EN 1439:2021

(Main)LPG equipment and accessories - Procedure for checking transportable refillable LPG cylinders before, during and after filling

LPG equipment and accessories - Procedure for checking transportable refillable LPG cylinders before, during and after filling

This document specifies the procedures to be adopted when checking transportable refillable LPG cylinders before, during and after filling.

This document is applicable to transportable refillable LPG cylinders of water capacity not exceeding 150 l and deemed to be fitted with valves designed according to EN ISO 14245 [4] and EN ISO 15995 [5].

This document does not apply to the requirements for filling LPG cylinders that are designed and equipped for filling by the user.

This document does not apply to the requirements for filling LPG containers on vehicles.

This document is applicable to the following:

— welded and brazed steel LPG cylinders with a specified minimum wall thickness (see EN 1442 and EN 12807 [1] or an equivalent standard);

— welded steel LPG cylinders without specified minimum wall thickness (see EN 14140 or an equivalent standard);

— welded aluminium LPG cylinders (see EN 13110 [2] or an equivalent standard);

— composite LPG cylinders (see EN 14427 or an equivalent standard); and

— over-moulded cylinders (OMC).

Specific requirements for the different types of cylinders are detailed in Annex A, Annex B, Annex C, Annex D and Annex G.

This document is intended to be applicable to cylinders complying with RID/ADR [6] [7] (including pi marked cylinders) and also to existing non RID/ADR cylinder populations.

Flüssiggas-Geräte und Ausrüstungsteile - Kontrollverfahren für Flaschen für Flüssiggas (LPG) vor, während und nach dem Füllen

Dieses Dokument legt die Verfahren zur Überprüfung von ortsbeweglichen, wiederbefüllbaren Flaschen für Flüssiggas (LPG, en: liquefied petroleum gas) vor, während und nach dem Füllen fest.

Dieses Dokument ist für ortsbewegliche, wiederbefüllbare Flaschen für Flüssiggas (LPG) mit einem Fassungsraum von höchstens 150 l anwendbar, die mit Ventilen nach EN ISO 14245 [4] und EN ISO 15995 [5] ausgestattet werden.

Dieses Dokument ist nicht anzuwenden für die Anforderungen für das Füllen von Flaschen für Flüssiggas (LPG), die für das Füllen durch den Benutzer ausgelegt und ausgerüstet sind.

Dieses Dokument ist nicht anzuwenden für die Anforderungen für das Füllen von Behältern für Flüssiggas (LPG) auf Fahrzeugen.

Dieses Dokument ist anzuwenden für Folgendes:

— geschweißte und hartgelötete Flaschen aus Stahl für Flüssiggas (LPG) mit festgelegter Mindest-wanddicke (siehe EN 1442 und EN 12807 [1] oder eine gleichwertige Norm);

— geschweißte Flaschen aus Stahl für Flüssiggas (LPG) ohne festgelegte Mindestwanddicke (siehe EN 14140 oder eine gleichwertige Norm);

— geschweißte Flaschen aus Aluminium für Flüssiggas (LPG) (siehe EN 13110 [2] oder eine gleichwertige Norm);

— Flaschen aus Verbundwerkstoff für Flüssiggas (LPG) (siehe EN 14427 oder eine gleichwertige Norm); und

— umformte Flaschen (OMC, en: over moulded cylinders).

Spezifische Anforderungen für verschiedene Flaschentypen sind in Anhang A, Anhang B, Anhang C, Anhang D und Anhang G beschrieben.

Dieses Dokument ist für die Anwendung bei Flaschen nach RID/ADR [6] [7] (einschließlich Flaschen mit Pi Kennzeichnung) vorgesehen, sowie für bestehende Flaschengruppen, die nicht RID/ADR entsprechen.

Équipements pour GPL et leurs accessoires - Procédure de vérification des bouteilles transportables et rechargeables pour GPL avant, pendant et après le remplissage

Le présent document décrit les procédures à employer lors de la vérification des bouteilles pour GPL transportables et rechargeables, avant, pendant et après le remplissage.

Le présent document s'applique aux bouteilles transportables et rechargeables pour gaz de pétrole liquéfié (GPL), d'une capacité en eau ne dépassant pas 150 l et réputées être équipées de robinets conçus conformément à l'EN ISO 14245 [4] et à l'EN ISO 15995 [5].

Le présent document ne s'applique pas aux exigences de remplissage des bouteilles pour GPL conçues et équipées pour être remplies par l'utilisateur.

Le présent document ne s'applique pas aux exigences concernant le remplissage de réservoirs GPL sur les véhicules.

Le présent document s'applique aux éléments suivants :

bouteilles pour GPL en acier soudé et brasé, avec une épaisseur minimale de paroi définie (voir l'EN 1442 et l'EN 12807 [1] ou une norme équivalente) ;

bouteilles pour GPL en acier soudé, sans épaisseur minimale de paroi définie (voir l'EN 14140 ou une norme équivalente) ;

bouteilles pour GPL en aluminium soudé (voir l'EN 13110 [2] ou une norme équivalente) ;

bouteilles pour GPL en matériau composite (voir l'EN 14427 ou une norme équivalente) ; et

bouteilles surmoulées (OMC).

Les exigences spécifiques relatives aux différents types de bouteilles sont décrites en détail dans les Annexes A, B, C, D et G.

Il est prévu que le présent document soit applicable à des bouteilles conformes au RID/ADR [6] [7] (y compris les bouteilles comportant un marquage pi), ainsi qu'aux familles de bouteilles existantes non conformes au RID/ADR.

Oprema in pribor za utekočinjeni naftni plin (UNP) - Postopek za preverjanje premičnih, ponovno polnjivih jeklenk za UNP pred polnjenjem, med njim in po njem

Ta dokument določa postopke, ki jih je treba sprejeti pri preverjanju prenosnih ponovno polnljivih jeklenk za utekočinjeni naftni plin, pred in med polnjenjem ter po polnjenju.

Ta dokument se uporablja za prenosne ponovno polnljive jeklenke za utekočinjeni naftni plin s prostornino vode, ki ne presega 150 l, za katere je predvideno, da so opremljene z ventili, zasnovanimi v skladu s standardoma EN ISO 14245 [4] in EN ISO 15995 [5].

Ta dokument ne zajema zahtev za polnjenje jeklenk za utekočinjeni naftni plin, ki so zasnovane in opremljene za polnjenje s strani uporabnika.

Ta dokument ne zajema zahtev za polnjenje posod za utekočinjeni naftni plin na vozilih.

Ta dokument se uporablja za naslednje izdelke:

– varjene in trdo spajkane jeklenke za utekočinjeni naftni plin iz jekla z določeno minimalno debelino stene (glej standarda EN 1442 in EN 12807 [1] ali enakovreden standard);

– varjene jeklenke za utekočinjeni naftni plin iz jekla brez določene minimalne debeline stene (glej standard EN 14140 ali enakovreden standard);

– varjene jeklenke za utekočinjeni naftni plin iz aluminija (glej standard EN 13110 [2] ali enakovreden standard);

– kompozitne jeklenke za utekočinjeni naftni plin (glej standard EN 14427 ali enakovreden standard); in

– prelite jeklenke (OMC).

Posebne zahteve za različne vrste jeklenk so podrobno opisane v dodatku A, dodatku B, dodatku C, dodatku D in dodatku G.

Ta osnutek standarda se uporablja za jeklenke v skladu z določbami RID/ADR [6][7] (vključno z jeklenkami z oznako pi) in tudi za obstoječe jeklenke, ki niso v skladu z določbami RID/ADR.

General Information

- Status

- Published

- Publication Date

- 26-Oct-2021

- Withdrawal Date

- 29-Apr-2022

- Technical Committee

- CEN/TC 286 - Liquefied petroleum gas equipment and accessories

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 27-Oct-2021

- Due Date

- 13-Apr-2022

- Completion Date

- 27-Oct-2021

Relations

- Effective Date

- 03-Nov-2021

Overview

EN 1439:2021 - "LPG equipment and accessories - Procedure for checking transportable refillable LPG cylinders before, during and after filling" is a CEN European Standard that defines the procedural checks to be carried out on transportable refillable LPG cylinders (water capacity ≤ 150 L) at filling plants. It covers visual, dimensional and safety checks performed before filling, checks during filling and post‑filling verification to ensure safe handling, correct fill quantity and regulatory compliance. The standard applies to welded/brazed steel, welded aluminium, composite and over‑moulded cylinders fitted with valves designed to EN ISO 14245 and EN ISO 15995, and is intended for cylinders within and outside RID/ADR fleets (including pi‑marked cylinders). It does not apply to user‑filled cylinders or filling on vehicles.

Key topics and requirements

- Segregation prior to filling: Procedures for grouping cylinders into suitable for filling, requiring periodic inspection, or needing further assessment. A competent person must carry out segregation following the flow diagram (Annex F).

- Acceptance criteria: Markings (tare mass, water capacity, allowed product), in‑test date, valve/pressure relief device condition, absence of unacceptable damage or corrosion, and operability of fixed liquid level devices where applicable.

- Reassessment and repairs: Requirements for reassessing cylinders set aside (missing tare or water capacity markings, damaged valves, leaks). Guidance on reconditioning, valve repair/replacement and safe venting; disposal options per EN 12816.

- Filling conditions and safe fill quantities: Operational constraints during filling (see Annex E for safe filling conditions) and methods of filling by mass, volume or fixed level. Post‑filling checks include verifying filled amount and actions for over/under‑filled cylinders.

- Specific cylinder types: Normative annexes provide tailored inspection/filling requirements for welded/brazed steel (Annex A/B), aluminium (Annex C), composite (Annex D) and over‑moulded cylinders (Annex G/H).

- Competent person: Emphasis that checks and judgments must be made by trained, qualified personnel.

Applications and users

- Filling plants and LPG distributors conducting cylinder filling operations.

- Cylinder inspectors, technical managers and safety officers responsible for operational procedures.

- Maintenance and reconditioning workshops handling valve repair/replacement and cylinder reassessment.

- Regulatory bodies and transport authorities referencing compliance with RID/ADR and national rules.

- Manufacturers and designers seeking clarity on practical inspection and filling interfaces.

Related standards (selection)

- EN ISO 14245, EN ISO 15995 (valves)

- EN 1442, EN 14140 (steel cylinder design/construction)

- EN 14427 (composite cylinders)

- EN 1440, EN 16728 (periodic inspection)

- EN 12816 (disposal), EN 14894 (marking), EN 13952 (filling operations)

- EN 549, EN 15202 (seals and valve connections)

This summary helps operational teams implement EN 1439:2021 procedures for safe, compliant LPG cylinder filling and post‑fill verification.

Frequently Asked Questions

EN 1439:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "LPG equipment and accessories - Procedure for checking transportable refillable LPG cylinders before, during and after filling". This standard covers: This document specifies the procedures to be adopted when checking transportable refillable LPG cylinders before, during and after filling. This document is applicable to transportable refillable LPG cylinders of water capacity not exceeding 150 l and deemed to be fitted with valves designed according to EN ISO 14245 [4] and EN ISO 15995 [5]. This document does not apply to the requirements for filling LPG cylinders that are designed and equipped for filling by the user. This document does not apply to the requirements for filling LPG containers on vehicles. This document is applicable to the following: — welded and brazed steel LPG cylinders with a specified minimum wall thickness (see EN 1442 and EN 12807 [1] or an equivalent standard); — welded steel LPG cylinders without specified minimum wall thickness (see EN 14140 or an equivalent standard); — welded aluminium LPG cylinders (see EN 13110 [2] or an equivalent standard); — composite LPG cylinders (see EN 14427 or an equivalent standard); and — over-moulded cylinders (OMC). Specific requirements for the different types of cylinders are detailed in Annex A, Annex B, Annex C, Annex D and Annex G. This document is intended to be applicable to cylinders complying with RID/ADR [6] [7] (including pi marked cylinders) and also to existing non RID/ADR cylinder populations.

This document specifies the procedures to be adopted when checking transportable refillable LPG cylinders before, during and after filling. This document is applicable to transportable refillable LPG cylinders of water capacity not exceeding 150 l and deemed to be fitted with valves designed according to EN ISO 14245 [4] and EN ISO 15995 [5]. This document does not apply to the requirements for filling LPG cylinders that are designed and equipped for filling by the user. This document does not apply to the requirements for filling LPG containers on vehicles. This document is applicable to the following: — welded and brazed steel LPG cylinders with a specified minimum wall thickness (see EN 1442 and EN 12807 [1] or an equivalent standard); — welded steel LPG cylinders without specified minimum wall thickness (see EN 14140 or an equivalent standard); — welded aluminium LPG cylinders (see EN 13110 [2] or an equivalent standard); — composite LPG cylinders (see EN 14427 or an equivalent standard); and — over-moulded cylinders (OMC). Specific requirements for the different types of cylinders are detailed in Annex A, Annex B, Annex C, Annex D and Annex G. This document is intended to be applicable to cylinders complying with RID/ADR [6] [7] (including pi marked cylinders) and also to existing non RID/ADR cylinder populations.

EN 1439:2021 is classified under the following ICS (International Classification for Standards) categories: 23.020.35 - Gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1439:2021 has the following relationships with other standards: It is inter standard links to EN 1439:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1439:2021 is associated with the following European legislation: EU Directives/Regulations: 2008/68/EC; Standardization Mandates: M/086, M/TDG, M/XXX. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 1439:2021 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2022

Nadomešča:

SIST EN 1439:2018

Oprema in pribor za utekočinjeni naftni plin (UNP) - Postopek za preverjanje

premičnih, ponovno polnjivih jeklenk za UNP pred polnjenjem, med njim in po

njem

LPG equipment and accessories - Procedure for checking transportable refillable LPG

cylinders before, during and after filling

Flüssiggas-Geräte und Ausrüstungsteile - Kontrollverfahren für Flaschen für Flüssiggas

(LPG) vor, während und nach dem Füllen

Équipements pour GPL et leurs accessoires - Procédure de vérification des bouteilles

transportables et rechargeables pour GPL avant, pendant et après le remplissage

Ta slovenski standard je istoveten z: EN 1439:2021

ICS:

23.020.35 Plinske jeklenke Gas cylinders

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1439

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2021

EUROPÄISCHE NORM

ICS 23.020.35 Supersedes EN 1439:2017

English Version

LPG equipment and accessories - Procedure for checking

transportable refillable LPG cylinders before, during and

after filling

Équipements pour GPL et leurs accessoires - Procédure Flüssiggas-Geräte und Ausrüstungsteile -

de vérification des bouteilles transportables et Kontrollverfahren für Flaschen für Flüssiggas (LPG)

rechargeables pour GPL avant, pendant et après le vor, während und nach dem Füllen

remplissage

This European Standard was approved by CEN on 6 September 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1439:2021 E

worldwide for CEN national Members.

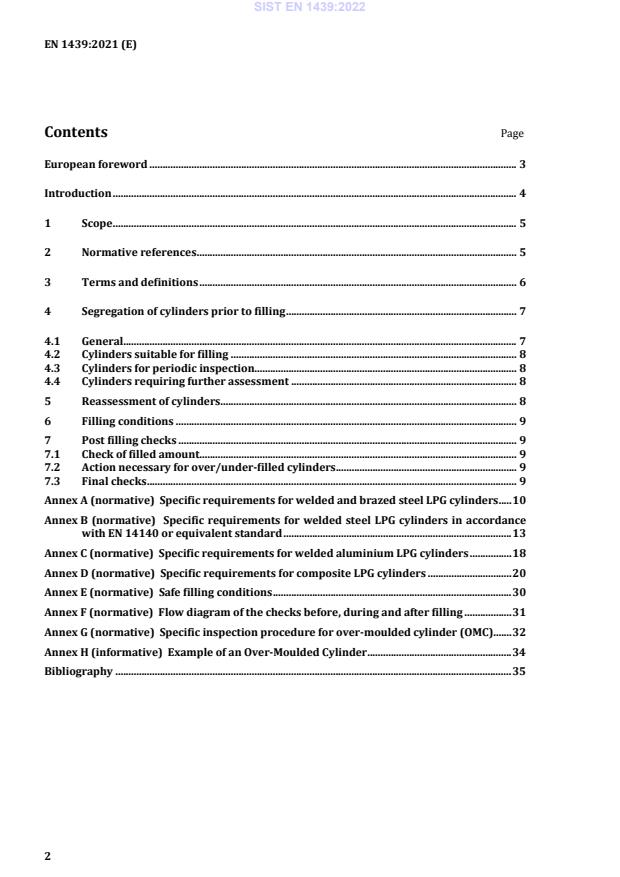

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Segregation of cylinders prior to filling . 7

4.1 General. 7

4.2 Cylinders suitable for filling . 8

4.3 Cylinders for periodic inspection. 8

4.4 Cylinders requiring further assessment . 8

5 Reassessment of cylinders. 8

6 Filling conditions . 9

7 Post filling checks . 9

7.1 Check of filled amount. 9

7.2 Action necessary for over/under-filled cylinders . 9

7.3 Final checks . 9

Annex A (normative) Specific requirements for welded and brazed steel LPG cylinders . 10

Annex B (normative) Specific requirements for welded steel LPG cylinders in accordance

with EN 14140 or equivalent standard . 13

Annex C (normative) Specific requirements for welded aluminium LPG cylinders . 18

Annex D (normative) Specific requirements for composite LPG cylinders . 20

Annex E (normative) Safe filling conditions . 30

Annex F (normative) Flow diagram of the checks before, during and after filling . 31

Annex G (normative) Specific inspection procedure for over-moulded cylinder (OMC) . 32

Annex H (informative) Example of an Over-Moulded Cylinder . 34

Bibliography . 35

European foreword

This document (EN 1439:2021) has been prepared by Technical Committee CEN/TC 286 “Liquefied

petroleum gas equipment and accessories”, the secretariat of which is held by NSAI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2022, and conflicting national standards shall be

withdrawn at the latest by April 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association.

This document supersedes EN 1439:2017.

In comparison with the previous edition, the main changes were performed in Annex D for composite

cylinders. Additional technical modifications have been made as follows:

— Clause 2 has been updated;

— definitions have been updated and modified (Clause 3);

— changes in requirement to Clause 4.2 d);

— changes in requirement to Annex B.

This document has been submitted for reference in:

— the RID and/or

— the technical annexes of the ADR.

NOTE These regulations take precedence over any clause of this document. It is emphasized that RID/ADR are

being revised regularly at intervals of two years which can lead to temporary non-compliances with the clauses of

this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to announce this Technical Specification: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document calls for the use of substances and procedures that can be injurious to health if adequate

precautions are not taken. It refers only to technical suitability and does not absolve the user from legal

obligations relating to health and safety at any stage.

It has been assumed in the drafting of this document that the execution of its provisions is entrusted to

appropriately qualified and experienced people. Where judgements are called for, it has been assumed

that they are made by competent persons who have been trained specifically for the tasks.

Protection of the environment is a key political issue in Europe and elsewhere. For CEN/TC 286 this is

covered in CEN/TS 16765 [3] and this Technical Specification should be read in conjunction with this

document. This Technical Specification provides guidance on the environmental aspects to be considered

regarding equipment and accessories produced for the LPG industry and the following is addressed:

a) design;

b) manufacture;

c) packaging;

d) use and operation; and

e) disposal.

1 Scope

This document specifies the procedures to be adopted when checking transportable refillable LPG

cylinders before, during and after filling.

This document is applicable to transportable refillable LPG cylinders of water capacity not exceeding

150 l and deemed to be fitted with valves designed according to EN ISO 14245 [4] and EN ISO 15995 [5].

This document does not apply to the requirements for filling LPG cylinders that are designed and

equipped for filling by the user.

This document does not apply to the requirements for filling LPG containers on vehicles.

This document is applicable to the following:

— welded and brazed steel LPG cylinders with a specified minimum wall thickness (see EN 1442 and

EN 12807 [1] or an equivalent standard);

— welded steel LPG cylinders without specified minimum wall thickness (see EN 14140 or an

equivalent standard);

— welded aluminium LPG cylinders (see EN 13110 [2] or an equivalent standard);

— composite LPG cylinders (see EN 14427 or an equivalent standard); and

— over-moulded cylinders (OMC).

Specific requirements for the different types of cylinders are detailed in Annex A, Annex B, Annex C,

Annex D and Annex G.

This document is intended to be applicable to cylinders complying with RID/ADR [6] [7] (including pi

marked cylinders) and also to existing non RID/ADR cylinder populations.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 549, Rubber materials for seals and diaphragms for gas appliances and gas equipment

EN 1440, LPG equipment and accessories - Transportable refillable traditional welded and brazed steel

Liquefied Petroleum Gas (LPG) cylinders - Periodic inspection

EN 1442, LPG equipment and accessories - Transportable refillable welded steel cylinders for LPG - Design

and construction

EN 10028-7, Flat products made of steels for pressure purposes - Part 7: Stainless steels

EN 12816, LPG equipment and accessories - Transportable refillable LPG cylinders - Disposal

EN 13952, LPG equipment and accessories - Filling operations for LPG cylinders

EN 14140:2014, LPG equipment and accessories - Transportable refillable welded steel cylinders for LPG -

Alternative design and construction

EN 14427, LPG equipment and accessories - Transportable refillable fully wrapped composite cylinders for

LPG - Design and construction

EN 14894, LPG equipment and accessories - Cylinder and drum marking

EN 15202, LPG equipment and accessories - Essential operational dimensions for LPG cylinder valve outlet

and associated equipment connections

EN 16728, LPG equipment and accessories - Transportable refillable LPG cylinders other than traditional

welded and brazed steel cylinders - Periodic inspection

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

liquefied petroleum gas

LPG

low pressure liquefied gas composed of one or more light hydrocarbons which are assigned to UN 1011,

UN 1075, UN 1965, UN 1969 or UN 1978 only and which consists mainly of propane, propene, butane,

butane isomers, butene with traces of other hydrocarbon gases

3.2

competent person

person which by combination of appropriate qualification, training, experience, and resources, is able to

make objective judgments on the subject

3.3

over-moulded cylinder

OMC

pressure receptacle intended for the carriage of LPG of a water capacity not exceeding 13 l made of a

coated steel inner cylinder with an over-moulded protective case made from cellular plastic, which is non

removable and bonded to the outer surface of the steel cylinder wall

3.4

periodic inspection

activities carried out at specified intervals, such as examining, measuring, testing or gauging the

characteristics of a pressure vessel or a pressure receptacle and comparing these with specified

requirements

3.5

filled to a level

filled to a fixed level using a fixed liquid level device

3.6

filled by mass

filled with LPG using a weighing machine

3.7

filled by volume

filled with a fixed volume of LPG

3.8

reconditioning

major repairs to cylinders, which can include hot work, welding or de-denting carried out by specialists

away from potential sources of flammable air/gas mixture

3.9

tare mass

sum of the mass of the empty cylinder, the mass of the valve including a dip tube where fitted, and the

mass of all other parts that are permanently attached to the cylinder when it is being filled, e.g. fixed valve

guard

3.10

filling plant

facility where filling and checking of LPG cylinders takes place

3.11

protective casing

layer of protective material which gives mechanical protection which, either cannot be removed without

destroying it or is only removable with special tools or is bonded to the cylinder wall

Note 1 to entry: This definition can be applied to cylinders with over-moulded layers or with separate casings.

3.12

filling ratio

ratio of the mass of gas introduced into a cylinder or pressure drum to the mass of water at 15 °C that

would fill the same cylinder or pressure drum fitted ready for use

3.13

competent authority

authority or authorities or any other body or bodies designated as such in each State and in each specific

case in accordance with domestic law

3.14

reference temperature

temperature used for the calculation of the safe filling quantity

4 Segregation of cylinders prior to filling

4.1 General

Cylinders shall be checked and segregated into the categories specified in 4.2 to 4.4 by a competent

person.

The flow diagram of the checks before, during and after filling given in Annex F (Figure F.1) shall be

followed.

4.2 Cylinders suitable for filling

The cylinder shall be deemed suitable for filling if the following conditions apply:

a) tare indication and water capacity are marked;

b) allowed quantity and identification of the product (butane, propane or mixtures thereof, the

properties of which were considered for the design of the cylinder) are indicated;

c) cylinder is within the test date as determined from the marked manufacture date or periodic

inspection date;

d) cylinder and valve do not have unacceptable physical damage, corrosion or other defects. For metallic

cylinders, the inspection of the foot-ring for corrosion or damage shall determine the need for a more

thorough external visual examination of the cylinder base;

e) cylinder is fitted with a pressure relief valve, if required by the manufacturing standard; and

f) when cylinders are filled to a level, the fixed liquid level device shall be checked for operability.

4.3 Cylinders for periodic inspection

A cylinder shall be set aside for periodic inspection in accordance with EN 1440 or EN 16728 when either

of the following conditions apply:

a) cylinder is out of test date; or

b) cylinder cannot be confirmed to be within test date.

4.4 Cylinders requiring further assessment

A cylinder shall be set aside for further assessment (see Clause 5), if:

a) the tare indication of a cylinder, filled by mass, is missing or illegible;

b) the water capacity of a cylinder, filled by volume, is missing or illegible;

c) the cylinder is judged to have unacceptable physical damage, corrosion or other defects;

d) the valve or pressure relief valve (if fitted) is damaged, severely corroded or has been previously

identified as leaking.

Cylinders identified as leaking shall be made safe prior to their reassessment.

5 Reassessment of cylinders

Cylinders that have been set aside (see 4.4) shall be examined by a competent person who shall determine

if they are suitable for filling or if they shall be sent for reconditioning, where permitted by the

appropriate annex of this document, or disposal in accordance with EN 12816 (where applicable).

Cylinders that are intended to be filled by mass, and where the indication of tare weight is missing or

illegible, shall be reassessed and have the indication of the tare mass applied in accordance with

EN 14894.

Cylinders that are intended to be filled by volume, and where the indication of water capacity is missing

or illegible, shall be reassessed and have the indication of the water capacity applied in accordance with

EN 14894.

Leaking cylinders and cylinders with damaged or leaking valves shall be safely vented. Cylinders leaking

through the body shall be disposed of in accordance with EN 12816 (where applicable). Leaking or

damaged valves shall be repaired or replaced. Replacement valve seals shall comply with the

requirements of EN 549 and EN 15202.

Valves can be removed from and refitted safely to a pressurized LPG cylinder, provided the facility

includes dedicated equipment. This equipment shall only be operated by a competent person working in

accordance with a written procedure.

The filling plant shall have means to ensure that, when a valve is fitted, its thread is of the same type as

the cylinder bung thread and its torque is compliant with both the cylinder and valve manufacturer’s

recommendations. The equipment used to fit valves shall be regularly checked, serviced and calibrated.

Rejection limits for physical, material and other defects on the cylinder shell or protective casing shall be

applied in accordance with Annex A, Annex B, Annex C, Annex D and Annex G.

6 Filling conditions

The filling plant operation and filling checks shall be in accordance with EN 13952.

Cylinders shall not be filled in excess of the safe filling quantity. The safe filling quantity is determined

from the safe filling ratio agreed by the relevant national competent authorities in accordance with

Annex E.

7 Post filling checks

7.1 Check of filled amount

Each cylinder shall be checked to ensure that the maximum mass has not been exceeded, either by check

weighing within the tolerances as determined by the relevant national competent authorities or by a

determination of the ullage space remaining. Where accepted by the relevant national competent

authorities, other systems of checking, such as sample weighing or statistical data application, may be

used when the filling mass is controlled automatically.

7.2 Action necessary for over/under-filled cylinders

If the cylinder is over-filled, the excess LPG shall be removed as soon as reasonably practical and the

cylinder re-checked for correct fill quantity.

If the cylinder is under-filled, the appropriate amount of LPG shall be added and the cylinder re-checked

for correct fill quantity.

7.3 Final checks

Cylinders, valves and valve seals shall be checked for leakage. Leaks shall be dealt with in accordance

with the procedures in Clause 5. The admissible leakage rate shall be either indicated in the national

regulation, specified by the national competent authority, or within the operators' instructions, but in any

case, not higher than 5 g/h.

Where equipment is used to check for leakage, it shall be checked, serviced and calibrated regularly.

Checks to ensure the correct functioning of the leak detectors on the filling line shall be made, as a

minimum, at the beginning of every shift.

Cylinders shall be checked prior to dispatch or storage, for the correct fitting of valve caps or plugs, valve

protection caps/guards and labelling, if required.

Annex A

(normative)

Specific requirements for welded and brazed steel LPG cylinders

Rejection limits for physical, material and other defects on the cylinder shell are given in Table A.1,

Table A.2 and Table A.3.

Table A.1 — Physical defects in the cylinder wall

Defect Description Rejection limit

Bulge Visible swelling of the cylinder. All.

Dent A depression in the cylinder that has When the depth of the dent exceeds 25 % of its

a

neither penetrated nor removed width at any point .

metal, when its width at any point is

greater than 2 % of the external

cylinder diameter.

Cut or A sharp impression where metal has Where the original calculated wall thickness is

gouge been removed or redistributed. known:

Depth of cut or gouge is such that the

undamaged (remaining) wall is less than the

minimum calculated wall thickness.

Where the original calculated wall thickness is

not known:

All.

Dent A depression in the cylinder within When the size of the dent, cut or gouge exceeds

containing which there is a cut or gouge. the dimensions for rejection as an individual

cut or defect.

gouge

Crack A split or rift in the cylinder shell. All.

Lamination Layering of the material within the All.

cylinder wall appearing as a

discontinuity, crack, lap or bulge at

the surface.

a

Appearance (e.g. sharp dent) and location (e.g. on shoulder of the cylinder) also play a part in the evaluation of

dent severity.

Table A.2 — Corrosion on the cylinder wall

Type of Description Rejection limit

corrosion

Isolated A pitting of metal occurring in When the depth of discrete pits exceeds 0,6 mm. A

corrosion pits isolated areas at a greater depth of corrosion can be accepted provided

concentration not greater that depth of corrosion does not reduce the wall

than 1 pit per 500 mm of thickness below the minimum calculated wall

surface area. thickness.

Area Reduction in wall thickness When the depth of penetration of any pit exceeds

corrosion over an area not exceeding 0,4 mm. A greater depth can be accepted provided

20 % of the cylinder surface. that the depth of corrosion does not reduce the wall

thickness below the minimum calculated wall

thickness.

General A reduction in wall thickness When the depth of penetration of any pit exceeds

corrosion over an area exceeding 20 % 0,2 mm. A greater depth can be accepted providing

of the cylinder surface. that the depth of corrosion does not reduce the wall

thickness below the minimum calculated wall

thickness.

Chain pitting A series of pits or corroded When the total length of corrosion in any direction

or line or cavities of limited width along exceeds 50 % of the circumference of the cylinder; or

channel the length or around the

When the depth of penetration exceeds 0,4 mm. A

corrosion cylinder circumference.

greater depth can be accepted providing that the

depth of corrosion does not reduce the wall

thickness below the minimum calculated wall

thickness; or

When the depth of corrosion cannot be measured.

Crevice Crevice corrosion occurs in When the depth of penetration exceeds 0,4 mm or

corrosion the area of the intersection of when the depth of corrosion cannot be me

...

The article discusses the specifications and procedures outlined in EN 1439:2021. This standard provides guidelines for checking transportable refillable LPG cylinders before, during, and after filling. The document applies to cylinders with a water capacity not exceeding 150 l and valves designed according to EN ISO 14245 and EN ISO 15995. However, it does not apply to cylinders designed for filling by the user or LPG containers on vehicles. The standard applies to various types of cylinders, including welded and brazed steel cylinders, welded steel cylinders without specified minimum wall thickness, welded aluminum cylinders, composite cylinders, and over-molded cylinders. Specific requirements for each type of cylinder are detailed in annexes. The standard is intended to be applicable to cylinders complying with RID/ADR (including pi marked cylinders) and existing non RID/ADR cylinder populations.

기사 제목: EN 1439:2021 - LPG 장비 및 액세서리 - 주입 전, 주입 중, 주입 후 이동 가능한 재충전용 LPG 실린더의 점검 절차 기사 내용: 이 문서는 주입 전, 주입 중 및 주입 후 이동 가능한 재충전용 LPG 실린더를 점검할 때 채택해야 할 절차를 명시하고 있습니다. 이 문서는 EN ISO 14245 [4] 및 EN ISO 15995 [5]에 따라 설계된 밸브가 장착된 최대 수용량이 150L를 초과하지 않는 이동 가능한 재충전용 LPG 실린더에 적용됩니다. 이 문서는 사용자에 의해 주입되도록 설계된 LPG 실린더의 주입 요구 사항에는 적용되지 않습니다. 또한, 차량에 장착된 LPG 용기의 주입 요구 사항에도 적용되지 않습니다. 이 문서는 다음에 적용됩니다: - EN 1442 및 EN 12807 [1] 또는 동등한 표준에 따라 설계된 교반 및 납땜된 강철 LPG 실린더; - EN 14140 또는 동등한 표준을 통해 최소 한계 벽 두께가 지정되지 않은 용접 강철 LPG 실린더; - EN 13110 [2] 또는 동등한 표준에 따른 용접 알루미늄 LPG 실린더; - EN 14427 또는 동등한 표준에 따른 복합 LPG 실린더; 및 - 오버 모울딩된 실린더 (OMC). 각 실린더 유형에 대한 특정 요구 사항은 부록 A, 부록 B, 부록 C, 부록 D 및 부록 G에 상세히 설명되어 있습니다. 이 문서는 RID/ADR [6] [7] (pi 표시된 실린더를 포함)에 준수하는 실린더 및 기존 RID/ADR이 아닌 실린더 모집단에 적용하기 위해 제작되었습니다.

記事タイトル:EN 1439:2021 - LPG機器およびアクセサリー - 充填前、充填中、充填後の移動可能な再充填可能なLPGシリンダーの点検手順 記事内容:この文書は、充填前、充填中、充填後の移動可能な再充填可能なLPGシリンダーの点検時に採用すべき手順を規定しています。 この文書は、EN ISO 14245 [4]およびEN ISO 15995 [5]に準拠したバルブが取り付けられた水容量が150Lを超えない移動可能な再充填可能なLPGシリンダーに適用されます。 この文書は、ユーザーによる充填が設計されたLPGシリンダーの充填要件には適用されません。 また、車両に搭載されたLPGコンテナの充填要件にも適用されません。 この文書は、以下の対象に適用されます: - EN 1442およびEN 12807 [1]または同等の規格に基づいて設計された溶接およびろう付けされた鋼製LPGシリンダー; - EN 14140または同等の規格により最小壁厚が指定されていない溶接鋼製LPGシリンダー; - EN 13110 [2]または同等の規格に基づく溶接アルミニウムLPGシリンダー; - EN 14427または同等の規格に基づく複合LPGシリンダー;および - オーバーモールドシリンダー(OMC)。 各シリンダータイプの特定の要件は、付録A、付録B、付録C、付録D、および付録Gに詳細に記載されています。 この文書は、RID/ADR [6] [7](piマークの付いたシリンダーを含む)および既存の非RID/ADRシリンダーの集団に適用することを意図しています。

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...