EN 13889:2003+A1:2008

(Main)Forged steel shackles for general lifting purposes - Dee shackles and bow shackles - Grade 6 - Safety

Forged steel shackles for general lifting purposes - Dee shackles and bow shackles - Grade 6 - Safety

This European Standard specifies requirements for forged steel Dee and bow shackles of grade 6 for general lifting purposes in a range of working load limits 0,5 t to 25 t maximum.

This standard applies only to those shackles with threaded pins.

Annex A gives information on the safe use of shackles, annex B gives information on types of pins, and annex C gives an example of a designation system for forged steel shackles.

The hazards covered are identified in clause 4.

Geschmiedete Schäkel für allgemeine Hebezwecke - Gerade und geschweifte Schäkel - Güteklasse 6 - Sicherheit

Diese Europäische Norm legt Anforderungen für geschmiedete, gerade und geschweifte Schäkel in

Güteklasse 6 für allgemeine Hebezwecke in einem Bereich von 0,5 t bis 25 t Tragfähigkeit fest.

Diese Europäische Norm gilt nur für Schäkel mit Schraubbolzen.

Anhang A enthält Hinweise über die Benutzung von Schäkeln, Anhang B enthält Angaben über Bolzen und

Anhang C enthält ein Beispiel für ein Bezeichnungssystem für geschmiedete Schäkel.

Die Gefährdungen, die abgedeckt werden, sind in Abschnitt 4 aufgeführt.

Manilles forgées en acier pour applications générales de levage - Manilles droites et manilles lyres - Classe 6 - Sécurité

La présente Norme européenne spécifie les prescriptions relatives aux manilles droites et aux manilles lyres forgées

en acier de classe 6 pour les applications générales de levage ayant des charges maximales d'utilisation comprises

entre 0,5 t et 25 t maximum.

La présente norme s'applique uniquement aux manilles ayant des axes filetés.

L'Annexe A donne des informations sur l'utilisation sûre des manilles, l'Annexe B donne des informations sur les

types d'axes, et l'Annexe C donne un exemple d'un système de désignation pour les manilles forgées en acier.

Les phénomènes dangereux couverts sont identifiés à l’article 4.

Kovane jeklene skobe za splošne dvigalne namene - Ravne in zakrivljene skobe - Kakovostni razred 6 - Varnost

General Information

- Status

- Published

- Publication Date

- 11-Nov-2008

- Withdrawal Date

- 27-Dec-2009

- Technical Committee

- CEN/TC 168 - Chains, ropes, webbing, slings and accessories - safaty

- Drafting Committee

- CEN/TC 168/WG 4 - Hooks and other accessories

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 03-Jun-2024

- Completion Date

- 03-Jun-2024

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 22-Dec-2008

Overview

EN 13889:2003+A1:2008 is the CEN European safety standard for forged steel Dee and bow shackles (Grade 6) used for general lifting purposes. It covers shackles with threaded pins and specifies requirements for design, materials, manufacturing, testing, marking and documentation for working load limits (WLL) from 0.5 t to 25 t. Annex A gives guidance on safe use, Annex B (normative) details pin types, and Annex C provides an example designation system. The standard supports conformity with the EU Machinery Directives (see informative annexes ZA/ZB).

Key topics and technical requirements

- Scope: Dee and bow shackles, Grade 6, threaded pins only, WLL 0.5 t–25 t.

- Dimensions & fit: Principal dimensions tied to WLL (see Table 2 of the standard) to ensure correct fit and to minimize errors of assembly.

- Design of threads: Screw threads must conform to ISO 261 (class 7H/8g) or ISO 263 (class 1A/1B); allowance for undercutting before galvanizing/coating.

- Pins: Types described (e.g., type W - screwed pin with eye and collar; type X - bolt with nut and cotter pin); Annex B specifies pin requirements.

- Materials & heat treatment:

- Steel produced by electric or oxygen process, fully killed, stabilized against strain-age embrittlement.

- Grain size: austenitic grain size 5 or finer (ISO 643).

- Hardening from above AC3 and tempering ≥ 420 °C (≥1 h) before proof testing.

- Manufacture & workmanship:

- Bodies forged hot in one piece; no welding; pins not cast; remove excess metal and sharp edges; surface finishes (descaled, plated, galvanized) acceptable.

- Testing & inspection:

- Manufacturing proof force (MPF) and breaking force requirements; verification and non‑destructive testing referenced (EN 10228 magnetic/penetrant); calibration per ISO 7500‑1.

- Marking, traceability & documentation:

- Mandatory marking, lot numbers, traceability codes, manufacturer’s certificate and instructions for use to ensure safe selection and compliance.

Practical applications and users

- Who uses it: shackle manufacturers, lifting equipment designers, riggers, maintenance and safety officers, procurement teams, conformity assessment bodies and inspectors.

- Where applied: cranes, slings, hoists, marine rigging, construction, offshore, manufacturing and any industry using shackles for load attachment.

- Benefits: standardized safety and interchangeability, reduced risk of accidental load release, consistent quality control and CE/Machinery Directive conformity evidence.

Related standards / references

- EN 292‑2 (safety of machinery principles), EN 10228 (NDT of forgings), ISO 261 / ISO 263 (threads), ISO 643 (grain size), ISO 7500‑1 (test machine verification).

Keywords: EN 13889, forged steel shackles, Dee shackle, bow shackle, Grade 6, working load limit, threaded pins, lifting accessories, safety standard, manufacturing proof force, traceability.

Frequently Asked Questions

EN 13889:2003+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Forged steel shackles for general lifting purposes - Dee shackles and bow shackles - Grade 6 - Safety". This standard covers: This European Standard specifies requirements for forged steel Dee and bow shackles of grade 6 for general lifting purposes in a range of working load limits 0,5 t to 25 t maximum. This standard applies only to those shackles with threaded pins. Annex A gives information on the safe use of shackles, annex B gives information on types of pins, and annex C gives an example of a designation system for forged steel shackles. The hazards covered are identified in clause 4.

This European Standard specifies requirements for forged steel Dee and bow shackles of grade 6 for general lifting purposes in a range of working load limits 0,5 t to 25 t maximum. This standard applies only to those shackles with threaded pins. Annex A gives information on the safe use of shackles, annex B gives information on types of pins, and annex C gives an example of a designation system for forged steel shackles. The hazards covered are identified in clause 4.

EN 13889:2003+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 53.020.30 - Accessories for lifting equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13889:2003+A1:2008 has the following relationships with other standards: It is inter standard links to EN 13889:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13889:2003+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 13889:2003+A1:2008 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kovane jeklene skobe za splošne dvigalne namene - Ravne in zakrivljene skobe - Kakovostni razred 6 - VarnostGeschmiedete Schäkel für allgemeine Hebezwecke - Gerade und geschweifte Schäkel - Güteklasse 6 - SicherheitManilles forgées en acier pour applications générales de levage - Manilles droites et manilles lyres - Classe 6 - SécuritéForged steel shackles for general lifting purposes - Dee shackles and bow shackles - Grade 6 - Safety53.020.30Pribor za dvigalno opremoAccessories for lifting equipmentICS:Ta slovenski standard je istoveten z:EN 13889:2003+A1:2008SIST EN 13889:2004+A1:2009en,fr,de01-januar-2009SIST EN 13889:2004+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13889:2003+A1

November 2008 ICS 53.020.30 Supersedes EN 13889:2003 English Version

Forged steel shackles for general lifting purposes - Dee shackles and bow shackles - Grade 6 - Safety

Manilles forgées en acier pour applications générales de levage - Manilles droites et manilles lyres - Classe 6 - Sécurité

Geschmiedete Schäkel für allgemeine Hebezwecke - Gerade und geschweifte Schäkel - Güteklasse 6 - Sicherheit This European Standard was approved by CEN on 25 April 2003 and includes Amendment 1 approved by CEN on 9 September 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13889:2003+A1:2008: ESIST EN 13889:2004+A1:2009

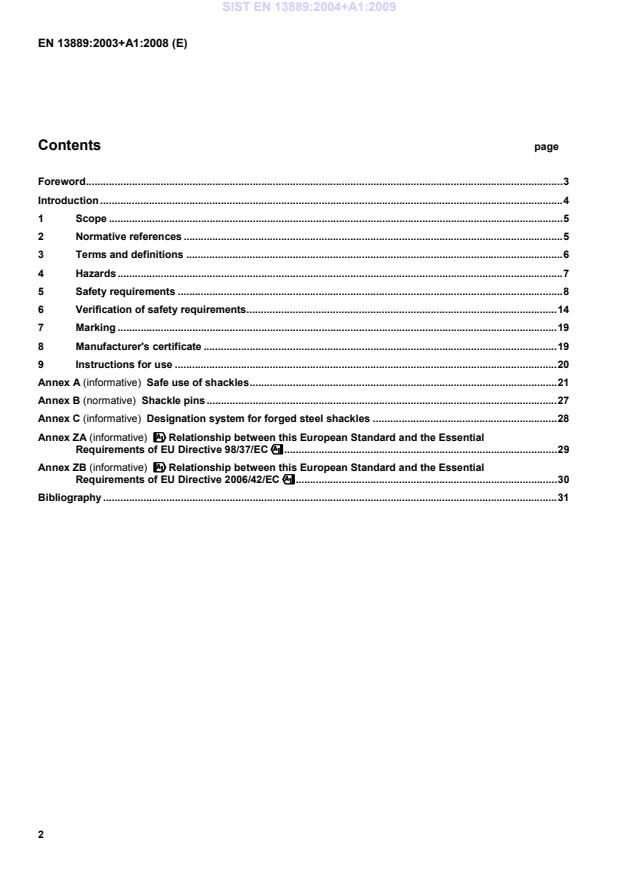

Safe use of shackles.21 Annex B (normative)

Shackle pins.27 Annex C (informative)

Designation system for forged steel shackles.28 Annex ZA (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC"""".29 Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""".30 Bibliography.31

3 Terms and definitions For the purposes of this European Standard the terms and definitions given in EN 10025: 1990 and the following apply: 3.1 shackle a lifting accessory comprising a body and pin as shown in Figures 1 and 2 which are readily separable and can be used to connect a load to a lifting machine directly or in conjunction with other lifting accessories.

3.2 body a part of the shackle formed to the shape of a dee or bow and terminating in eyes as shown in Figures 1 and 2.

3.3 pin a component of circular section which passes through the eyes of the shackle, as shown in Figures 1, 2 and B.1 and which can be readily disassembled.

3.4 dee shackle a shackle the crown of which forms a semicircle of internal radius half the width, W, between the eyes as shown in Figure 1. 3.5 bow shackle a shackle the crown of which forms more than a semicircle of internal radius more than half the width, W, between the eyes as shown in Figure 2. 3.6 working load limit WLL maximum mass that a shackle is authorized to sustain in general service NOTE This term has the same meaning as the term maximum working load used in EN 292-2: 1991, annex A. 3.7 manufacturing proof force MPF force applied to the shackle during the manufacturing proof test 3.8 breaking force BF maximum force reached during the static tensile test of a shackle at which the shackle fails to retain the load 3.9 traceability code series of letters and/or numbers marked on a shackle that enables its manufacturing history, including identity of the cast of steel used, to be traced

3.10 lot number of shackles of the same type and dimensions, manufactured during the same production run from the same cast of steel and subjected to the same heat treatment process

3.11 type W pin screwed pin with eye and collar and which screws into one eye of the shackle body

3.13 competent person designated person, suitably trained, qualified by knowledge and practical experience, and with the necessary instruction to enable the required test and examination to be carried out NOTE EN ISO 9001 gives guidance on training. 4 Hazards Accidental release of a load, or release of a load due to failure of shackle puts at risk, either directly or indirectly the safety or health of those persons within the danger zone. In order to provide the necessary strength and durability of shackles EN 13889 gives requirements for the design, manufacture and testing to ensure the specified levels of performance are met. Since failure can be caused by the incorrect choice of grade and specification of shackle EN 13889 also gives the requirements for marking and the manufacturer's certificate. Errors of fitting can also lead to failure and EN 13889 contains dimensional requirements to allow correct fit. Risk of injury due to sharp edges, sharp angles or rough surfaces when handling is also covered by this standard. Those aspects of safe use associated with good practice are given in annex A. Table 1 contains those hazards, which require action to reduce risk identified by risk assessment as being specific and significant for shackles.

Table 1 — Hazards and associated requirements Hazards identified in annex A Relevant clause Relevant clause/ EN 1050: 1996,

of annex A of EN 292-2: 1991 subclause of

EN 13889 1 Mechanical hazard 1.3.2

due to inadequacy 4.1.2.3

of strength 1.3.2 4.1.2.3 4.1.2.5 5 5 5

4.2.4 6

4.3.2 7

4.2.4 8

1.7.4 9 1.3 Cutting hazard 1.3.4 5.3 1.8 Friction or abrasion hazard 1.3.4 5.3 15 Errors of fitting hazard 1.5.4 5.1

Key: 1 Crown 2 Body 3 Example of screwed pin with eye and collar – type W 4 Eye 5 Bolt type pin with hexagon head, hexagon nut and split cotter pin – type X Figure 1 — Dimensions of dee shackles SIST EN 13889:2004+A1:2009

Key: 1 Crown 2 Body 3 Example of screwed pin with eye and collar – type W 4 Eye 5 Bolt type pin with hexagon head, hexagon nut and split cotter pin – type X Figure 2 — Dimensions of Bow shackles SIST EN 13889:2004+A1:2009

Table 2 — Limiting values for Dee shackles and Bow shackles

WLL Nominal bow diameter dn Nominal pin diameter Dn Nominal inside width Wn at pin

Minimum eye diameter en Dee shackle: minimum inside length S Bow shackle: minimum inside length

S Minimum inside width of bow

Emin t mm mm mm mm mm mm mm 0,5 6,50 8 12 15,5 20 27 19 0,75 8 9,5

13,5 18,5 25 29 20 1 10 11 16,5 22 27 32 24 1,5 11,2 12,2 19 25 33 39 27 2 13,5 16 21,5 29,5 38 44 30 3,25 16,5 19 27 38 47 57 39 4,75 20 22 31,5 44 52 65 48 6,5 23 25 36,5 50 65 76 55 8,5 25,5 28 43 56 74 88 64 9,5 29 32 46,5 64 83 101 70 12 33 35 51,5 70 87 108 78 13,5 36,5 38 57 76 104 126 85 17 39,5 42 60 84 115 139 94 25 46 51 74 100 139 168 119 NOTE: Tolerances: - Bow dia, dn :0,5 t up to and including 2 t : +1,5/ - 1 mm

3,25 t up to and including 12 t : +/- 2,5 mm

13,5 t up to and including 25 t : +/- 3 mm Allow bow diameter dn to be oval, + 10 % for sizes 3,25 t up to and including 17 t, + 25 % for size 25 t (same tolerances as above) - Pin dia, Dn : 0,5 t up to and including 2 t : +/- 1 mm

3,25 t up to and including 25 t : +/- 2 mm - Inside width at pin,Wn : 0,5 t up to and including 2 t : +/- 2,5 mm

3,25 t up to and including 9,5 t : +/- 3 mm

12 t up to and including 25 t : +/- 4 mm

5.2 Design 5.2.1 Screw threads Screw threads shall conform either to ISO 261 class 7H/8g or to ISO 263 class 1A/1B. NOTE For hot dip galvanized or coated pins it is permissible for the threads to be undercut prior to galvanizing or coating. SIST EN 13889:2004+A1:2009

Cast analysis Check analysis

%

%

Sulfur 0,025 0,030 Phosphorus 0,025 0,030

Table 4 — Mechanical properties Working load limit WLL Manufacturing proof force MPF Minimum breaking force BFmin t kN kN 0,5 9,8 24,5 0,75 14,7 36,8 1 19,6 49,1 1,5 29,4 73,6 2 39,2 98,1 3,25 63,7 160 4,75 93,1 233 6,5 128 319 8,5 167 417 9,5 187 466 12 236 589 13,5 265 662 17 334 834 25 491 1226

NOTE The mechanical properties specified in Table 4 are calculated values. It is common practice for manufacturers to round MPF and BF up to higher values that may appear in their published catalogues. SIST EN 13889:2004+A1:2009

...

Die Norm EN 13889:2003+A1:2008 behandelt die Anforderungen an geschmiedete Stahl-Schäkel, die für allgemeine Hebezwecke verwendet werden, wobei sowohl Dee-Schäkel als auch Bogen-Schäkel der Klasse 6 betrachtet werden. Die festgelegten Arbeitslastgrenzen liegen zwischen 0,5 t und 25 t, was eine breite Anwendbarkeit in verschiedenen Hebeanwendungen ermöglicht. Ein herausragendes Merkmal dieser Norm ist die Spezifikation für Schäkel mit Gewindebolzen, die für die Sicherheit und Effizienz beim Heben entscheidend sind. Darüber hinaus wird im Anhang A wertvolle Information zur sicheren Nutzung von Schäkel bereitgestellt, was die Sicherheit der Anwender und die Integrität der Hebevorrichtungen erhöht. Anhang B gibt einen Überblick über die verschiedenen Arten von Bolzen, die für die Schäkel verwendet werden können, und Anhang C stellt ein Beispiel für ein Bezeichnungssystem für geschmiedete Stahlschäkel bereit, welches die Identifikation und Auswahl der geeigneten Schäkel erleichtert. Die Norm identifiziert auch in Klausel 4 die zu berücksichtigenden Gefahren, was zeigt, dass Sicherheitsaspekte von größter Bedeutung sind. Diese umfassende Betrachtung der Risiken sowie die klaren Richtlinien zur Verwendung und Identifikation stärken die Relevanz der Norm EN 13889 für die Industrie, da sie nicht nur die Qualität der Produkte gewährleistet, sondern auch die Sicherheit der Nutzer fördert. In Summe stellt diese Norm einen wichtigen Rahmen für die Verwendung von Schäkel in Hebeanwendungen dar und ist somit ein unverzichtbares Instrument in der Sicherstellung von Sicherheitsstandards in der Branche.

The standard EN 13889:2003+A1:2008 outlines comprehensive specifications for forged steel shackles, specifically focusing on Dee and bow shackles of grade 6 utilized in general lifting applications. The standard is designed to ensure safety and reliability for shackles used within a significant range of working load limits, from 0.5 tons to a maximum of 25 tons, thereby catering to various lifting needs in diverse industrial environments. One of the primary strengths of this standard is its clear delineation of requirements applicable only to shackles featuring threaded pins, which enhances user clarity and helps to minimize potential misapplication. This specificity is crucial for manufacturers and users alike, providing a focused framework that informs the design and application of shackles. The inclusion of informative annexes further establishes the document’s relevance and strength. Annex A addresses safe usage protocols for shackles, which serves as an essential resource for ensuring operational safety. This guidance is critical in mitigating risks associated with lifting operations. Annex B expands on types of pins, providing essential information regarding compatibility and safety considerations. Furthermore, Annex C introduces a systematic designation format for forged steel shackles, facilitating easier identification and standardization across the industry. Clause 4 of the standard effectively identifies hazards associated with the use of shackles, which is imperative for risk management and safety assurance in lifting operations. By addressing potential hazards, the standard ensures that users can implement appropriate safety measures, thereby enhancing operational confidence. In conclusion, EN 13889:2003+A1:2008 encapsulates important requirements and guidance for forged steel shackles, reinforcing its role as a foundational tool for establishing safety and efficacy in lifting operations across various sectors. Its detailed scope, strengths, and informative annexes promote standardized practices that enhance user knowledge and compliance within the industry.

標準文書「EN 13889:2003+A1:2008」は、一般的な吊り上げ目的に使用される鍛造鋼製のD型およびボウシャックルに関する要件を定めています。この標準は、6級のシャックルに特化しており、最大作業負荷制限は0.5トンから25トンまでの範囲で適用されます。特に、ねじ込みピンを使用するシャックルに限定されている点が重要です。 この標準の強みは、鋼製シャックルの安全な使用を確保するための明確な基準を提供していることです。附属書Aでは、シャックルの安全な使用に関する情報が具体的に示されており、使用者がリスクを理解し、安全に操作できるようなガイダンスが含まれています。また、附属書Bではピンの種類に関する情報を提供し、適切なピンの選定を促進しています。さらに、附属書Cでは、鍛造鋼製シャックルのための指定システムの例が示されており、製品の識別や選定を容易にしています。 この標準が持つ関連性は、吊り上げ作業の安全性を向上させるための基盤となることです。さまざまな業界や作業環境で使用されるシャックルの基準として、EN 13889は、作業者の安全を第一に考えた設計がなされています。危害が識別されている第4条においても、利用者が潜在的なリスクを認識し、それに対処するための指針が示されています。 総じて、この標準は、鍛造鋼製シャックルの適切な使用と安全を確保するために不可欠な要素を提供しており、業界全体で広く受け入れられている重要な文書です。

La norme EN 13889:2003+A1:2008 stipule des exigences précises pour les manilles en acier forgé, notamment les manilles en forme de D et celles en forme de boucle de grade 6 destinées à des usages de levage général. Son champ d'application couvre une large gamme de limites de charge de travail de 0,5 t à 25 t, ce qui la rend particulièrement pertinente pour divers secteurs où la sécurité est primordiale. L'une des forces de cette norme réside dans sa spécificité concernant les manilles équipées de goupilles filetées. Cette précision assure aux utilisateurs que les manilles utilisées sont conformes à des critères de sécurité stricts, minimisant ainsi les risques potentiels liés à leur emploi dans des environnements exigeants. En outre, l'annexe A fournit des informations cruciales sur l'utilisation sécurisée des manilles, tandis que l'annexe B présente différents types de goupilles, offrant ainsi une compréhension approfondie des options disponibles. L'annexe C, avec son exemple de système de désignation pour les manilles en acier forgé, facilite également le choix des équipements adaptés. Les risques identifiés dans la clause 4 montrent que la norme prend au sérieux la nécessité d'une évaluation rigoureuse des dangers associés aux manilles, renforçant ainsi la confiance des utilisateurs quant à leur sécurité pendant les opérations de levage. Dans l'ensemble, la norme EN 13889:2003+A1:2008 représente un cadre essentiel pour le matériel de levage, garantissant que les manilles en acier forgé de grade 6 sont non seulement conformes aux exigences de performance, mais également à des standards de sécurité élevés, ce qui espace sa pertinence sur le marché et pour les professionnels du secteur.

EN 13889:2003+A1:2008 표준은 일반 리프팅 목적을 위한 단조 강철 디 쇠고랑(Dee shackles) 및 보 쇠고랑(bow shackles)의 요구사항을 명확히 규정하고 있습니다. 이 표준은 특히 0.5t에서 25t까지의 최대 작업 하중 제한을 포함하여, 6급의 강도를 가진 쇠고랑에 적용됩니다. 이 표준은 나사형 핀(threaded pins)이 있는 쇠고랑에만 해당하며, 안전한 사용을 위한 지침이 포함되어 있습니다. 표준의 강점 중 하나는 부속 A에서 쇠고랑의 안전한 사용에 대한 정보를 제공하는 것으로, 사용자가 위험성을 최소화할 수 있도록 돕습니다. 또한 부속 B에서는 다양한 핀의 유형에 대해 설명하며, 부속 C에서는 단조 강철 쇠고랑에 대한 명명 시스템의 예시를 제공하여 제품의 이해도를 높입니다. 이러한 정보들은 일반 리프팅 작업에서 안전성을 보장하고 효율적인 사용을 도모합니다. 표준이 다루는 위험 요소들은 조항 4에서 명시되어 있어, 사용자들이 적절한 예방 조치를 취할 수 있도록 돕습니다. EN 13889는 강철 쇠고랑의 설계 및 사용에 있어 중요한 지침으로, 산업 전반에서 안전성을 확보하는 데 기여할 것입니다. 우수한 품질 기준을 제시함으로써 이 표준은 산업 종사자들이 신뢰할 수 있는 제품을 선택할 수 있는 근거를 제공합니다.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...