concern.

4.9 This guide does not address QualityAssurance/ Quality

Control (QA/QC) or sampling design strategy. See U.S. Army

4.2 This guide provides the data to make cost comparisons

Corps of Engineers Engineering Regulation ER 1110-1-263

of the remedial treatment processes.

and Engineering Manual EM 200-1-3 for information on

4.3 Analysis of treatment process design data can often be

QA/QC. This needs to be addressed in the Quality Assurance

performed at the site with instruments and test kits.

Project Plan (QAPP).

4.4 Tables 1 and 2 are a guide to selecting and obtaining

physical and chemical treatment process design data. Data

5. Keywords

marked with an “X” is needed to evaluate alternatives and

5.1 analysis; environmental assessment; hazardous waste;

select a remedial treatment process. Once the remedial process

remediation; sampling; solid waste

is selected the additional data that are needed to design the

selected remedial treatment process are marked with an “O”.

4.5 Tables 3 and 4 list laboratory and field methods for

analyzing this data. More than one analytical method may be

United States Army Corps of Engineers, Technical Project Planning (TPP)

listed. The most suitable method must be chosen for each

Processes, Engineering Manual—EM 200-1-2, Publications of the Headquarters,

application. available at http://www.usace.army.mil/inet/usace-docs/

D7294 − 06

A

TABLE 3 Water Analytical Methods

Field Test Methods

B B

Parameters Laboratory Methods Detection Range Detection Range

C

Meter/Kit

D,E F +G H

pH EPA 150.1/150.2 ; SM 4500-H ; 0 - 14 pH units Meter

Test Methods D1293

D,E,I G

ORP SM 2580 ; Practice D1498 Meter

D,E F G

Temperature EPA 170.1 ; SM 2550 0 - 100°C

D,E F G

Dissolved Oxygen (DO) EPA 360.1 ; SM 4500-O 360.2 0 - 20 mg/L Spectrophotometer 1 - 10 mg/L

H

(spec)/Meter

D,E F G

Conductivity EPA 120.1 ; SM 2510 1 - 1,000 µS/cm Meter 200 mS

D,E F

Turbidity EPA 180.1 0 - 40 NTU Spec/Meter 0 - 4,400 NTU/0.1 - 100 NTU

F

Total dissolved solids EPA 160.1 10 - 20,000 mg/L Meter 0 - 200 mg/L

F H

Ammonia EPA 350.1/350.2/350.3 ; SM 4500- 0.01 - 2.0 mg/L Spec/Kit 0 - 2.5 mg/L

G

NH

F

Kjeldahl (TKN) EPA 351.1/351.2/351.3/ 351.4 ;SM 0.05 - 2.0 mg/L Spec/Kit 1 - 150 mg/L

G

4500-N

org

Anions

- F

F 0013B—electrode EPA 340.1/340.2/340.3 ; SM 4500- 0.1 - 1,000 mg/L Spec/Kit 0 - 2 mg/L/0 - 2 mg/L

G

F- 0300

- F

Cl EPA 325.1/325.2/325.3 ; SM 4500 1 - 200 mg/L Spec/Kit 0-20/5-400

G

Cl- 0300

- F G H

NO EPA 352.1 ; SM 4500-NO3- ; Test 0.1 - 2 mg/L as N Spec/Kit 0 - 30/0 - 10 mg/L

Method D4327 0300

- F G H

NO EPA 354.1 ; SM 4500-NO2- 0300 0.01 - 1.0 mg/L as N Spec/Kit 0 - 0.3/0 - 1.0 mg/L

2- F H

SO EPA 375.1/375.2/375.3/ 375.4 ;SM 3 - 400 mg/L Spec/Kit 0 - 70/50 - 200 mg/L

2-G

4500-SO ;

Test Method D4327 0300

- G J

SO SM 4500-SO3-B . EPA 377.1 Kit

- 2- F G H

Alkalinity (HCO ,CO ) EPA 310.1/310.2 ; SM 2320

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.