ISO/DIS 19078

(Main)Gas cylinders -- Inspection of the cylinder installation, and requalification of high pressure cylinders for the on-board storage of natural gas as a fuel for automotive vehicles

Gas cylinders -- Inspection of the cylinder installation, and requalification of high pressure cylinders for the on-board storage of natural gas as a fuel for automotive vehicles

Bouteilles à gaz -- Inspection de l'installation de bouteilles, et la requalification des bouteilles haute pression pour le stockage à bord des véhicules automobiles du gaz naturel utilisé comme combustible

General Information

RELATIONS

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 19078

ISO/TC 58/SC 4 Secretariat: ANSI

Voting begins on: Voting terminates on:

2003-08-28 2004-01-28

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Gas cylinders — Inspection of the cylinder installation, andrequalification of high pressure cylinders for the on-board

storage of natural gas as a fuel for automotive vehicles

Bouteilles à gaz — Inspection de l'installation de bouteilles, et la requalification des bouteilles haute pression

pour le stockage à bord des véhicules automobiles du gaz naturel utilisé comme combustible

ICS 23.020.30; 43.060.40In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.To expedite distribution, this document is circulated as received from the committee secretariat.

ISO Central Secretariat work of editing and text composition will be undertaken at publication

stage.Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.© International Organization for Standardization, 2003

---------------------- Page: 1 ----------------------

ISO/DIS 19078

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright noticeThis ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying,

recording or otherwise, without prior written permission being secured.Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii ISO 2003 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 19078

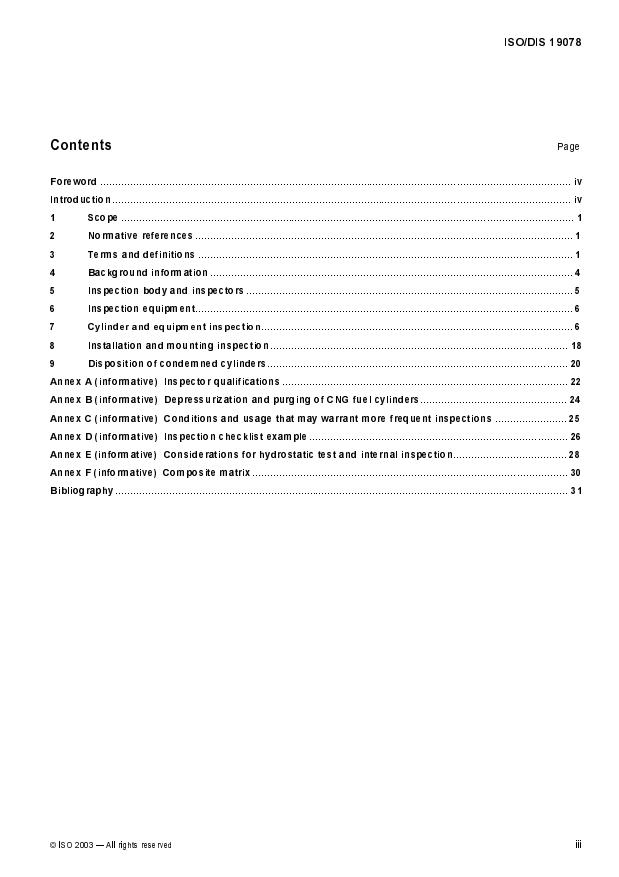

Contents Page

Foreword ....................................................................................................................... ...................................... iv

Introduction......................................................................................................................................................... iv

1 Scope ....................................................................................................................................................... 1

2 Normative references .............................................................................................................................. 1

3 Terms and definitions ............................................................................................................................. 1

4 Background information ......................................................................................................................... 4

5 Inspection body and inspectors ............................................................................................................. 5

6 Inspection equipment.............................................................................................................................. 6

7 Cylinder and equipment inspection........................................................................................................ 6

8 Installation and mounting inspection................................................................................................... 18

9 Disposition of condemned cylinders.................................................................................................... 20

Annex A (informative) Inspector qualifications ............................................................................................... 22

Annex B (informative) Depressurization and purging of CNG fuel cylinders................................................. 24

Annex C (informative) Conditions and usage that may warrant more frequent inspections ........................ 25

Annex D (informative) Inspection checklist example ...................................................................................... 26

Annex E (informative) Considerations for hydrostatic test and internal inspection...................................... 28

Annex F (informative) Composite matrix ......................................................................................................... 30

Bibliography....................................................................................................................................................... 31

© ISO 2003 — All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 19078

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards adopted

by the technical committees are circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies casting a vote.Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights.

ISO shall not be held responsible for identifying any or all such patent rights.ISO 19078 was prepared by Technical Committee ISO/TC 58, Gas cylinders, Subcommittee SC 4, Operational

requirements for gas cylinders.iv © ISO 2003 — All rights reserved

---------------------- Page: 4 ----------------------

ISO/DIS 19078

Introduction

This International Standard provides information and procedures for the periodic visual examination and inspection

of natural gas fuel cylinders and the condition of the installation. These cylinders are installed in vehicles and are

certified by the manufacturer to meet the requirements of ISO 11439. This International Standard may be used for

the inspection of other natural gas fuel cylinders that are certified to meet other specifications and standards with

the approval of the national authority of use. These cylinders are designed to store natural gas at high pressures.

This International Standard requires that appropriate information, such as an installation and maintenance manual

from the cylinder manufacturer, be reviewed and used during the inspection, together with all current cylinder

manufacturer’s recommendations and guidance documents.© ISO 2003 — All rights reserved v

---------------------- Page: 5 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 19078

Gas cylinders — Inspection of the cylinder installation, and

requalification of high pressure cylinders for the on-board storage

of natural gas as a fuel for automotive vehicles

1 Scope

This International Standard specifies the requirements for the inspection of the installation and requalification of

high pressure cylinders designed and manufactured to ISO 11439 or other equivalent national standards for the on-

board storage of natural gas as a fuel for automotive vehicles. The purpose of this document is to provide guidance

for the inspection of these cylinders in accordance with manufacturer’s recommendations and to provide criteria for

the acceptance or rejection in the absence of guidance from the manufacturer with subsequent disposition as

necessary.2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references,

only the edition cited applies. For undated references, the latest edition of the referenced document (including any

amendments) applies.ISO 11439:2000, Gas cylinders — High pressure cylinders for the on-board storage of natural gas as a fuel for

automotive vehicles3 Terms and definitions

For the purposes of this International Standard, the following terms and definitions apply.

3.1abrasion

damage to cylinder or equipment caused by wearing, grinding or rubbing away of material by friction

NOTE Abrasion may be the result of many cycles of something rubbing lightly on the surface of the cylinder or equipment

or due to a few cycles, perhaps only one, of heavy rubbing.3.2

impact

forceful blow to the surface of the cylinder that may cut, gouge or significantly indent the surface

NOTE Impact may also induce such damage as delaminations, which are not readily apparent by visual examination.

3.3condemned

cylinder or piece of equipment no longer fit for service and for which rework is not allowed

3.4crazing

hairline cracking of the resin giving it an opaque, “frosty” appearance

© ISO 2003 — All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/DIS 19078

3.5

cut

damage caused by a sharp object coming into contact with a composite surface

3.6

delamination

form of composite damage in which a separation develops between layers of the composite

NOTE Delaminations usually result from excessive localized loading normal to the surface of the laminate.

3.7destroyed

alteration of a fuel cylinder or piece of equipment to make it physically unusable

3.8domes

curved end portions of the fuel cylinder

3.9

external coating

clear or coloured surface treatment applied to the cylinder for environmental protection and/or improved

appearance3.10

helical

winding in the longitudinal circumferential direction for both the cylindrical and dome regions of the cylinder

NOTE The strands of reinforcing fibres are oriented at an angle to the longitudinal axis of the cylinder.

3.11hoop direction

hoop pattern

winding in the cylindrical region of the cylinder

NOTE The strands of reinforcing fibres are oriented at an angle of nearly 90 degrees to the longitudinal axis of the cylinder.

3.12inspection body

individual or organization that performs the visual inspection of compressed natural gas (CNG) cylinders used in

natural gas vehicles (NGVs)3.13

inspection mark

mark, label or tag placed by an inspector on the cylinder indicating acceptance of the cylinder

3.14Level 1 damage

Level 1 condition

minor damage that may occur during normal use

NOTE Such damage should have no adverse effects on the safety of the cylinder and its continued use. Scratched paint or

nicks that have no appreciable depth in metal or similar damage in the composite, cylinder paint or resin where there are no

visible frayed fibres are considered to be in this level of damage (see Table 1).

3.15Level 2 damage

Level 2 condition

damage that is more severe than Level 1 but keeps open the possibilities of rework or the container returned to

service based on the recommendations of the manufacturer2 © ISO 2003 — All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS 19078

NOTE Level 2 conditions may be deeper, longer or more severe than those of Level 1, but are allowed by the manufacturer

by test results (see 7.4.5). Level 2 conditions are either reworked to the manufacturer’s acceptable condition or evaluated to be

Level 3 and condemned (see Table 1).3.16

Level 3 damage

Level 3 condition

damage that requires a cylinder to be condemned

NOTE A Level 3 condition is such that the cylinder must be rendered unfit for continued service and cannot be reworked

(see Table 1).3.17

liner

internal component of the cylinder that prevents leakage of gas through the composite cylinder structure

3.18manufacturer

cylinder manufacturer, unless otherwise stated

3.19

marking(s)

cylinder marking(s) containing the information required by the appropriate standard or regulation

3.20mounting brackets and/or straps

devices used to secure fuel cylinders in a vehicle

3.21

overpressurization

pressures exceeding those allowed during the filling procedures specified in ISO 11439

3.22pressure relief device

PRD

device that will release the contained gas in specific emergency conditions

NOTE The PRD may be activated by excessive temperature, excessive internal pressure, or both.

3.23regulatory authority

national entity or entities that have jurisdiction to specify requirements for the cylinders and equipment addressed in

this International Standard3.24

reinforcing fibres

continuous fibrous strands such as carbon, aramid and glass in the composite that withstand loads caused by

pressurization3.25

rejected cylinder

cylinder or equipment that shall be removed from service (i.e. de-installed from the vehicle)

NOTE For Level 2 damage, the cylinder is evaluated further before reworking or condemning. For Level 3 damage, the

cylinder or equipment is subsequently condemned.3.26

resin

material that is used to bind and hold the fibres in place

© ISO 2003 — All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/DIS 19078

NOTE It is usually a thermoplastic or thermosetting resin.

3.27

working pressure

settled pressure at a uniform temperature of 15 °C marked on the cylinder

3.28

stress corrosion cracking

SCC

phenomenon resulting in a split or rift in the materials caused by a combination of load and aggressive environment

NOTE Such cracks in composite materials are typically sharply defined and perpendicular to the fibre direction. They may

appear as a family of cracks or as a single crack.3.29

valve

device installed in one of the threaded openings of the cylinder that is used to regulate gas flow into or from the

cylinderNOTE A manual valve is turned on or off with a handle. A solenoid valve is turned on or off electronically. Some solenoid

valves may be operated manually with special tools.3.30

vent line

high pressure line used to conduct gas from a pressure relief device to a location outside the vehicle where gas

may be discharged safely4 Background information

4.1 General

NGV fuel cylinders may be designed and qualified to one of a number of appropriate specifications or standards.

This includes, but is not limited to, ISO 11439. These cylinders have markings that identify the standards to which

they are built and identify the type of construction used.4.2 Cylinder types and descriptions

4.2.1 CNG-1 metal

CNG-1 cylinders are all metallic and can be of any alloy of steel or aluminium that meets qualification requirements

outlined in the appropriate design standard.4.2.2 CNG-2 metal liner partially reinforced with resin impregnated continuous filament (hoop-wrapped)

CNG-2 cylinders have a metallic liner with sufficient strength and thickness to carry the entire longitudinal load at

the required burst pressure and to withstand the standard-specified factor of the nominal working pressure without

rupture. Metal liner materials are those identified under CNG-1 cylinders (see 4.2.1). They are reinforced with fibres

wound only in the hoop (circumferential) direction. Reinforcing fibres are carbon, aramid, glass or combinations

thereof.4.2.3 CNG-3 metal liner totally reinforced with resin impregnated continuous filament (fully wrapped)

CNG-3 cylinders have a metallic liner that is generally load-carrying but they do not have sufficient strength and

thickness to carry the longitudinal load at the burst pressure. They are reinforced with fibres wound in both a helical

(polar) and hoop pattern. Reinforcing fibres are carbon, aramid, glass or combinations thereof. Metal liner materials

are those identified under CNG-1 cylinders (see 4.2.1).4 © ISO 2003 — All rights reserved

---------------------- Page: 9 ----------------------

ISO/DIS 19078

4.2.4 CNG-4 non-metallic liner totally reinforced with resin impregnated continuous filament (all

composite)CNG-4 cylinders have a non-metallic liner that does not carry load. The liner is typically a thermoplastic material.

Reinforcing fibres are carbon, aramid, glass or combinations thereof. They are reinforced with fibres wound in both

a helical (polar) pattern and hoop direction. Metallic bosses are used to accept valves or PRDs. Boss materials are

typically aluminium or stainless steel.4.3 Required marking information

The appropriate standard shall be reviewed for exact wording required and the requirements for letter sizes.

The following marking information required in ISO 11439 shall be verified:a) “CNG ONLY”;

b) “DO NOT USE AFTER XX/XXXX”, (providing the month and year of expiry);

c) manufacturer’s identification;

d) cylinder identification (a serial number unique for every cylinder);

e) working pressure at temperature;

f) ISO standard, along with cylinder type and certification registration number (if applicable);

g) approved PRD type;h) date of manufacture (month and year);

i) any additional markings as required by the regulatory authority of the country(ies) of use.

When labels are used, all cylinders shall have a unique identification number and the manufacturer's name

stamped on an exposed metal surface to permit tracing in the event that the label is destroyed.

4.4 Additional markingThe following additional information may be included:

a) specific PRDs and valves approved for use with the cylinder;

b) operating temperature range;

c) nominal water capacity;

d) initial pressure test date;

e) inspector’s mark.

5 Inspection body and inspectors

The inspection body shall be certified in the country of use. See Annex A for an example of minimum inspector

qualifications.In order to assure all concerned that the cylinders are fit for continued safe use, the inspection shall be carried out

only by persons who are competent in the subject (see Annex A). The inspector shall have the equipment

described in Clause 6 and documentation referenced in 7.3.2 available and within easy access during the

© ISO 2003 — All rights reserved 5---------------------- Page: 10 ----------------------

ISO/DIS 19078

inspection. The vehicle to be inspected shall be positioned such that access to the surface of the cylinder is

unimpeded to the inspector or positioned according to the vehicle manufacturer (see 7.4.2). If the inspector finds

areas as described in Clause 7 that require additional inspection or testing, the cylinder shall be depressurized

following recommendations in Annex B and the manufacturer’s instructions, then removed from the vehicle. If the

inspector determines that the cylinder necessitates permanent removal from service, it shall be carried out in

accordance with Clause 9.6 Inspection equipment

6.1 Adequate light, capable of brightly illuminating all surfaces shall be used, to properly examine the external

surfaces of cylinders, mounting brackets, valves, vent lines, etc.CAUTION — To avoid combustion or fire, use explosion-proof lights or be sure the area is well ventilated.

6.2 Inspection mirrors, angled, or other suitable devices to aid in the examination of cylinder surfaces that are

partially concealed by the installation.6.3 Hand tools, various, necessary for the removal of covers, shields or other installed equipment so that the

external cylinder surfaces, brackets, valves, PRDs and other components can be viewed.

6.4 Torque wrench, to verify that the mounting bracket bolts are tightened properly.

6.5 Depth gauge, to determine the depth of cuts, pits and abrasions. It is recommended that a commercial type pit

or depth gauge be used for this purpose. Alternatively, equipment to estimate imperfection depths is acceptable.

6.6 Rule and straightedge, in combination, for evaluating indentations and bulges.

6.7 Rule or tape measure, for determining the length of noted cuts and the general area of abrasion.

6.8 Commercial-type leak test fluid (NOT containing ammonia, harsh corrosives or chemicals incompatible with

the system materials) or a methane gas detector, to test for leakage. The fluid is usually a mild soap solution that

meets the above criteria. Additional information is provided in 7.4.8.7 Cylinder and equipment inspection

7.1 Inspection interval

CAUTION — Failure to perform diligent and accurate inspections on a regular basis or promptly (in the

case of a potentially damaging incident or unusual behaviour) may result in a serious accident causing

severe damage or injury or both.NGV fuel storage systems shall be visually inspected by a qualified inspection body (see Clause 5) at intervals of

36 months or less (see Annex C). The country of use may require more frequent visual inspections.

7.2 Conditions requiring immediate inspectionAn inspection shall be performed prior to filling or returning a CNG cylinder to service if:

a) the fuel cylinder or vehicle in which it is installed is involved in a fire;b) the fuel cylinder is exposed to excessive heat;

c) the fuel cylinder is dropped or subjected to impact;

d) the NGV is in a collision;

6 © ISO 2003 — All rights reserved

---------------------- Page: 11 ----------------------

ISO/DIS 19078

e) the cylinder is suspected to have damage from cargo, vehicle and/or environmental conditions;

f) the cylinder is believed to have been damaged by any means;g) there is unusual behaviour including, but not limited to:

1) the presence of any odour added to natural gas (possible leaking cylinder or fuel system);

2) unexpected loss of gas pressure;3) rattling or other indications of looseness,

4) unusual snapping or hissing sounds;

Note Some minor noise is not unusual for composite materials when cylinders are being pressurized or depressurized.

h) the cylinder is re-installed after removal from the vehicle,I) the cylinder installation is changed significantly,

j) the fuel cylinder is transferred to another vehicle, or

k) the cylinder has been overpressurized according to the limits of its design.

7.3 Preparation for inspection — all cylinder types

7.3.1 Background vehicle information

CAUTION — A cylinder shall not be pressurized with air or an oxidizing gas mixture prior to use or

inspection. This can create a reactive mixture and be very dangerous.The cylinder owner/vehicle operator should be questioned regarding any known conditions or incidents that may

have caused damage to the cylinder. These include but are not limited toa) overpressurization;

b) dropping of the cylinder;

c) impacts to the cylinder;

d) exposure to excessive heat or fire,

e) vehicle accidents (including collisions of 8 km/h or more),

f) exposure to harsh chemicals.

The cylinder owner/vehicle operator should also be questioned regarding any unusual observations regarding the

cylinder, service history of the cylinder and any cylinder repairs that may have been made since its last inspection.

7.3.2 Background manufacturer informationBefore starting the inspection, pertinent information from the cylinder manufacturer, vehicle manufacturer (when the

compressed natural gas fuel system is factory installed) and after-market installers (when the compressed natural

gas fuel system is installed after the vehicle is manufactured and installed by someone other than the vehicle

manufacturer) shall be reviewed. As a minimum, this shall include a survey of the original specifications (e.g.

subclause 5.2.3 in ISO 11439:2000) including inspection criteria for the specific cylinder and vehicle model. This

review should include a study of the maintenance manual and recommendations and guidance documents for the

cylinder and its installation.© ISO 2003 — All rights reserved 7

---------------------- Page: 12 ----------------------

ISO/DIS 19078

7.3.3 Surface of the cylinder

The surface of the cylinder shall be clean and free from dirt or other debris that impedes the ability to clearly

determine the condition of the external surface of the cylinder (see 7.4.2). Shields or covers that inhibit the

inspection shall be removed or opened to gain access to the cylinder surface area for inspection.

7.3.4 Depressurizing cylindersCylinders that require immediate inspection (see 7.2) shall be depressurized prior to examination. Cylinders with

known or suspected Level 2 damage shall be depressurized prior to inspection. Cylinders with Level 3 damage and

cylinders to be destroyed shall be depressurized (see 9.2). Otherwise, installed cylinders do not require

depressurizing prior to inspection. Compliance with all authorities having jurisdiction in the depressurization

process and release of CNG to the atmosphere is mandatory. Depressurization guidelines are found in Annex B.

7.4 Cylinder inspection — all cylinder types7.4.1 Cylinder acceptance and rejection criteria

Table 1 outlines acceptance and rejection criteria for cylinders. Table 1 shall not be used without a thorough

understanding and knowledge of this section as well as the manufacturer’s instructions.

Table 1 — Cylinder conditionsDecision

Damage Definition Note

Level 1 Level 2 Level 3

Accept Possible repair Reject

All cylinder types

Marking and Stamped and Required All information is not Required information is Manufacturer may

labelling attached information information is legible; manufacturer not legible for any trace supply new labelling

present and legible may supply information ability; repair not if serial number is

for repair possible legibleCuts/scratches/ A sharp impression When depth is less Greater than Level 1 When the depth is Composite cylinders

gouges where material has than 0,25 mm and damage that is accepted greater than 1,25 mm may be repaired if

been removed or no fibres and can be repaired fibres are not cut orredistributed (composite according to separated

cylinders) were cut manufacturer's

or broken specifications

(composite cylinders

only)

Abrasion An area that is When the depth is Greater than Level 1 When the depth is 1,25 Composite cylinders

scuffed or worn less than 0,25 mm damage that is accepted mm or greater, or if may be repaired if

thinner by rubbing or and can be repaired fibres are exposed fibres are notscraping according to exposed, cut or

manufacturer's separated

specifications

(composite cylinders

only)

Charring/soot Blackening or None or washes off Minor discolouration; Permanent charring; Follow

browning of an area manufacturer’s discolouration manufacturer’s testrecommendation guidelines for Level

2 damage

Gas leakage Loss of contents None detected If through composite Test confirms leak

through a defect (not material, see 7.4.8 andintended to include get manufacturer’s

loss by permeation) advice

Chemical attack Cylinder is subjected Cleans off; no Chemical unknown; Permanent Manufacturer shall

to a chemical that residue or effect effects on cylinder discolouration, provide guidance on

dissolves or and chemical is materials unknown; loss/disruption of exposure todestroys the known not to affect moves to Level 3 if these material, chemical is chemicals; (see also

material container materials cannot be resolved known to affect cylinder Stress corrosion

materials; cannot cracking section,determine if materials following)

have been affected

8 © ISO 2003 — All rights reserved

---------------------- Page: 13 ----------------------

ISO/DIS 19078

Decision

Damage Definition Note

Level 1 Level 2 Level 3

Accept Possible repair Reject

Weathering Effects of the sun’s Minor gloss loss or Only coating or non- Structural materials Repainting with

ultraviolet radiation chalking structural material is affected manufacturer'saffected; may be guidance may put

repainted (see 7.4.10) Level

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.