EN 12201-2:2011+A1:2013

(Main)Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 2: Pipes

Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 2: Pipes

This part of EN 12201 specifies the characteristics of pipes made from polyethylene (PE 100, PE 80 and PE 40) for buried and above ground applications, intended for the conveyance of water for human consumption, raw water prior to treatment, drainage and sewerage under pressure, vacuum sewer systems, and water for other purposes.

NOTE 1 For PE components intended for the conveyance of water for human consumption and raw water prior to treatment attention is drawn to 5.3 of this European Standard. Components manufactured for water for general purposes, drainage and sewerage may not be suitable for water supply for human consumption.

It also specifies the test parameters for the test methods referred to in this standard.

In conjunction with Part 1 and Parts 3 to 5 of EN 12201, it is applicable to PE pipes, their joints and to joints with components of PE and other materials intended to be used under the following conditions:

a) allowable operating pressure, PFA, up to 25 bar );

b) an operating temperature of 20 °C as a reference temperature;

c) buried in the ground;

d) sea outfalls;

e) laid in water;

f) above ground, including pipes suspended below bridges.

NOTE 2 For applications operating at constant temperatures greater than 20 °C and up to 40 °C, see Annex A of

EN 12201-1:2011.

NOTE 3 Pipes constructions including barrier layers are not covered by this document.

EN 12201 covers a range of allowable operating pressures and gives requirements concerning colours and additives.

It covers three types of pipe:

- PE pipes (outside diameter dn) including any identification stripes;

- PE pipes with co-extruded layers on either or both the outside and/or inside of the pipe (total outside diameter dn) as specified in Annex B, where all layers have the same MRS rating;

- PE pipes (outside diameter dn) with a peelable, contiguous thermoplastics additional layer on the outside of the pipe (‘coated pipe’) as specified in Annex C.

NOTE 4 It is the responsibility of the purchaser or specifier to make the appropriate selections from these aspects, taking into account their particular requirements and any relevant national guidance or regulations and installation practices or codes.

NOTE 5 Assessment of the resistance to slow crack growth of the PE pipe compound used for the manufacture of products to this document is required in accordance with Table 2 of EN 12201-1:2011.

Kunststoff-Rohrleitungssysteme für die Wasserversorgung und für Entwässerungs- und Abwasserdruckleitungen - Polyethylen (PE) - Teil 2: Rohre

Dieser Teil der EN 12201 legt die Anforderungen an erdverlegte und oberirdisch verlegte Rohre aus Polyethy-len (PE 100, PE 80 und PE 40) fest, die für den Transport von Trinkwasser, des zur Aufbereitung vorgesehenen Rohwassers, für Entwässerungs- und Abwasserdruckleitungen, Unterdruckentwässerungs-systeme sowie für den Transport von Brauchwasser vorgesehen sind.

ANMERKUNG 1 In Zusammenhang mit Rohrleitungsteilen aus PE für den Transport von Trinkwasser einschließlich des aufzubereitenden Rohwassers wird auf diese Europäische Norm, 5.3 verwiesen. Rohrleitungsteile, die für den Transport von Brauchwasser sowie für Entwässerungs- und Abwasserleitungen gefertigt wurden, sind möglicherweise nicht für die Versorgung mit Trinkwasser geeignet.

Er legt auch die Prüfparameter für die Prüfverfahren fest, auf die in dieser Norm verwiesen wird.

Zusammen mit den Teilen 1 sowie 3 bis 5 der EN 12201 gilt dieser Teil für Rohre aus PE, deren Verbin¬dungen untereinander, mit anderen Rohrleitungsteilen aus PE sowie mit Rohrleitungsteilen aus anderen Werkstoffen, die zur Verwendung unter den folgenden Bedingungen vorgesehen sind:

a) maximal zulässiger Betriebsdruck PFA bis 25 bar );

b) eine Betriebstemperatur von 20 °C als Bezugstemperatur;

c) erdverlegt;

d) Entwässerung ins Meer (Siele);

e) in Gewässern verlegt;

f) oberirdisch verlegt, einschließlich Düker und Brückenleitungen.

ANMERKUNG 2 Für Anwendungsgebiete, in denen konstante Betriebstemperaturen von über 20 °C bis höchstens 40 °C auf¬treten, siehe EN 12201-1:2011, Anhang A.

ANMERKUNG 3 Rohre mit Sperrschichten werden in diesem Dokument nicht behandelt.

EN 12201 enthält Festlegungen über maximal zulässige Betriebsdrücke und legt Anforderungen an die Ein-färbung von Rohrleitungsteilen sowie die Verwendung von Zusatzstoffen fest.

Drei Arten von Rohren werden behandelt:

- PE-Rohre (Außendurchmesser dn), einschließlich Identifizierungsstreifen;

- PE-Rohre mit koextrudierten Schichten auf der Außenseite und/oder der Innenseite des Rohres (Gesamt-Außendurchmesser dn), wie in Anhang B festgelegt, wobei alle Schichten denselben MRS-Wert aufweisen;

- PE-Rohre (Außendurchmesser dn), mit einer abziehbaren, aufliegenden thermoplastischen Zusatz¬schicht auf der Außenseite des Rohres („beschichtetes Rohr“), wie in Anhang C festgelegt.

ANMERKUNG 4 Der Anwender bzw. Auftraggeber ist unter Berücksichtigung der eigenen Anforderungen sowie der geltenden nationalen Empfehlungen oder Festlegungen und Verlegepraktiken für die entsprechende Auswahl dieser Kriterien verantwortlich.

ANMERKUNG 5 Die Bewertung des Widerstandes gegen langsames Risswachstum von PE-Formmassen, die für die Herstellung von Produkten nach diesem Dokument verwendet werden, ist nach EN 12201-1:2011, Tabelle 2, erforderlich.

Systèmes de canalisations en plastique pour l'alimentation en eau et pour les branchements et les collecteurs d'assainissement avec pression - Polyéthylène (PE) - Partie 2 : Tubes

La présente partie de l’EN 12201 spécifie les caractéristiques des tubes en polyéthylène (PE 100, PE 80 et PE 40) pour des applications enterrées et non enterrées prévues pour le transport d'eau destinée à la consommation humaine, y compris l'eau brute avant traitement, les branchements et les collecteurs d'assainissement avec pression, les réseaux d'évacuation des eaux usées sous vide et l'eau destinée à d'autres usages

NOTE 1 Pour les composants en PE prévus pour le transport d'eau destinée à la consommation humaine et d'eau brute avant traitement, l'attention est attirée au 5.3 de la présente Norme européenne. Les composants fabriqués pour l'eau destinée à des usages généraux et pour l'assainissement peuvent s'avérer inaptes pour l'alimentation en eau destinée à la consommation humaine.

Elle spécifie également les paramètres d'essai des méthodes d'essai auxquelles il est fait référence dans la présente norme.

Conjointement avec la Partie 1 et les Parties 3 à 5 de l'EN 12201, elle s'applique aux tubes en PE et à leurs assemblages, ainsi qu’à leurs assemblages avec des composants en PE et autres matières, destinés à être utilisés dans les conditions suivantes :

a) avec une pression de service admissible, PFA, jusqu'à 25 bar 1) ;

b) à une température de service de 20 °C comme température de référence ;

c) enterrés dans le sol ;

d) comme émissaires de rejet en mer ;

e) posés dans l'eau ;

f) non enterrés, y compris canalisations suspendues sous des ponts.

NOTE 2 Pour les applications à température de service constante supérieure à 20 °C et jusqu'à 40 °C, voir Annexe A de l’EN 12201 1:2011.

NOTE 3 Les systèmes de canalisations incluant des couches barrières ne sont pas couverts par ce document.

L’EN 12201 couvre une plage de pressions de service admissibles et définit des exigences concernant les couleurs et les additifs.

Elle concerne trois types de tubes :

- les tubes en PE (diamètre extérieur dn) y compris toutes bandes d'identification éventuelles ;

- les tubes en PE comportant des couches co-extrudées soit sur leur surface externe ou interne, soit sur leurs deux surfaces (diamètre extérieur total dn), tel que spécifié dans l'Annexe B, où toutes les couches ont la même classification MRS ;

- les tubes en PE (diamètre extérieur dn) comportant une couche supplémentaire thermoplastique contiguë pelable sur leur surface externe («tube revêtu»), tel que spécifié dans l’Annexe C.

NOTE 4 Il incombe à l'acheteur ou au prescripteur la responsabilité de réaliser une sélection convenable de ces aspects en prenant en compte les exigences particulières ainsi que les directives ou règles nationales et les pratiques et codes de pose en usage dans son pays.

NOTE 5 L’évaluation de la résistance à la propagation lente de la fissure de la composition pour tube en PE utilisée pour fabriquer des produits correspondant au présent document est nécessaire, conformément au Tableau 2 de l’EN 12201 1:2011.

Cevni sistemi iz polimernih materialov za oskrbo z vodo in za odvodnjavanje in kanalizacijo pod tlakom - Polietilen (PE) - 2. del: Cevi (vključno z dopolnilom A1)

Ta del standarda EN 12201 določa značilnosti polietilenskih cevi (PE 100, PE 80 in PE 40) za podzemno in nadzemno uporabo, namenjenih za prenos pitne vode, neobdelane vode pred obdelavo, odvodnjavanje in kanalizacijo pod tlakom, vakuumske kanalizacijske sisteme in vode za druge namene. Določa tudi preskusne parametre za preskusne metode iz tega standarda. V povezavi s 1. delom in 3. do 5. delom standarda EN 12201 se uporablja za cevi iz polietilena, njihove spoje ter spoje s komponentami iz polietilena in drugih materialov, namenjene uporabi v naslednjih pogojih: a) dovoljen obratovalni tlak PFA do 25 bar, b) delovna temperatura 20 °C kot referenčna temperatura, c) položeni v zemljo, d) izpusti v morje; e) položeni v vodo, f) nad tlemi, vključno s cevmi, obešenimi pod mostovi. Standard EN 12201 zajema razpon dovoljenih obratovalnih tlakov in določa zahteve glede barv in aditivov. Zajema tri vrste cevi: – polietilenske cevi (zunanji premer dn) s kakršnimi koli identifikacijskimi črtami; – polietilenske cevi s koekstrudiranimi sloji na zunanji in/ali notranji strani cevi (celotni zunanji premer dn), kot je opredeljeno v dodatku B, pri čemer imajo vsi sloji enako oceno MRS; – polietilenske cevi (zunanji premer dn) s termoplastičnim dodatnim slojem, ki ga je mogoče odluščiti, na zunanji strani cevi (»prevlečena cev«), kot je opredeljeno v dodatku C.

General Information

- Status

- Withdrawn

- Publication Date

- 24-Sep-2013

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 155 - Plastics piping systems and ducting systems

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 31-Jan-2024

- Completion Date

- 14-Apr-2025

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 15-Aug-2012

- Effective Date

- 19-Jan-2023

Frequently Asked Questions

EN 12201-2:2011+A1:2013 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 2: Pipes". This standard covers: This part of EN 12201 specifies the characteristics of pipes made from polyethylene (PE 100, PE 80 and PE 40) for buried and above ground applications, intended for the conveyance of water for human consumption, raw water prior to treatment, drainage and sewerage under pressure, vacuum sewer systems, and water for other purposes. NOTE 1 For PE components intended for the conveyance of water for human consumption and raw water prior to treatment attention is drawn to 5.3 of this European Standard. Components manufactured for water for general purposes, drainage and sewerage may not be suitable for water supply for human consumption. It also specifies the test parameters for the test methods referred to in this standard. In conjunction with Part 1 and Parts 3 to 5 of EN 12201, it is applicable to PE pipes, their joints and to joints with components of PE and other materials intended to be used under the following conditions: a) allowable operating pressure, PFA, up to 25 bar ); b) an operating temperature of 20 °C as a reference temperature; c) buried in the ground; d) sea outfalls; e) laid in water; f) above ground, including pipes suspended below bridges. NOTE 2 For applications operating at constant temperatures greater than 20 °C and up to 40 °C, see Annex A of EN 12201-1:2011. NOTE 3 Pipes constructions including barrier layers are not covered by this document. EN 12201 covers a range of allowable operating pressures and gives requirements concerning colours and additives. It covers three types of pipe: - PE pipes (outside diameter dn) including any identification stripes; - PE pipes with co-extruded layers on either or both the outside and/or inside of the pipe (total outside diameter dn) as specified in Annex B, where all layers have the same MRS rating; - PE pipes (outside diameter dn) with a peelable, contiguous thermoplastics additional layer on the outside of the pipe (‘coated pipe’) as specified in Annex C. NOTE 4 It is the responsibility of the purchaser or specifier to make the appropriate selections from these aspects, taking into account their particular requirements and any relevant national guidance or regulations and installation practices or codes. NOTE 5 Assessment of the resistance to slow crack growth of the PE pipe compound used for the manufacture of products to this document is required in accordance with Table 2 of EN 12201-1:2011.

This part of EN 12201 specifies the characteristics of pipes made from polyethylene (PE 100, PE 80 and PE 40) for buried and above ground applications, intended for the conveyance of water for human consumption, raw water prior to treatment, drainage and sewerage under pressure, vacuum sewer systems, and water for other purposes. NOTE 1 For PE components intended for the conveyance of water for human consumption and raw water prior to treatment attention is drawn to 5.3 of this European Standard. Components manufactured for water for general purposes, drainage and sewerage may not be suitable for water supply for human consumption. It also specifies the test parameters for the test methods referred to in this standard. In conjunction with Part 1 and Parts 3 to 5 of EN 12201, it is applicable to PE pipes, their joints and to joints with components of PE and other materials intended to be used under the following conditions: a) allowable operating pressure, PFA, up to 25 bar ); b) an operating temperature of 20 °C as a reference temperature; c) buried in the ground; d) sea outfalls; e) laid in water; f) above ground, including pipes suspended below bridges. NOTE 2 For applications operating at constant temperatures greater than 20 °C and up to 40 °C, see Annex A of EN 12201-1:2011. NOTE 3 Pipes constructions including barrier layers are not covered by this document. EN 12201 covers a range of allowable operating pressures and gives requirements concerning colours and additives. It covers three types of pipe: - PE pipes (outside diameter dn) including any identification stripes; - PE pipes with co-extruded layers on either or both the outside and/or inside of the pipe (total outside diameter dn) as specified in Annex B, where all layers have the same MRS rating; - PE pipes (outside diameter dn) with a peelable, contiguous thermoplastics additional layer on the outside of the pipe (‘coated pipe’) as specified in Annex C. NOTE 4 It is the responsibility of the purchaser or specifier to make the appropriate selections from these aspects, taking into account their particular requirements and any relevant national guidance or regulations and installation practices or codes. NOTE 5 Assessment of the resistance to slow crack growth of the PE pipe compound used for the manufacture of products to this document is required in accordance with Table 2 of EN 12201-1:2011.

EN 12201-2:2011+A1:2013 is classified under the following ICS (International Classification for Standards) categories: 23.040.05 - Pipeline and its parts for external sewage systems; 23.040.20 - Plastics pipes; 93.030 - External sewage systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12201-2:2011+A1:2013 has the following relationships with other standards: It is inter standard links to EN 12201-2:2011, EN 12201-2:2011/FprA1, EN 12201-2:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12201-2:2011+A1:2013 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 12201-2:2011+A1:2013 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kunststoff-Rohrleitungssysteme für die Wasserversorgung und für Entwässerungs- und Abwasserdruckleitungen - Polyethylen (PE) - Teil 2: RohreSystèmes de canalisations en plastique pour l'alimentation en eau et pour les branchements et les collecteurs d'assainissement avec pression - Polyéthylène (PE) - Partie 2 : TubesPlastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 2: Pipes93.030Zunanji sistemi za odpadno vodoExternal sewage systems91.140.60Sistemi za oskrbo z vodoWater supply systems23.040.20Cevi iz polimernih materialovPlastics pipesICS:Ta slovenski standard je istoveten z:EN 12201-2:2011+A1:2013SIST EN 12201-2:2011+A1:2013en,fr,de01-december-2013SIST EN 12201-2:2011+A1:2013SLOVENSKI

STANDARDSIST EN 12201-2:20111DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12201-2:2011+A1

September 2013 ICS 23.040.20 Supersedes EN 12201-2:2011

English Version

Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 2: Pipes

Systèmes de canalisations en plastique pour l'alimentation en eau et pour les branchements et les collecteurs d'assainissement avec pression - Polyéthylène (PE) - Partie 2 : Tubes

Kunststoff-Rohrleitungssysteme für die Wasserversorgung und für Entwässerungs- und Abwasserdruckleitungen - Polyethylen (PE) - Teil 2: Rohre This European Standard was approved by CEN on 8 July 2011 and includes Amendment 1 approved by CEN on 12 August 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12201-2:2011+A1:2013: E SIST EN 12201-2:2011+A1:2013

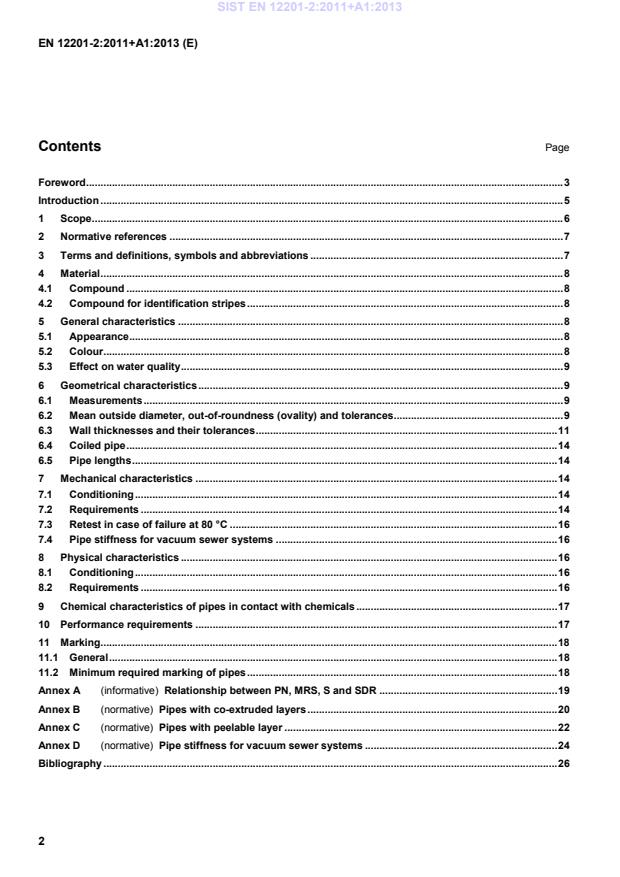

Relationship between PN, MRS, S and SDR . 19 Annex B (normative)

Pipes with co-extruded layers . 20 Annex C (normative)

Pipes with peelable layer . 22 Annex D (normative)

Pipe stiffness for vacuum sewer systems . 24 Bibliography . 26

The start and finish of text introduced or altered by amendment is indicated in the text by tags !". !This document includes Amendment A1 to EN 12201-2:2011 that comprises technical changes to: Subclause 6.3, Wall thicknesses and their tolerances; Subclause 8.2, Requirements, Table 5, Physical Requirements, physical longitudinal reversion test." System Standards are based on the results of the work being undertaken in ISO/TC 138, "Plastics pipes, fittings and valves for the transport of fluids", which is a Technical Committee of the International Organization for Standardization (ISO). They are supported by separate standards on test methods to which references are made throughout the System Standard.

The System Standards are consistent with general standards on functional requirements and on recommended practice for installation.

EN 12201 consists of the following parts: EN 12201-1:, Plastics piping systems for water supply, and for drainage and sewerage under pressure — Polyethylene (PE) — Part 1: General; EN 12201-2:, Plastics piping systems for water supply, and for drainage and sewerage under pressure — Polyethylene (PE) — Part 2: Pipes (this standard); EN 12201-3:, Plastics piping systems for water supply, and for drainage and sewerage under pressure — Polyethylene (PE) — Part 3: Fittings; EN 12201-4 , Plastics piping systems for water supply, and for drainage and sewerage under pressure — Polyethylene (PE) — Part 4: Valves for water supply systems; EN 12201-5, Plastics piping systems for water supply, and for drainage and sewerage under pressure — Polyethylene (PE) — Part 5: Fitness for purpose of the system; CEN/TS 12201-7, Plastics piping systems for water supply — Polyethylene (PE) — Part 7: Guidance for the assessment of conformity.

In this revision, the scope of this standard includes two additional types of pipe;- SIST EN 12201-2:2011+A1:2013

According to the CEN/CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 12201-2:2011+A1:2013

EN 12201-1:2011, EN 12201-3:2011 [1] and prEN 12201-4:2011 [2]. Characteristics for fitness of purpose are covered in EN 12201-5:2011 and CEN/TS 12201-7 [3] gives guidance for the assessment of conformity. This Part of EN 12201 covers the characteristics of pipes. SIST EN 12201-2:2011+A1:2013

NOTE 2 For applications operating at constant temperatures greater than 20 °C and up to 40 °C, see Annex A of

EN 12201-1:2011. NOTE 3 Pipes constructions including barrier layers are not covered by this document.

EN 12201 covers a range of allowable operating pressures and gives requirements concerning colours and additives. It covers three types of pipe: PE pipes (outside diameter dn) including any identification stripes; PE pipes with co-extruded layers on either or both the outside and/or inside of the pipe (total outside diameter dn) as specified in Annex B, where all layers have the same MRS rating; PE pipes (outside diameter dn) with a peelable, contiguous thermoplastics additional layer on the outside of the pipe (‘coated pipe’) as specified in Annex C. NOTE 4 It is the responsibility of the purchaser or specifier to make the appropriate selections from these aspects, taking into account their particular requirements and any relevant national guidance or regulations and installation practices or codes. NOTE 5 Assessment of the resistance to slow crack growth of the PE pipe compound used for the manufacture of products to this document is required in accordance with Table 2 of EN 12201-1:2011.

1) 1 bar = 0,1 MPa = 105 Pa; 1 MPa = 1 N/mm2. SIST EN 12201-2:2011+A1:2013

EN ISO 13968, mlastics piping and ducting systems

#—Thermoplastics pipes

#— Determination of ring flexibility (ISO 13968:2008) ISO 4433-1:1997, Thermoplastics pipes — Resistance to liquid chemicals — Classification — Part 1: Immersion test method ISO 4433-2:1997, Thermoplastics pipes — Resistance to liquid chemicals — Classification — Part 2: Polyolefin pipes ISO 6259-3:1997, Thermoplastics pipes — Determination of tensile properties — Part 3: Polyolefin pipes ISO 11357-6, Plastics — Differential scanning calorimetry (DSC) — Part 6: Determination of oxidation induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT) 3 Terms and definitions, symbols and abbreviations For the purposes of this document, the terms and definitions, symbols and abbreviations given in

EN 12201-1 apply.

The ends of the pipe shall be cut cleanly and square to the axis of the pipe. 5.2 Colour Pipes intended for the conveyance of water for human consumption shall be black or blue. In addition, black pipes may be identified by blue stripes, according to national preference. Blue pipes or black pipes with blue stripes are intended for the conveyance of water for human consumption only.

Pipes intended for other purposes, drainage and sewerage shall be black or black with brown stripes or according to national preference.

The outer coextruded layer of coextruded pipes (see Annex B) or the outer peelable layer of peelable layer pipes (see Annex C) for pipe intended for the conveyance of water for human consumption shall be either black or blue. In addition identification stripes may be used according to national preference for the application. The outer coextruded layer of coextruded pipes (see Annex B) or the outer peelable layer of peelable layer pipes (see Annex C) for pipe intended for other purposes shall be either black or black with brown stripes or brown or according to national preference. In addition identification stripes of a different colour may be used according to national preference for the application.

NOTE 1 In some countries, pipes made from non-pigmented compound in conjunction with an external peelable layer are permitted, providing the compound conforms to the requirements of this standard. If this is allowed in a country, this should be clearly stated in the national foreword. NOTE 2 For above ground installations, all components other than black should be protected from direct UV light. NOTE 3 The national preference for colour should be stated in the National Foreword. SIST EN 12201-2:2011+A1:2013

For compounds intended to be used for components in contact with water for human consumption, attention is drawn to the requirements of national regulations. 6 Geometrical characteristics 6.1 Measurements The dimensions of the pipe shall be measured in accordance with EN ISO 3126 and rounded to the next 0,1 mm. In the case of dispute the measurements of dimensions shall be made not less than 24 h after manufacture after being conditioned for at least 4 h at (23 ± 2) °C. NOTE 1 Indirect measurement during the stage of production is allowed at shorter time periods providing evidence is shown of correlation. NOTE 2 The national preference for pipe size and PN rating may be given in the National Foreword. 6.2 Mean outside diameter, out-of-roundness (ovality) and tolerances The mean outside diameters, dem, and the out-of-roundness (ovality) shall be in accordance with Table 1. For coiled pipes, the maximum out-of roundness shall be specified by agreement between the manufacturer and the end-user. Pipe extruded from PE 40 materials shall be limited to diameters up to and including 63 mm. NOTE 1 In some countries pipe in PE 40 materials may be used in diameters up to and including 90 mm. If this is the case this should be stated in the National Foreword. SIST EN 12201-2:2011+A1:2013

1 000

1 200 1 400 1 600 1 800 2 000

2 250

2 500 16 20 25 32 40 50 63 75 90 110 125 140 160 180 200 225 250 280 315 355 400 450 500 560 630 710 800 900 1 000 1 200 1 400 1 600 1 800 2 000

2 250

2 500

16,0 20,0 25,0 32,0 40,0 50,0 63,0 75,0 90,0 110,0 125,0 140,0 160,0 180,0 200,0 225,0 250,0 280,0 315,0 355,0 400,0 450,0 500,0 560,0 630,0 710,0 800,0 900,0 1 000,0 1 200,0 1 400,0 1 600,0

1 800,0 2 000,0

2 250,0

2 500,0 16,3 20,3 25,3 32,3 40,4 50,4 63,4 75,5 90,6 110,7 125,8 140,9 161,0 181,1 201,2 226,4 251,5 281,7 316,9 357,2 402,4 452,7 503,0 563,4 633,8 716,4 807,2 908,1 1 009,0 1 210,8 c 1 412,6 c 1 614,4 c 1 816,2 c

2 018,0 c

2270,3 c

2522,5 c

1,2 1,2 1,2 1,3 1,4 1,4 1,5 1,6 1,8 2,2 2,5 2,8 3,2 3,6 4,0 4,5 5,0 9,8 11,1 12,5 14,0 15,6 17,5 19,6 22,1 24,9 28,0 — — — — — —

—

—

—

a

In accordance with ISO 11922-1:1997 [7] grade B for sizes ≤ 630 and grade A for sizes > 710 except for dn 40 and 50. b In accordance with ISO 11922-1:1997 [7] grade N for sizes ≤ 630 and is measured at the point of manufacture. c

Tolerance calculated as 0,009dn and does not conform to grade A in ISO 11922-1:1997 [7]. d For straight lengths of pipe with diameters ≥ 900 the ma

...

EN 12201-2:2011+A1:2013は、ポリエチレン(PE)製の管に関する標準文書であり、特に水供給や排水および圧力下の下水道に焦点を当てています。この標準の範囲は、埋設および地上で使用されるPE管の特性を規定しており、人間の消費用水、処理前の原水、圧力下の排水および下水道、真空下水道システム、その他の用途に使用される水の輸送を意図しています。 この標準の強みは、特定の運用圧力(最大25バール)と運用温度(基準温度20℃)に関する明確な指針を提供する点です。これにより、広範な使用条件-埋設、海洋放出口、水中配置、橋の下に吊るされた状態など-に適したPE管の設計と製造が可能になります。また、色や添加物に関する要求事項も規定されており、設計者や施行者が必要に応じて適切な選択を行いやすくなっています。 EN 12201は、PE管の種類に応じて、外径を基にした分類や共押出成型層を持つ管の仕様を含み、さらに外部に剥がせる熱可塑性の追加層を持つ管についても言及しています。このように、各種PE管の特性を明示化することで、実際の使用における安全性と適合性を確保しています。 この標準は、PE管の使用を考慮する上で非常に重要であり、特に人間の消費用に適さない用途とその注意点も明記されていることで、利用者が誤った選択を避けられるよう配慮されています。したがって、EN 12201-2:2011+A1:2013は、PE配管システムにおける水供給と排水に関する重要な基準であり、その適用の広範さと具体的な指針は、業界のニーズに対して非常に関連性の高いものとなっています。

EN 12201-2:2011+A1:2013 표준 문서는 수돗물 공급 및 배수, 하수도 압력 시스템 등 다양한 용도로 사용되는 폴리에틸렌(PE) 파이프의 특성을 명시하고 있습니다. 이 문서는 PE 100, PE 80 및 PE 40으로 제작된 파이프들에 대한 규정을 포함하고 있으며, 지하 및 지상에 설치 가능한 응용 프로그램을 대상으로 합니다. 표준의 주요 강점은 수돗물 및 원수의 수송에 적합한 파이프의 요구사항을 명확하게 규정하고 있다는 점입니다. 인체가 소비하는 물을 전달하는 데 필요한 물질적 특성과 테스트 매개변수를 제시하여, 수돗물에 대한 안전성을 보장할 수 있도록 하고 있습니다. 특히, 파이프의 설치 조건에 대한 세부안을 제공하여, 사용자의 특정 요구사항 및 관련 국가 지침이나 규정에 맞추어 적절한 선택을 할 수 있도록 도와줍니다. 또한, EN 12201 표준은 색상 및 첨가물에 대한 요구 사항을 포함하여 더 넓은 범위의 운영 압력을 다루고 있습니다. PE 파이프는 고유한 지름을 가진 일반적인 형태 외에도, 코엑스트루전 층이 있는 파이프 및 장착 가능한 복합층이 있는 코팅 파이프도 포함하고 있어 다양한 사용 조건을 만족할 수 있게 설계되어 있습니다. 이러한 모든 요소들은 표준이 현대의 물 관리 및 수처리 시스템에서 필수적인 역할을 하도록 도와줍니다. 따라서 EN 12201-2:2011+A1:2013 표준은 물 공급 및 하수도 시스템의 안전성 및 효율성을 보장하는 데 중요한 기준으로, 산업 전반에서의 적용 가능성을 높이고 있습니다.

The standard EN 12201-2:2011+A1:2013 establishes a clear framework regarding the characteristics and use of polyethylene (PE) pipes, essential for a variety of applications including the conveyance of water for human consumption, drainage, and sewerage under pressure. This document is pivotal as it categorizes the PE types (PE 100, PE 80, and PE 40) and delineates their suitability for specific applications, which is crucial for ensuring safety and compliance. One of the key strengths of EN 12201-2 is its comprehensive scope, covering various configuration options of PE pipes including those with co-extruded layers and coatings. The standard addresses critical parameters such as operating pressure limits up to 25 bar and standard operating temperatures, thereby providing essential considerations for engineers and designers in selecting the appropriate PE piping systems for their projects. Moreover, it includes guidelines for different installation scenarios, such as buried pipes and those installed above ground or in water, enhancing its relevance across diverse environments. Another significant aspect is the emphasis on ensuring that components intended for potable water meet stringent quality criteria, warning that not all PE materials may be suitable for conveying water for human consumption. This precaution enables manufacturers and specifiers to adhere to health and safety regulations, which is critical in maintaining public health standards. In terms of test parameters, the standard outlines required test methods for assessing the quality and performance of PE pipes, thereby bolstering reliability in usage. EN 12201-2 emphasizes the importance of considering local regulations and installation practices, ensuring that users can tailor the application of PE piping systems according to their specific project needs. Overall, EN 12201-2:2011+A1:2013 stands out for its comprehensive approach to PE pipes, offering valuable guidelines that not only facilitate compliance but also enhance the performance and safety of plastic piping systems in water supply and sewerage applications. Its relevance is underscored by the necessity for standardization in ensuring quality across various applications and installations.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...