ISO 13296:2005

(Main)Diesel engines — High-pressure fuel injection pipe assemblies — General requirements and dimensions

Diesel engines — High-pressure fuel injection pipe assemblies — General requirements and dimensions

ISO 13296:2005 specifies dimensions and requirements for high-pressure fuel injection pipe assemblies and assembled pipe sets used on diesel (compression-ignition) engines.

Moteurs diesels — Lignes assemblées d'injection de carburant à haute pression — Exigences générales et dimensions

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13296

Second edition

2005-02-15

Diesel engines — High-pressure fuel

injection pipe assemblies — General

requirements and dimensions

Moteurs diesels — Lignes assemblées d'injection de carburant à haute

pression — Exigences générales et dimensions

Reference number

ISO 13296:2005(E)

©

ISO 2005

---------------------- Page: 1 ----------------------

ISO 13296:2005(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2005

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2005 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 13296:2005(E)

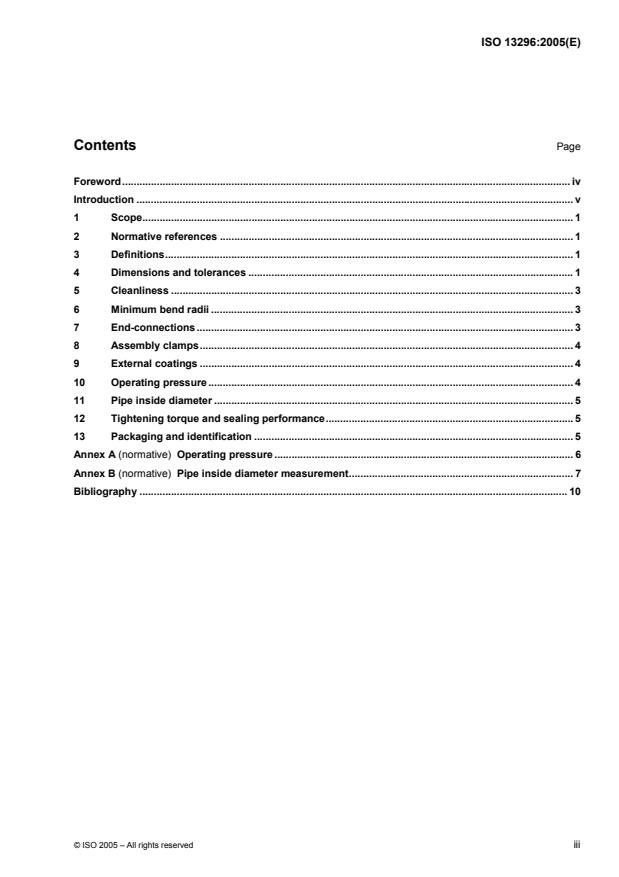

Contents Page

Foreword. iv

Introduction . v

1 Scope. 1

2 Normative references . 1

3 Definitions. 1

4 Dimensions and tolerances . 1

5 Cleanliness . 3

6 Minimum bend radii . 3

7 End-connections . 3

8 Assembly clamps. 4

9 External coatings . 4

10 Operating pressure . 4

11 Pipe inside diameter . 5

12 Tightening torque and sealing performance. 5

13 Packaging and identification . 5

Annex A (normative) Operating pressure . 6

Annex B (normative) Pipe inside diameter measurement. 7

Bibliography . 10

© ISO 2005 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 13296:2005(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

ISO 13296 was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 7, Injection

equipment and filters for use on road vehicles.

This second edition cancels and replaces the first edition (ISO 13296:1997), which has been technically

revised. It also incorporates the Technical Corrigendum ISO 13296:1997/Cor.1:2000.

iv © ISO 2005 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 13296:2005(E)

Introduction

The International Organization for Standardization (ISO) draws attention to the fact that it is claimed that

compliance with this International Standard may involve the use of a patent concerning an apparatus to

measure the inside diameter of the pipe assembly, as described in Annex B.

ISO takes no position concerning the evidence, validity and scope of this patent right.

The holder of this patent right has assured ISO that he is willing to negotiate licenses under reasonable and

non-discriminatory terms and conditions with applicants throughout the world. In this respect, the statement of

the holder of this patent right is registered with ISO. Information may be obtained from:

DaimlerChrysler AG

70322 Stuttgart

Germany

This information is given for the convenience of the users of this International Standard and does not

constitute an endorsement of the apparatus for which a patent is held by the above-mentioned company.

Other apparatus may be used if it can be shown to lead to the same results.

Attention is drawn to the possibility that some of the elements of this International Standard may be the

subject of patent rights other than those identified above. ISO shall not be held responsible for identifying any

or all such patent rights.

© ISO 2005 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 13296:2005(E)

Diesel engines — High-pressure fuel injection pipe

assemblies — General requirements and dimensions

1 Scope

This International Standard specifies dimensions and requirements for high-pressure fuel injection pipe

assemblies and assembled pipe sets used on diesel (compression-ignition) engines.

NOTE High-pressure pipes for use on test benches are specified in ISO 4093.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 2974, Diesel engines — High-pressure fuel injection pipe end-connections with 60° female cone

ISO 7876-4, Fuel injection equipment — Vocabulary — Part 4: High-pressure pipes and end-connections

ISO 8535-1, Compression-ignition engines — Steel tubes for high-pressure fuel injection pipes — Part 1:

Requirements for seamless cold-drawn single-wall tubes

ISO 8535-2, Compression-ignition engines — Steel tubes for high-pressure fuel injection pipes — Part 2:

Requirements for composite tubes

ISO 12345, Diesel engines — Cleanliness assessment of fuel injection equipment

3 Definitions

For the purposes of this document, the definitions given in ISO 7876-4 apply.

4 Dimensions and tolerances

The requirement and configuration drawing for a pipe assembly shall include at least the following:

a) indication of compliance with this International Standard;

b) the outside diameter and inside diameter of the pipe and indication of compliance with ISO 8535-1 or

ISO 8535-2; and

c) a graphic representation of the centreline of the pipe with the connection ends and each bend intersection

labelled as a point, with each point listed in a table with Cartesian coordinates x, y and z with the

orthogonal distance from the axis and the bend radius;

NOTE The coordinates are used to specify the theoretical exact centreline of the pipe. See the example given in

Figure 1.

© ISO 2005 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 13296:2005(E)

d) the developed length of the pipe as an approximated value; and

e) the surface finish requirements of the pipe and connector nuts.

The dimensional tolerance of a pipe assembly shall be stated in terms of the actual outside contour of the tube

in relation to the specified maximum outside contour and the variance of the actual connection end from

specified position, as agreed upon between supplier and customer.

Dimensions in millimetres

Key

1 connector nut M12

2 pipe

3 connector nut M14

a

developed length

Point x y z Radius

A 0 0 0 0

B

65 0 0 15,75

C 65 100 0 15,75

D 140 100 0 15,75

E 140 150 0 15,75

F

40 150 0 15,75

G 40 185 0 0

Figure 1 — Example of a requirement and configuration drawing

2 © ISO 2005 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 13296:2005(E)

5 Cleanliness

The bore of a high-pressure fuel injection pipe assembly shall be clean, and this shall be assessed in

accordance with ISO 12345. Unless otherwise agreed between manufacturer and client, cleanliness of pipe

assemblies shall be designated using the Fuel Injection Equipment Cleanliness Code (FIECC), as defined in

ISO 12345.

6 Minimum bend radii

The radius of an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.