IEC TR 60286-3-4:2021/COR1:2022

(Corrigendum)Corrigendum 1 - Packaging of components for automatic handling - Part 3-4: Packaging of surface mount components on continuous embossed tapes for Auto Loading Feeder

Corrigendum 1 - Packaging of components for automatic handling - Part 3-4: Packaging of surface mount components on continuous embossed tapes for Auto Loading Feeder

General Information

Relations

Buy Standard

Standards Content (Sample)

IEC TR 60286-3-4:2021/COR1:2022 – 1 –

IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

IEC TR 60286-3-4

Edition 1.0 2021-10

PACKAGING OF COMPONENTS FOR AUTOMATIC HANDLING –

Part 3-4: Packaging of surface mount components

on continuous embossed tapes for Auto Loading Feeder

CO RRI G E NDUM 1

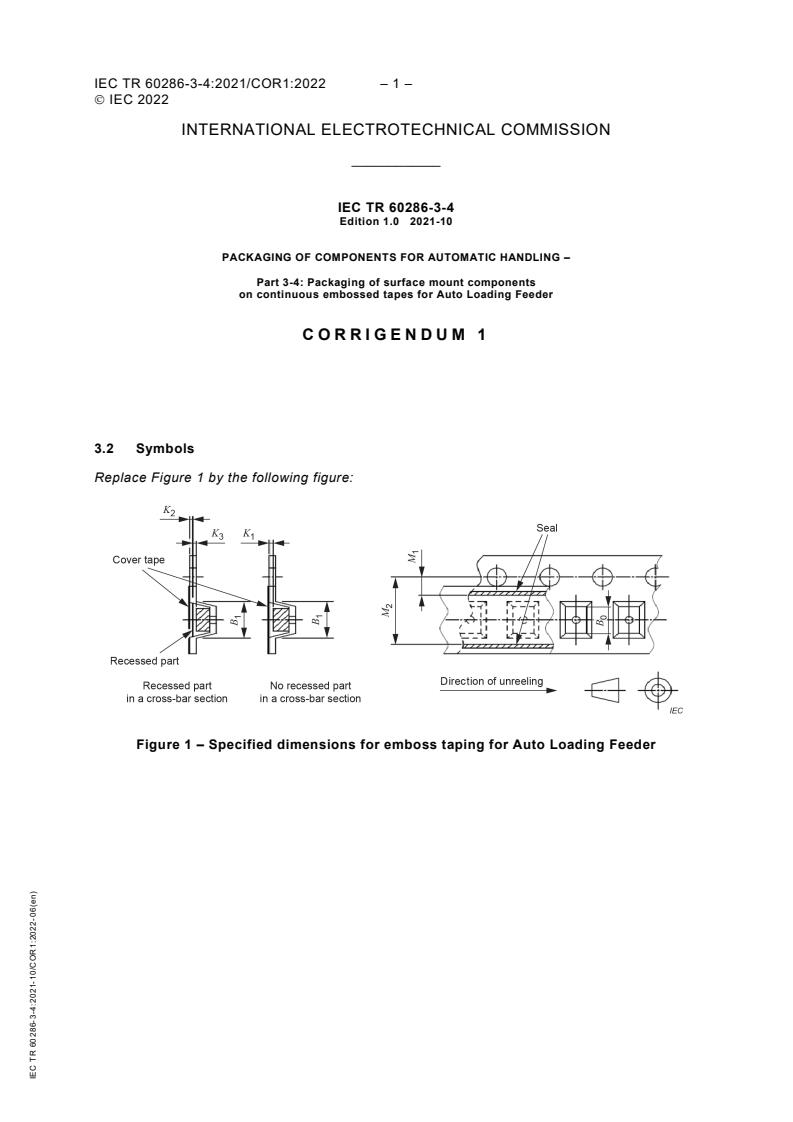

3.2 Symbols

Replace Figure 1 by the following figure:

Figure 1 – Specified dimensions

...

This May Also Interest You

IEC 60286-3:2022 is applicable to the tape packaging of electronic components without leads or with lead stumps, intended to be connected to electronic circuits. It includes only those dimensions that are essential for the taping of components intended for the above-mentioned purposes. This document also includes requirements related to the packaging of singulated die products including bare die and bumped die (flip chips). This edition includes the following significant technical changes with respect to the previous edition:

addition terms and definitions.

addition of a table of the classification to symbols concerning drive hole diameter and distance between the reel hole centre and the drive hole centre;

addition of drive hole to the reel (optional);

revision of reel hole diameter tolerances;

revision of 72 mm tape size carrier tape width dimension tolerances;

addition of Annex B (informative);

addition of component size 0201M.

- Standard170 pagesEnglish languagesale 15% off

IEC 60286-2:2022 applies to the tape packaging of components with two or more unidirectional leads for use in electronic equipment. It provides dimensions and tolerances necessary to tape components with unidirectional leads. In general, the tape is applied to the component leads.

It covers requirements for taping techniques used with equipment for automatic handling, pre-forming of leads, insertion and other operations and includes only those dimensions which are essential to the taping of components intended for the above-mentioned purposes.

This edition includes the following significant technical changes with respect to the previous edition:

a) complete revision of structure;

b) consolidation of essential parameters and requirements in Clause 4.

- Standard70 pagesEnglish and French languagesale 15% off

IEC TR 60286-3-3:2021(E) describes the possible requirements for paper taping for the Auto Loading Feeder mechanism to mount electronic components without leads or with stump type leads used for electric circuits. This document is applicable to the punched carrier tape with the bottom cover tape (nominal tape width: 8 mm only) among the tapes of Type 1a, and the pressed carrier tape (nominal tape width: 8 mm) of Type 1b in IEC 60286-3.

- Technical report22 pagesEnglish languagesale 15% off

IEC TR 60286-3-4:2021(E) considers the proposed requirements for emboss taping for the Auto Loading Feeder mechanism to mount electric components without leads or with stump type leads used for electric circuits. This document is applicable to the embossed carrier tape, with single round sprocket holes, with tape pitches of 2 mm or more (nominal tape width: 8 mm only) among the tapes of Type 2a in IEC 60286-3.

The contents of the corrigendum of June 2022 have been included in this copy.

- Technical report26 pagesEnglish languagesale 15% off

- Standard9 pagesEnglish and French languagesale 15% off

IEC TR 60286-7:2019 contains information about the introduction of an innovative bulk blister packing system for miniaturized components, for example chip type components of size 1005 (metric) and smaller. It includes a proposal for standardization of the interface between the packaging and automatic assembly systems and requirements to the properties of the packaging.

- Technical report24 pagesEnglish and French languagesale 15% off

IEC 60286-3:2019 is available as IEC 60286-3:2019 RLV which contains the International Standard and its Redline version, showing all changes of the technical content compared to the previous edition.

IEC 60286-3:2019 is applicable to the tape packaging of electronic components without leads or with lead stumps, intended to be connected to electronic circuits. It includes only those dimensions that are essential for the taping of components intended for the above-mentioned purposes. This document also includes requirements related to the packaging of singulated die products including bare die and bumped die (flip chips). This edition includes the following significant technical changes with respect to the previous edition:

- addition of a table of the classification to symbols concerning tape, reel and common symbols;

- additions of a figure of example of polarity and orientation and a figure of example of dot seal;

- revision of requirements for camber;

- addition of a definition of design value with regard to tilt.

- Standard84 pagesEnglish and French languagesale 15% off

IEC 61051-1:2018 is available as IEC 61051-1:2018 RLV which contains the International Standard and its Redline version, showing all changes of the technical content compared to the previous edition.

IEC 61051-1:2018 is a generic specification and is applicable to varistors with symmetrical voltage-current characteristics for use in electronic equipment. It establishes standard terms, inspection procedures and methods of test for use in sectional and detail specifications for quality assessment or any other purpose. This edition includes the following significant technical changes with respect to the previous edition:

a) 10 new terms and definitions – leaded varistors, surface mount varistors(SMV), electrostatic discharge (ESD), ESD clamping voltage, equivalent rectangular pulse duration, maximum peak current derating characteristic, rated average dissipation power, rated energy, abnormal overvoltage withstanding duration and temperature derating curve – have been added (see 3.6, 3.7, 3.14, 3.15, 3.19, 3.20, 3.23, 3.24, 3.25 and 3.29);

b) General requirements for electrical tests and 7 new test items – clamping voltage, ESD clamping voltage, maximum peak current, rated average dissipation power, rated energy, electrostatic discharge (ESD), robustness of terminations of surface mount varistors – have been added (see 6.5, 6.11, 6.12, 6.13, 6.14, 6.15, 6.16 and 6.17.8);

c) In 6.6, 6.7, 6.8, 6.9.3, 6.23.2, 6.23.4 and 6.26, following test items have been revised:

- Varistor voltage, leakage current and capacitance: more detailed requirements and information have been added;

- Voltage proof – foil method: the space between the edge of the foil and each termination has been changed from 1 mm ~ 1,5 mm to 3 mm ~ 3.5 mm for testing varistors not having axial terminations and the minimum space between the foil and the termination has been changed from 1 mm to 3 mm for testing varistors having axial terminations;

- Climatic sequence – dry heat: the method has been changed from Ba to Bb;

- Climatic sequence – cold: the method has been changed from Aa to Ab;

- Endurance at upper category temperature: the method of “applying test voltages in cycles of 1,5 h on and 0,5 h off” has been changed to the method of applying test voltages continuously throughout the test lasting for 1 000 h;

d) The test items of pulse current, voltage under pulse condition and bump have been deleted from the section of test and measurement procedures;

e) Annex A and the contents referring to the test fixture specified in Annex A have been deleted;

f) All contents related to silicon carbide varistors have been deleted;

g) A new normative annex entitled “Test pulses used in this specification” (Annex B) has been added;

h) A new informative annex entitled "Recommended measurement/test methods for characteristics and parameters for application reference" (Annex C) has been added, in which guidelines of measuring/testing characteristics and parameters for application reference including voltage vs. current characteristic, maximum peak current derating characteristic, thermal resistance and abnormal overvoltage withstanding duration have been given.

- Standard117 pagesEnglish and French languagesale 15% off

IEC 60286-1:2017 applies to the tape packaging of components with axial leads for use in electronic equipment. In general, the tape is applied to the component leads.

It covers requirements for taping techniques used with equipment for the preforming of leads, automatic handling, insertion and other operations, and includes only those dimensions which are essential to the taping of components intended for the above-mentioned purposes.

This edition includes the following significant changes with respect to the previous edition:

a) a complete revision of the structure (detailed in Annex A) and reworked layout.

- Standard53 pagesEnglish and French languagesale 15% off

- Standard24 pagesEnglish and French languagesale 15% off

IEC 60286-2:2015 applies to the tape packaging of components with two or more unidirectional leads for use in electronic equipment. In general, the tape is applied to the component leads. It covers requirements for taping techniques used with equipment for automatic handling, pre-forming of leads, insertion and other operations and includes only those dimensions which are essential to the taping of components intended for the above-mentioned purposes. This edition includes the following significant changes with respect to the previous edition:

- A complete revision of the structure and reworked layout.

- A two page overview containing a clear overview of all symbols and references.

- Addition of annexes of known radial tape formats.

- Improved figures.

- Standard68 pagesEnglish and French languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.