ASTM D873-02

(Test Method)Standard Test Method for Oxidation Stability of Aviation Fuels (Potential Residue Method)

Standard Test Method for Oxidation Stability of Aviation Fuels (Potential Residue Method)

SIGNIFICANCE AND USE

The results (of these tests) can be used to indicate storage stability of these fuels. The tendency of fuels to form gum and deposits in these tests has not been correlated with field performance (and can vary markedly) with the formation of gum and deposits under different storage conditions.

SCOPE

1.1 This test method covers the determination of the tendency of aviation reciprocating, turbine, and jet engine fuels to form gum and deposits under accelerated aging conditions. (Warning—This test method is not intended for determining the stability of fuel components, particularly those with a high percentage of low boiling unsaturated compounds, as these may cause explosive conditions within the apparatus.)

Note 1—For the measurement of the oxidation stability (induction period) of motor gasoline, refer to Test Method D 525.

1.2 The accepted SI unit of pressure is the kilo pascal (kPa); the accepted SI unit of temperature is °C.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D873–02 British Standard 4456

Designation: 138/99

Standard Test Method for

Oxidation Stability of Aviation Fuels (Potential Residue

1

Method)

This standard is issued under the fixed designation D 873; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This test method has been approved by the sponsoring committees and accepted by the Cooperating Societies in accordance with

established procedures.

This standard has been approved for use by agencies of the Department of Defense.

5

1. Scope tion Fuels by Laboratory Filtration

6

2 E 1 Specification for ASTM Thermometers

1.1 This test method covers the determination of the

tendencyofaviationreciprocating,turbine,andjetenginefuels

3. Terminology

to form gum and deposits under accelerated aging conditions.

3.1 Definitions of Terms Specific to This Standard

(Warning—This test method is not intended for determining

3.1.1 The following definitions of terms are all expressed in

the stability of fuel components, particularly those with a high

terms of milligrams per 100 mL of sample, after “X” hours

percentage of low boiling unsaturated compounds, as these

aging, “X” being the accelerated aging (oxidation) period at

may cause explosive conditions within the apparatus.)

100°C.

NOTE 1—For the measurement of the oxidation stability (induction

3.1.1.1 insoluble gum—depositadheringtotheglasssample

period) of motor gasoline, refer to Test Method D 525.

container after removal of the aged fuel, precipitate, and

1.2 The accepted SI unit of pressure is the kilo pascal (kPa);

soluble gum. Insoluble gum is obtained by measuring the

the accepted SI unit of temperature is °C.

increase in mass of the glass sample container.

1.3 This standard does not purport to address all of the

3.1.1.2 potential gum—sum of the soluble and insoluble

safety concerns, if any, associated with its use. It is the

gum.

responsibility of the user of this standard to establish appro-

3.1.1.3 precipitate—sediment and suspended material in the

priate safety and health practices and determine the applica-

aged fuel, obtained by filtering the aged fuel and washings

bility of regulatory limitations prior to use.

from the glass sample container.

3.1.1.4 soluble gum—deterioration products present at the

2. Referenced Documents

end of a specific aging period. These deterioration products

2.1 ASTM Standards:

exist in solution in the aged fuel and as the toluene-acetone

D 381 Test Method for Existent Gum in Fuels by Jet

soluble portion of the deposit on the glass sample container.

3

Evaporation

The soluble gum is obtained as a nonvolatile residue by

D 525 Test Method for Oxidation Stability of Gasoline

evaporating the aged fuel and the toluene-acetone washings

3

(Induction Period Method)

from the glass sample container.

D 4057 Practice for Manual Sampling of Petroleum and

3.1.1.5 total potential residue—sum of the potential gum

4

Petroleum Products

and the precipitate.

D 5452 Test Method for Particulate Contamination inAvia-

4. Summary of Test Method

4.1 The fuel is oxidized under prescribed conditions in a

1

pressure vessel filled with oxygen. The amounts of soluble

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

gum, insoluble gum, and precipitate formed are weighed.

D02.14 on Stability and Cleanliness of Liquid Fuels.

(Warning—In addition to other precautions, to provide pro-

Current edition approved Dec. 10, 2002. Published March 2003. Originally

tection against the possibility of explosive rupture of the

approved in 1946. Last previous edition approved in 1999 as D 873–99a.

2

Further information can be found in the June 1978, January 1979, and June

1986 editions of the Institute of Petroleum Review.

3 5

Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 05.03.

4 6

Annual Book of ASTM Standards, Vol 05.02. Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

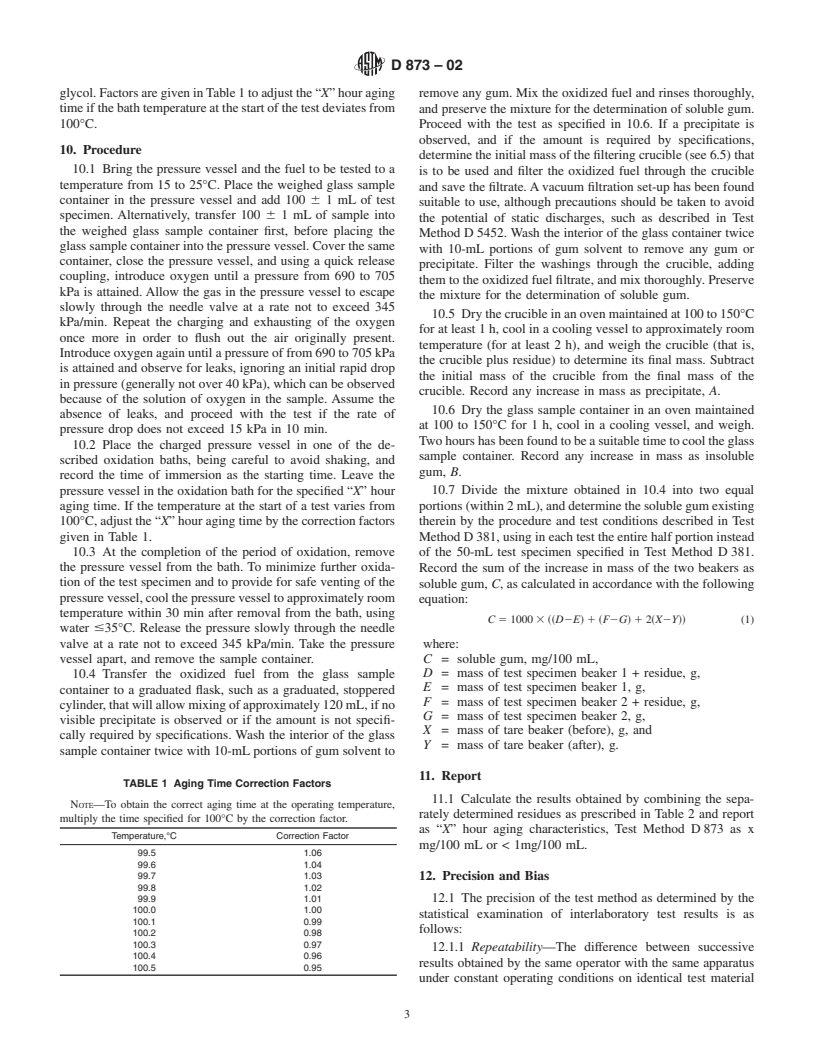

---------------------- Page: 1 ----------------------

D873–02

pressure vessel, the pressure vessel should be operated behind 7.2 Oxygen, commercially available extra dry oxygen of not

an appropriate safety shield.) less than 99.6 % purity.

5. Significance and Use

8. Sampling

5.1 The results (of these tests) can be used to indicate

8.1 Sample in accordance with the procedure for oxidation

storage stability of these fuels. The tendency of fuels to form

stability, as described in Prac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.