ASTM D873-02(2007)

(Test Method)Standard Test Method for Oxidation Stability of Aviation Fuels (Potential Residue Method)

Standard Test Method for Oxidation Stability of Aviation Fuels (Potential Residue Method)

SIGNIFICANCE AND USE

The results (of these tests) can be used to indicate storage stability of these fuels. The tendency of fuels to form gum and deposits in these tests has not been correlated with field performance (and can vary markedly) with the formation of gum and deposits under different storage conditions.

SCOPE

1.1 This test method covers the determination of the tendency of aviation reciprocating, turbine, and jet engine fuels to form gum and deposits under accelerated aging conditions. (Warning—This test method is not intended for determining the stability of fuel components, particularly those with a high percentage of low boiling unsaturated compounds, as these may cause explosive conditions within the apparatus.)

Note 1—For the measurement of the oxidation stability (induction period) of motor gasoline, refer to Test Method D 525.

1.2 The accepted SI unit of pressure is the kilo pascal (kPa); the accepted SI unit of temperature is °C.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D873 − 02(Reapproved 2007)

Designation: 138/99 British Standard 4456

Standard Test Method for

Oxidation Stability of Aviation Fuels (Potential Residue

Method)

This standard is issued under the fixed designation D873; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D5452 Test Method for Particulate Contamination in Avia-

tion Fuels by Laboratory Filtration

1.1 This test method covers the determination of the

E1 Specification for ASTM Liquid-in-Glass Thermometers

tendencyofaviationreciprocating,turbine,andjetenginefuels

to form gum and deposits under accelerated aging conditions.

3. Terminology

(Warning—This test method is not intended for determining

the stability of fuel components, particularly those with a high

3.1 The following definitions of terms are all expressed in

percentage of low boiling unsaturated compounds, as these

terms of milligrams per 100 mL of sample, after “X” hours

may cause explosive conditions within the apparatus.)

aging, “X” being the accelerated aging (oxidation) period at

100°C.

NOTE 1—For the measurement of the oxidation stability (induction

period) of motor gasoline, refer to Test Method D525.

3.2 Definitions of Terms Specific to This Standard:

1.2 The accepted SI unit of pressure is the kilo pascal (kPa);

3.2.1 insoluble gum—deposit adhering to the glass sample

the accepted SI unit of temperature is °C.

container after removal of the aged fuel, precipitate, and

1.3 This standard does not purport to address all of the

soluble gum. Insoluble gum is obtained by measuring the

safety concerns, if any, associated with its use. It is the

increase in mass of the glass sample container.

responsibility of the user of this standard to establish appro-

3.2.2 potential gum—sum of the soluble and insoluble gum.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3.2.3 precipitate—sediment and suspended material in the

aged fuel, obtained by filtering the aged fuel and washings

2. Referenced Documents

from the glass sample container.

2.1 ASTM Standards:

3.2.4 soluble gum—deteriorationproductspresentattheend

D381 Test Method for Gum Content in Fuels by Jet Evapo-

of a specific aging period.These deterioration products exist in

ration

solution in the aged fuel and as the toluene-acetone soluble

D525 Test Method for Oxidation Stability of Gasoline (In-

portion of the deposit on the glass sample container. The

duction Period Method)

solublegumisobtainedasanonvolatileresiduebyevaporating

D4057 Practice for Manual Sampling of Petroleum and

the aged fuel and the toluene-acetone washings from the glass

Petroleum Products

sample container.

3.2.5 total potential residue—sum of the potential gum and

This test method is under the jurisdiction of ASTM Committee D02 on

the precipitate.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.14 on Stability and Cleanliness of Liquid Fuels.

This test method has been approved by the sponsoring committees and accepted

4. Summary of Test Method

by the Cooperating Societies in accordance with established procedures.

Current edition approved Nov. 1, 2007. Published January 2008. Originally

4.1 The fuel is oxidized under prescribed conditions in a

approved in 1946. Last previous edition approved in 2002 as D873–02. DOI:

pressure vessel filled with oxygen. The amounts of soluble

10.1520/D0873-02R07.

2 gum, insoluble gum, and precipitate formed are weighed.

Further information can be found in the June 1978, January 1979, and June

1986 editions of the Institute of Petroleum Review.

(Warning—In addition to other precautions, to provide pro-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tection against the possibility of explosive rupture of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

pressure vessel, the pressure vessel should be operated behind

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. an appropriate safety shield.)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D873 − 02 (2007)

5. Significance and Use 7.2 Oxygen, commercially available extra dry oxygen of not

less than 99.6 % purity.

5.1 The results (of these tests) can be used to indicate

storage stability of these fuels. The tendency of fuels to form

8. Sampling

gum and deposits in these tests has not been correlated with

8.1 Sample in accordance with the procedure for oxidation

field performance (and can vary markedly) with the formation

stability, as described in Practice D4057.

of gum and deposits under different storage conditions.

9. Preparation of Apparatus

6. Apparatus

9.1 Thoroughly clean a glass sample container to remove

traces of any adhering material. Immerse the container and its

6.1 Oxidation Pressure Vessel, Burst Disc Assembly, Glass

cover in a mildly alkaline or neutral pH laboratory detergent

Sample Container and Cover, Accessories and Pressure Gage,

cleaning solution. The type of detergent and conditions for its

as described in the Annex to Test Method D525.(Warning—

use need to be established in each laboratory. The criterion for

Provision shall be made to safely vent any expelled gases or

satisfactory cleaning shall be a matching of the quality of that

flames away from the operator, other personnel, or flammable

obtained with chromic acid cleaning solutions (or some other

materials as a safety precaution if the burst-disc ruptures.)

equivalently strong oxidizing non-chromium containing acid

NOTE 2—Pressure vessels conforming toTest Method D525-80 are also

cleaning solutions) on used sample containers and covers

suitable, but the specified burst-disc shall be attached. The burst disc

(fresh chromic acid, 6-h soaking period, rinsing with distilled

assembly shall be mechanically designed to ensure that it cannot be

water and drying). For this comparison, visual appearance and

incorrectly fitted.

mass loss on heating the glassware under test conditions may

6.2 Thermometer, having a range as shown below and

be used. Detergent cleaning avoids the potential hazards and

conforming to the requirements as prescribed in Specification

inconveniences related to the handling of highly corrosive and

E1, or specifications for IP thermometers:

strongly oxidizing acid solutions; this procedure remains the

Thermometer Range Thermometer Number

reference cleaning practice and, as such, may function as an

ASTM IP

95 to 103°C 22C 24C alternate to the preferred procedure, cleaning with detergent

solutions. Remove from the cleaning solution by means of

NOTE 3—Other temperature sensing devices that cover the temperature

corrosion-resistant steel forceps and handle only with forceps

range of interest, such as thermocouples or platinum resistance thermom-

thereafter. Wash thoroughly first with tap water and then with

eters, that can provide equivalent or better accuracy and precision, may be

used in place of the thermometers specified in 6.2.

deionizedordistilledwater,anddryinanovenat100to150°C

for 1 h. Cool the sample containers and covers for at least 2 h

6.3 Drying Oven, air oven maintained at 100 to 150°C.

inthecoolingvesselinthevicinityofthebalance.Weightothe

6.4 Forceps, corrosion-resistant, steel.

nearest 0.1 mg, and record mass.

9.1.1 Experience indicates that the amount of insoluble gum

6.5 Filtering Crucible, sintered-glass, fine porosity.

is negligible in aviation reciprocating engine fuels. Therefore,

6.6 Oxidation Bath, as described in the Annex to Test

the glass sample container need not be weighed when testing

Method D525. The liquid shall be water or a mixture of

such fuels unless visible evidence of insoluble matter remains

ethylene glycol and water, as required. The temperature can be

in the container after treatment with gum solvent. In such

controlled thermostatically at 100 6 0.2°C, or by maintaining

cases, the test must be repeated and the mass of the container

it at its boiling point, which must be between 99.5 to 100.5°C.

recorded.

If a liquid medium other than water is used, an appropriate

9.2 Drain any fuel from the pressure vessel and wipe the

mechanical stirrer/mixer shall be used to maintain uniformity

inside of the pressure vessel and pressure vessel closure, first

of the liquid bath at 100 6 0.2°C.Anon self-resettable device

with a clean cloth moistened with gum solvent and then with a

shall be fitted on all new baths to ensure that the heater is

clean, dry cloth. Remove the filler rod from the stem, and

switched off if the liquid bath falls below a safe level. Users of

carefully clean any gum or fuel from the stem, rod, and needle

older baths without this device are strongly urged to have the

valve with gum solvent. The pressure vessel, the valve, and all

equipment retrofitted to ensure safe operation.

connecting lines shall be thoroughly dry before each test is

NOTE 4—Electric heating blocks are known to be used. These blocks

started. (Warning—Volatile peroxides, which may have

can have heating capacities, heating rates, and heat transfer characteristics

formed during a previous te

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D873–99a Designation:D873–02 (Reapproved 2007) British Standard 4456

Designation: 138/99

Standard Test Method for

Oxidation Stability of Aviation Fuels (Potential Residue

Method)

This standard is issued under the fixed designation D 873; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval. This test method has been approved by the

sponsoring committees and accepted by the Cooperating Societies in accordance with established procedures.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1This test method covers the determination of the tendency of aviation reciprocating, turbine, and jet engine fuels to form gum

and deposits under accelerated aging conditions.

NOTE1—Caution:This test method

1.1 This test method is not intended for determining the stability of fuel components, particularly those with a high percentage

of low boiling unsaturated compounds, as these may cause explosive conditions within the apparatus. covers the determination of

the tendency of aviation reciprocating, turbine, and jet engine fuels to form gum and deposits under accelerated aging conditions.

(Warning—This test method is not intended for determining the stability of fuel components, particularly those with a high

percentage of low boiling unsaturated compounds, as these may cause explosive conditions within the apparatus.)

NOTE2—For 1—For the measurement of the oxidation stability (induction period) of motor gasoline, refer to Test Method D 525.

1.2 The accepted SI unit of pressure is the kilo pascal (kPa); the accepted SI unit of temperature is °C.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 381 Test Method for Existent Gum Content in Fuels by Jet Evaporation

D 525 Test Method for Oxidation Stability of Gasoline (Induction Period Method)

D 4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D 5452 Test Method for Particulate Contamination in Aviation Fuels by Laboratory Filtration

E 1 Specification for ASTM Liquid-in-Glass Thermometers

3. Terminology

3.1Definitions of Terms Specific to This Standard

3.1.1The following definitions of terms are all expressed in terms of milligrams per 100 mL of sample, after “

3.1 The following definitions of terms are all expressed in terms of milligrams per 100 mL of sample, after “ X” hours aging,

“X” being the accelerated aging (oxidation) period at 100°C.

This test method is under the jurisdiction of ASTM Committee D-2 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.14 on

Stability and Cleanliness of Liquid Fuels.

Current edition approved June 10, 1999. Published October 1999. Originally published as D873–46T. Last previous edition D873–99.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.14 on

Stability and Cleanliness of Liquid Fuels.

This test method has been approved by the sponsoring committees and accepted by the Cooperating Societies in accordance with established procedures.

Current edition approved Nov. 1, 2007. Published January 2008. Originally approved in 1946. Last previous edition approved in 2002 as D 873–02.

Further information can be found in the June 1978, January 1979, and June 1986 editions of the Institute of Petroleum Review .

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 05.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D873–02 (2007)

3.1.1.1potential gum— sum of the soluble and insoluble gum.

3.1.1.2precipitate— sediment and suspended material in the aged fuel, obtained by filtering the aged fuel and washings from

the glass sample container.

3.1.1.3insoluble gum— deposit adhering to the glass sample container after removal of the aged fuel, precipitate, and soluble

gum. Insoluble gum is obtained by measuring the increase in mass of the glass sample container.

3.1.1.4soluble gum— deterioration products present at the end of a specific aging period. These deterioration products exist in

solution in the aged fuel and as the toluene-acetone soluble portion of the deposit on the glass sample container. The soluble gum

isobtainedasanonvolatileresiduebyevaporatingtheagedfuelandthetoluene-acetonewashingsfromtheglasssamplecontainer.

3.1.1.5total potential residue

3.2 Definitions of Terms Specific to This Standard:

3.2.1 insolublegum—depositadheringtotheglasssamplecontainerafterremovaloftheagedfuel,precipitate,andsolublegum.

Insoluble gum is obtained by measuring the increase in mass of the glass sample container.

3.2.2 potential gum—sum of the soluble and insoluble gum.

3.2.3 precipitate—sediment and suspended material in the aged fuel, obtained by filtering the aged fuel and washings from the

glass sample container.

3.2.4 soluble gum—deterioration products present at the end of a specific aging period. These deterioration products exist in

solution in the aged fuel and as the toluene-acetone soluble portion of the deposit on the glass sample container. The soluble gum

isobtainedasanonvolatileresiduebyevaporatingtheagedfuelandthetoluene-acetonewashingsfromtheglasssamplecontainer.

3.2.5 total potential residue—sum of the potential gum and the precipitate.

4. Summary of Test Method

4.1 The fuel is oxidized under prescribed conditions in a pressure vessel filled with oxygen. The amounts of soluble gum,

insoluble gum, and precipitate formed are weighed. Note3—(Precaution:Warning—In addition to other precautions, to provide

protection against the possibility of explosive rupture of the pressure vessel, the pressure vessel should be operated behind an

appropriate safety shield.)

5. Significance and Use

5.1 The results (of these tests) can be used to indicate storage stability of these fuels. The tendency of fuels to form gum and

deposits in these tests has not been correlated with field performance (and can vary markedly) with the formation of gum and

deposits under different storage conditions.

6. Apparatus

6.1 Oxidation Pressure Vessel, Burst Disc Assembly, Glass Sample Container and Cover, Accessories and Pressure Gage,as

described in the Annex to Test Method D 525. . (Warning—Provision shall be made to safely vent any expelled gases or flames

away from the operator, other personnel, or flammable materials as a safety precaution if the burst-disc ruptures.)

NOTE4—PressurevesselsconformingtoTestMethodD525/1980arealsosuitable,butthespecifiedburst-discshallbeattached.Theburstdiscassembly

shall be mechanically designed to ensure that it cannot be incorrectly fitted.

NOTE5—Precaution:Provision shall be made to safely vent any expelled gases or flames away from the operator, other personnel, or flammable

materials as a safety precaution if the burst-disc ruptures.

6.2 2—Pressure vessels conforming to Test Method D 525-80 are also suitable, but the specified burst-disc shall be attached.

The burst disc assembly shall be mechanically designed to ensure that it cannot be incorrectly fitted.

6.2 Thermometer, having a range as shown below and conforming to the requirements as prescribed in Specification E 1, or

specifications for IP thermometers:

Thermometer Number

Thermometer Range Thermometer Thermometer Number

ASTM Range IP

95 to 103°C 22C 24C

NOTE6—Other 3—Other temperature sensing devices that cover the temperature range of interest, such as thermocouples or platinum resistance

thermometers, that can provide equivalent or better accuracy and precision, may be used in place of the thermometers specified in 6.2.

6.3 Drying Oven, air oven maintained at 100 to 150°C.

6.4 Forceps, corrosion-resistant, steel.

6.5 Filtering Crucible, sintered-glass, fine porosity.

6.6 Oxidation Bath, as described in theAnnex to Test Method D 525. The liquid shall be water or a mixture of ethylene glycol

and water, as required.The temperature can be controlled thermostatically at 100 6 0.2°C, or by maintaining it at its boiling point,

which must be between 99.5 to 100.5°C. If a liquid medium other than water is used, an appropriate mechanical stirrer/mixer shall

be used to maintain uniformity of the liquid bath at 100 + -6 0.2°C. A non self-resettable device shall be fitted on all new baths

to ensure that the heater is switched off if the liquid bath falls below a safe level. Users of older baths without this device are

strongly urged to have the equipment retrofitted to ensure safe operation.

NOTE 74—Electric heating blocks are known to be used. These blocks can have heating capacities, heating rates, and heat transfer characteristics that

D873–02 (2007)

differ from those of a liquid bath. An electric heating block may be used in place of the liquid bath as long as the sample heating rate and sample

temperature are demonstrated to be equivalent to that of the liquid bath.

6.7 Cooling Vessel— A desiccator or other type of tightly covered vessel for cooling the beakers before weighing. The use of

a drying agent is not recommended.

7. Reagents and Materials

7.1 Gum Solvent—A mixture of equal volumes of toluene and acetone.

7.2 Oxygen, commercially available extra dry oxygen of not less than 99.6 % purity.

8. Sampling

8.1 Sample in accordance with the procedure for oxidation stability, as described in Practice D 4057.

9. Preparation of Apparatus

9.1 Thoroughly clean a glass sample container to remove traces of any adhering material. Immerse the container and its cover

in a mildly alkaline or neutral pH laboratory detergent cleaning solution. The type of detergent and conditions for its use need to

be established in each laboratory. The criterion for satisfactory cleaning shall be a matching of the quality of that obtained with

chromic acid cleaning solutions (or some other equivalently strong oxidizing non-chromium containing acid cleaning solutions)

on used sample containers and covers (fresh chromic acid, 6-h soaking period, rinsing with distilled water and drying). For this

comparison, visual appearance and mass loss on heating the glassware under test conditions may be used. Detergent cleaning

avoids the potential hazards and inconveniences related to the handling of highly corrosive and strongly oxidizing acid solutions;

this procedure remains the reference cleaning practice and, as such, may function as an alternate to the preferred procedure,

cleaningwithdetergentsolutions.Removefromthecleaningsolutionbymeansofcorrosion-resistantsteelforcepsandhandleonly

with forceps thereafter. Wash thoroughly first with tap water and then with deionized or distilled water, and dry in an oven at 100

to 150°C for 1 h. Cool the sample containers and covers for at least2hinthe cooling vessel in the vicinity of the balance. Weigh

to the nearest 0.1 mg, and record mass.

9.1.1 Experience indicates that the amount of insoluble gum is negligible in aviation reciprocating engine fuels. Therefore, the

glass sample container need not be weighed when testing such fuels unless visible evidence of insoluble matter remains in the

container after treatment with gum solvent. In such cases, the test must be repeated and the mass of the container recorded.

9.2 Drain any fuel from the pressure vessel and wipe the inside of the pressure vessel and pressure vessel closure, first with a

clean cloth moistened with gum solvent and then with a clean, dry cloth. Remove the filler rod from the stem, and carefully clean

any gum or fuel from the stem, rod, and needle valve with gum solvent. The pressure vessel, the valve, and all connecting lines

shall be thoroughly dry before each test is started. Note8—(Caution:Warning—Volatile peroxides, which may have formed

during a previous test, may accumulate in the equipment, producing a potentially explosive environment. Special care in cleaning

after each test is needed to ensure that the filler rod, stem, and needle valve are free of these peroxides. )

9.3 If a thermostatically controlled constant temperature oxidation bath is used, adjust the temperature to 100 6 0.1°C and

maintain it within this temperature range for the duration of the test.

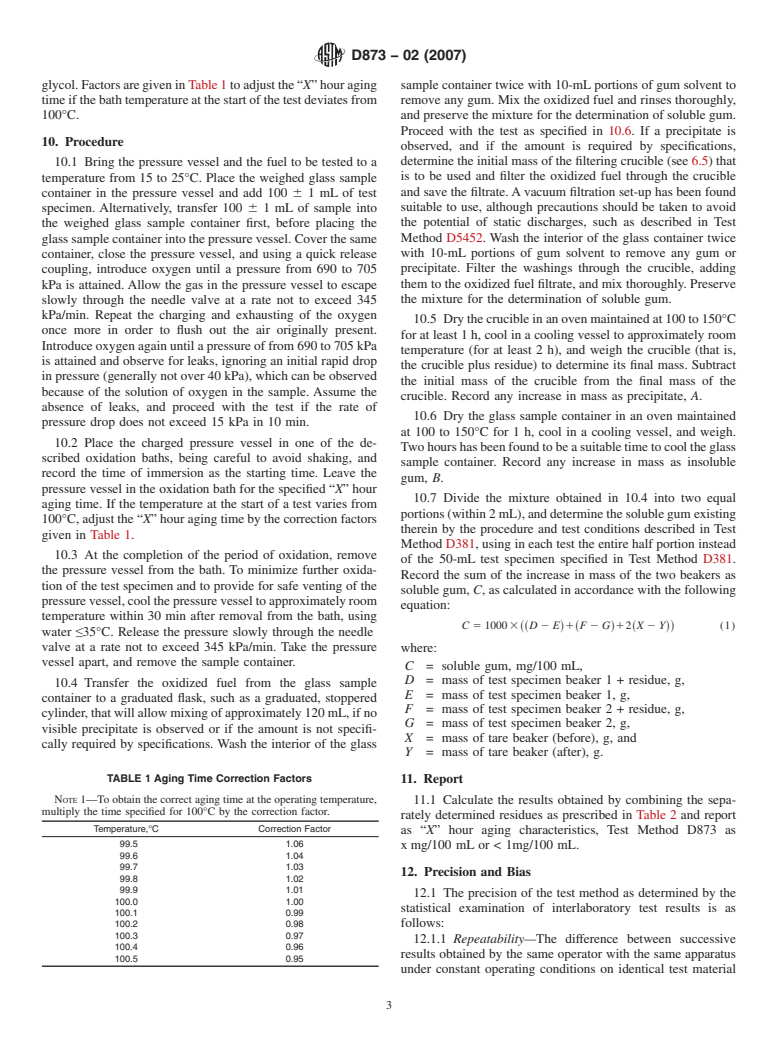

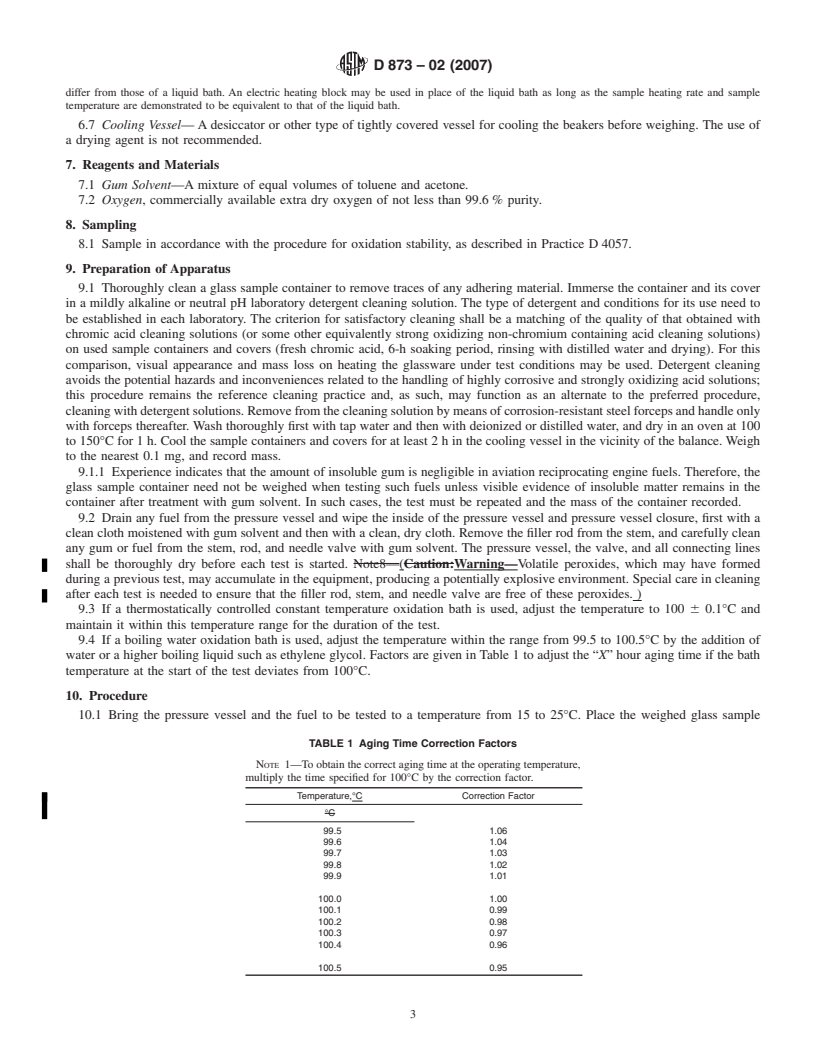

9.4 If a boiling water oxidation bath is used, adjust the temperature within the range from 99.5 to 100.5°C by the addition of

water or a higher boiling liquid such as ethylene glycol. Factors are given in Table 1 to adjust the “X” hour aging time if the bath

temperature at the start of the test deviates from 100°C.

10. Procedure

10.1 Bring the pressure vessel and the fuel to be tested to a temperature from 15 to 25°C. Place the weighed glass sample

TABLE 1 Aging Time Correction Factors

NOTE 1—To obtain the correct aging time at the operating temperature,

multiply the time specified for 100°C by the correction factor.

Temperature,°C Correction Factor

°C

99.5 1.06

99.6 1.04

99.7 1.03

99.8 1.02

99.9 1.01

100.0 1.00

100.1 0.99

100.2 0.98

100.3 0.97

100.4 0.96

100.5 0.95

D873–02 (2007)

container in the pressure vessel and add 100 6 1 mL of test specimen. Alternatively, transfer 100 + -6 1 mL of sample into the

weighed glass sample container first, before placing the glass sample container into the pressure vessel. Cover the same container,

close the pressure vessel, and using a quick release coupling, introduce oxygen until a pressure from 690 to 705 kPa is attained.

Allow the gas in the pressure vessel to escape slowly through the needle valve at a rate not to exceed 345 kPa/min. Repeat the

charging and exhausting of the oxygen once more in order to flush out the air originally present. Introduce oxygen again until a

pressure of from 690 to 705 kPa is attained and observe for leaks, ignoring an initial rapid drop in pressure (generally not over

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.